Polyurethane node material for submarine oil-gas pipeline interface wet type thermal insulation, and preparation method thereof

A technology of oil and gas pipelines and polyurethane, which is applied in the field of polyurethane node materials and its preparation, can solve the problems of less than 100% closed cell rate, high water absorption rate of materials, and low thermal conductivity, and achieve fast post-curing, low mold temperature, The effect of short production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The following examples are used to further illustrate the preparation and application details of the present invention, and do not constitute a limitation to the spirit and scope of the present invention.

[0032] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0033] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0034] The raw materials used in the following examples are as follows:

[0035] Polypropylene glycol (PPG), hydroxyl value 50-60mgKOH / g, Shandong Bluestar Dongda Company;

[0036] Polytetrahydrofuran ether glycol (PTMEG), hydroxyl value 35-400mgKOH / g, German BASF company;

[0037] 1,4-Butanediol (BDO), Diethylene Glycol (DEG), Shanghai Lingfeng Chemical Co., Ltd.;

[0038] Catalyst CT-2X, Aladdin reagent company;

[0039] 4,4'-MDI, Huntsman Shanghai Polyurethane Co., Ltd.

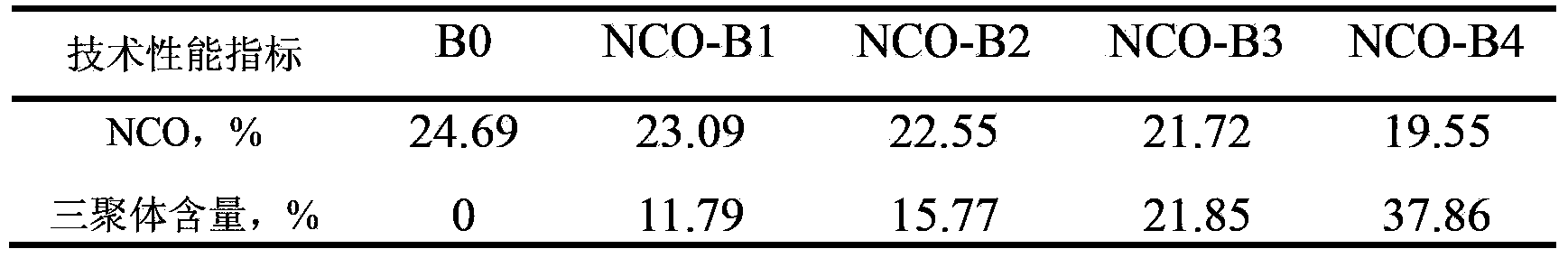

[0040] NCO-B is trimerized modified MDI...

