Patents

Literature

73results about How to "Preventing a short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc secondary battery

ActiveUS20140315099A1Improve reliabilityPreventing a short circuitSilver accumulatorsSolid electrolytesElectrolyteIon

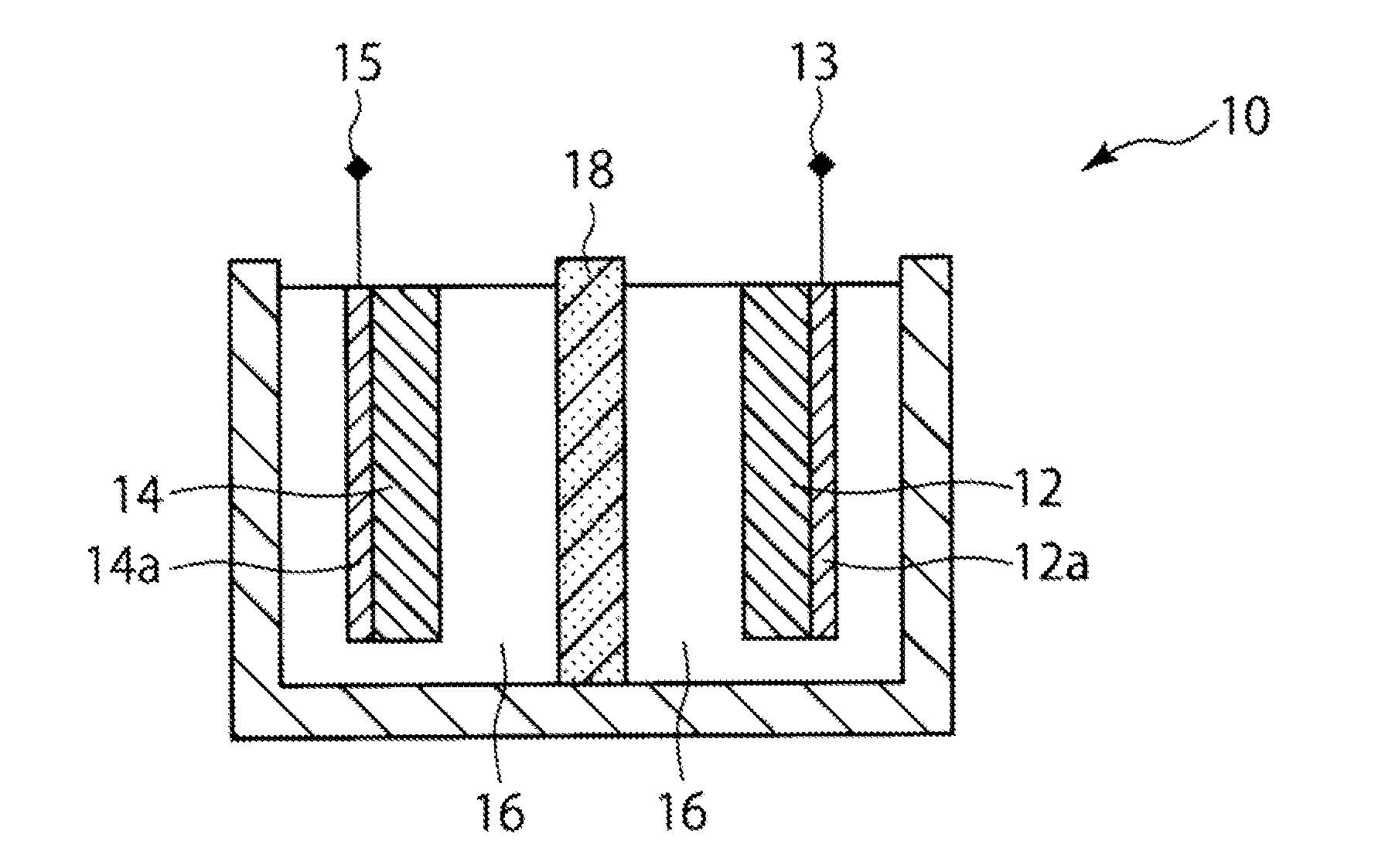

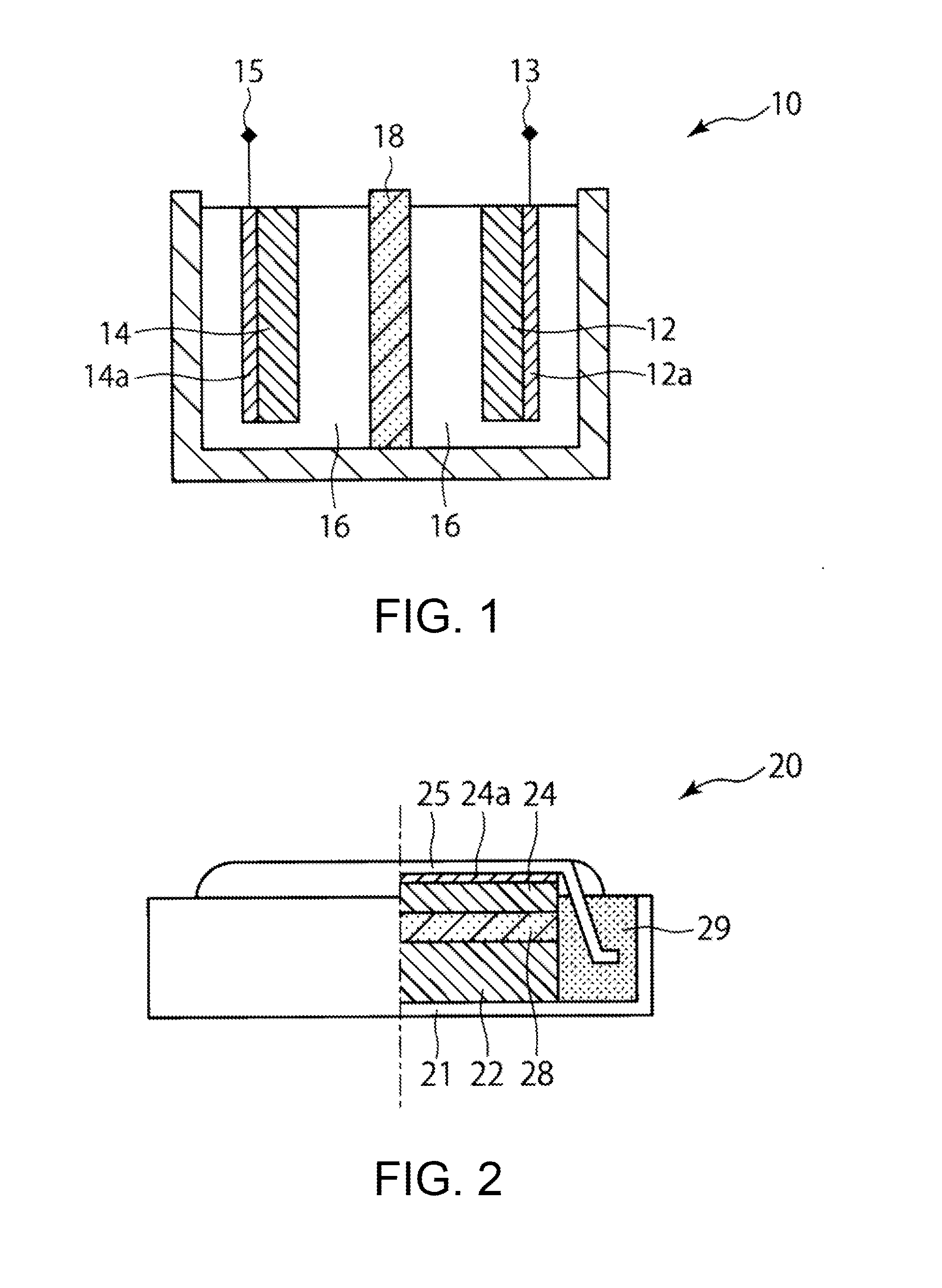

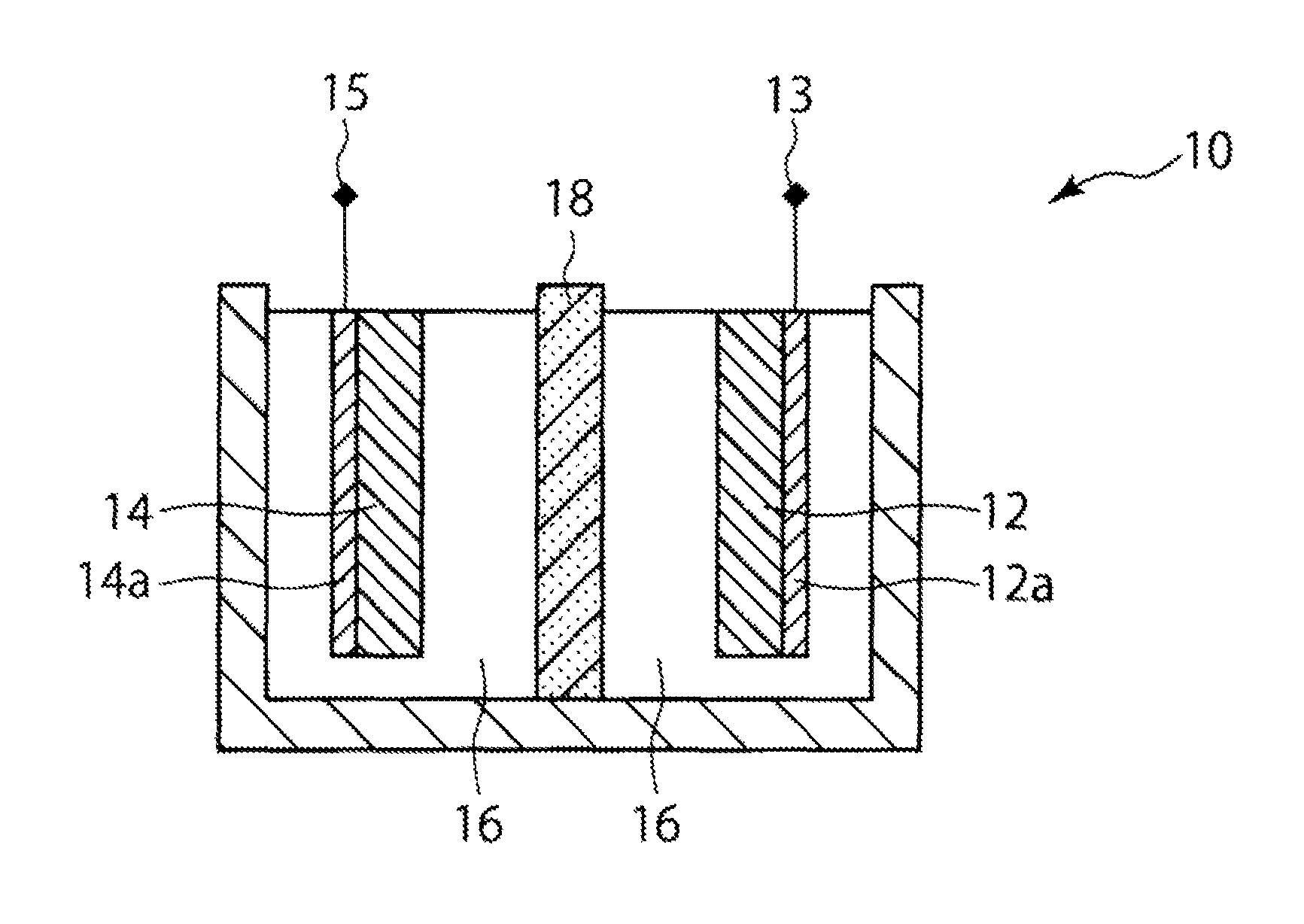

Provide is a zinc secondary battery capable of preventing a short circuit between the positive and negative electrodes caused by zinc dendrites. The zinc secondary battery of the present invention comprises a positive electrode; a negative electrode containing zinc; an electrolytic solution in which the positive electrode and the negative electrode are immersed or with which the positive electrode and the negative electrode are in contact, wherein the electrolytic solution is an aqueous solution containing an alkali metal hydroxide; and a separator being placed between the positive electrode and the negative electrode and separating the positive electrode and the negative electrode from each other, wherein the separator comprises an inorganic solid electrolyte body having hydroxide ion conductivity.

