Micro-strip rectangular double annular circular-seam resonator-based frequency selectivity surface structure

A frequency-selective, surface-structured technology, applied in waveguide-type devices, circuits, electrical components, etc., can solve the problem of inability to have the same response to electromagnetic waves, and achieve the effects of small attenuation, adjustable resonant frequency, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

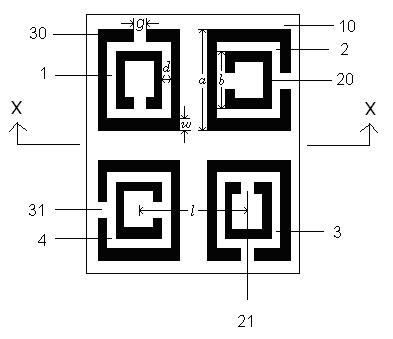

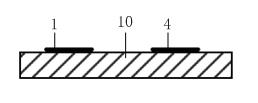

[0023] refer to figure 1 and figure 2 , this embodiment provides a frequency selective surface structure based on microstrip rectangular double-slit resonators, including four microstrip rectangular double-slit resonators 1 , 2 , 3 , 4 and a dielectric substrate 10 . Each microstrip rectangular double-ring slot resonator 1, 2, 3, 4 respectively includes an inner ring 20 and an outer ring 30, each inner ring 20 and each outer ring 30 are respectively provided with an inner ring slot 21, an outer ring ring Seam 31, the inner ring seam 21 and the outer ring seam 31 are set opposite to each other. The inner annular seams 21 on the microstrip rectangular double annular seam resonators 1 , 2 , 3 , 4 are arranged facing different directions, and similarly, the outer annular seams 31 are also arranged facing different directions.

[0024] Such as Figure 5 As shown, four microstrip rectangular double-annular slot resonators 1, 2, 3, and 4 with different annular slot directions co...

Embodiment 2

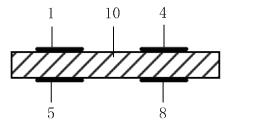

[0031] refer to image 3 , the present embodiment is to deposit the frequency selective surface structure of the microstrip rectangular double annular slot resonator on the upper and lower surfaces of the dielectric substrate 10, from image 3 It can be seen that the upper surface of the dielectric substrate 10 is deposited with microstrip rectangular double-circular slot resonators 1 and 4 , and the lower surface of the dielectric substrate 10 is deposited with microstrip rectangular double-circular slot resonators 5 and 8 . refer to Figure 5 As shown, in this embodiment, the microstrip rectangular double annular slot resonators are arranged on the dielectric substrate 10 in a periodic microstrip array. Other Microstrip Rectangular Double Circular Slot Resonators not shown in image 3 superior.

[0032] The material of the dielectric substrate 10 in this embodiment is high-frequency hybrid ceramics, and its dielectric constant and thickness are 4.6 and 1.4 mm, respectivel...

Embodiment 3

[0038] refer to Figure 4 , this embodiment is a frequency selective surface structure in which a microstrip rectangular double annular slot resonator is deposited in the middle of the dielectric layer, and a microstrip rectangular double annular slot resonator 1, 4 is deposited between the dielectric substrate layer 10 and the dielectric substrate layer 11 , the microstrip rectangular double annular slot resonator is arranged in the middle of the dielectric layers 10 and 11 in a periodic microstrip array. The rest of the microstrip rectangular double annular slot resonators are not in Figure 4 on display.

[0039] The material of the dielectric substrate 10 in this embodiment is high-frequency hybrid ceramics, and its dielectric constant and thickness are 4.6 and 0.7 mm, respectively. The material of the microstrip rectangular double annular slot resonators 1, 2, 3, 4 is copper. The material of the dielectric substrate 10 in the present invention can be sapphire, ruby, hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com