Antioxidation coating material of Nano silicate in use for annealing billet in series

A technology of nano-silicate and anti-oxidation coatings, which is applied in the field of anti-oxidation coatings to solve the loss on ignition of hot-rolled steel billets. It can solve the problems of no site, unacceptable production volume, and inability to adapt to high temperatures, etc., and achieves service life. Improvement, easy access to raw materials, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

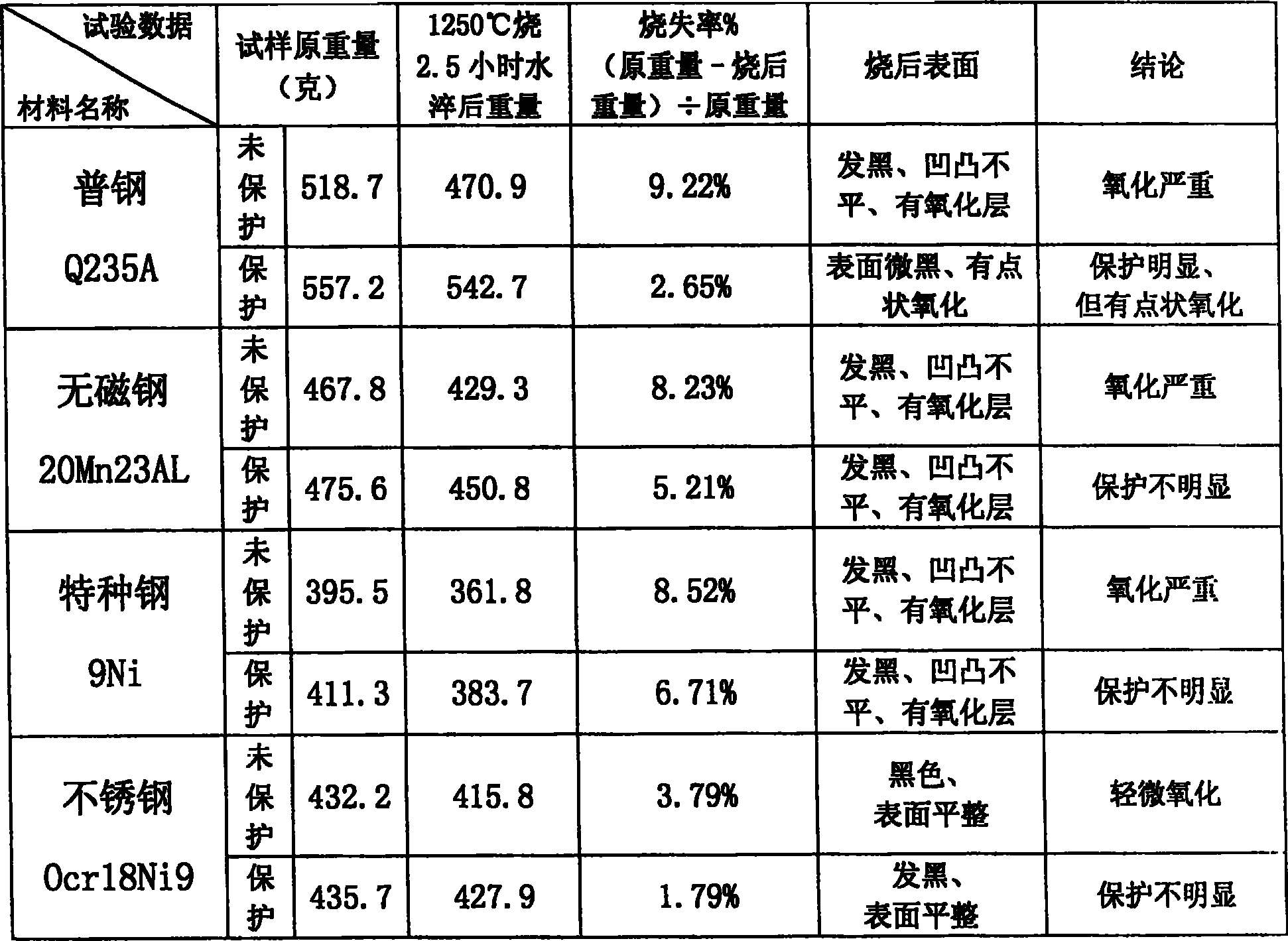

Examples

Embodiment 1

[0037] Embodiment 1: prepare nano-silicate anti-oxidation coating (following percentage by weight).

[0038] (1) Prepare modified potassium water glass: get potassium water glass modulus (molar ratio) to be 1.35, specific gravity 1.53g / cm 3 100 g of potassium water glass was mixed with 65 g of high alumina powder with a particle size of 50 nanometers, and stirred and reacted for 50 hours at 100° C. to obtain modified potassium water glass.

[0039] (2) Prepare modified sodium water glass: get sodium water glass modulus (molar ratio) as 4.5, specific gravity 1.35g / cm 3 100 g of sodium water glass was mixed with 0.1 g of zirconia with a particle size of 50 nanometers, and stirred and reacted for 50 hours at 100° C. to obtain modified sodium water glass.