Owner:NGK INSULATORS LTD

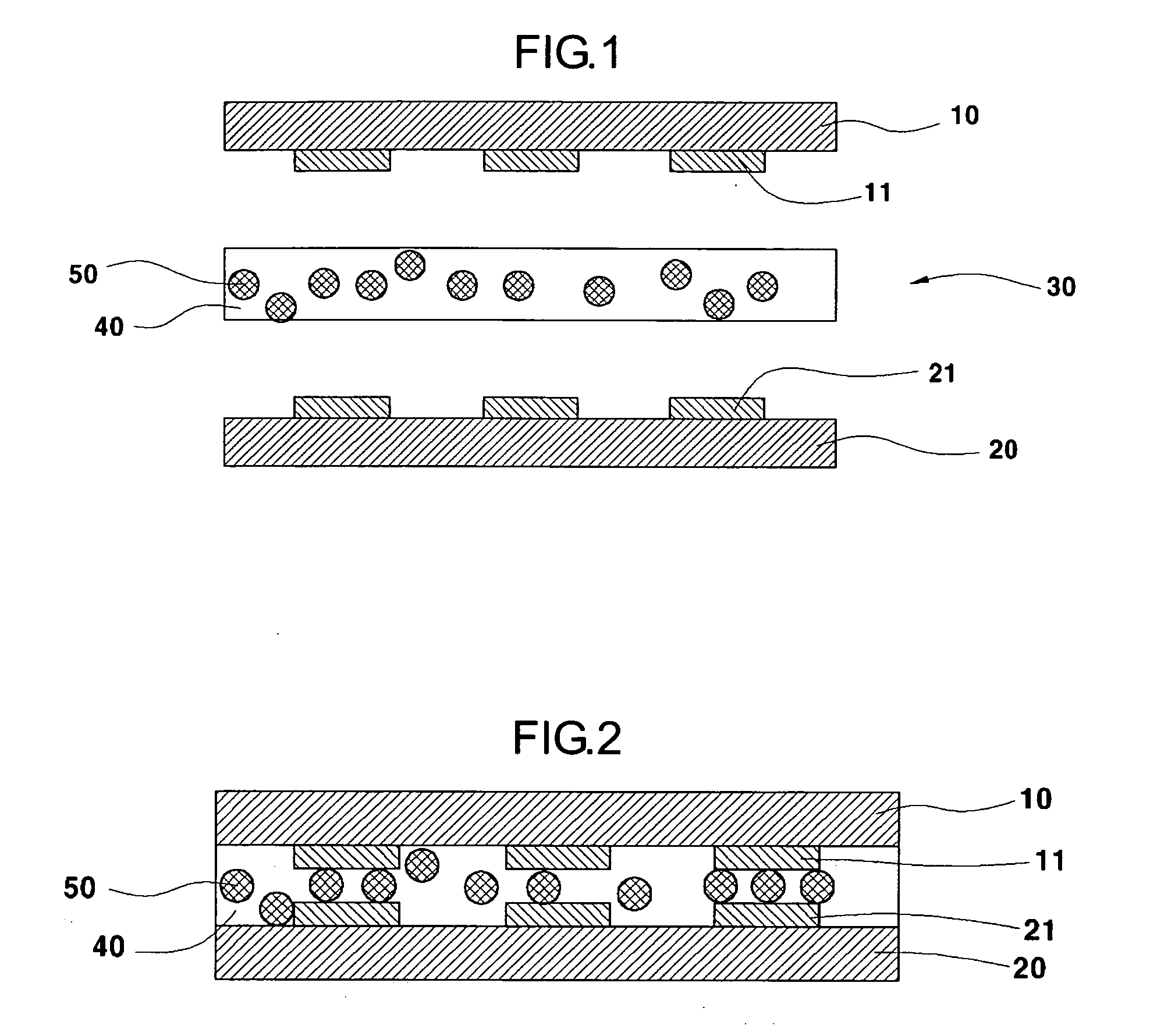

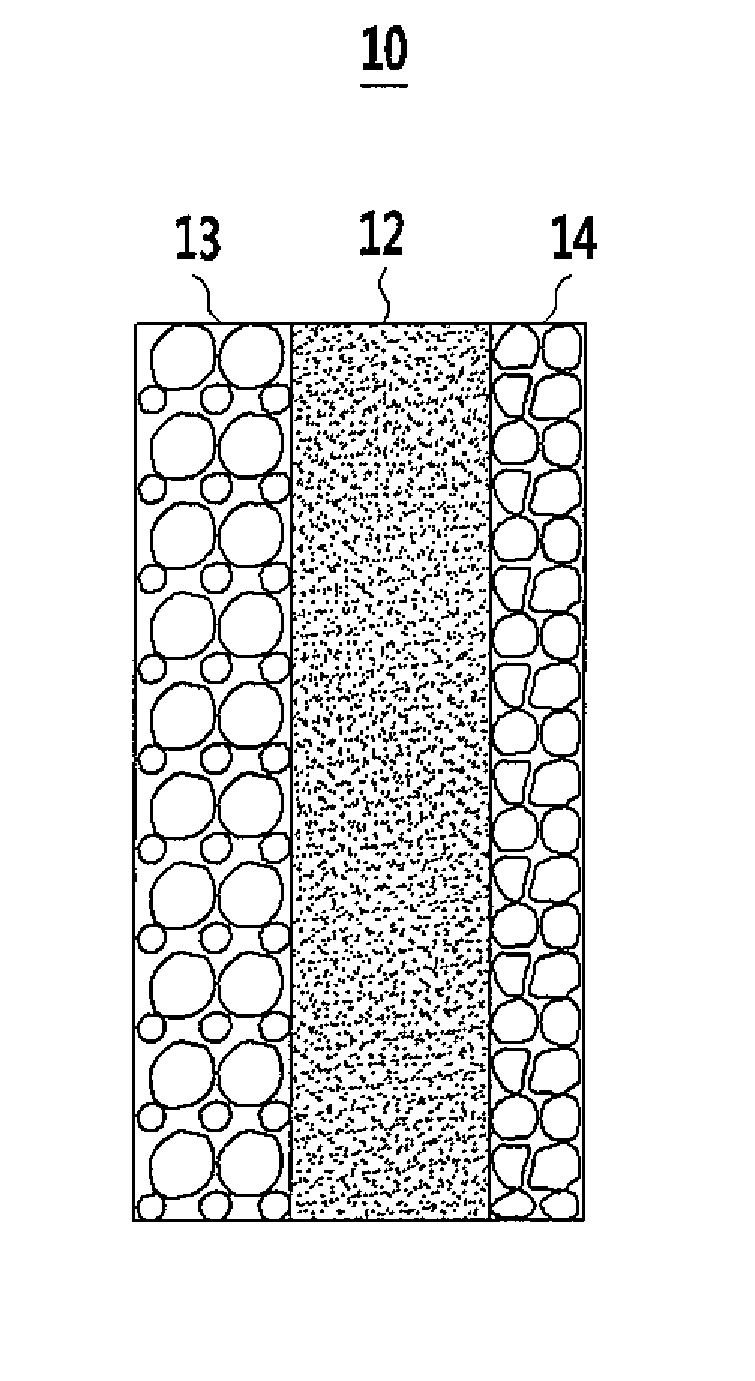

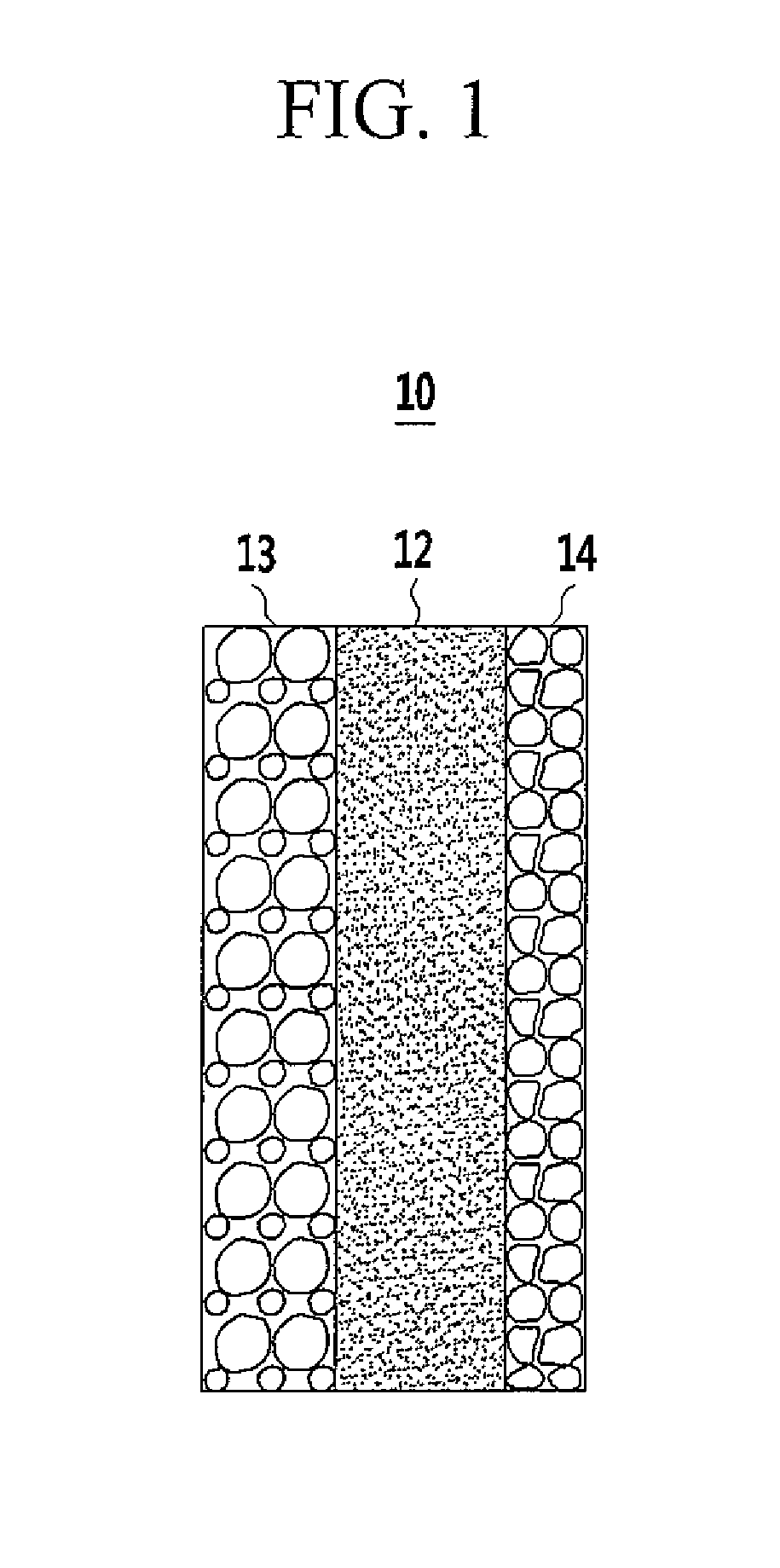

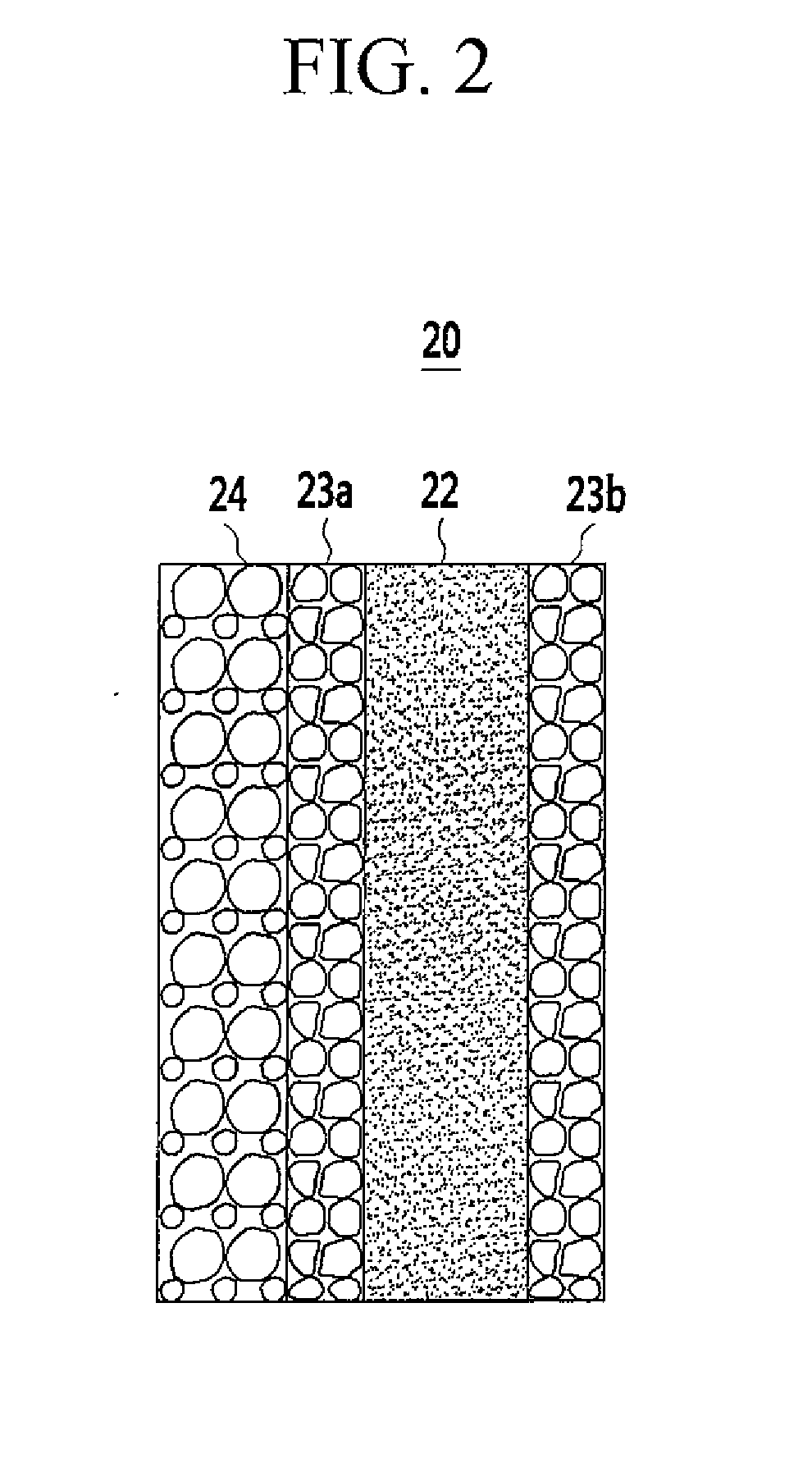

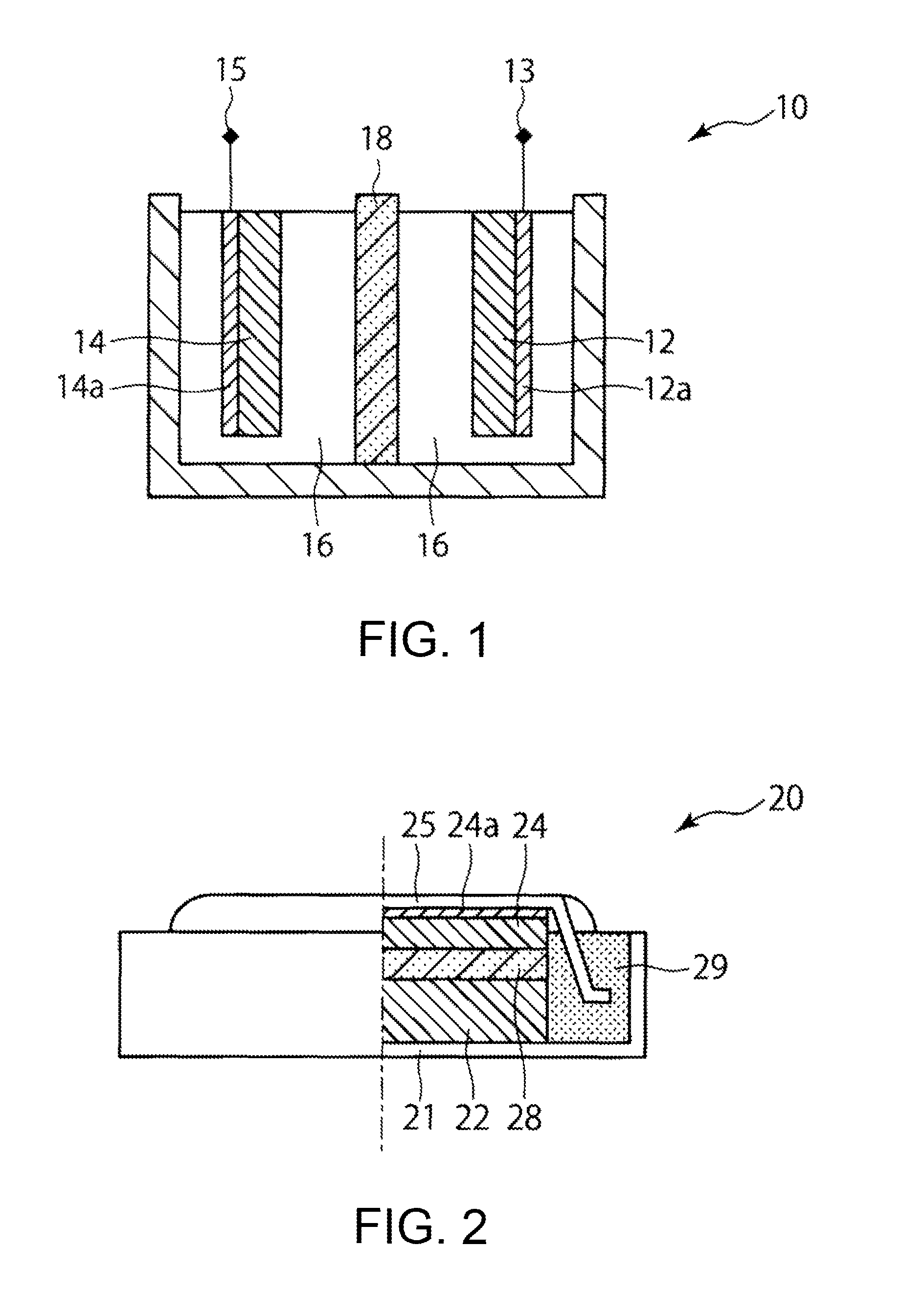

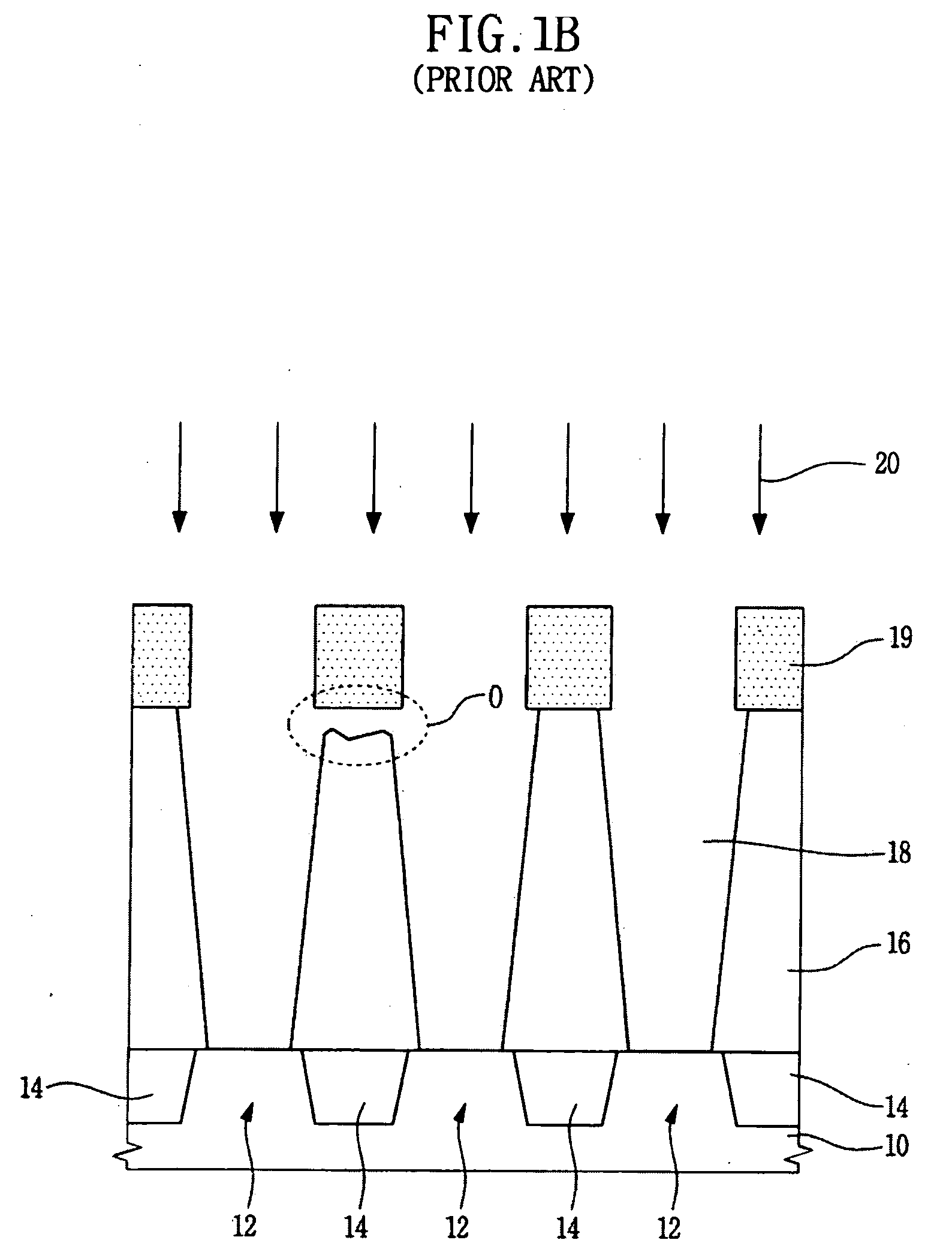

Separator, Manufacturing Method Of The Same, And Electrochemical Device Having The Same

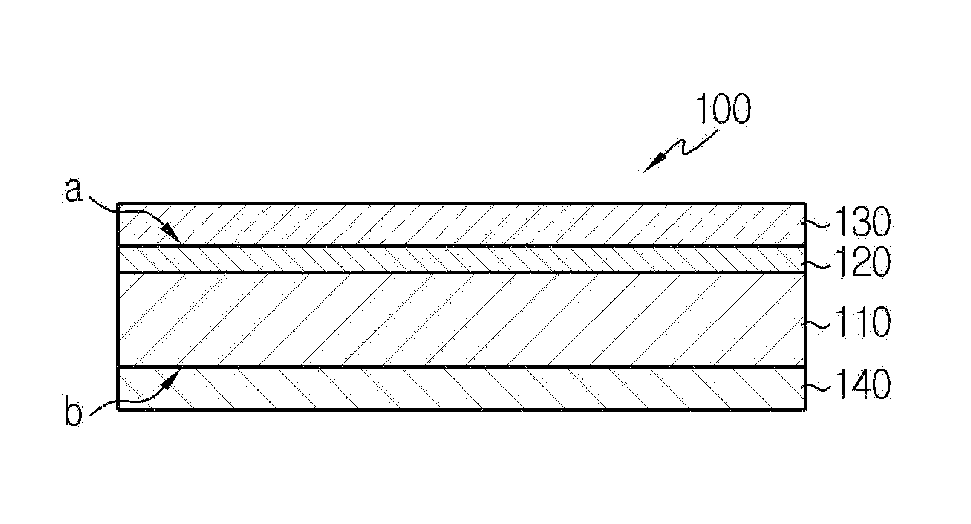

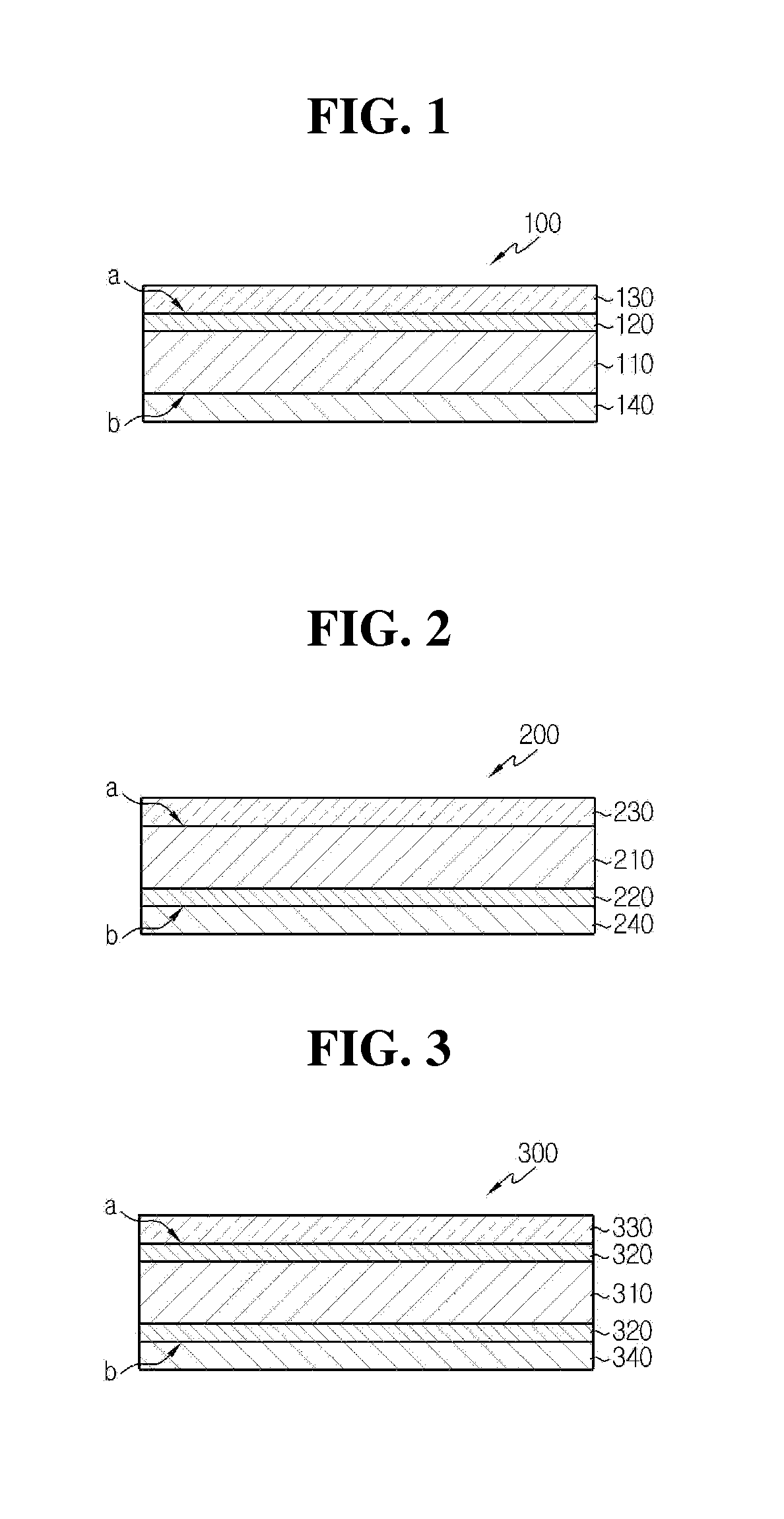

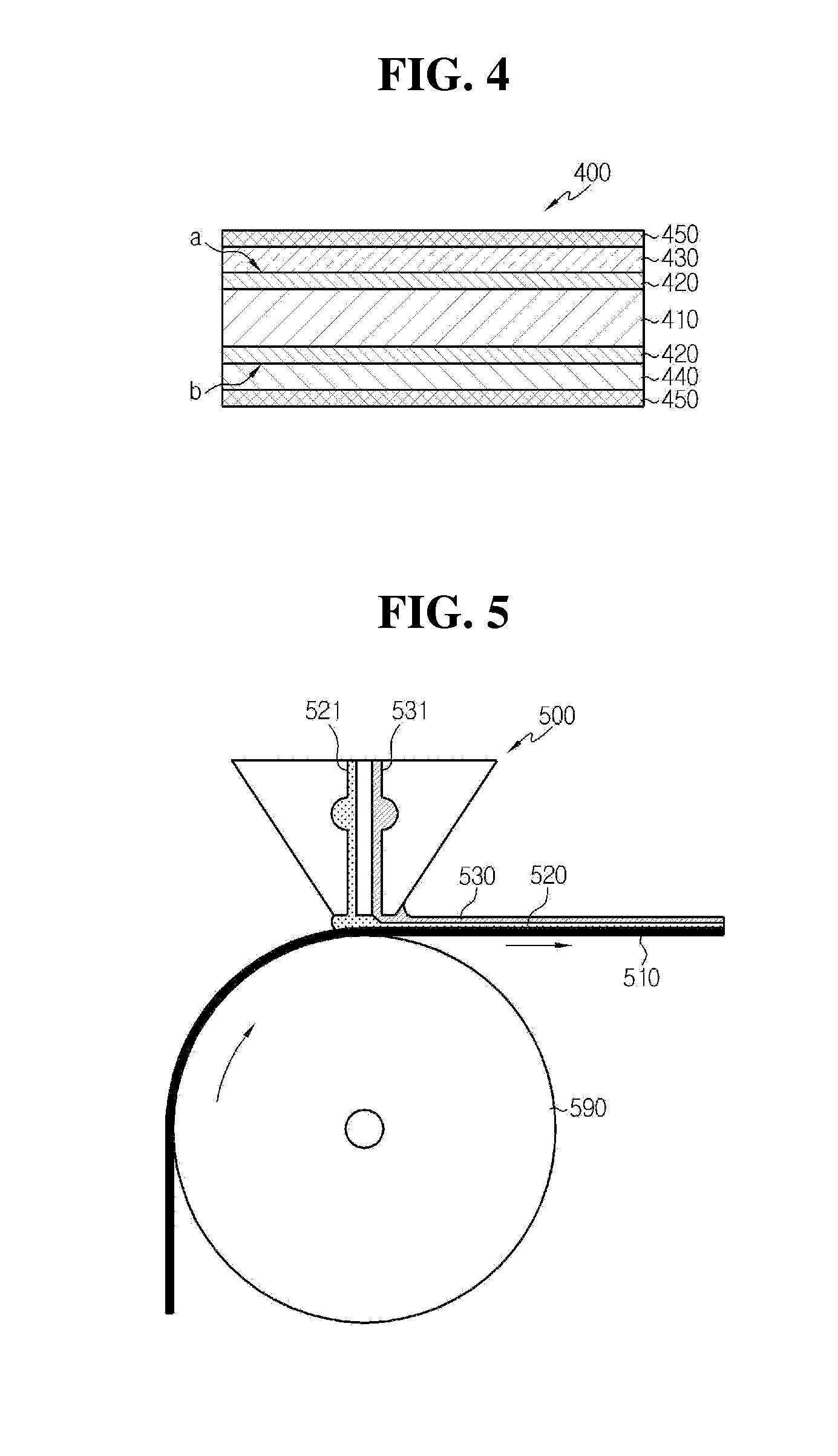

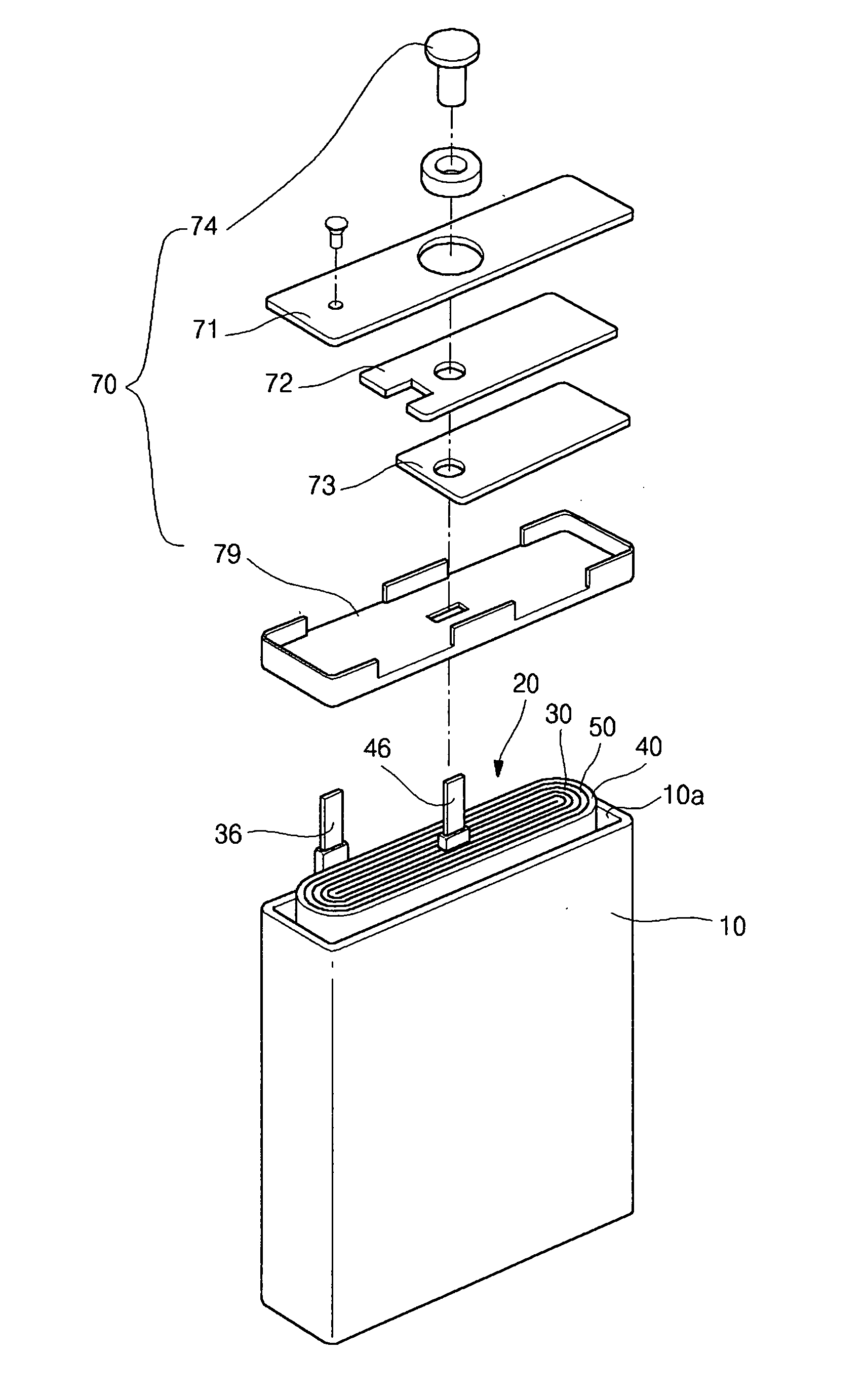

ActiveUS20130244082A1Superior output characteristicPrevent transfer rate of be reduceCell electrodesFinal product manufacturePorous compositePorous coating

The separator of the present invention comprises a porous composite having a porous substrate and a first porous coating layer formed on at least one surface of the porous substrate and comprising a mixture of inorganic particles and a first binder polymer; and a second porous coating layer formed on a first surface of the porous composite and comprising a mixture of cathode active material particles, a second binder polymer and a first conductive material, a third porous coating layer formed on a second surface of the porous composite and comprising a mixture of anode active material particles, a third binder polymer and a second conductive material, or both of the second porous coating layer and the third porous coating layer. Also, the separator of present invention may further comprise a fourth porous coating layer formed on at least one outermost surface thereof and comprising a fourth binder polymer.

