Wet type polyurethane joint material for thermal insulation for seabed oil and gas pipeline interface and preparation method of wet type polyurethane joint material

An oil and gas pipeline and polyurethane technology, applied in the field of polyurethane node materials and their preparation, can solve the problems of less than 100% closed cell rate, high water absorption rate of materials, low thermal conductivity, etc., and achieve low water absorption rate, low mold temperature, The effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The following examples are used to further illustrate the preparation and application details of the present invention, and do not constitute a limitation to the spirit and scope of the present invention.

[0037] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0038] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0039] The raw materials used in the following examples are as follows:

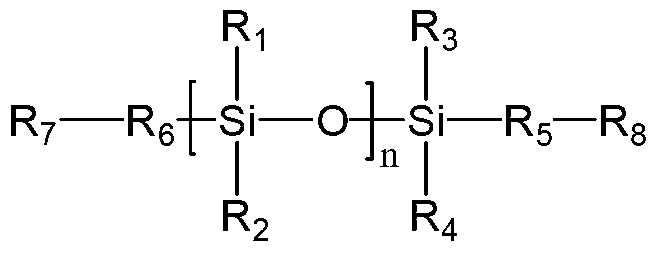

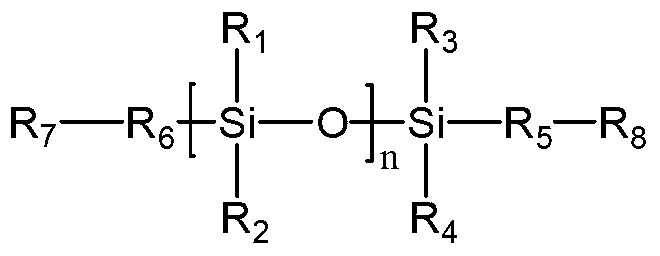

[0040] Hydroxyl-terminated polysiloxane DS-3, with a hydroxyl value of 40-50 mgKOH / g, from Rhodia, France;

[0041] Polypropylene glycol (PPG-1), hydroxyl value 50-60mgKOH / g, Shandong Bluestar Dongda Company;

[0042] Polyether polyol GE-2, hydroxyl value 160-175mgKOH / g, Shanghai Gaoqiao Petrochemical;

[0043] 1,4-Butanediol (BDO), Diethylene Glycol (DEG), Shanghai Lingfeng Chemical Co., Ltd.;

[0044] Catalyst CT-2X, Aladdin reagent company...

Embodiment 1

[0052] In a reactor with a vacuum and heating device, mix DS-3 (52.5 parts), PPG-1 (192.5 parts) and GE-2 (105 parts) evenly and dry them under vacuum at 95°C for 2.5h, then cool slowly After cooling down to 60°C, add dried BDO (85.17 parts) and catalyst CT-2X (2.85 parts), mix and stir for 15 minutes, and vacuum degas to obtain component A.

[0053] Control the temperature of component A to 30°C, add 564.83 parts of NCO-B, stir quickly and evenly degas, pour it into a mold with a mold temperature of 70°C, and obtain the non-foaming polyurethane joint for the submarine pipeline field interface of the present invention Material.

[0054] The gel time of the non-foamed polyurethane node material prepared in this example is 5 minutes, and the demoulding time is 18 minutes.

[0055] After testing, the initial tensile strength of the node material prepared in this example is 3.22MPa, the hardness (Shore A) is 70, the tensile strength after post-curing is 18.22MPa, and the elongati...

Embodiment 2

[0057] In a reaction kettle with a vacuum and heating device, mix DS-3 (17.5 parts), PPG-1 (210.0 parts), GE-2 (122.5 parts) evenly and vacuum dry at 95°C for 2.5h, then cool slowly After cooling down to 50°C, add dried BDO (83.70 parts) and catalyst CT-2X (2.85 parts), mix and stir for 15 minutes, and vacuum degas to obtain component A.

[0058] Control the temperature of component A to 30°C, add 566.30 parts of NCO-B, stir quickly and evenly degas, pour it into a mold with a mold temperature of 70°C, and obtain the non-foaming polyurethane joint for the submarine pipeline field interface of the present invention Material.

[0059] The gel time of the non-foamed polyurethane node material prepared in this example is 4 minutes, and the demoulding time is 16 minutes.

[0060] After testing, the initial strength of the node material prepared in this example is 4.13MPa, the hardness (Shore A) is 78, the tensile strength after post-curing is 14.46MPa, and the elongation at break ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com