An intelligent monitoring three-dimensional composite underwater vehicle shell and its preparation method

A technology of underwater vehicles and composite materials, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of short battery life of underwater vehicles, increased weight of underwater vehicles, and course control Slowness and other problems, to achieve good mechanical stability, reduce self-weight, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The cylindrical metal sealing layer is prepared by high-strength stainless steel with a thickness of 3mm, and the length of the entire cylinder is 1m. The surface of the metal sealing cylinder is prepared with threads at a depth of 1 mm.

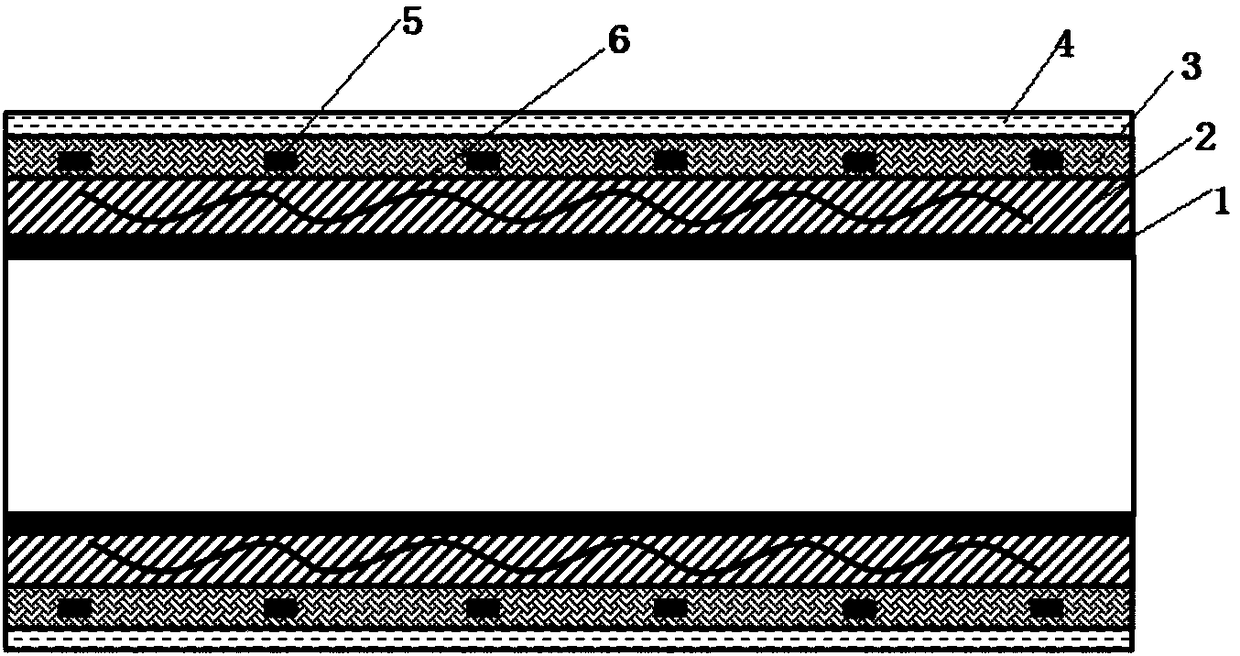

[0061] Then prepare a rigid layer on the surface of the metal sealing sleeve, using high-strength carbon fiber as the main fiber, auxiliary glass fiber, the ratio of carbon fiber to auxiliary fiber in the hybrid fiber is controlled within the range of 5:1, and a three-dimensional four-way braided structure is selected. Six sets of strain-sensing sheets are embedded in the middle of the prefabricated body with a thickness of 3 mm. The strain-sensing sheets are uniformly arranged along the length of the cylinder and evenly distributed on the cross-sectional circle according to the angle. Three-dimensional five-directional weaving technology is used on the inner and outer surfaces of the rigid layer prefabricated body structure. The pre...

Embodiment 2

[0065] Aluminum alloy with a thickness of 3 mm is used to prepare a cylindrical metal sealing layer, and the length of the entire cylinder is 1.6 m. The surface of the metal sealing cylinder is prepared with threads at a depth of 1 mm.

[0066] Then prepare a rigid layer on the surface of the metal sealing sleeve, using high-modulus carbon fiber as the main fiber, auxiliary glass fiber, the ratio of carbon fiber to auxiliary fiber in the hybrid fiber is controlled within the range of 5:1, and a three-dimensional five-way weaving structure is selected. Eight sets of strain-sensing sheets are embedded in the middle of the 4mm thickness of the rigid layer prefabricated body. The strain-sensing sheets are uniformly arranged along the length of the cylinder and evenly distributed on the cross-sectional circle according to the angle. Three-dimensional seven-way weaving technology is used on the inner and outer surfaces of the rigid layer prefabricated structure. The prepared rigid ...

Embodiment 3

[0070] A cylindrical metal sealing layer is prepared by using a titanium alloy with a thickness of 2mm, and the length of the entire cylinder is 2m. The surface of the metal sealing cylinder is prepared with threads at a depth of 1mm.

[0071] Then prepare a rigid layer on the surface of the metal sealing sleeve, using high-modulus carbon fiber as the main fiber, auxiliary basalt fiber, the ratio of carbon fiber to auxiliary fiber in the hybrid fiber is controlled within the range of 6:1, and a three-dimensional five-way weaving structure is selected. 10 sets of strain-sensing sheets are embedded in the middle of the 2mm thickness of the rigid layer prefabricated body. The strain-sensing sheets are uniformly arranged along the length of the cylinder and evenly distributed on the cross-sectional circle according to the angle. Three-dimensional seven-way weaving technology is used on the inner and outer surfaces of the rigid layer prefabricated structure. The prepared rigid lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com