Owner:TORAY BATTERY SEPARATOR FILM +1

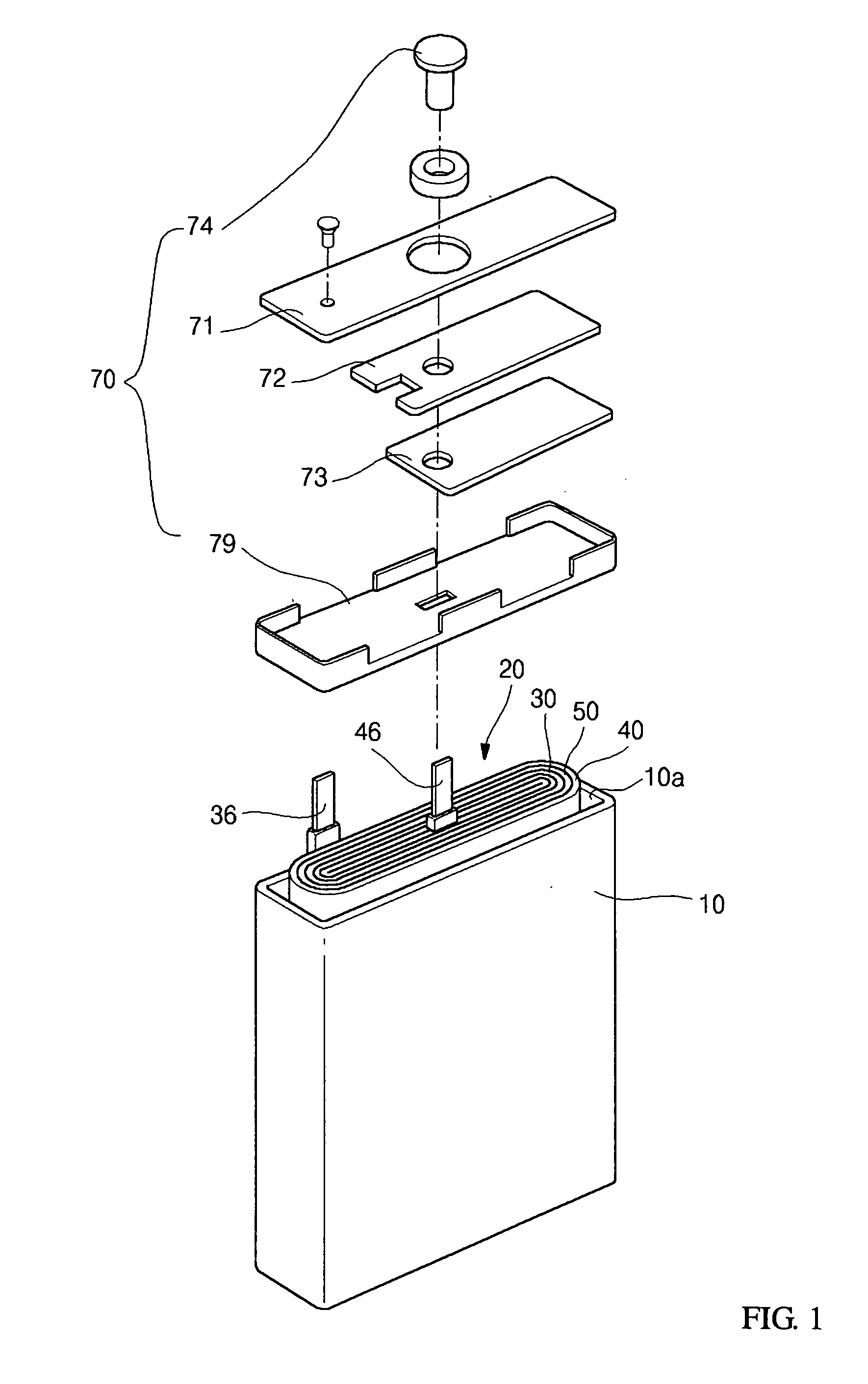

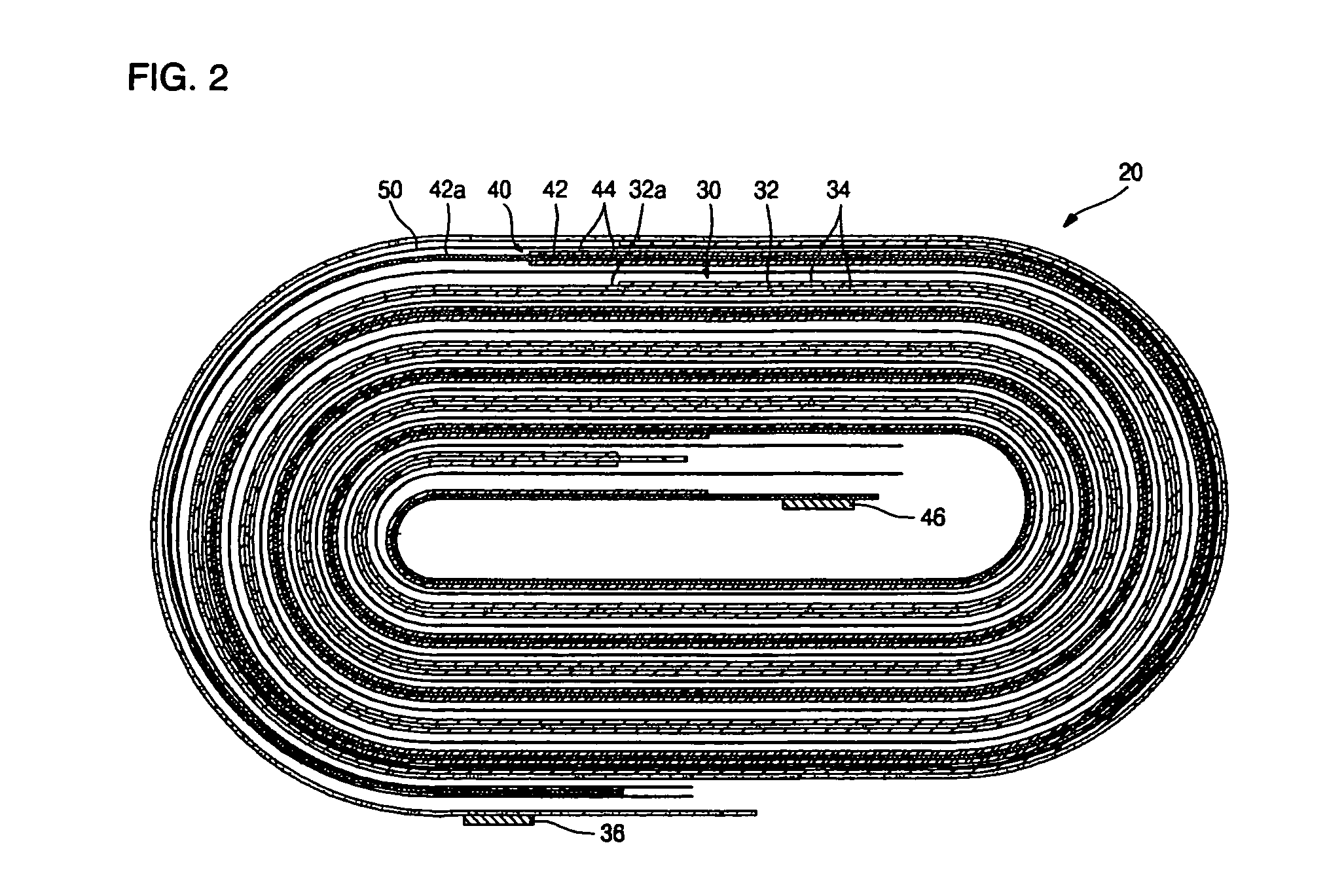

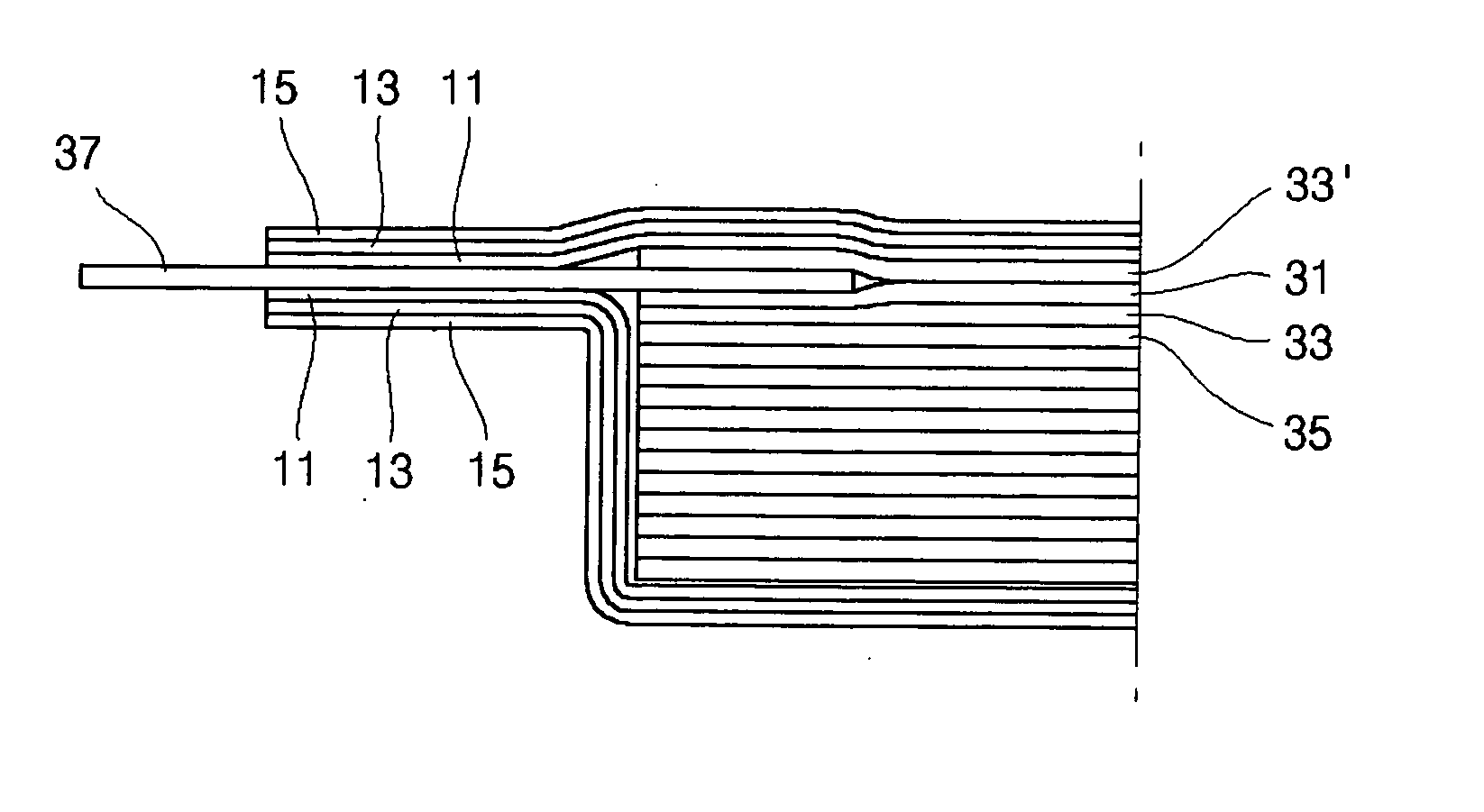

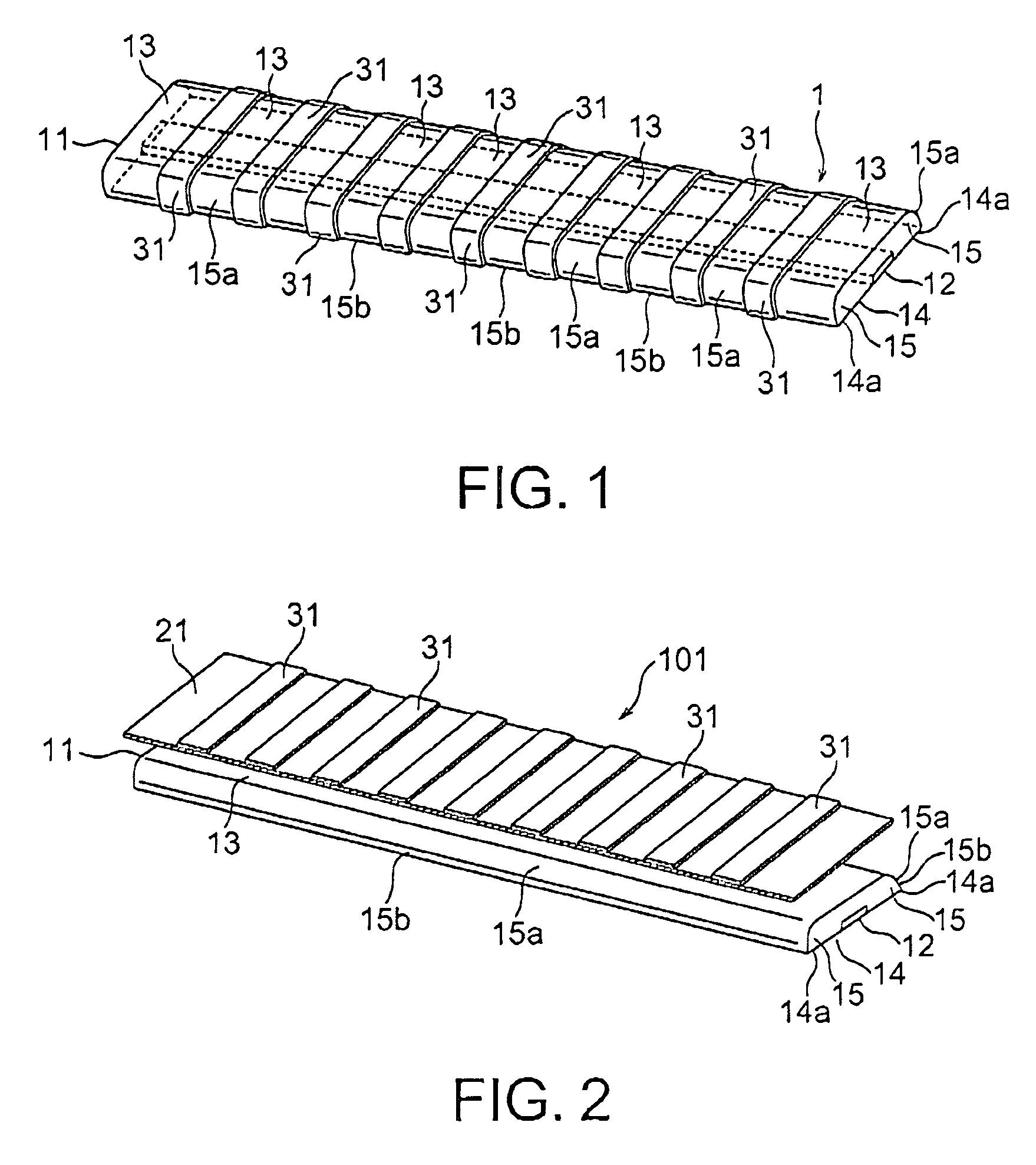

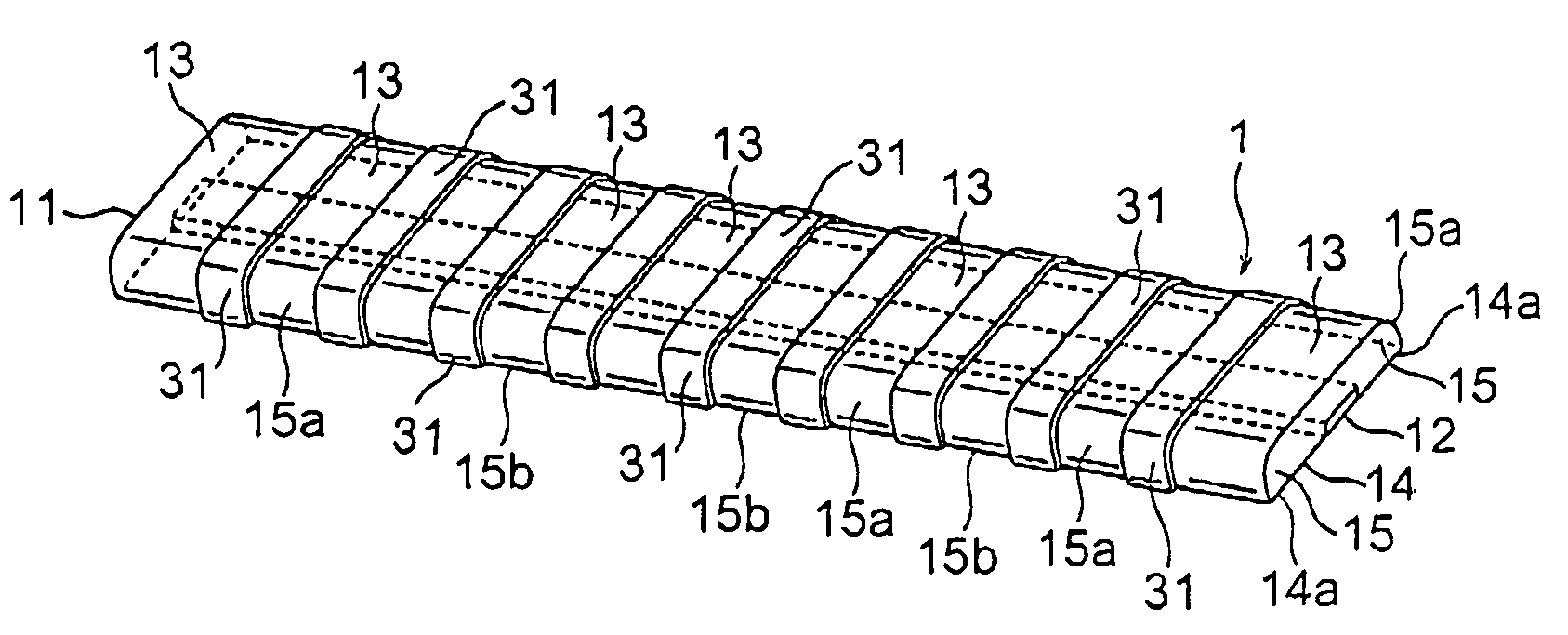

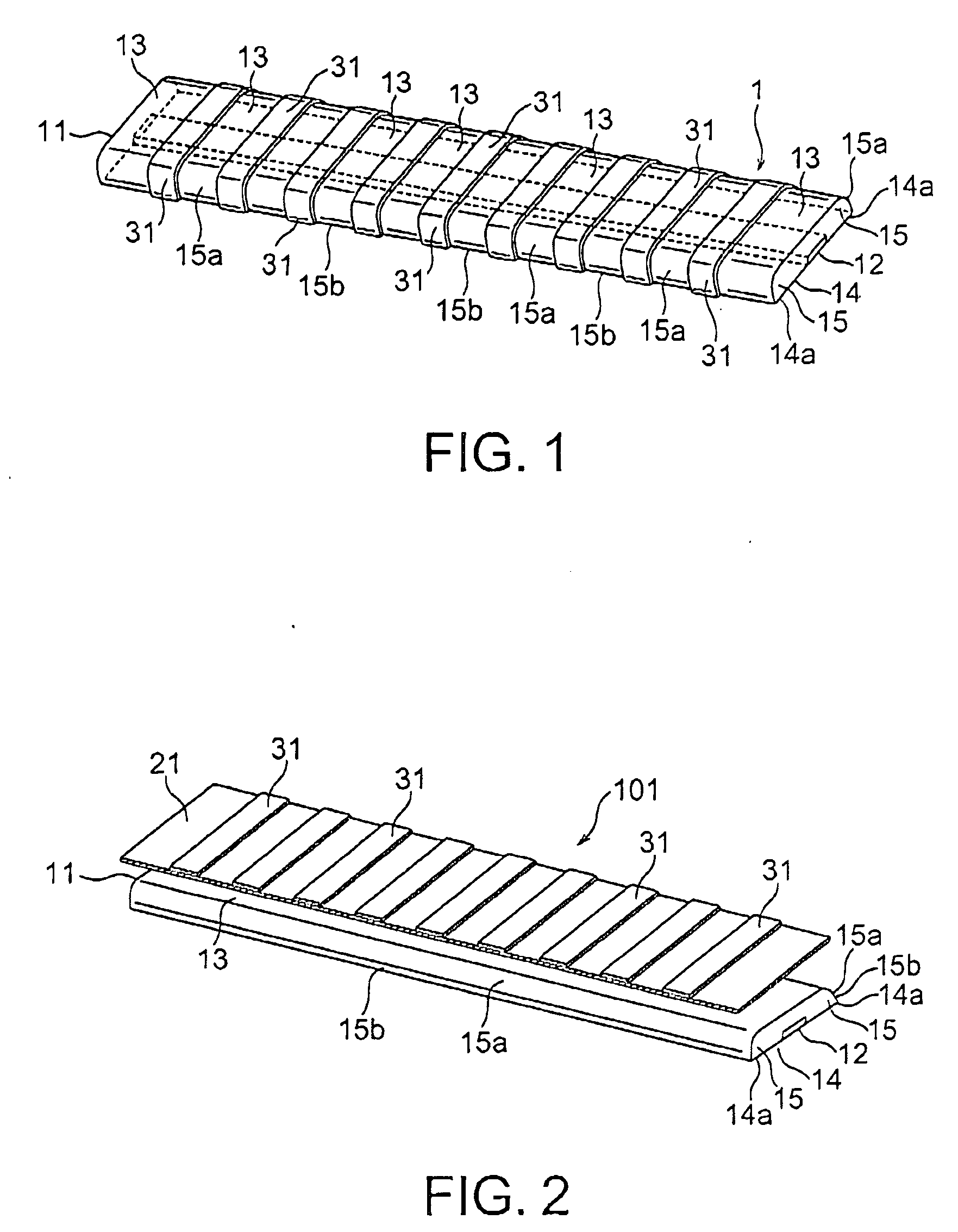

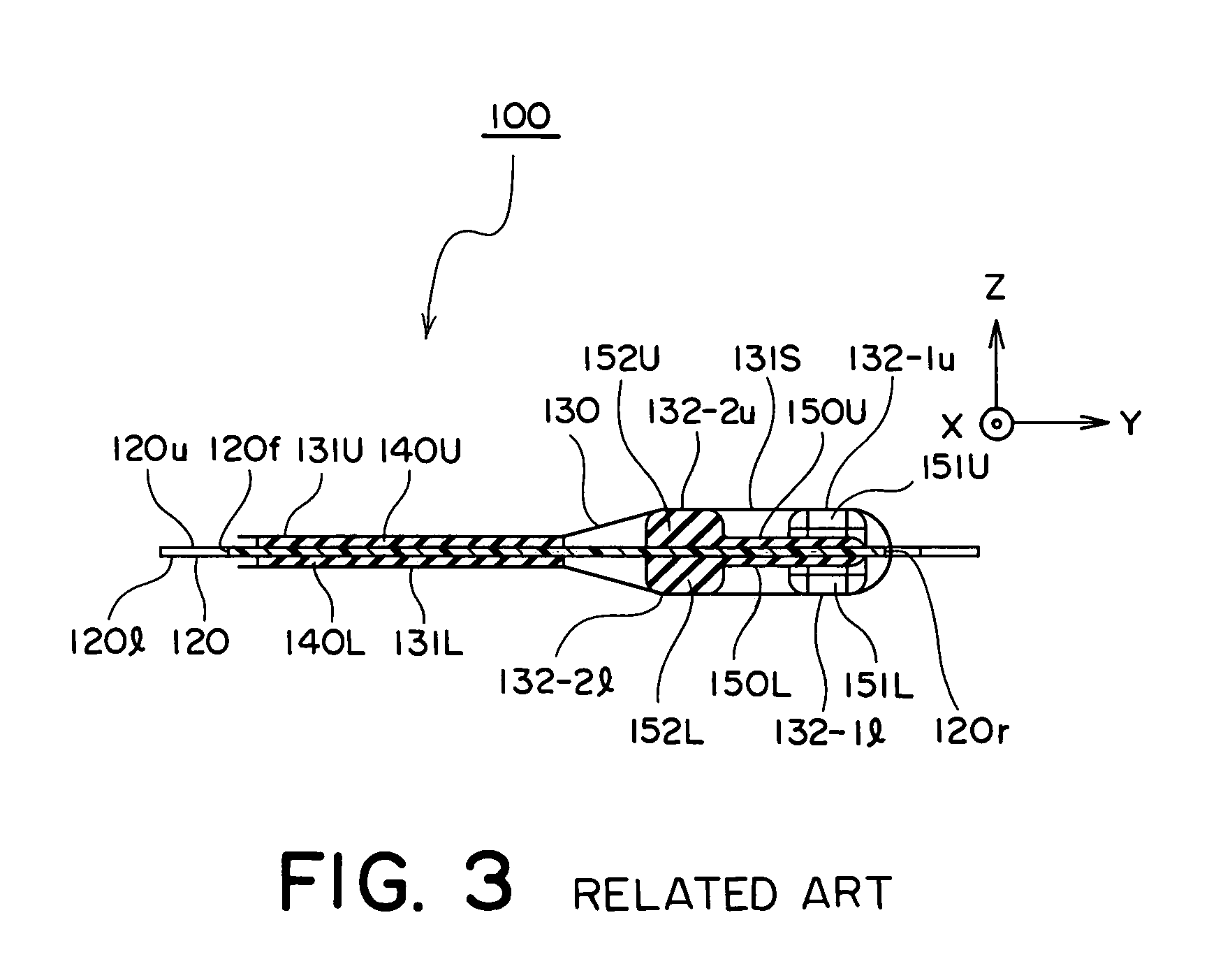

Electrode assembly and lithium ion secondary battery using the same

ActiveUS20060008701A1Preventing a short circuitNon-aqueous electrolyte accumulatorsFinal product manufactureLithiumElectrode

An electrode assembly and a lithium ion secondary battery using the same capable of preventing a short circuit from being created in an outer peripheral portion of the electrode assembly. Uncoated areas of positive and negative electrode plates and an active material layer in the inner and outer peripheral portions of the electrode assembly are optimally aligned such that the thickness of the electrode assembly is uniformly formed widthwise along the electrode assembly.

