Sliding type zoom lens support and lamp structure

A zoom lens and sliding bracket technology, which is applied in the direction of lighting devices, light sources, and light source fixation, can solve the problems of inapplicability, complex structure of rotating and zooming, etc., and achieve the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

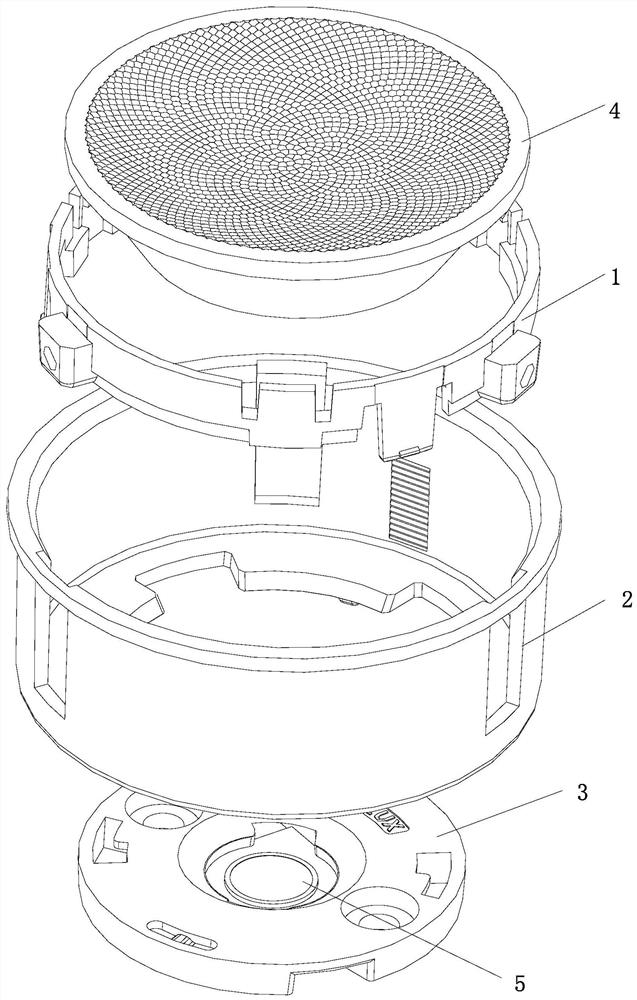

[0033] Such as Figure 4 As shown, a sliding zoom lens bracket includes a sliding bracket 1 and a fixed bracket 2 that are mated and connected to each other. The sliding bracket 1 can slide up and down along the fixed bracket 2 .

[0034] Such as Figure 5 As shown, the sliding bracket 1 is a ring structure, including a main ring body 11, the upper part of the main ring body 11 is provided with an upper buckle 12, and the inner wall of the main ring body 11 is provided with a step 14, the upper buckle 12 and the step 14 It is used to fix the lens 4.

[0035] The lower part of the main ring body 11 is provided with a lower buckle 13, the lower buckle 13 is a PC plastic part, an ABS plastic part, a nylon part or an aluminum part, and the thickness of the lower buckle 13 is 0.5mm-1.5mm, preferably about 1mm. The lower buckle 13 has a certain degree of elasticity, thereby reducing the requirements for the processing technology of the bracket.

[0036] The outer wall of the main...

