Composite ultraviolet-proof finishing liquid and preparation method and application thereof

An anti-ultraviolet and finishing liquid technology, which is applied in the field of textile fabrics, can solve the problems of poor ultraviolet absorption ability, etc., and achieve the effects of excellent anti-ultraviolet function and light resistance, good anti-ultraviolet performance, and strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1.1 The composition and content of the composite UV-resistant finishing solution in this embodiment are as follows:

[0030] Nano ZnO, TiO2, SiO2 powder mixture 30g / L, of which ZnO, TiO 2 and SiO 2 The mass ratio is 1:1:1, synergist FK-80725g / L, polyoxyethylene ether 0.5g / L, polyethylene glycol (200) dimethacrylate 25g / L, azobisisobutyronitrile 0.5g / L, ethanol and methanol mixture 25g / L, of which ethanol 15g / L, methanol 10g / L, urea 12g / L, glycerin 2g / L, leveling agent BYK246 0.5g / L, defoamer 902W 0.2g / L, curing agent KH560 1.5g / L.

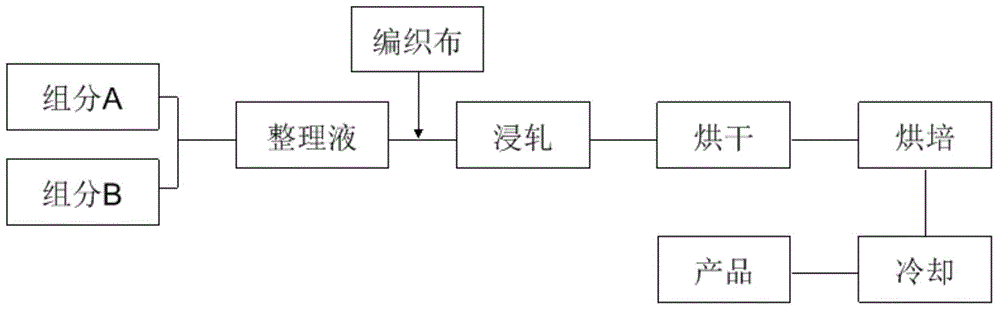

[0031] 1.2 The preparation method of the finishing solution is as follows: figure 1 As shown, put the nano-ZnO, TiO2, SiO2 powder mixture into water, stir rapidly to dissolve it in water, then add polyoxyethylene ether and synergist FK-807 to obtain component A after uniform miscibility. Dissolve polyethylene glycol (200) dimethacrylate and a small amount of azobisisobutyronitrile in a mixture of ethanol and methanol to form a solution ...

Embodiment 2

[0034] 2.1 The composition and content of the composite UV-resistant finishing solution in this embodiment are as follows:

[0035] Nano ZnO, TiO2, SiO2 powder mixture 25g / L, of which ZnO, TiO 2 and SiO 2 The mass ratio is 1:1:1, synergist FK-80720g / L, polyoxyethylene ether 0.7g / L, aryl β-diketone ligand 15g / L, azobisisobutyronitrile 1g / L , ethanol and methanol mixture 29g / L, of which ethanol 17g / L, methanol 12g / L, urea 10g / L, glycerin 3g / L, leveling agent BYK246 0.3g / L, defoamer 902W 0.6g / L, solidified Agent KH560 1g / L.

[0036] 2.2 The preparation method of the finishing solution is as follows: figure 1As shown, put the nano-ZnO, TiO2, SiO2 powder mixture into water, stir rapidly to dissolve it in water, then add polyoxyethylene ether and synergist FK-807 to obtain component A after uniform miscibility. Dissolve aryl β-diketone ligands and a small amount of azobisisobutyronitrile in a mixture of ethanol and methanol to form a solution to obtain component B. After mixing ...

Embodiment 3

[0039] 3.1 The composition and content of the composite UV-resistant finishing solution in this embodiment are as follows:

[0040] Nano ZnO, TiO2, SiO2 powder mixture 27g / L, of which ZnO, TiO 2 and SiO 2 The mass ratio is 1:1:1, synergist FK-80730g / L, polyoxyethylene ether 1g / L, amino acid schiff base 30g / L, azobisisobutyronitrile 0.7g / L, ethanol and methanol mixture 35g / L, including ethanol 20g / L, methanol 10g / L, urea 15g / L, glycerin 4g / L, leveling agent BYK246 1g / L, defoamer 902W 1g / L, curing agent KH560 2g / L.

[0041] 3.2 The preparation method of the finishing solution is as follows: figure 1 As shown, put the nano-ZnO, TiO2, SiO2 powder mixture into water, stir rapidly to dissolve it in water, then add polyoxyethylene ether and synergist FK-807 to obtain component A after uniform miscibility. Dissolve amino acid schiff base and a small amount of azobisisobutyronitrile in the mixture of ethanol and methanol to form a solution to obtain component B. After mixing compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com