Owner:SAMSUNG SDI CO LTD

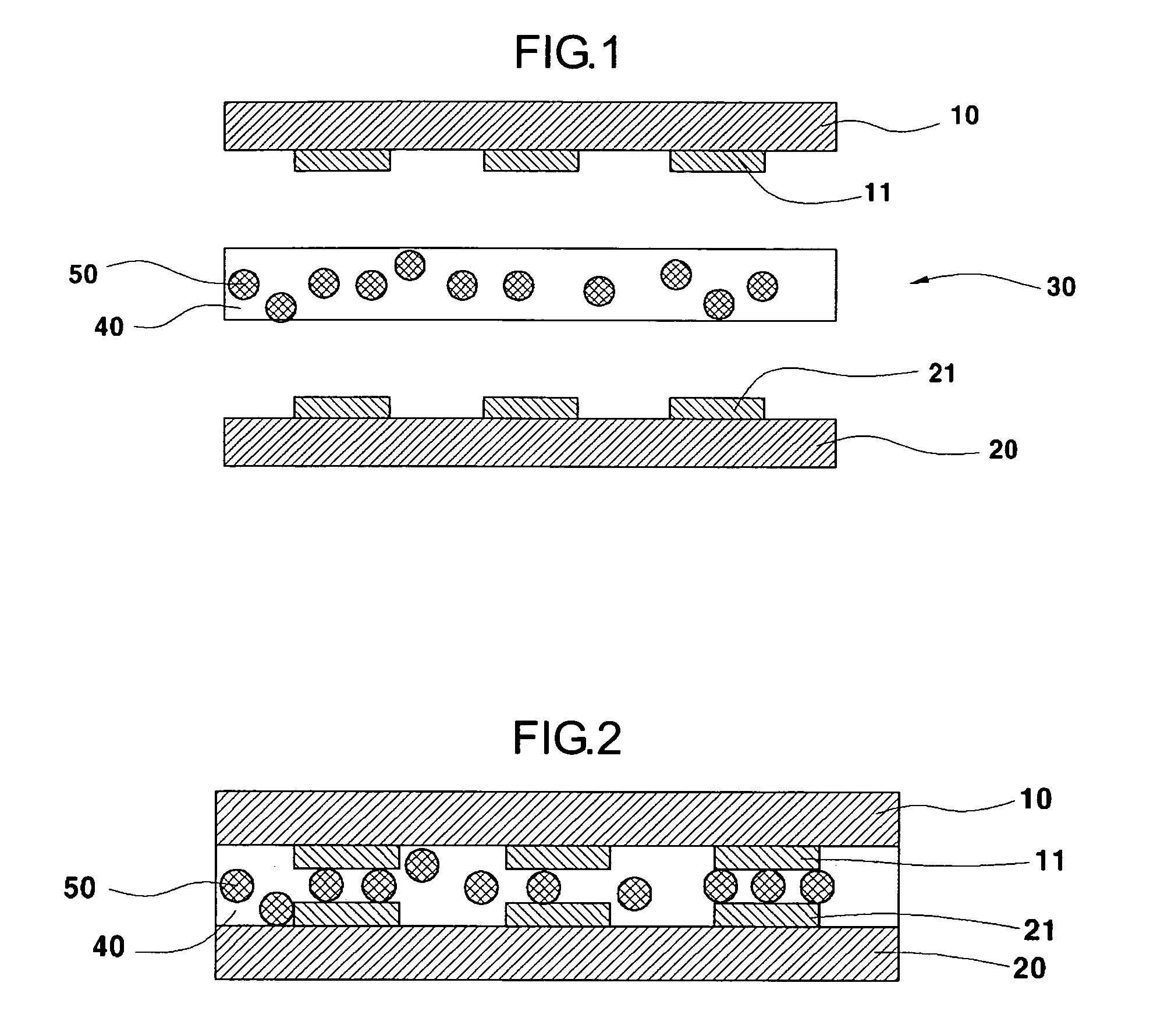

Isotropic conductive adhesive and adhesive film using the same

InactiveUS20050288427A1Minimizes its contractionImprove connection reliabilityImpression capsConductive materialAnisotropic conductive adhesiveIsotropic conductive adhesives

The present invention discloses an anisotropic conductive adhesive comprising an insulating adhesive component and a number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains a crosslinked rubber resin. The anisotropic conductive adhesive of the present invention prevents exfoliation of an adhesive or reduction in adhesive strength of circuit by minimizing its the heat-contraction occurring in the process of a polymerization or a hardening reaction when connecting micro-circuits, whereby a short circuit between adjacent electrodes can be prevented when connecting the circuits, and excellent connection reliability according to a long-term use is achieved.

