Ultraviolet-proof shell fabric and manufacturing method thereof

A production method and anti-ultraviolet technology, which is applied in the field of anti-ultraviolet fabrics and its production, can solve the problems of high strength of bamboo fiber, difficult to make clothes, easy to break, etc., and achieve the effect of overcoming high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

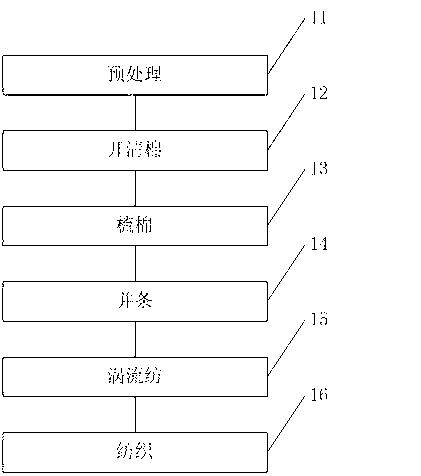

Method used

Image

Examples

Embodiment 1

[0050] 50% bamboo fiber and 50% polyester, at first the bamboo fiber is dried, then sprayed to give oil to wet treatment, spray oil to give wet penetrating agent in the bamboo fiber, wherein the composition of the penetrating agent includes emulsifier 13%, softening agent 10%, the balance is soft water, the addition of penetrant is 10% of the weight percentage of bamboo fiber; polyester fiber is oiled and wetted at the same time.

[0051] Then it passes through the plucking machine, the cotton blending machine and the carding opener in turn, wherein the beater speed of the plucker is 750r / min, and the two parallel beater speeds of the cotton blender are 760r / min and 810r / min respectively. The beating speed of the needle opener is 600r / min, the feeding roller speed of the vibrating cotton box is 35r / min, the roller speed of the lapping machine is 20r / min, the comprehensive beating speed is 800r / min, and the humidity in the workshop is 49% , the polyester fiber opening and clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com