High-strength low-temperature-resistant adhesive as well as preparation method and application thereof

An adhesive and low-temperature-resistant technology, applied in the field of aerospace materials, can solve the problems of low impact strength and unsatisfactory bonding strength, and achieve good bonding strength and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

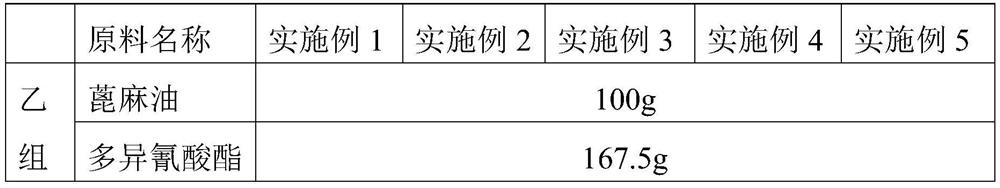

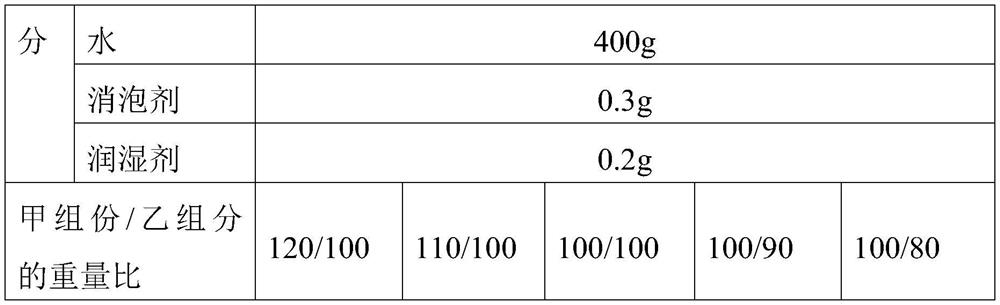

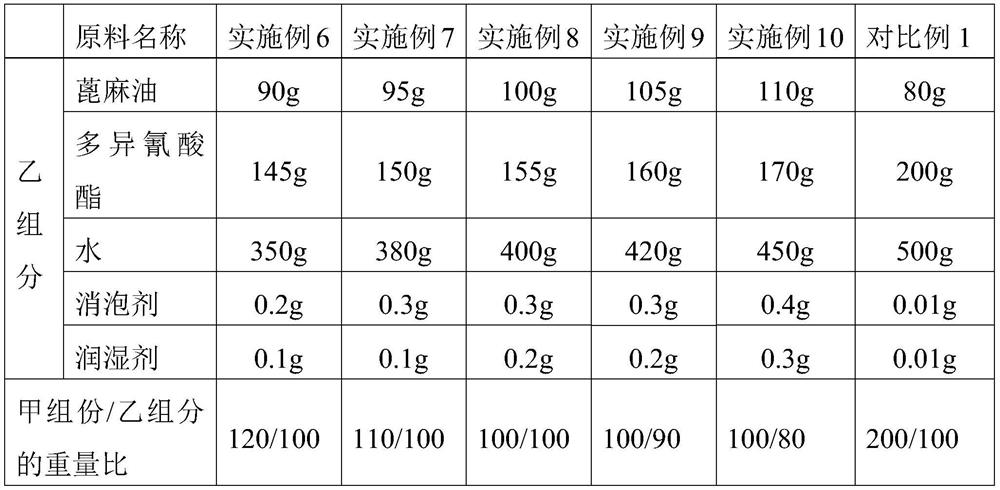

Examples

preparation example Construction

[0057] The preparation method of above-mentioned adhesive comprises the following steps:

[0058] (1) Take castor oil and polyisocyanate, add them to reactor F1, mix at room temperature for 45-75min, then gradually raise the temperature of reactor F1 to 70-80°C, react for 3-5h, cool down to 45-55°C, keep warm After 8-12h, intermediate product A is obtained;

[0059] (2) Weigh the water and add it to the reaction kettle F2, gradually heat the reaction kettle F2 to 35~95°C, add the intermediate product A obtained in step (1) dropwise, the rate of addition is 3~5kg / min, at 35~95℃, Insulate at 95°C for 5-20 hours, vacuumize the reactor F2 until the vacuum degree reaches -0.08MPa, then gradually raise the temperature to 110-115°C, remove moisture, adjust the vacuum degree to above 0.098MPa, and keep warm at 110-115°C 1.5 to 2.5 hours to obtain the intermediate product B; the water content of the intermediate product B is below 0.1%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com