Owner:H&S HIGH TECH +1

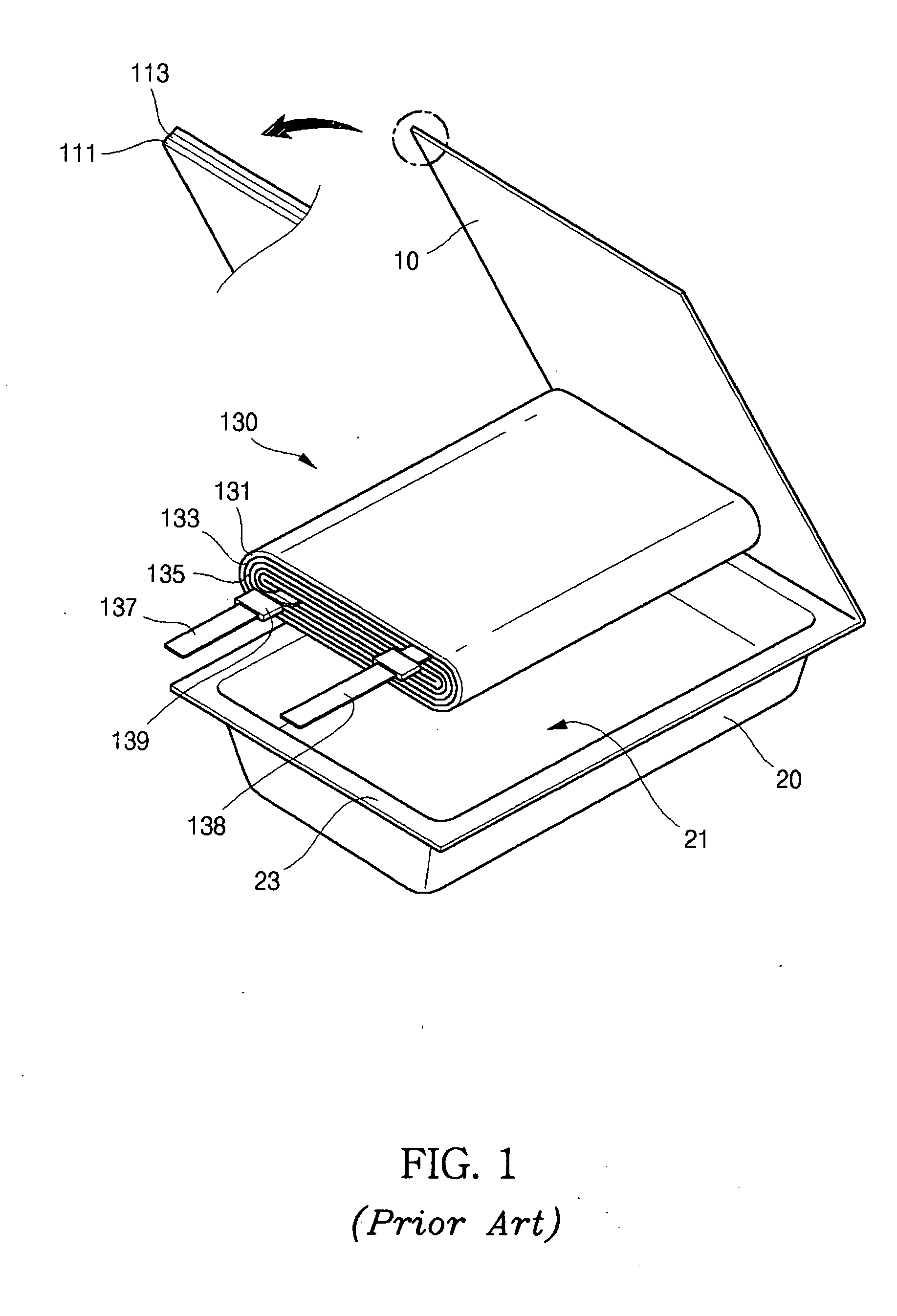

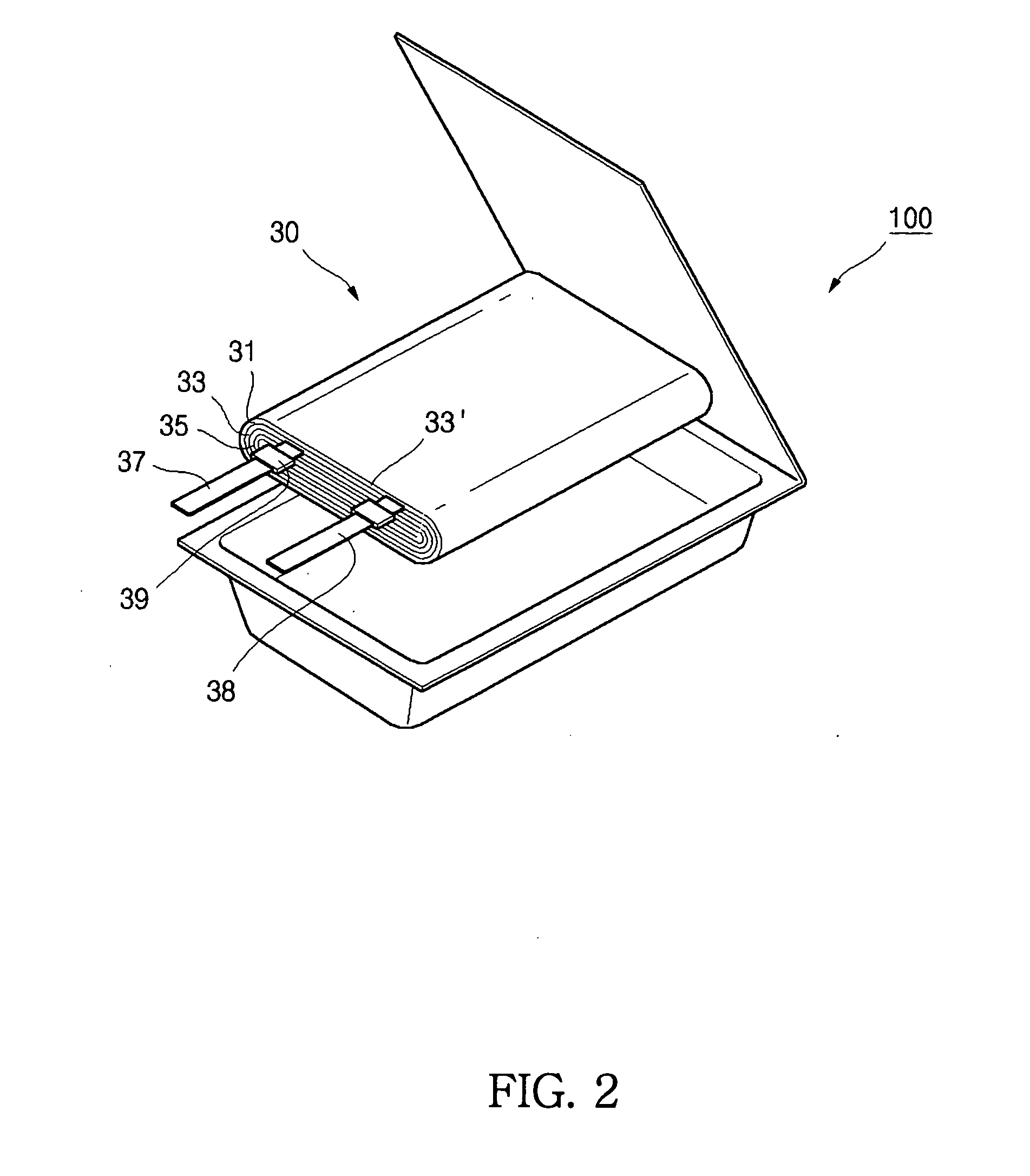

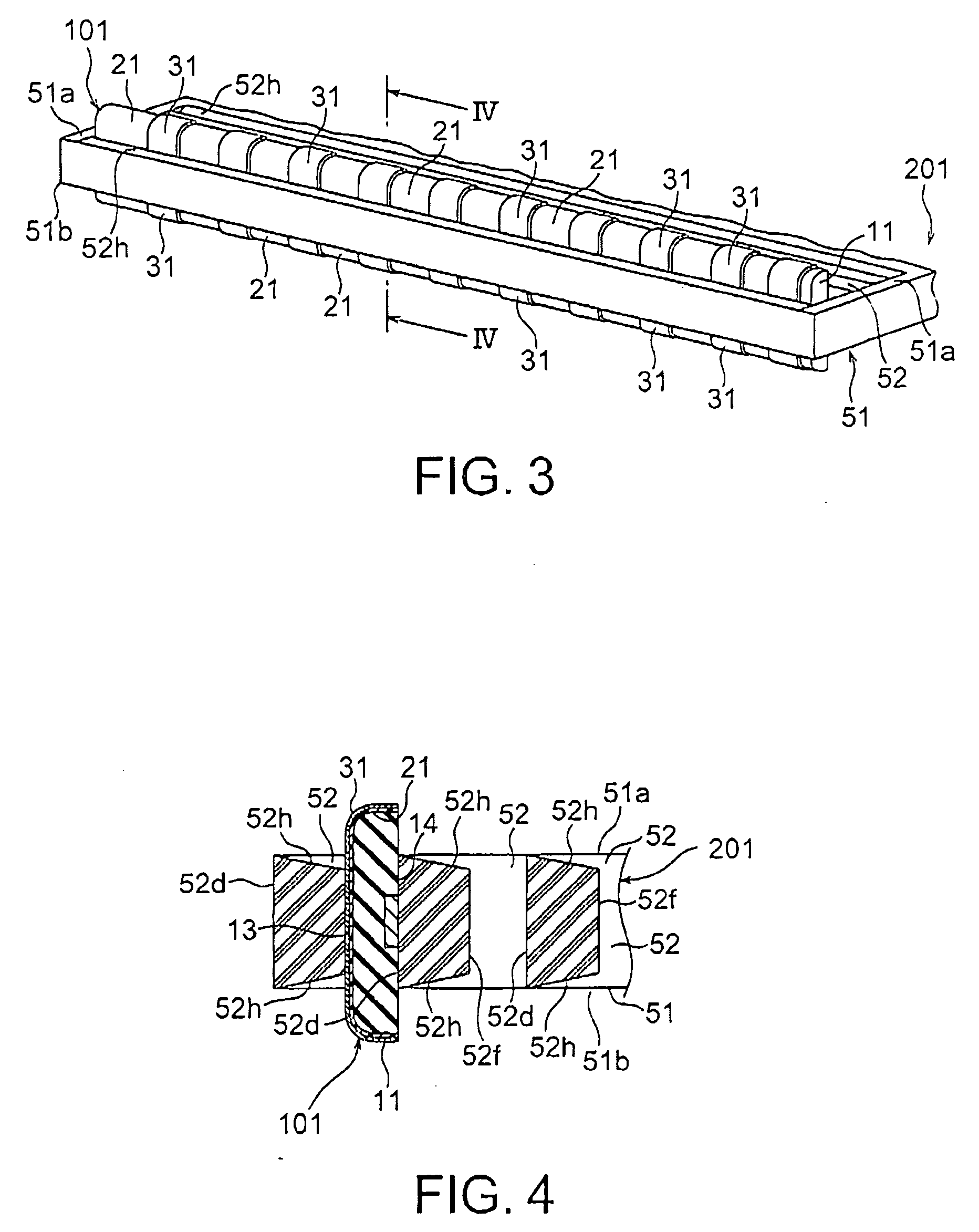

Secondary battery having jelly roll configuration type electrode assembly

InactiveUS20060154145A1Avoid concentrationSmall sizeFinal product manufactureElectrode carriers/collectorsElectrical polarityEngineering

A secondary battery including a jelly roll configuration type electrode assembly formed by winding a stack of two electrodes having different polarities and at least one separator for preventing a short circuit between the two electrodes, a case for containing the electrode assembly, and electrode tabs for connecting the two electrodes of the electrode assembly to an outside of the case, wherein a level for extracting the electrode tabs from the electrode assembly is substantially equal to a level for extracting the electrode tabs from the case. The electrode assembly may be formed to be a jelly roll having an elliptical shape or a track shape. In one exemplary embodiment, the electrode tabs are used in a pouch having a hollow for containing the electrode assembly in only one side. Also, the electrode tabs are extend linearly from the pouch.

