Transparent lacquer protective film and application thereof

A technology of protective film and clear paint, applied in the direction of pressure-sensitive film/sheet, film/sheet release liner, film/sheet adhesive, etc., can solve the problem of burns, large water contact angle and poor impact resistance and other problems, to achieve the effect of easy operation, low water contact angle, and high impact resistance water contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation method of transparent paint protective film provided by the invention comprises the steps:

[0070] a. Accurately weigh the parts by weight of each component of the self-repairing layer, add it to an organic solvent, and stir evenly to obtain a self-repairing glue coating liquid;

[0071] b. Evenly coat the self-healing glue coating solution on the upper surface of the substrate layer, and then enter the oven to bake at a temperature of 40-125°C to form a self-healing layer on the upper surface of the substrate layer, and the winding place is The surface of the self-repairing layer is laminated with a PET release film layer by a pressing roller to obtain a semi-finished product;

[0072] c. Coating pressure-sensitive adhesive on the lower surface of the base material layer of the semi-finished product, then entering the oven to bake at a temperature of 40-150°C, forming a pressure-sensitive adhesive layer on the lower surface of the base material layer o...

Embodiment 1

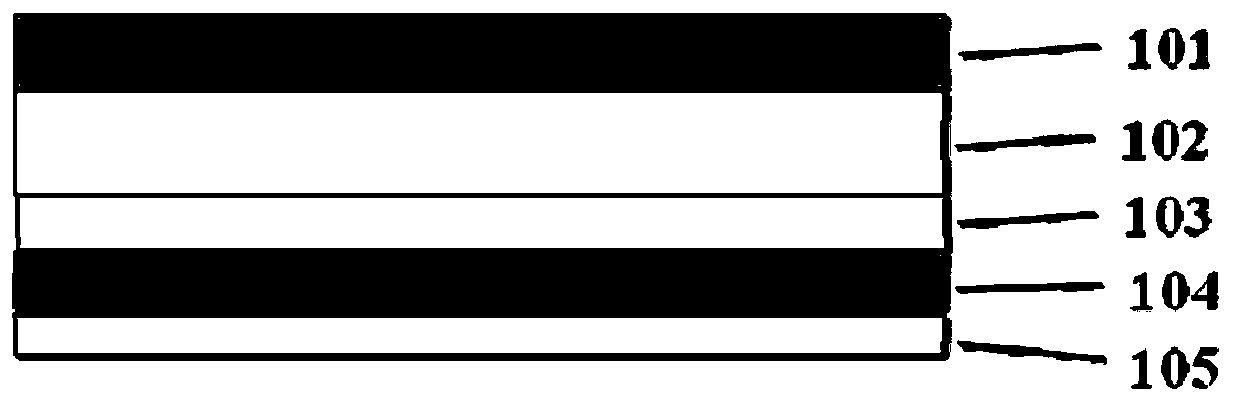

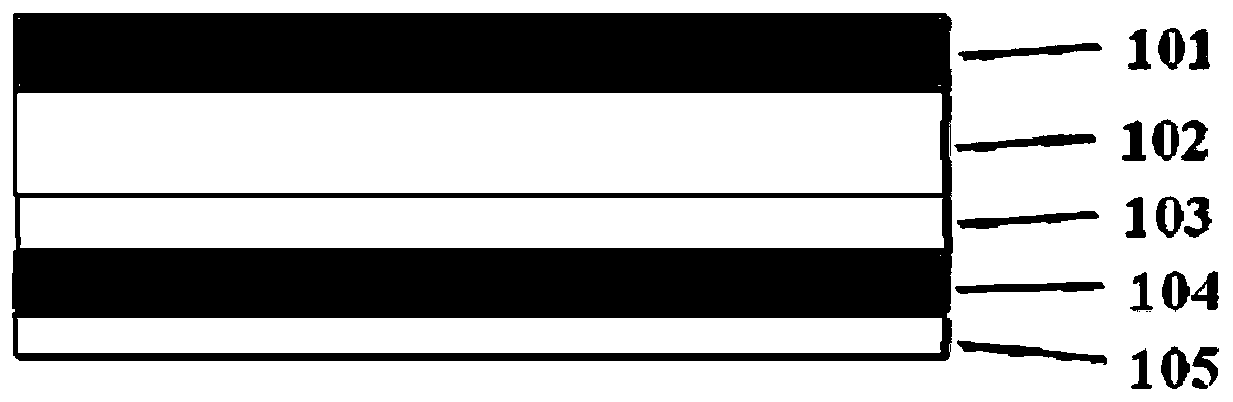

[0081] The invention provides a transparent paint protection film, which includes a self-repairing layer, a base material layer and a pressure-sensitive adhesive layer; wherein the self-repairing layer is arranged on one side of the base material layer, and the The other side of the substrate layer is provided with the pressure-sensitive adhesive layer.

[0082] The raw material of the self-healing layer of the transparent paint protection film is composed of the following materials: polyol resin: 55 parts by weight; crosslinking agent: 18 parts by weight; inorganic nanoparticles: 26.3 parts by weight; catalyst: 0.2 parts by weight; Ultraviolet absorbent: 0.5 parts by weight; wherein the polyol resin is polyester polyol resin, specifically 651MPA of Covestro; the crosslinking agent is TDI trimer, specifically E1660 of Covestro; the inorganic nanoparticles are The nano-alumina particles have a particle size of 40nm; the catalyst is dibutyltin dilaurate; the ultraviolet absorber...

Embodiment 2

[0089] The raw material of the self-healing layer of the transparent paint surface protective film as described in Example 1 is made up of following materials: polyol resin: 78 weight parts; Crosslinking agent: 11 weight parts; Inorganic nanoparticles: 5 weight parts; Catalyst: 3.0 parts by weight; UV absorber: 3.0 parts by weight; wherein the polyol resin is polyester polyol resin, specifically UXP2698 of Covestro; the crosslinking agent is HDI trimer, specifically HT-790B of Wanhua Chemical ; The inorganic nanoparticles are nano silicon oxide particles with a particle size of 10nm; the catalyst is dibutyltin dilaurate; the ultraviolet absorber is a benzotriazole ultraviolet absorber.

[0090] Wherein, the organic solvent in the self-healing glue coating solution is ethyl acetate; the material of the base material layer is TPU, and the thickness is 250 μm; the thickness of the self-healing layer is 8 μm; the pressure-sensitive adhesive layer It is an acrylate layer with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com