Hydrophone and manufacturing method thereof

A production method and technology of hydrophone, applied in the field of sonar, can solve the problems of high performance and high pressure resistance, low hydrostatic pressure resistance, poor corrosion resistance, etc., and achieve high sensitivity, high hydrostatic pressure resistance, high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

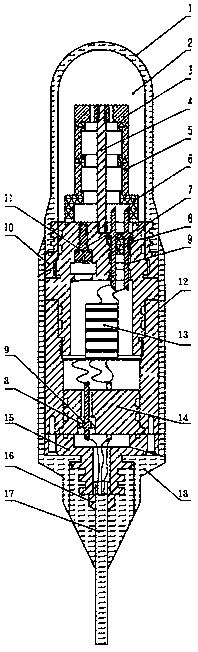

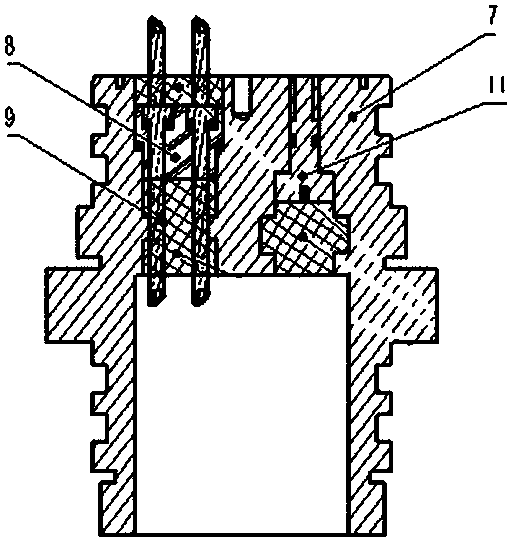

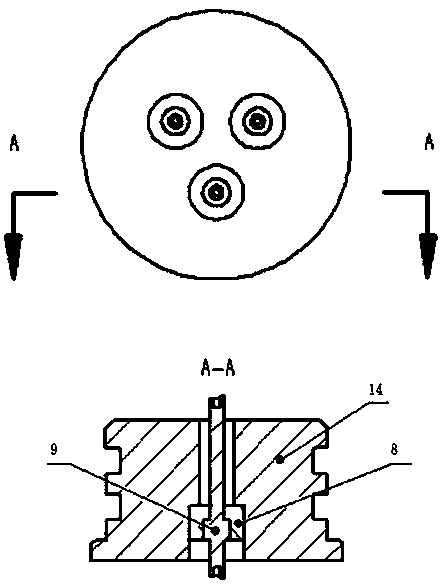

[0046]A hydrophone, comprising a shell, silicone oil, pressure-sensitive elements, electromagnetic shielding net, electrode socket, oil needle, preamplifier, electronic warehouse, connector, the shell is a cylinder with an open lower end and a hemispherical top, The electronic chamber is a cylinder with upper and lower ends open, and the upper end of the electronic chamber is connected to the lower end of the housing; the pressure sensitive element is a plurality of circular tubular piezoelectric ceramic tubes, and the middle of each piezoelectric ceramic tube is passed through a decoupling material. Separated; the electrode socket includes a pin and a plug, and the plug is used for insulation and watertightness; the connector includes an upper fixed cover, a support frame, a fixed screw, a base, a tailstock, and a lower fixed cover. The cover has a through hole, and the upper fixed cover is located at the upper end of the pressure-sensitive element, and the support frame is lo...

Embodiment 2

[0048] A hydrophone includes a shell, silicone oil, pressure-sensitive elements, electrode sockets, oil needles, preamplifiers, electronic compartments, and connectors. The shell is a cylinder with an open lower end and a hemispherical top. The shell adopts JA- S-casting polyurethane and related processes are vulcanized together with metal rubber seats. The wall thickness is 4mm, and the spacing is watertight and sound-permeable. The electronic compartment is a cylinder with openings at both upper and lower ends. Connection; the pressure-sensitive element is two piezoelectric ceramic round tubes connected in series, the size is Φ25×Φ19×15 mm, and the middle of the piezoelectric ceramic round tubes is separated by a decoupling material; the electrode socket includes pins and plugs , the pin is made of brass, the plug is made of polysulfone, and the plug is used for insulation and watertightness; the connecting piece includes an upper fixed cover, a support frame, a fixed screw, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com