Mosquito-repelling and sun-proof composite functional microcapsule and preparation method thereof

A composite function and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, biochemical fiber treatment, etc., can solve the problems of unsatisfactory one-time preparation and single function of microcapsules, and achieve excellent anti-ultraviolet effect and mosquito repellent Long-lasting effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of acid-analyzed lignin

[0033] Weigh 0.6g of alkali lignin particles and 0.06g of sodium lauryl sulfate and disperse them in 30mL deionized water, stir them evenly with a magnetic stirrer, and adjust the pH value of the solution to about 11 with 4mol / L NaOH solution , filter to remove insoluble impurities, then use 1mol / L hydrochloric acid to adjust the pH value of the solution to 2-3, stir evenly to obtain an acid-analyzed lignin suspension, which is ready for use.

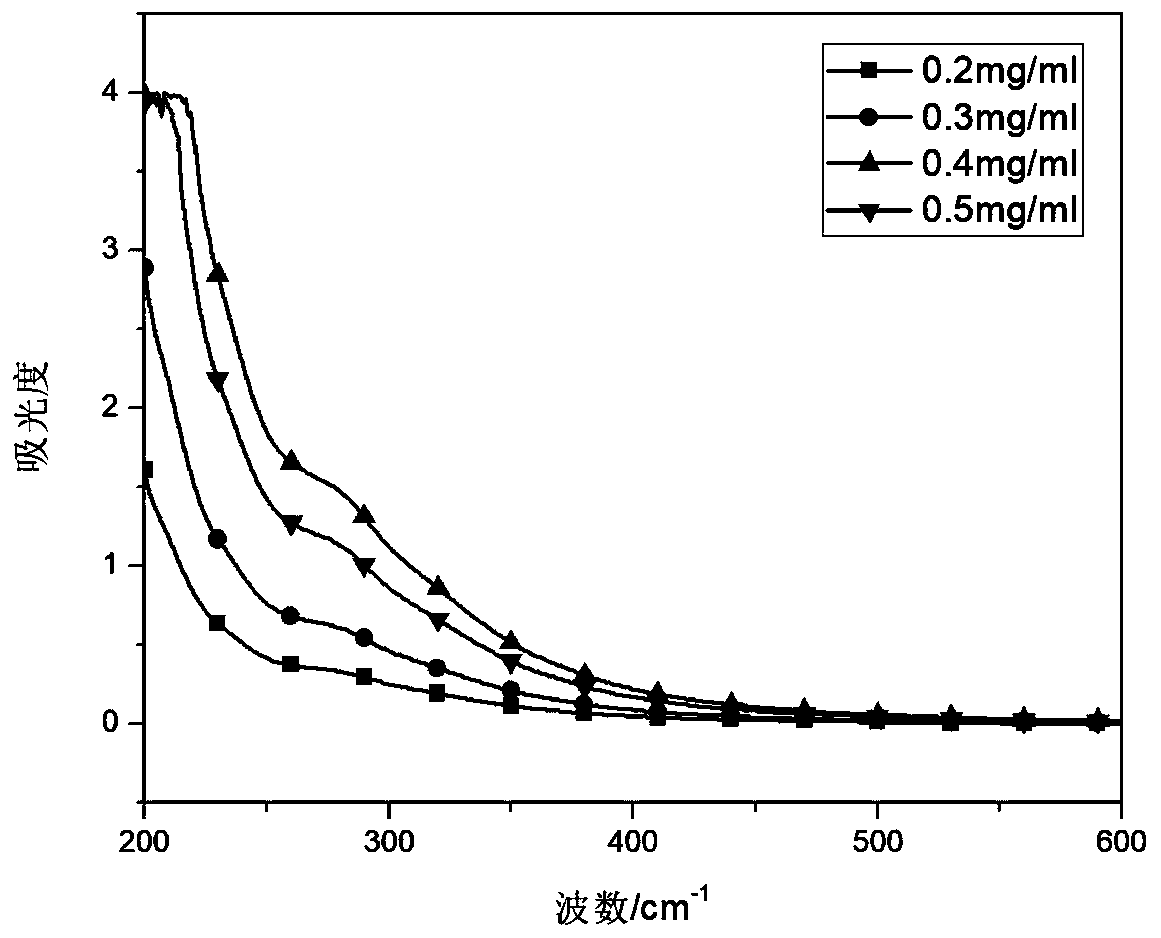

[0034] (2) Preparation of mosquito repellent sunscreen lotion

[0035] Get 7.84g of citronella oil, 0.16g of 2-hydroxy-4-methoxybenzophenone and 2.52g of isophorone diisocyanate and mix evenly, which is the oil phase. Disperse the acid-analyzed lignin suspension in step (1) into 26 mL of deionized water, which is the water phase. Slowly add the oil phase into the water phase, and emulsify for 10 min under high-speed shear at 10,000 r / min to obtain the mosquito repellent sunscreen emulsi...