Owner:SAMSUNG SDI CO LTD

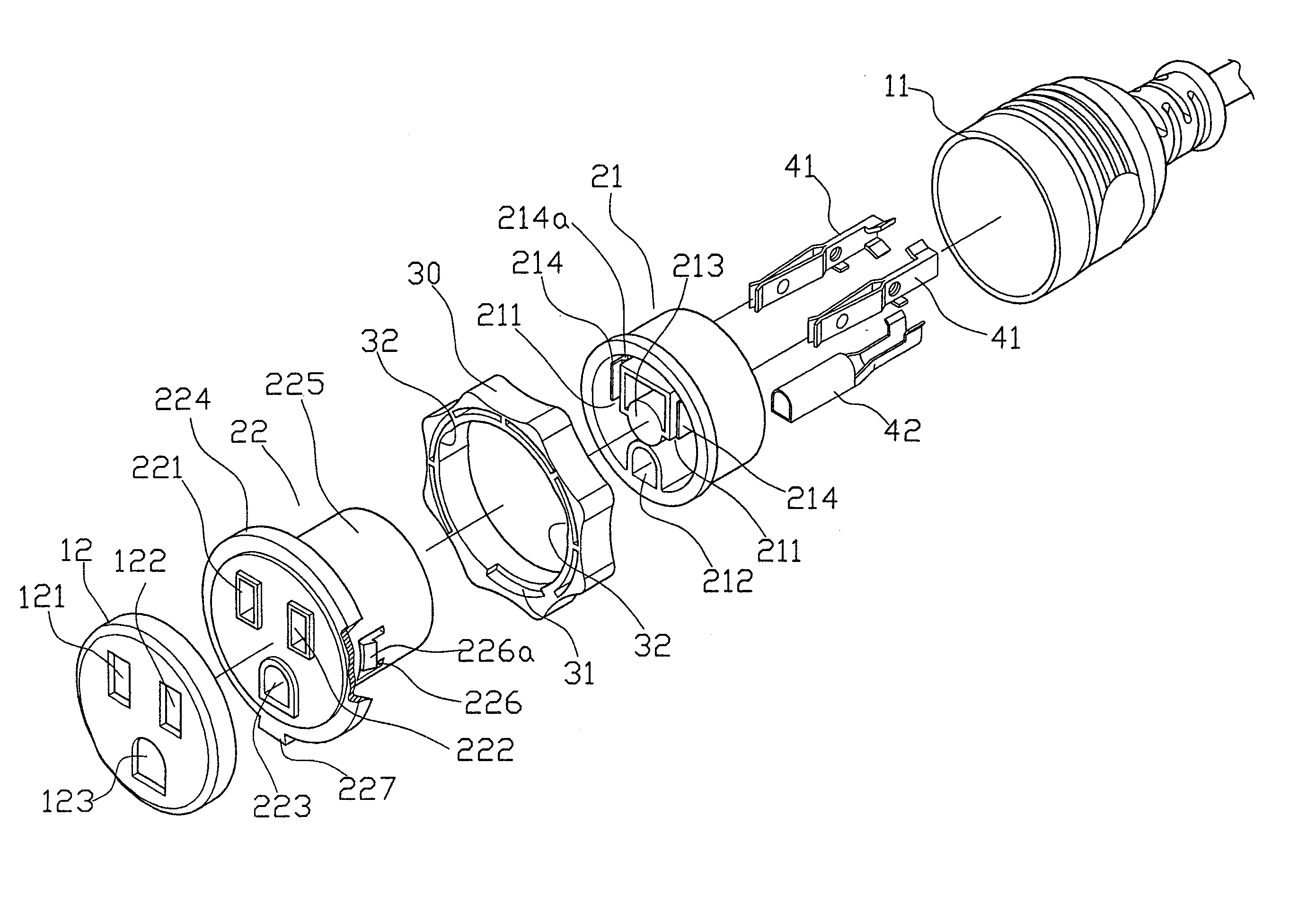

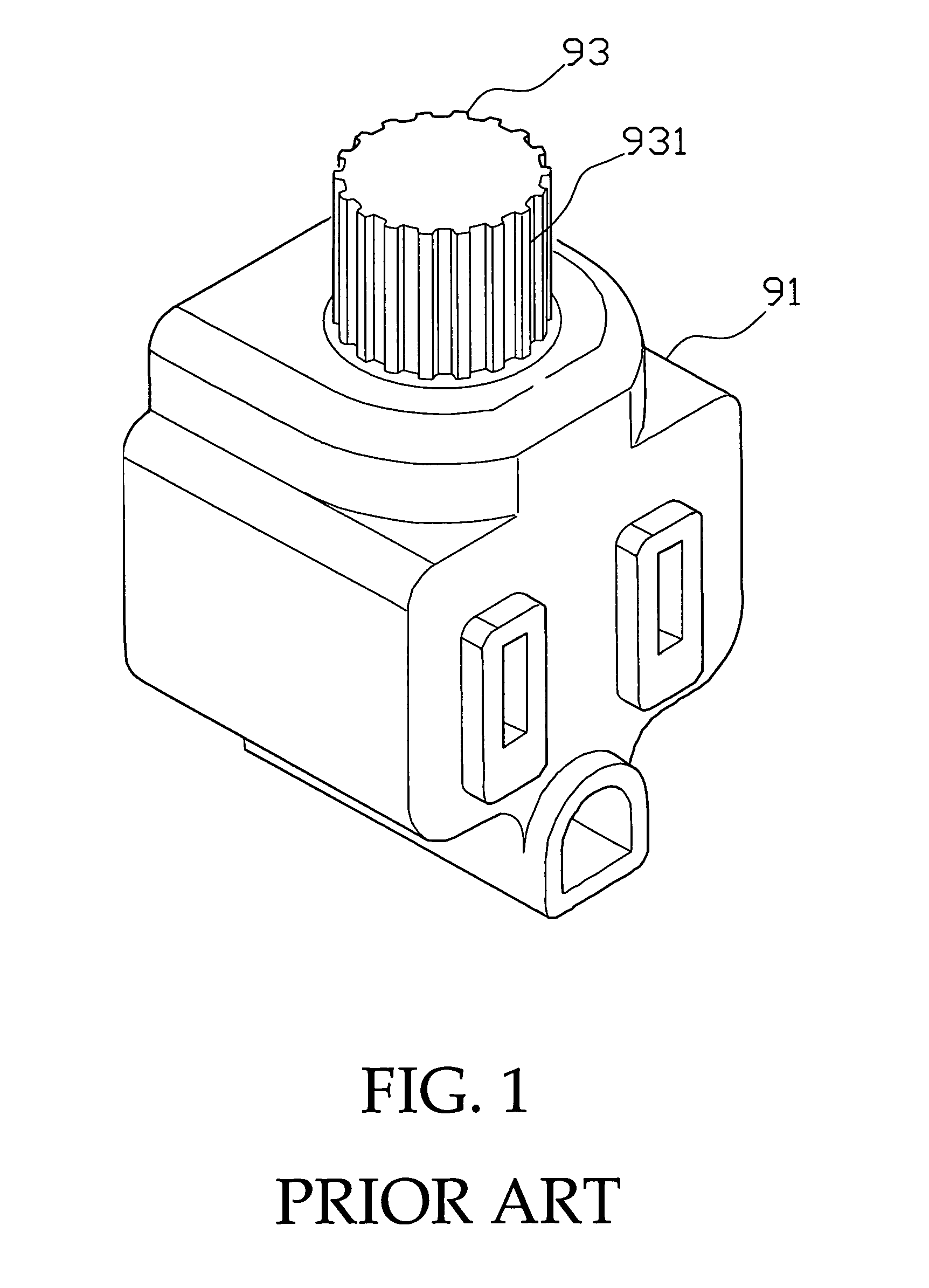

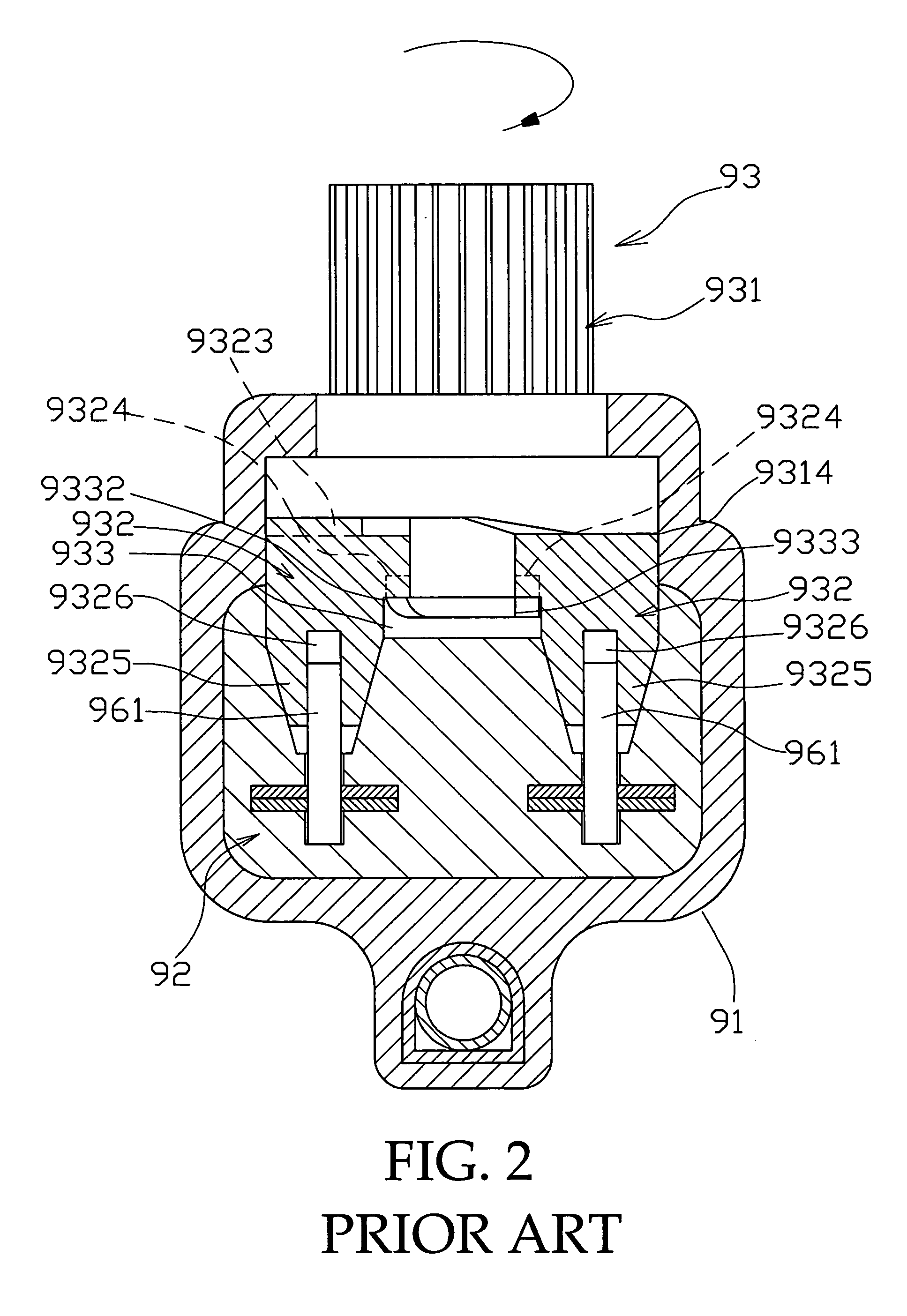

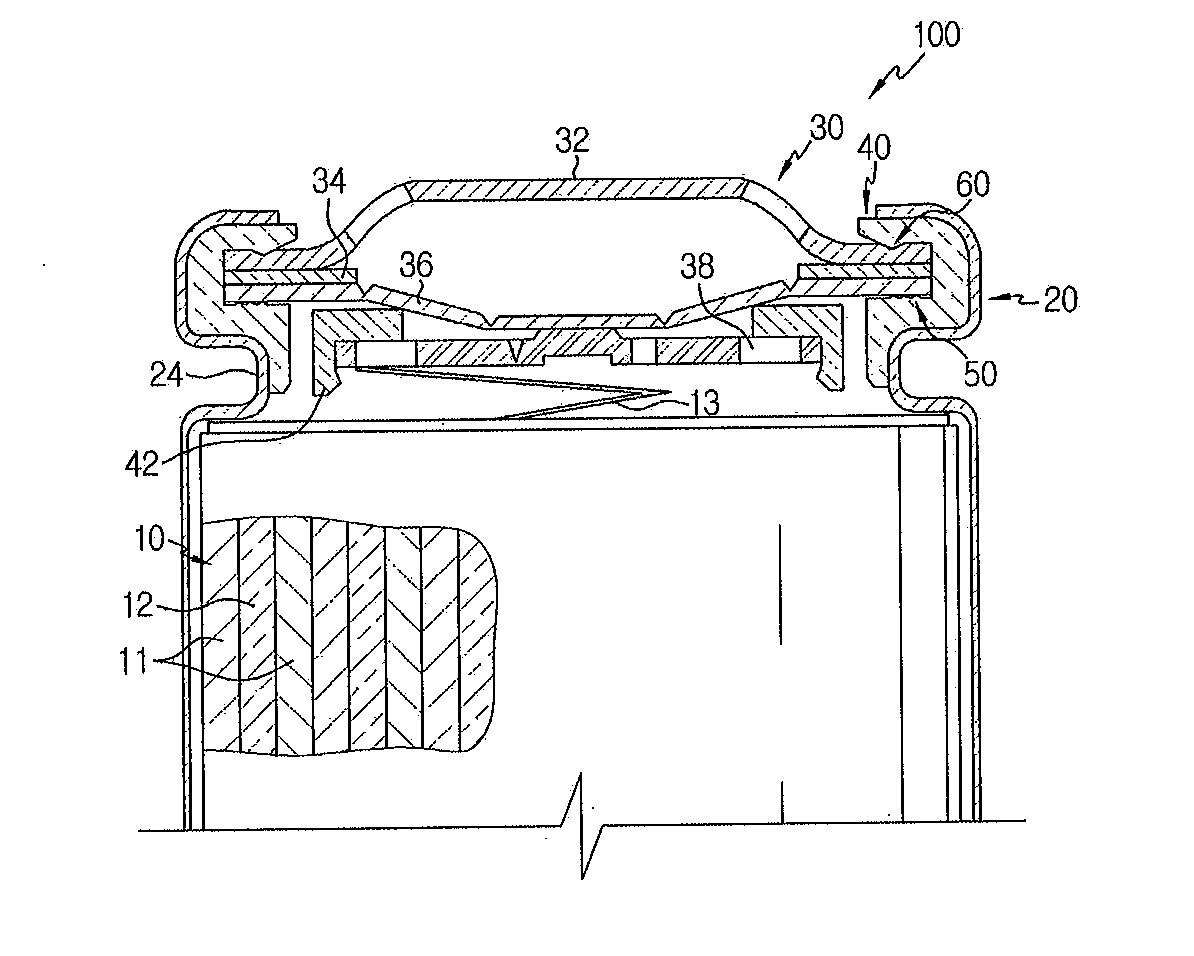

Electric socket having means to lock the blades of inserted electric plug

ActiveUS7182615B1Small sizePreventing a short circuitEngagement/disengagement of coupling partsTwo pole connectionsElectricityMetal electrodes

An electric socket is disclosed to include a housing provided at one end of a cable and having insertion slots for the insertion of the metal electrodes of an electric plug, a socket body mounted inside the housing and holding two metal electrode clamps on the inside for receiving the metal electrodes of an electric plug, a holding down structure provided inside the socket body, and a rotating ring mounted on the socket body and exposed to the outside of the housing and rotatable between a first position to force the holding down structure against the metal electrode clamps and to further lock the metal electrodes of the inserted electric plug and a second position to release the holding down structure from the metal electrode clamps.