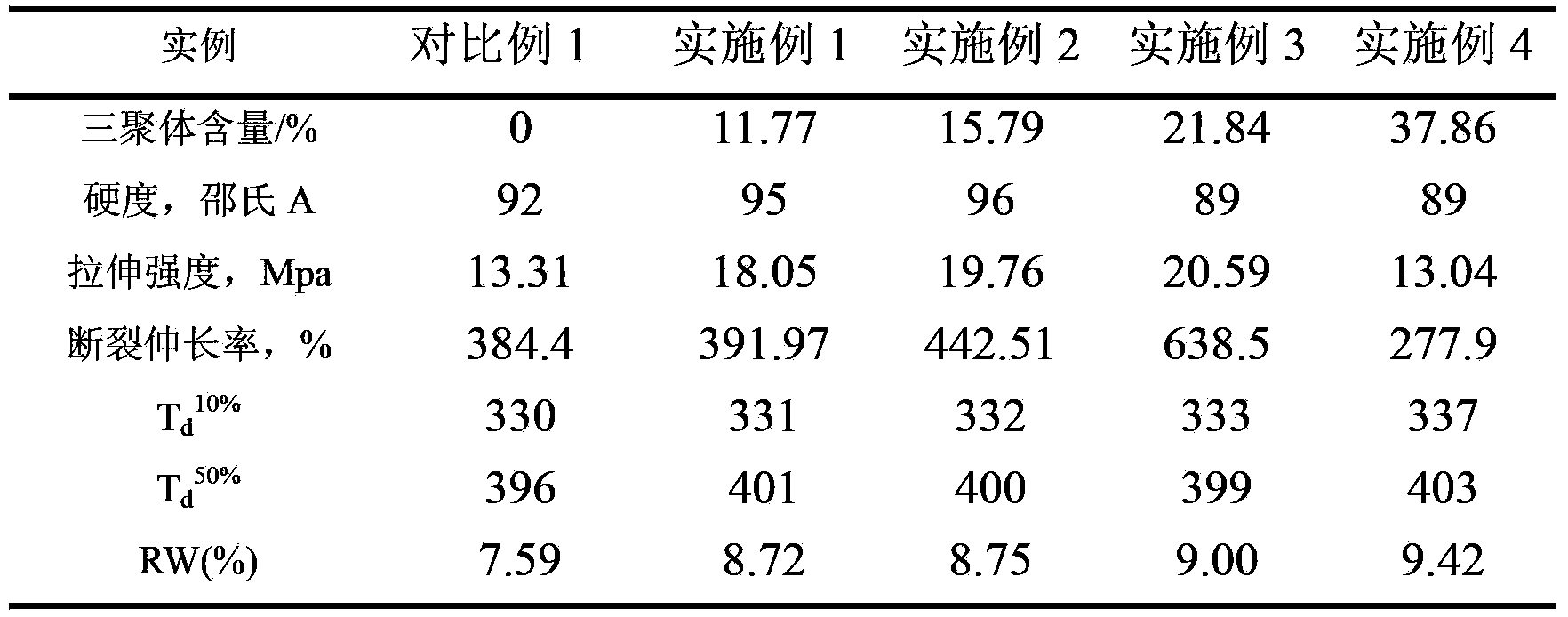

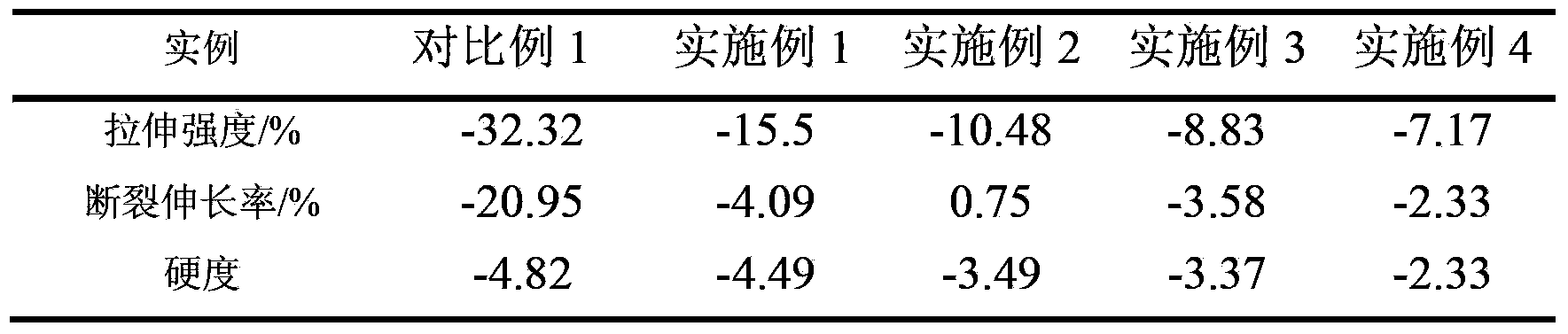

Embodiment 1

[0050]In a reactor with a vacuum and heating device, mix PPG (415.22 parts) and PTMEG (47.66 parts) uniformly and vacuum-dry at 95°C for 2.5h, and slowly cool down to 50°C, and the dried BDO (81.48 parts) and catalyst CT-2X (2.85 parts) were added, mixed and stirred for 15 minutes, and vacuum degassed to obtain component A.

[0051] Control the temperature of materials A and B at 30°C, add 455.63 parts of NCO-B1 to the above-mentioned component A, stir quickly and evenly degas, pour it into a mold with a mold temperature of 80°C, and obtain the submarine pipeline field interface of the present invention Use non-foamed polyurethane node material containing isocyanurate rings.

Embodiment 2

[0053] In a reactor equipped with a vacuum and heating device, mix PPG (415.22 parts) and PTMEG (47.21 parts) evenly and vacuum-dry at 95°C for 2.5 hours, and slowly cool down to 60°C, and the dried BDO (79.56 parts) and catalyst CT-2X (2.85 parts) were added, mixed and stirred for 15 minutes, and vacuum degassed to obtain component A.

[0054] Control the temperature of A and B materials at 30°C, add 458 parts of NCO-B2 to the above-mentioned component A, stir quickly and evenly degas, pour it into a mold with a mold temperature of 80°C, and obtain the submarine pipeline field interface of the present invention Use non-foamed polyurethane node material containing isocyanurate rings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com