Embodiment 2

[0040] (1) Preparation of acid analysis lignin

[0041] Weigh 1.2g of alkali lignin particles and 0.09g of sodium lauryl sulfate and disperse them in 30mL of deionized water, stir them evenly with a magnetic stirrer, and use 4mol / L NaOH solution to adjust the pH value of the solution to about 11 , filter to remove insoluble impurities, then use 1mol / L hydrochloric acid to adjust the pH value of the solution to 2-3, stir evenly to obtain an acid-analyzed lignin suspension, which is ready for use.

[0042] (2) Preparation of mosquito repellent sunscreen lotion

[0043] Get 7.84g of citronella oil, 0.16g of 2-hydroxy-4-methoxybenzophenone and 2.52g of isophorone diisocyanate and mix evenly, which is the oil phase. Disperse the acid-analyzed lignin suspension in step (1) into 26 mL of deionized water, which is the water phase. Slowly add the oil phase into the water phase, and emulsify for 10 min under high-speed shear at 10,000 r / min to obtain the mosquito repellent sunscreen e...

Embodiment 3

[0048] (1) Preparation of acid analysis lignin

[0049] Weigh 0.6g of alkali lignin particles and 0.06g of sodium lauryl sulfate and disperse them in 30mL deionized water, stir them evenly with a magnetic stirrer, and adjust the pH value of the solution to about 11 with 4mol / L NaOH solution , filter to remove insoluble impurities, then use 1mol / L hydrochloric acid to adjust the pH value of the solution to 2-3, stir evenly to obtain an acid-analyzed lignin suspension, which is ready for use.

[0050] (2) Preparation of mosquito repellent sunscreen lotion

[0051] Get 7.36g of citronella oil, 0.64g of 2-hydroxy-4-methoxybenzophenone and 2.52g of isophorone diisocyanate and mix evenly, which is the oil phase. Disperse the acid-analyzed lignin suspension in step (1) into 26 mL of deionized water, which is the water phase. Slowly add the oil phase into the water phase, and emulsify for 10 min under high-speed shear at 10,000 r / min to obtain the mosquito repellent sunscreen emulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

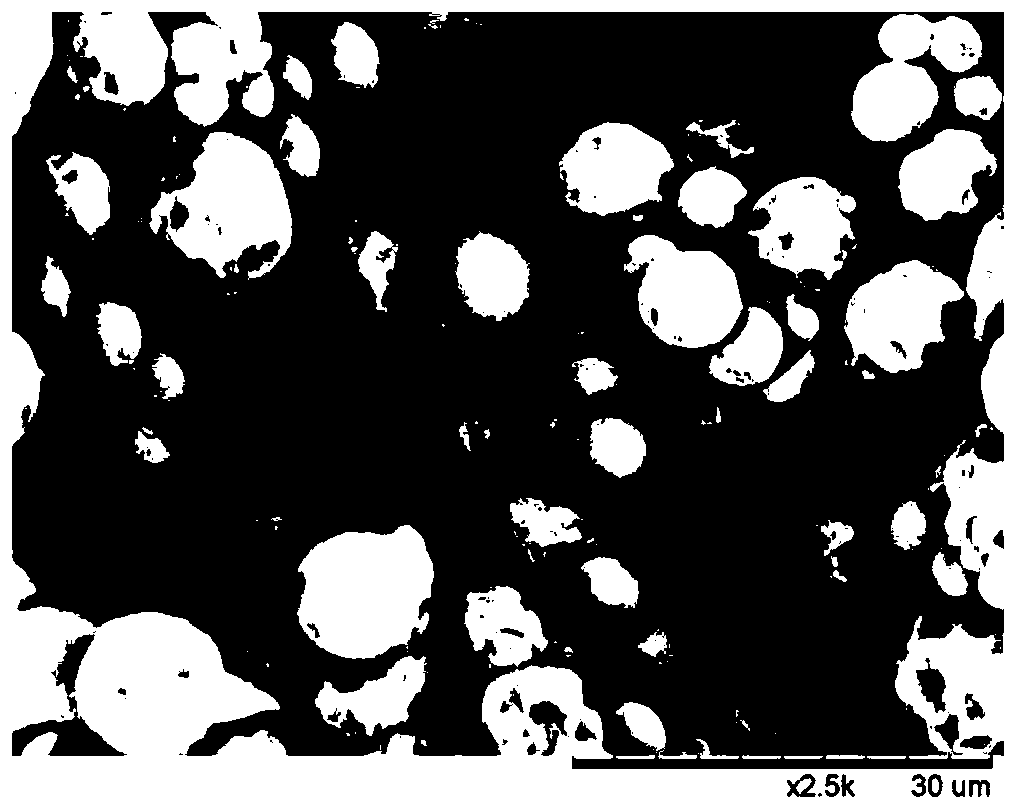

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com