Embodiment 2

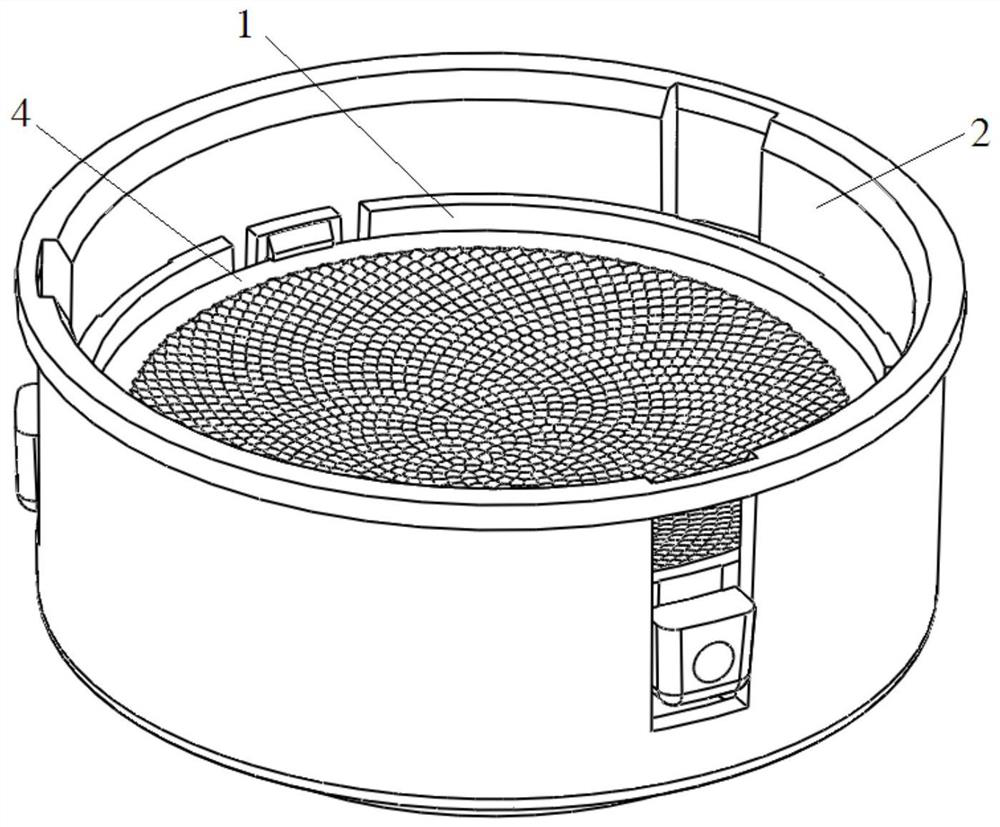

[0043]A lamp structure, including a sliding zoom lens bracket according to Embodiment 1. The sliding bracket 1 is fixedly connected with a lens 4 , and the fixed bracket 2 is fixedly connected with an LED light source 5 . Specifically, such as figure 1 , image 3 As shown, in this embodiment, the lens 4 is a TIR lens, the lens 4 is fixed on the sliding bracket 1 through the upper buckle 12 and the step 14, the LED light source 5 is installed on the light source bracket 3, and the light source bracket 3 and the fixed bracket 2 are fixed through the buckle 26 Connect with the positioning post 27 turnbuckles.

Embodiment 3

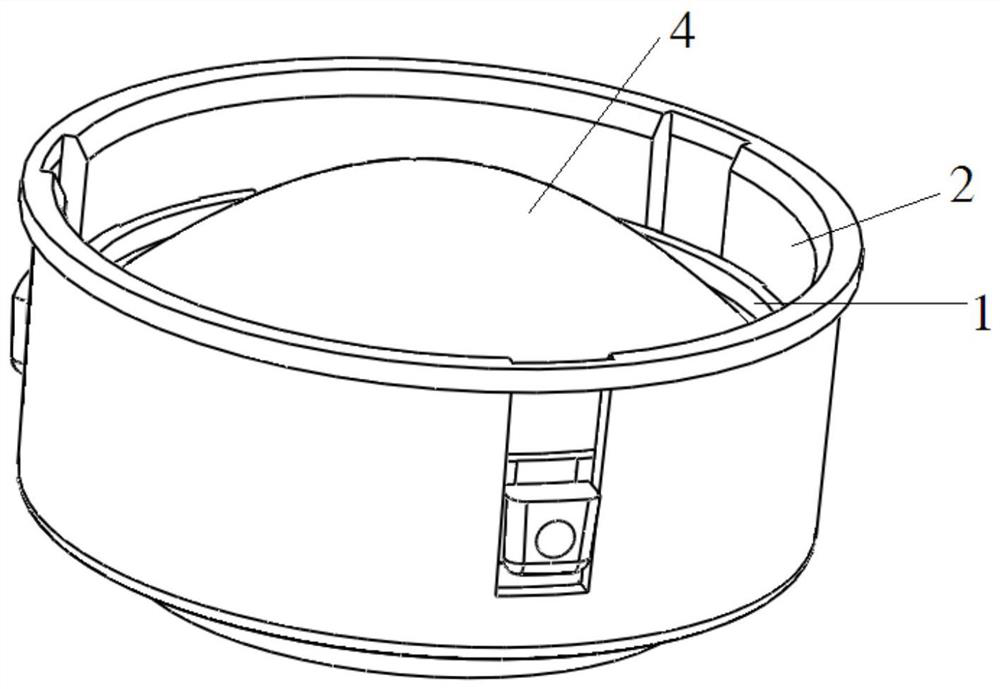

[0045] The difference between this embodiment and embodiment 2 is that, as figure 2 As shown, in this embodiment, the lens 4 is a convex lens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com