Melt-blown composite nano-antibacterial super-soft non-woven material and preparation method thereof

A technology of non-woven materials and anti-bacterial materials, applied in the field of non-woven materials, can solve the problems of poor anti-bacterial durability, poor hand feeling of anti-bacterial non-woven materials, not resistant to washing and friction, etc., to achieve long-lasting anti-bacterial performance, good UV protection function, The effect of long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the melt-blown composite nano antibacterial supersoft nonwoven material of the present invention comprises the following steps:

[0032] 1) Prepare flexible melt-blown materials, nanofiber antibacterial materials, and nanofiber hydrophilic materials respectively;

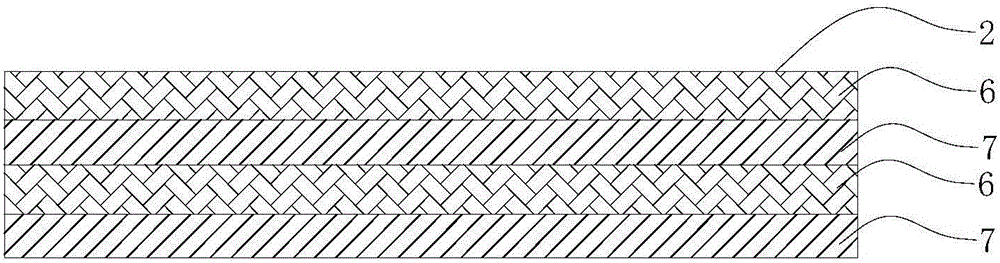

[0033] 2)) Alternately laminating the nano-titanium dioxide material and the nano-fiber anti-bacterial material to prepare the nano-fiber anti-bacterial body material;

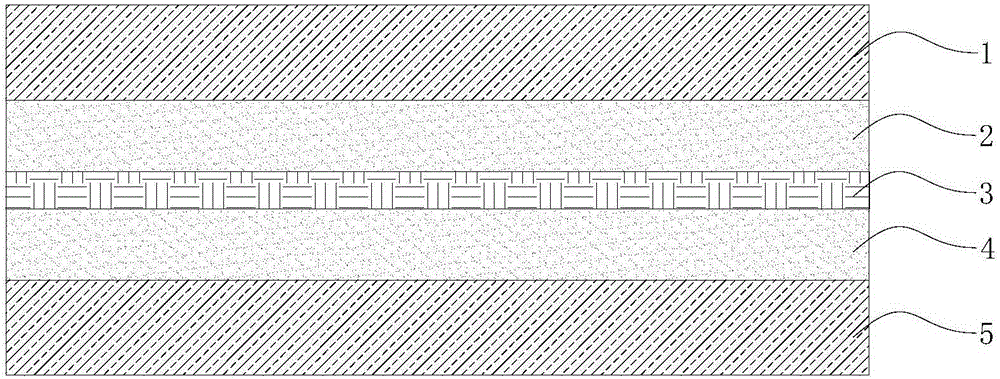

[0034] 3) Nanofiber antibacterial body materials are respectively arranged on both sides of the nanofiber hydrophilic material to form a nonwoven material with the first nanofiber antibacterial layer 2, the nanofiber hydrophilic layer 3, and the second nanofiber antibacterial layer 4;

[0035] 4) Flexible melt-blown materials are respectively arranged on both sides of the nonwoven material described in step 3), forming the first flexible melt-blown layer 1, the first nanofiber antibacterial layer 2, and the nanofiber...

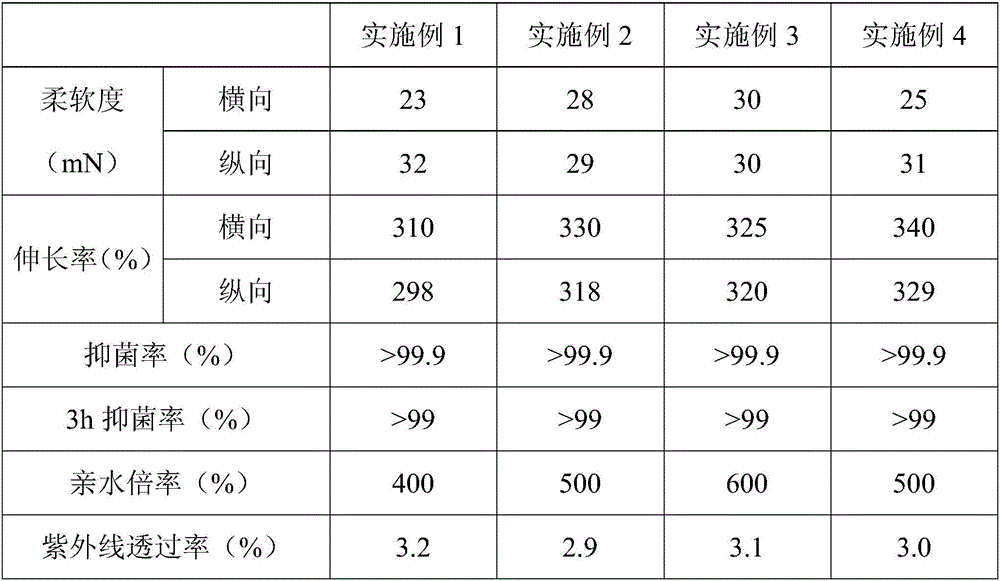

Embodiment 1

[0038] 1) Polypropylene is used as a raw material to prepare polypropylene staple fibers with an average diameter of 1 μm through a melt-blown spinning process, and the prepared polypropylene staple fibers, cotton fibers, and ES fibers are prepared in a mass ratio of 15:8:3, Processed into flexible meltblown materials by hot air bonding;

[0039] 2) Add silver-based antibacterial agent to polypropylene, and prepare nanofiber antibacterial material through electrospinning process after melting, wherein the mass ratio of polypropylene to silver-based antibacterial agent is 20:1, and nano titanium dioxide material and nanofiber antibacterial Materials are alternately stacked to prepare nanofiber antibacterial materials, wherein the diameter of nano titanium dioxide is 20nm;

[0040] 3) After the polypropylene is melted, the nanofiber material is prepared by an electrospinning process, and the hydrophilic agent is diluted with high-purity water to prepare a hydrophilic solvent. Af...

Embodiment 2

[0043] 1) Use polypropylene as raw material to prepare polypropylene staple fibers with an average diameter of 1.5 μm through a melt-blown spinning process, and prepare polypropylene staple fibers, cotton fibers, and ES fibers in a mass ratio of 5:5:1 , processed into flexible meltblown materials by hot air bonding;

[0044] 2) Add silver-based antibacterial agent to polypropylene, and prepare nanofiber antibacterial material through electrospinning process after melting. Materials are alternately stacked to prepare nanofiber antibacterial materials, wherein the diameter of nano titanium dioxide is 30nm;

[0045] 3) After the polypropylene is melted, the nanofiber material is prepared by an electrospinning process, and the hydrophilic agent is diluted with high-purity water to prepare a hydrophilic solvent. After the hydrophilic solvent is coated on the nanofiber material, the nanofiber is prepared by drying hydrophilic material;

[0046] 4) Nanofiber antibacterial body mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com