Preparation method and application of textile ultraviolet-proof finishing agent

A technology of anti-ultraviolet and finishing agent, applied in fiber treatment, plant fibers, textiles and papermaking, etc., can solve the problems of high ultraviolet transmittance, low UPF value, poor washing fastness of fabrics, etc., and achieve good washing fastness. , Excellent washing fastness, improved effect of UV protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 100 parts of polyoxypropylene diol (Mw=1000), 49 parts of isophorone diisocyanate, 12 parts of N-methyldiethanolamine, 0.5 parts of triethylenediamine, 50 parts of dipropylene glycol dimethyl ether, in 80- React at 100°C for 4-6 hours, then lower the temperature of the prepolymer to 40-60°C, add 6 parts of glacial acetic acid, continue stirring for 30 minutes, and then add 100 parts of N-(ethoxycarbonylphenyl)- Add N'-methyl-N'-phenylformamidine to the above prepolymer and stir evenly to obtain a transparent viscous liquid, then add 683 parts of water to this liquid for emulsification for 1 hour, and finally obtain a stable milky white belt Blu-ray liquid.

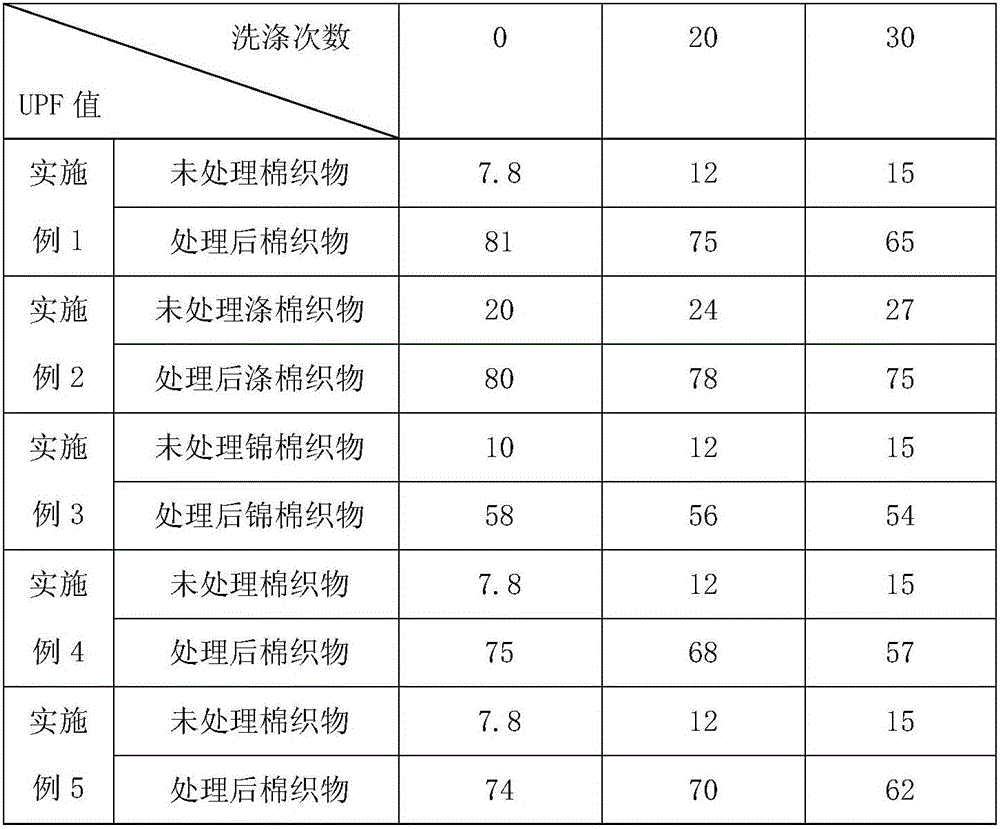

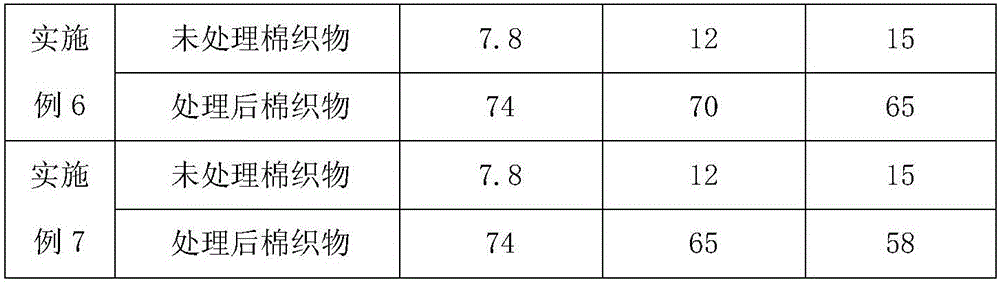

[0034] Get this emulsion 50g, dilute to 1000g solution with water, then use cotton fabric (140g / m 2 ) to perform one dipping and one padding (liquid-carrying rate 60-80%), and finally bake at 170° C. for 1 minute to obtain an anti-ultraviolet finished cotton fabric. The UPF value was determined using a textil...

Embodiment 2

[0036] Take 100 parts of polytetramethylene ether glycol (Mw=1000), 75 parts of hexamethylene diisocyanate, 35 parts of N-ethyldiethanolamine, 0.1 part of dibutyltin dilaurate, 60 parts of dipropylene glycol diethyl ether, React at 80-100°C for 4-6 hours, then lower the temperature of the prepolymer to 40-60°C, add 17 parts of glacial acetic acid, continue stirring for 30 minutes, and then add 100 parts of 2-(2H-benzotri Add azol-2-yl)-6-dodecyl-4-methylphenol into the above prepolymer and stir evenly to obtain a transparent viscous liquid, then add 613 parts of water to this transparent viscous liquid for emulsification After 1 hour, a stable opalescent liquid with blue light was finally obtained.

[0037] Get this emulsion 50g, dilute to 1000g solution with water, then use cotton-polyester blended woven fabric (120g / m 2 )-soaking-rolling (with liquid rate 60-80%) finishing solution, and finally baking at 160° C. for 2 minutes to obtain the finished fabric. Then use the tex...

Embodiment 3

[0039]Take 150 parts of polyoxypropylene diol (Mw=2000), 100 parts of isophorone diisocyanate, 35 parts of N-methyldiethanolamine, 0.4 parts of N,N-dimethylcyclohexylamine, N-methylpyrrolidone 50 parts, reacted at 80-100°C for 4-6 hours, then cooled the prepolymer to 40-60°C, added 11 parts of hydrochloric acid, continued to stir for 30 minutes, and then added 100 parts of N-(ethoxy Carbonylphenyl)-N'-methyl-N'-phenylformamidine was added to the above prepolymer and stirred evenly to obtain a transparent viscous liquid, and finally 554 parts of water were added to the transparent viscous liquid to emulsify to obtain Stable opalescent liquid with blue light.

[0040] Get this emulsion 50g, dilute to 1000g solution with water, use cotton nylon blended fabric (120g / m 2 )-soaking-and-rolling (liquid-carrying rate 60-80%) finishing solution, and finally baking at 170° C. for 1 minute to obtain a finished cotton-nylon blended fabric. Use the textile UV protection factor tester (ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com