White printing paste, preparation method and application of white printing paste

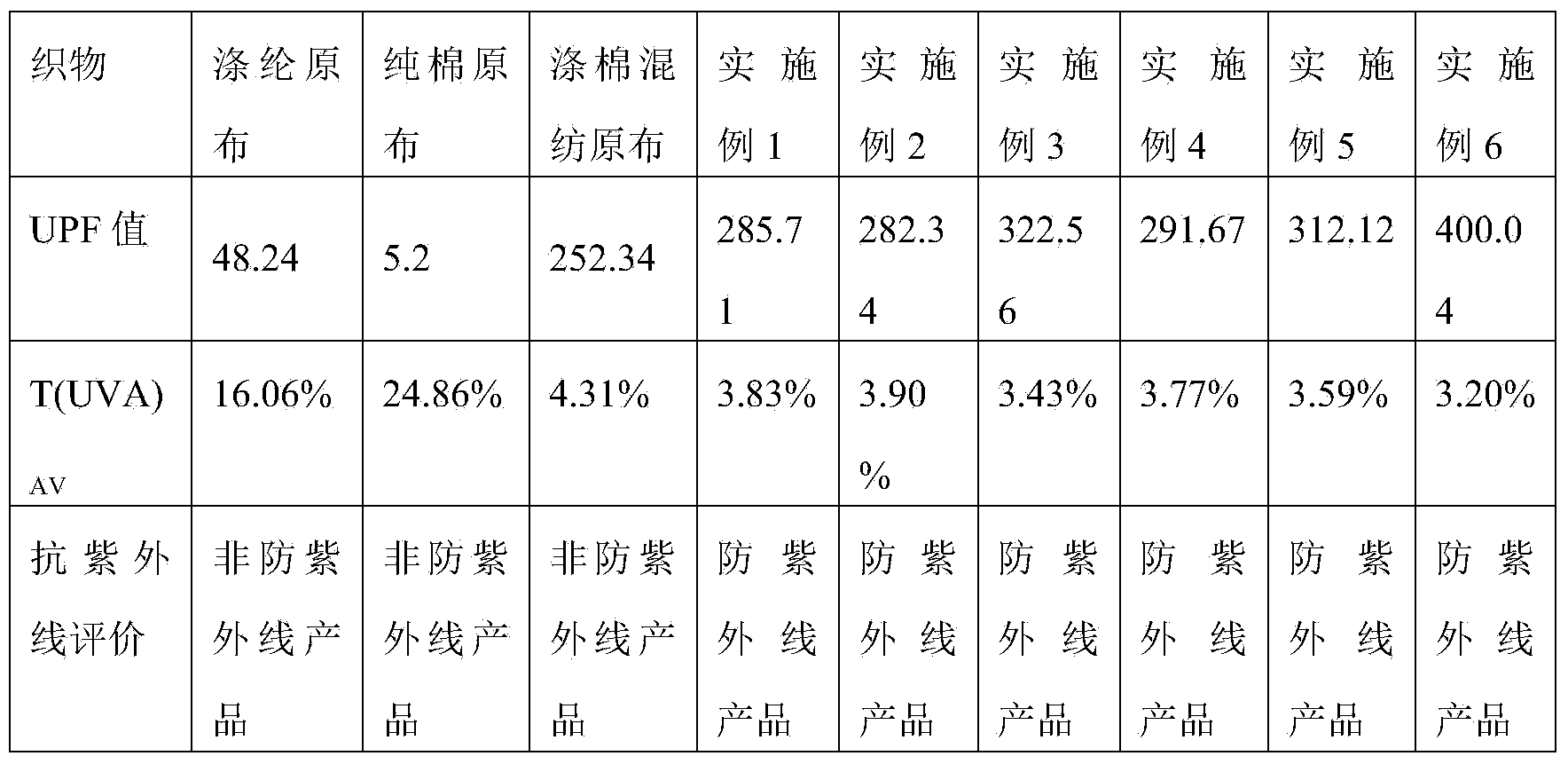

A printing paste, white pigment technology, applied in dyeing, textile and papermaking, etc., can solve the problems of little development of snow camouflage and protective textile materials, affecting the safety of individual soldiers in snow combat, and high requirements for base materials. Achieve good UV protection, avoid easy delamination, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0029] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0030] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0031] Parts and percentages in the following examples are all in units of weight.

Embodiment 1

[0033] 1) Add 0.1 part of dispersant polycarboxylate and 1 part of white pigment silicon dioxide to 91.9 parts of deionized water at room temperature, shake in an ultrasonic oscillator for 30 minutes, so that the pigment is evenly dispersed in deionized water;

[0034] 2) Add 2 parts of thickener sodium alginate and 5 parts of adhesive polyacrylate to the dispersed solution, and stir for 1 hour at 2000 rpm to prepare the required printing paste.

[0035] 3) Pass the prepared printing paste through a screen printing machine, evenly print it on the polyester base fabric, pre-bake it at 80°C for 5 minutes, then bake it at 120°C for 3 minutes, and wash it once with standard water to obtain the snow camouflage protection fabric.

Embodiment 2

[0037] 1) Add 2 parts of dispersant polyphosphate and 20 parts of white pigment aluminum oxide into 43 parts of deionized water at room temperature, and vibrate in an ultrasonic oscillator for 30 minutes to evenly disperse the pigment in the deionized water;

[0038] 2) Add 5 parts of synthetic thickener and 30 parts of adhesive polyurethane to the dispersed solution, and stir for 2 hours at a speed of 5000 rpm to prepare the required printing paste.

[0039] 3) Pass the prepared printing paste through a screen printing machine, evenly print it on the polyester base fabric, pre-bake it at 90°C for 5 minutes, then bake it at 160°C for 3 minutes, and wash it once with standard water to obtain the snow camouflage protection fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com