Method for preparing ceramic regulation catalytic filling for sea water desulfuration

A technology of catalytic packing and structured packing, applied in the field of preparation of catalytic packing, can solve the problems of poor acid and alkali corrosion resistance, short service life, low desulfurization efficiency, etc. The effect of absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Ceramic structured packing (250Y type ceramic packing, provided by Jiangxi Anyuan Chemical Packing Co., Ltd.) was diluted with 15% (V / V) HNO 3 After treatment, immerse in 400 mL of MnSO with a concentration of 0.9 mol / L 4 In the solution, immerse for 8 hours under stirring at 60°C, then add saturated (NH 4 ) 2 CO 3 The total solution is 360mL. Then the 250Y filler covered with precipitation was taken out from the precipitation solution and aged at 40°C for 6 hours, washed with deionized water, and dried at 120°C for 4 hours to prepare for modification. K with a concentration of 0.1mol / L 2 CO 3 The solution was treated at room temperature for 3 hours, then dried at 120°C for 3 hours, and calcined at 350°C for 3 hours to obtain a loaded 5.8% MnO 2 Modified 250Y ceramic catalytic packing, No. AYC-OUCL-01.

Embodiment 2

[0016] A piece of ceramic structured packing (250Y type ceramic packing, provided by Jiangxi Anyuan Chemical Packing Co., Ltd.) was subjected to 15% (V / V) dilute HNO 3 After treatment, immerse in 200mL of MnSO with a concentration of 0.9mol / L 4 With 200mL of FeSO with a concentration of 0.9mol / L 4 In the mixed solution, immerse for 8 hours under stirring at 60°C, then add saturated (NH 4 ) 2 CO 3 The total solution is 360mL. Then the 250Y filler covered with precipitation was taken out from the precipitation solution and aged at 40°C for 6 hours, washed with deionized water, and dried at 120°C for 4 hours to prepare for modification. K with a concentration of 0.1mol / L 2 CO 3 The solution was treated at room temperature for 3 hours, then dried at 120°C for 3 hours, and calcined at 350°C for 3 hours to obtain a loaded 2.9% MnO 2 , 5.3% Fe 2 o 3 Modified 250Y ceramic catalytic packing, No. AYC-OUCL-02.

Embodiment 3

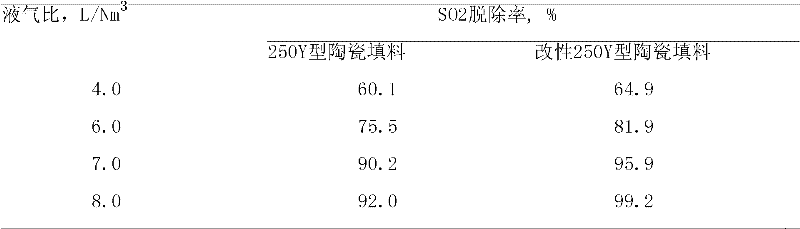

[0018] 2 pieces of AYC-OUCL-01 modified ceramic catalytic fillers (total height 20cm) prepared in Example 1 are packed in the bottom of the seawater desulfurization absorption tower, and 5 pieces of industrial 250Y ceramic structured packing (total height 50cm) are loaded on it, and the packing layer The total height is 70cm. seawater flue gas SO 2 Removal reaction. The seawater temperature entering the tower is 30°C, the seawater flow rate is 20, 40, 60, 80L / h respectively, and the corresponding liquid-gas ratio is 4.0, 6.0, 7.0, 8.0L / Nm 3 . Simulated flue gas flow into the tower: 10Nm 3 / h, flue gas SO 2 The concentration is 2100mg / m 3 , SO 2 The results of the removal reaction are shown in Table 1.

[0019] Table 1 AYC-OUC-01 catalytic filler SO 2 Comparison of removal rate

[0020]

[0021] It can be seen that the absorption efficiency of the absorption tower equipped with partially modified ceramic catalytic packing is 4-15% higher than that of the unmodified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com