Double-ironing cyclic extrusion solidification method for remanufacturing titanium abandoned cuttings

A curing method and double diameter reduction technology, applied in manufacturing tools, solid waste removal, presses, etc., can solve the problems of weakening the mechanical properties of materials, difficult to refine the microstructure, weakening the strength of materials, etc., to eliminate pore defects, The effect of preventing continuous distribution and aggregation and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

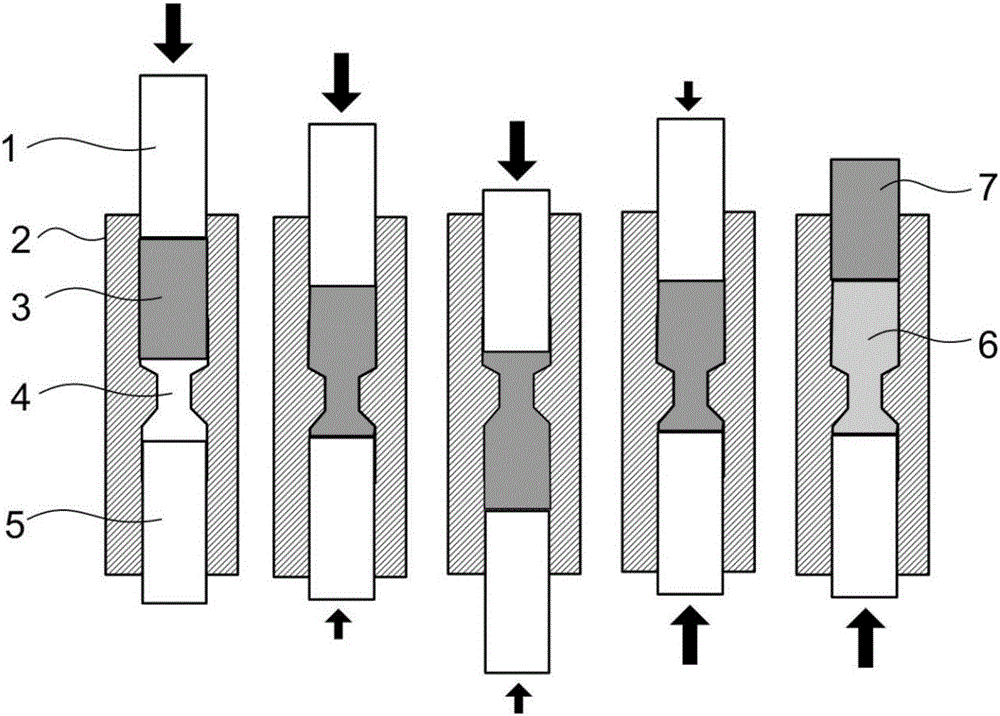

[0033] Such as figure 1 As shown, the specific steps of the double-shrinking cyclic extrusion solidification method for the remanufacturing of titanium waste chips proposed by the present invention are as follows: Ti chip recovery pretreatment, BM treatment of Ti chips, wrapping packaging of BM-Ti chips, wrapping packaging BM - Room temperature cold extrusion of Ti chips, high-temperature solidification processing of double-reduced cyclic extrusion, ejection, demoulding and quenching of Ti material samples.

[0034] Step (1)-Ti chip recovery pretreatment: use the chips generated by end milling Ti 2 (ASTM Grade 2) as raw materials, collect the chips, and use Inductively coupled plasma atomic emission spectroscopy (ICP for short) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com