Bedding fabric with antibacterial and cool functions and post-finishing process thereof

A functional and cool technology, applied in the field of finishing of home textile fabrics and home textile fabrics, can solve the problems of poor wrinkle resistance and poor spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

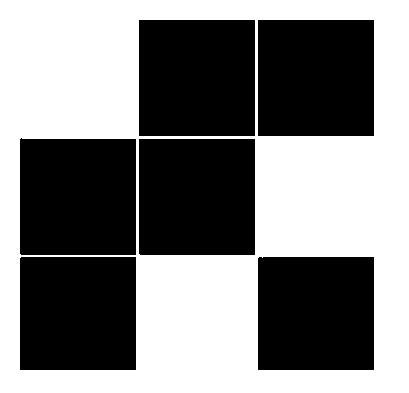

[0028] Specifications: (linen 30% + chitin fiber 50% + polyester filament 20%) 40S* (linen 30% + chitin fiber 50% + polyester filament 20%) 40S / 133*76, door width 250cm, two upper Take a look at the twill weave, the organization diagram is as follows figure 1 shown.

Embodiment 2

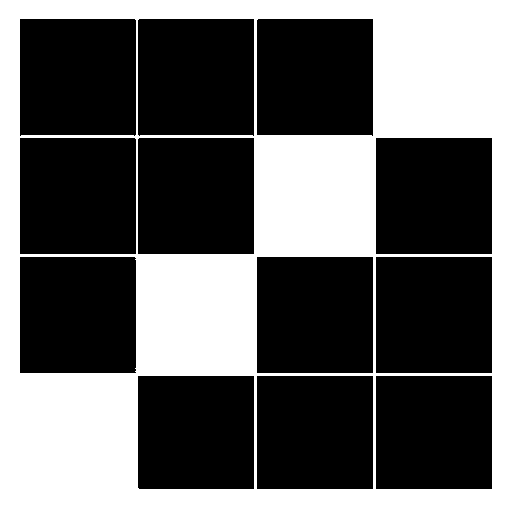

[0030] Specifications: (flax 45% + chitin fiber 35% + polyester filament 20%) 60S* (linen 45% + chitin fiber 35% + polyester filament 20%) 60S / 182*120, door width 250cm, Mikami Take a look at the twill weave, the organization diagram is as follows figure 2 shown.

Embodiment 3

[0032] Specifications: (flax 60% + chitin fiber 20% + polyester filament 20%) 60S* (linen 60% + chitin fiber 20% + polyester filament 20%) 60S / 182*120, door width 250cm, Mikami Take a look at the twill weave, the organization diagram is as follows figure 2 shown.

[0033] The technical route of Sirofill spinning: the roving made by blending flax and chitin fiber is fed into the spinning frame from the back roller, the polyester filament is fed into the spinning frame from the front roller, and the chitin fiber roving is drafted on the front roller. Afterwards, it is mixed with polyester filaments and kept at a fixed distance from the holding point of the front roller to form a twisted triangular area, which is twisted together to form a sirofil composite yarn. The filaments of Sirofill spinning do not pass through the drafting zone, but are fed directly from the front roller. The feeding route is: yarn guide bar→yarn guide hook→anti-jump device→tension controller→yarn guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com