[0040] (3) Preparation of modified lithium water glass: get silicon dioxide containing 30%, lithium containing 2%, specific gravity 1.18g / cm 3 Lithium water glass 100g is mixed with the chromium oxide 0.1g powder of particle ...

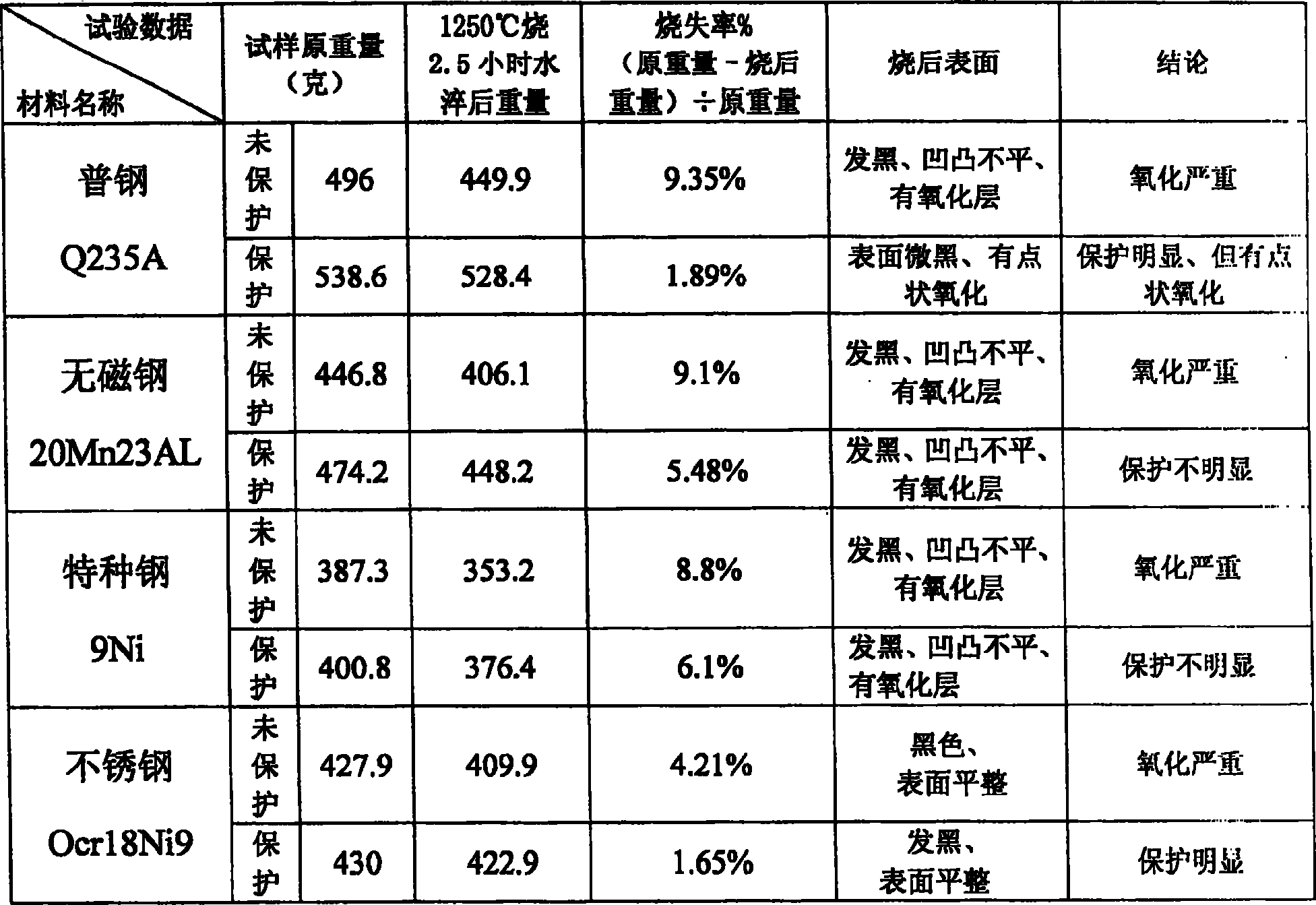

Embodiment 2

[0047] Embodiment 2: preparation nano-silicate anti-oxidation coating (below is weight percent)

[0048] (1) Prepare modified potassium water glass: get potassium water glass modulus (molar ratio) to be 1.35, specific gravity 1.53g / cm 3 100 g of potassium water glass was mixed with 65 g of high alumina powder with a particle size of 50 nanometers, and stirred and reacted for 50 hours at 100° C. to obtain modified potassium water glass.

[0049] (2) Prepare modified sodium water glass: get sodium water glass modulus (molar ratio) as 4.5, specific gravity 1.35g / cm 3 100 g of sodium water glass was mixed with 0.1 g of zirconia powder with a particle size of 50 nanometers, and stirred and reacted for 50 hours at 100° C. to obtain modified sodium water glass.

