Ultraviolet-proof fabric

An anti-ultraviolet and anti-ultraviolet finishing technology, applied in the field of fabrics, can solve the problems of short ultraviolet anti-ultraviolet performance and coolness durability of fabrics, reduced anti-ultraviolet performance, easy failure of active ingredients, etc., and achieve excellent anti-ultraviolet function, good lightfast color. The effect of fastness and high practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

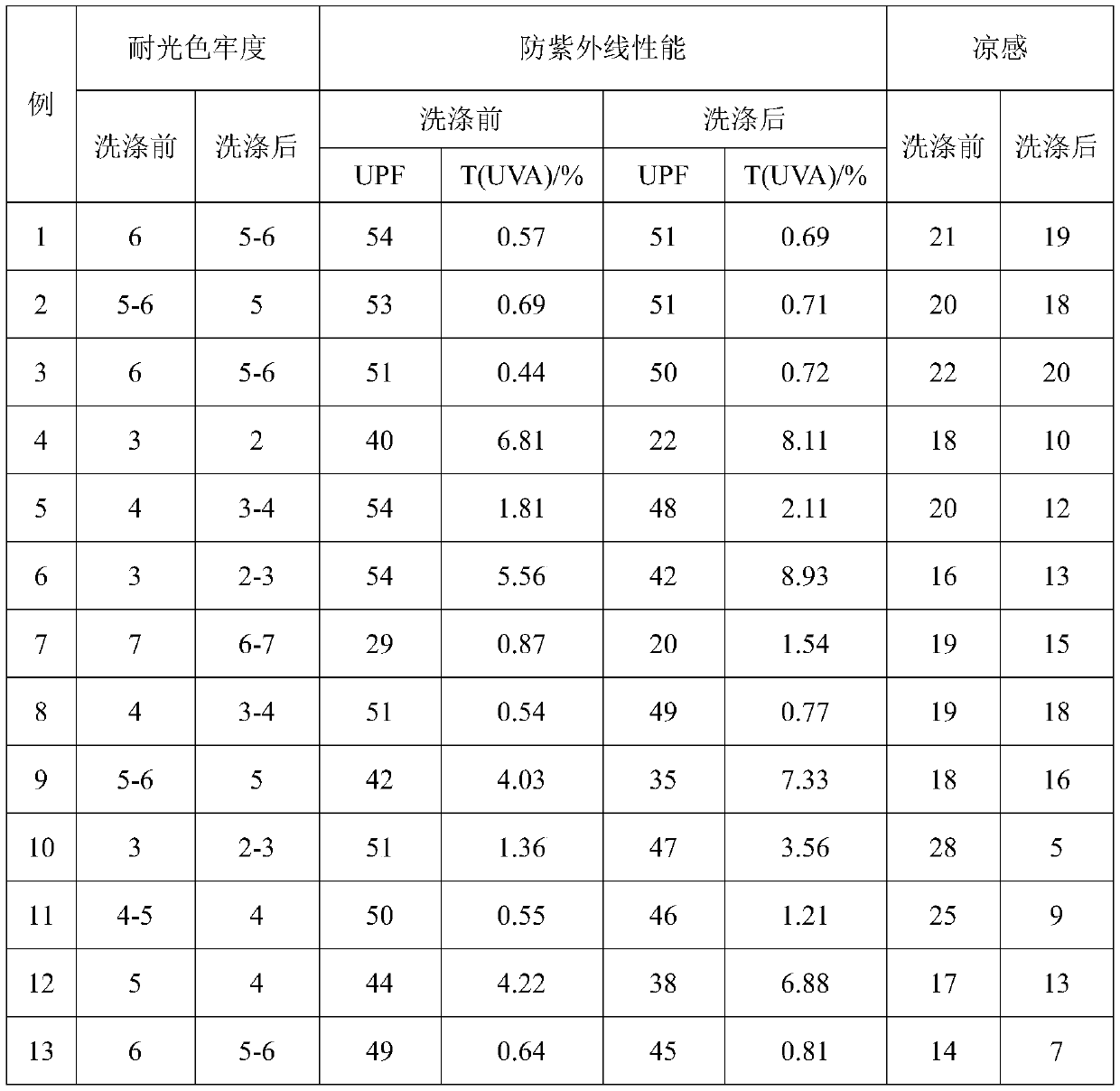

Examples

preparation example Construction

[0083] In a preferred embodiment, the preparation method of the UV-resistant finishing agent comprises the following steps:

[0084] a. Preparation of A solution: under stirring conditions, add silane coupling agent and nano-titanium dioxide into water in sequence, and mix well to obtain A solution;

[0085] b. Preparation of solution B: under stirring conditions, add cyclodextrin and plant extracts to water at 70-80°C in sequence, and mix well to obtain hot solution B;

[0086] c. Finishing agent preparation: Mix the A solution obtained in step a and the hot B solution obtained in step b evenly, add a thickener, mix evenly and cool to room temperature to obtain the UV-resistant finishing agent.

[0087] In a more preferred embodiment, the preparation method of the UV-resistant finishing agent comprises the following steps:

[0088] a. Preparation of A solution: under stirring conditions, add silane coupling agent and nano-titanium dioxide into water in sequence, and mix well...

Embodiment 1

[0107] Embodiment 1 of the present invention provides an anti-ultraviolet fabric, which is obtained by finishing with an anti-ultraviolet finishing agent, and the anti-ultraviolet finishing agent includes the following raw materials in parts by weight:

[0108] Component A: 50 parts of nano titanium dioxide, 2 parts of silane coupling agent, 200 parts of water;

[0109] Component B: 4 parts of cyclodextrin, 3 parts of plant extract, 50 parts of water;

[0110] Component C: 1 part of thickener.

[0111] The nano titanium dioxide in the component A is silicon dioxide modified nano titanium dioxide;

[0112] The preparation of the silicon dioxide modified nano titanium dioxide comprises the following steps:

[0113] (1) In parts by weight, add 5 parts of nano-titanium dioxide under stirring conditions, add 50 parts of water and mix uniformly to obtain a uniform mixed solution A;

[0114] (2) In the mixed solution A prepared in step (1), add 5 parts of water glass and 1 part of...

Embodiment 2

[0131] Embodiment 2 of the present invention provides an anti-ultraviolet fabric, which is obtained by finishing with an anti-ultraviolet finishing agent, and the anti-ultraviolet finishing agent includes the following raw materials in parts by weight:

[0132] Component A: 45 parts of nano titanium dioxide, 1 part of silane coupling agent, 190 parts of water;

[0133] Component B: 3 parts of cyclodextrin, 2 parts of plant extract, 45 parts of water;

[0134] Component C: 1 part of thickener.

[0135] The nano titanium dioxide in the component A is silicon dioxide modified nano titanium dioxide;

[0136] The preparation method of described silicon dioxide modified nano titanium dioxide is the same as embodiment 1;

[0137] The phenyl-containing silane coupling agent in the component A is ((chloromethyl)phenylethyl)trimethoxysilane (CAS No.: 68128-25-6);

[0138] The cyclodextrin in the component B is β-cyclodextrin (CAS number: 7585-39-9);

[0139] The plant extract in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com