Strain monitoring two-dimensional winding composite material underwater vehicle shell and preparation method thereof

A technology of winding composite materials and underwater vehicles, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems affecting the course control of underwater vehicles, reducing the number of carried equipment, and affecting navigation equipment Function and battery life and other issues, to achieve good mechanical stability, reduce self-weight, enhance the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

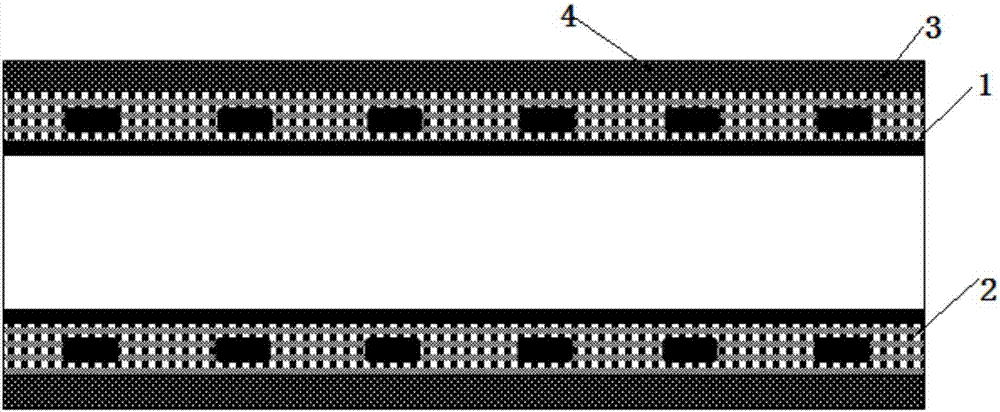

Image

Examples

Embodiment 1

[0057] (1) Preparation of the inner metal sealing layer. The internal metal sealing layer is prepared by high-strength stainless steel with a length of 1m and a thickness of 1mm. Copper ore sand is sprayed on the surface of the sealing layer, and the air pressure of 0.8MPa is used for spray roughening treatment. The final roughness is controlled within the range of Ra 0.6 .

[0058] (2) Preparation of rigid strength layer. Prepare a rigid strength layer on the surface of the roughened internal metal sealing layer, using high-strength T300 carbon fiber and high modulus MJ40 carbon fiber, mixed in a ratio of 2:1, and wrapping the rigid strength layer on the surface of the metal sealing layer at an angle of 3 degrees For the prefabricated body, the mixed fiber is impregnated with 30% epoxy resin while winding, and the final thickness of the impregnated resin and wound fiber is 6mm, and then cured at 120°C for 3 hours.

[0059] (3) Introduction of strain sensing device. During ...

Embodiment 2

[0062] (1) Preparation of the inner metal sealing layer. The internal metal sealing layer is prepared by high-strength aluminum alloy with a length of 2m and a thickness of 1mm. The surface of the sealing layer is sprayed with quartz sand and roughened by spraying with an air pressure of 0.7MPa. The final roughness is controlled at Ra0.8 scope.

[0063] (2) Preparation of rigid strength layer. Prepare a rigid strength layer on the surface of the roughened internal metal sealing layer, using high-strength T700 carbon fiber and high modulus MJ60 carbon fiber, mixed in a ratio of 3:1, and wrapping the rigid strength layer on the surface of the metal sealing layer at an angle of 20 degrees For the prefabricated body, the mixed fiber is impregnated with 40% phenolic resin while winding, and the final thickness of the impregnated resin and wound fiber is 5mm, and then cured at 120°C for 2 hours.

[0064] (3) Introduction of strain sensing device. During the preparation and windin...

Embodiment 3

[0067] (1) Preparation of the inner metal sealing layer. A high-strength titanium alloy with a length of 1.5m and a thickness of 1mm is used to prepare the internal metal sealing layer. The surface of the sealing layer is sprayed with emery and roughened with an air pressure of 0.5MPa. The final roughness is controlled at Ra1.2 scope.

[0068] (2) Preparation of rigid strength layer. Prepare a rigid strength layer on the surface of the roughened internal metal sealing layer, using high-strength T800 carbon fiber and high modulus MJ40 carbon fiber, mixed in a ratio of 4:1, and wrapping the rigid strength layer on the surface of the metal sealing layer at an angle of 30 degrees For the prefabricated body, the mixed fiber is impregnated with 40% epoxy resin while winding, and the final thickness of the impregnated resin and wound fiber is 6mm, and then cured at 130°C for 2 hours.

[0069] (3) Introduction of strain sensing device. During the winding process for the preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com