[0050] (3) Preparation of modified lithium water glass: get silicon dioxide containing 30%, lithium containing 2%, specific gravity 1.18g / cm 3 100 g of lithium water glass, mixed with 0.1 g of chromium oxide powder with a ...

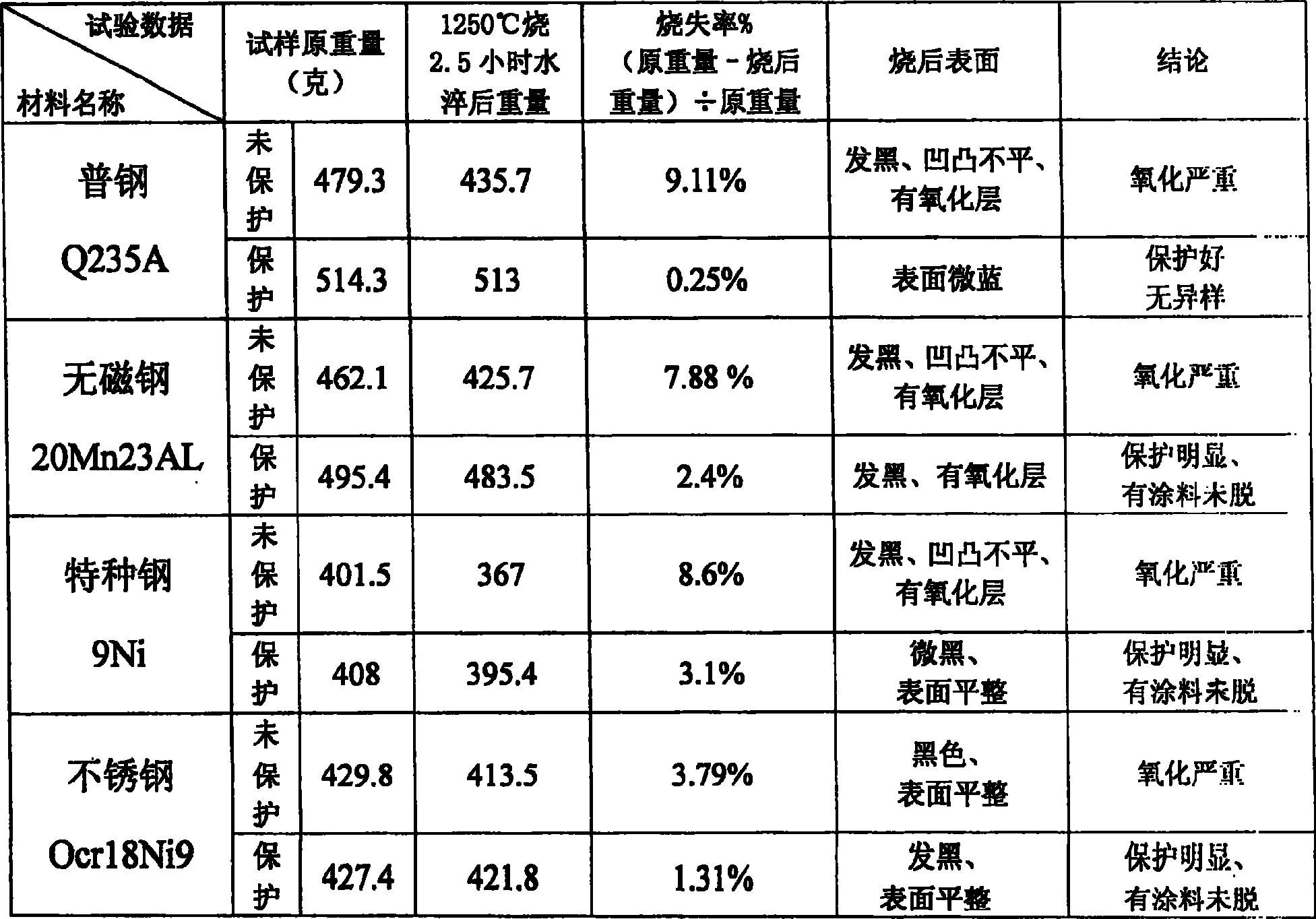

Embodiment 3

[0058] (1) Prepare modified potassium water glass: get potassium water glass modulus (molar ratio) to be 1.35, specific gravity 1.53g / cm 3 100 g of potassium water glass was mixed with 65 g of high alumina powder with a particle size of 50 nanometers, and stirred and reacted for 50 hours at 100° C. to obtain modified potassium water glass.

[0059] (2) Prepare modified sodium water glass: get sodium water glass modulus (molar ratio) as 4.5, specific gravity 1.35g / cm 3 100 g of sodium water glass was mixed with 0.1 g of zirconia with a particle size of 50 nanometers, and stirred and reacted for 50 hours at 100° C. to obtain modified sodium water glass.

[0060] (3) Preparation of modified lithium water glass: get silicon dioxide containing 30%, lithium containing 2%, specific gravity 1.18g / cm 3 Lithium water glass 100g is mixed with the chromium oxide 0.1g powder of particle size 20 nanometers, at 100 ℃, stirring reaction 50 hours obtains modified lithium water glass.

[0061...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com