Owner:TA HSING ELECTRIC WIRE & CABLE

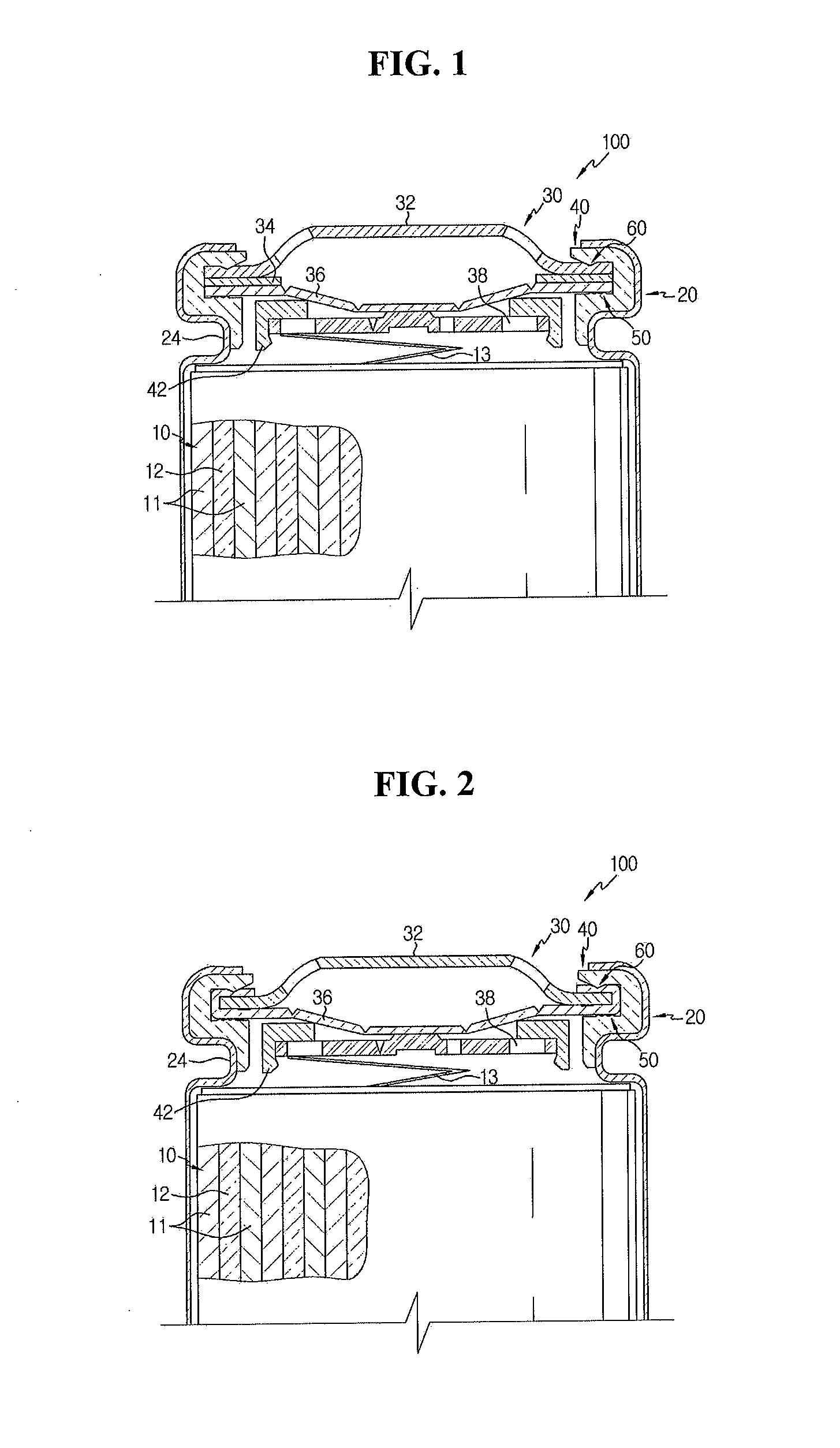

Cylindrical secondary battery

ActiveUS20130273401A1High heat resistanceModerate hardnessSmall-sized cells cases/jacketsCell sealing materialsEngineeringMelting point

Provided is a cylindrical secondary battery, comprising an electrode assembly having a cathode plate, an anode plate, and a separator interposed therebetween; a case for receiving the electrode assembly; a cap assembly for sealing an open-end of the case; and a gasket interposed between the case and the cap assembly, wherein the gasket is made of a polymer resin having a melting point of 200° C. or higher and a hardness of 100D or less.

Owner:LG ENERGY SOLUTION LTD

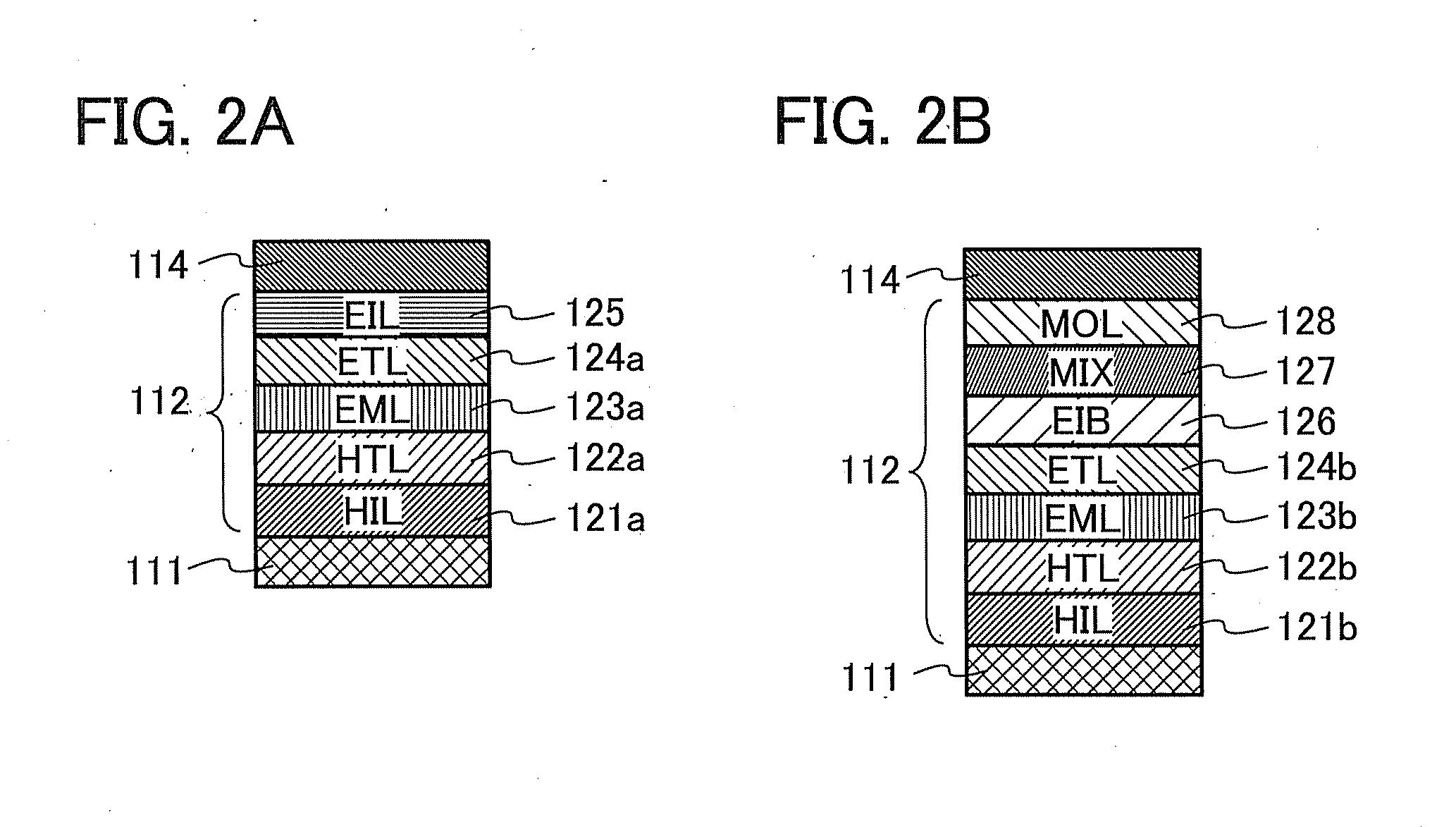

Light-Emitting Element, Manufacturing Method Thereof, and Lighting Device

InactiveUS20120126277A1Reduction in emission characteristicEasily deterioratedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectroluminescence

A light-emitting element includes a conductive layer functioning as a first electrode, an electroluminescent layer, and a conductive layer functioning as a second electrode, and further includes an insulating material filling a defect portion in the electroluminescent layer so that the defect portion is sealed. In the light-emitting element, the conductive layer functioning as a second electrode overlaps with the conductive layer functioning as a first electrode with the electroluminescent layer and the insulating material interposed therebetween and is in contact with a top surface of the electroluminescent layer.

Owner:SEMICON ENERGY LAB CO LTD

Printed circuit board

InactiveUS20070184675A1Prevent short-circuitingHigh reliabilityPrinted circuit aspectsPrinted circuit manufactureCopper foilResist

A highly reliable printed circuit board which is capable of preventing a short circuit between traces from being caused by a solder bridge formed by excess solder. The printed circuit board has a solder resist covering copper foil traces formed on a substrate and the substrate, for insulation. The solder resist is formed such that exposed portions of the substrate between adjacent ones of the conductive traces each have a shape protruding in a direction of where the other printed circuit board is connected, with respect to exposed portions of the adjacent ones of the conductive traces, in a boundary between the connection part and a portion on which an insulating layer is formed.

Owner:CANON KK

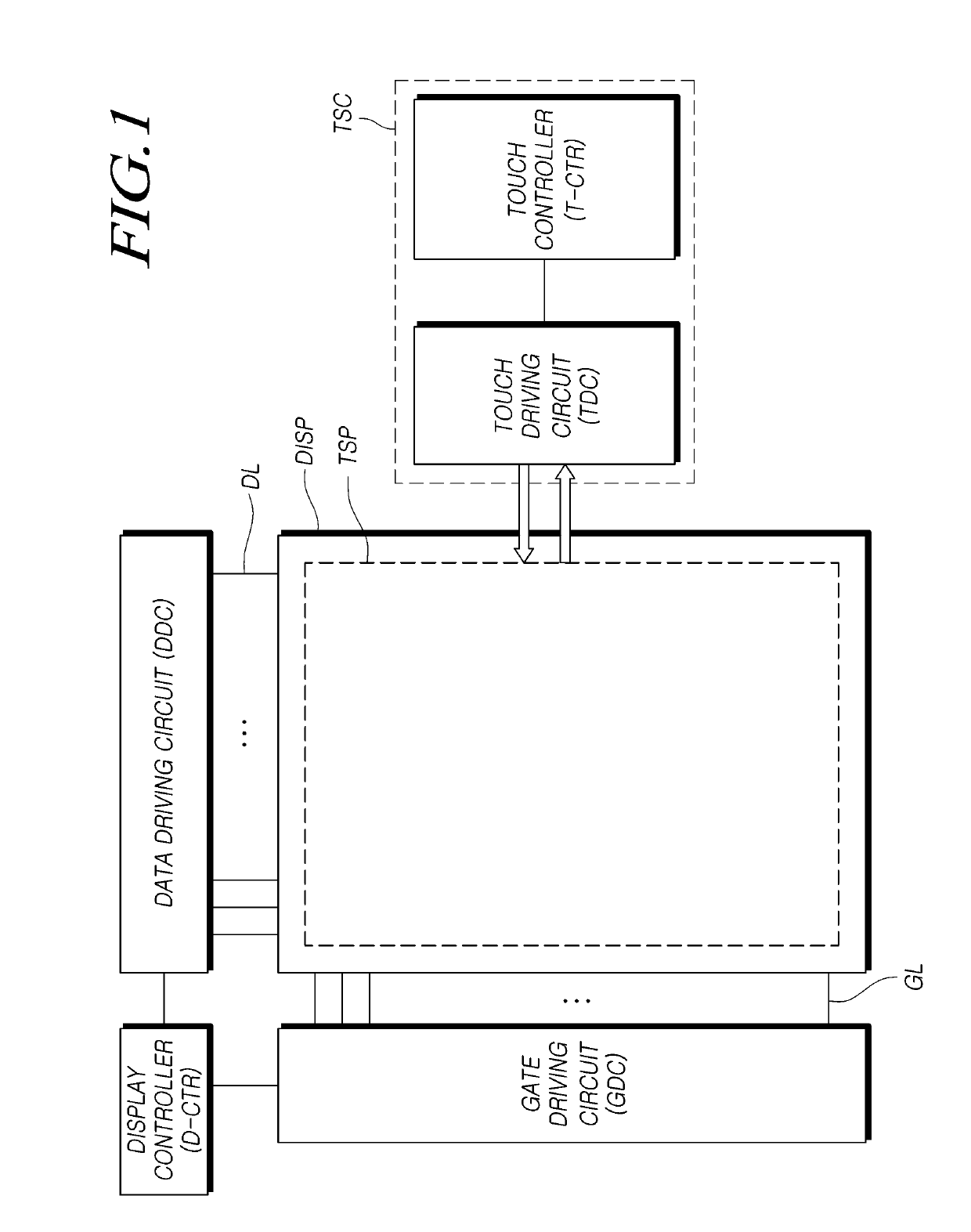

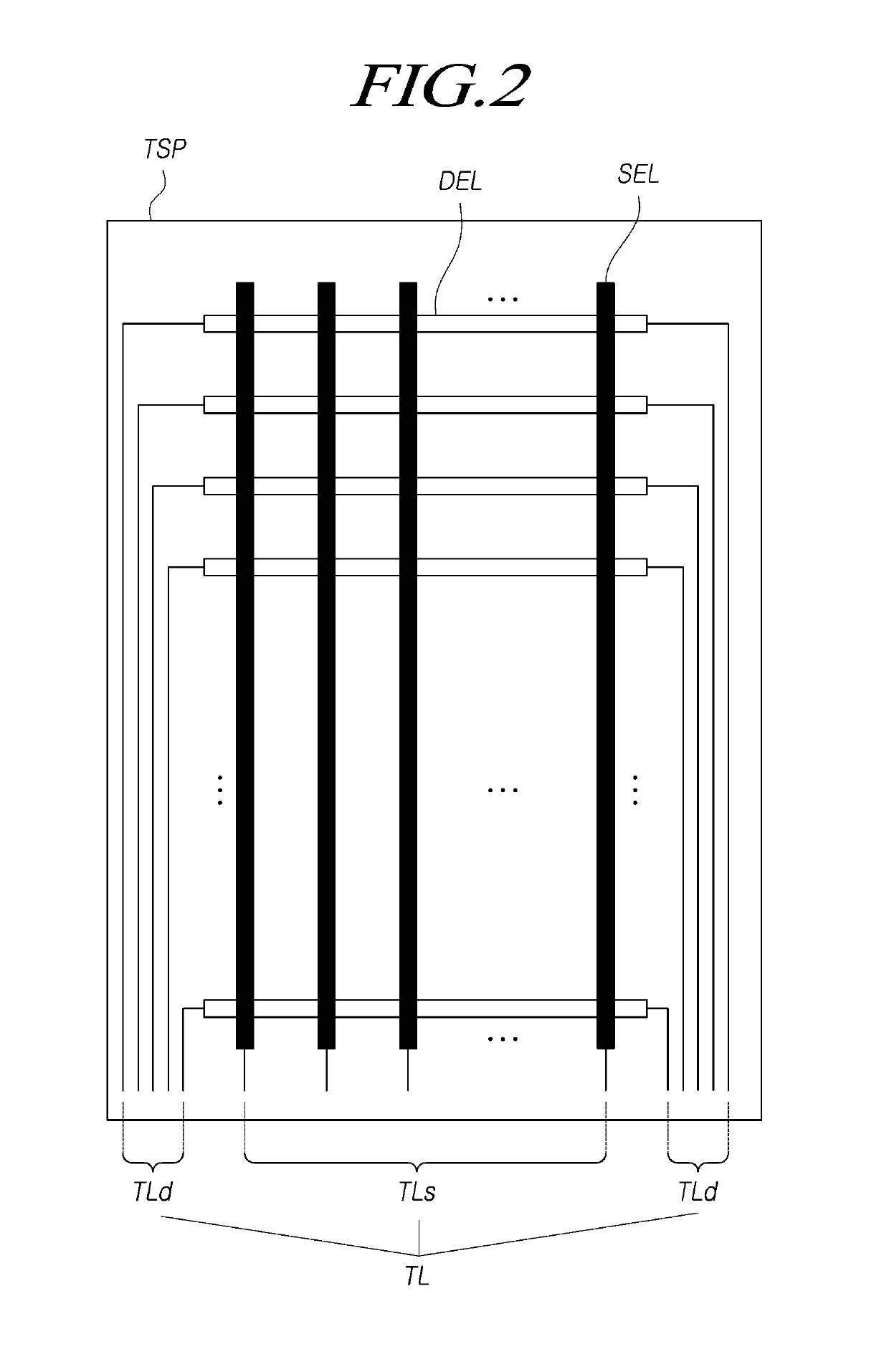

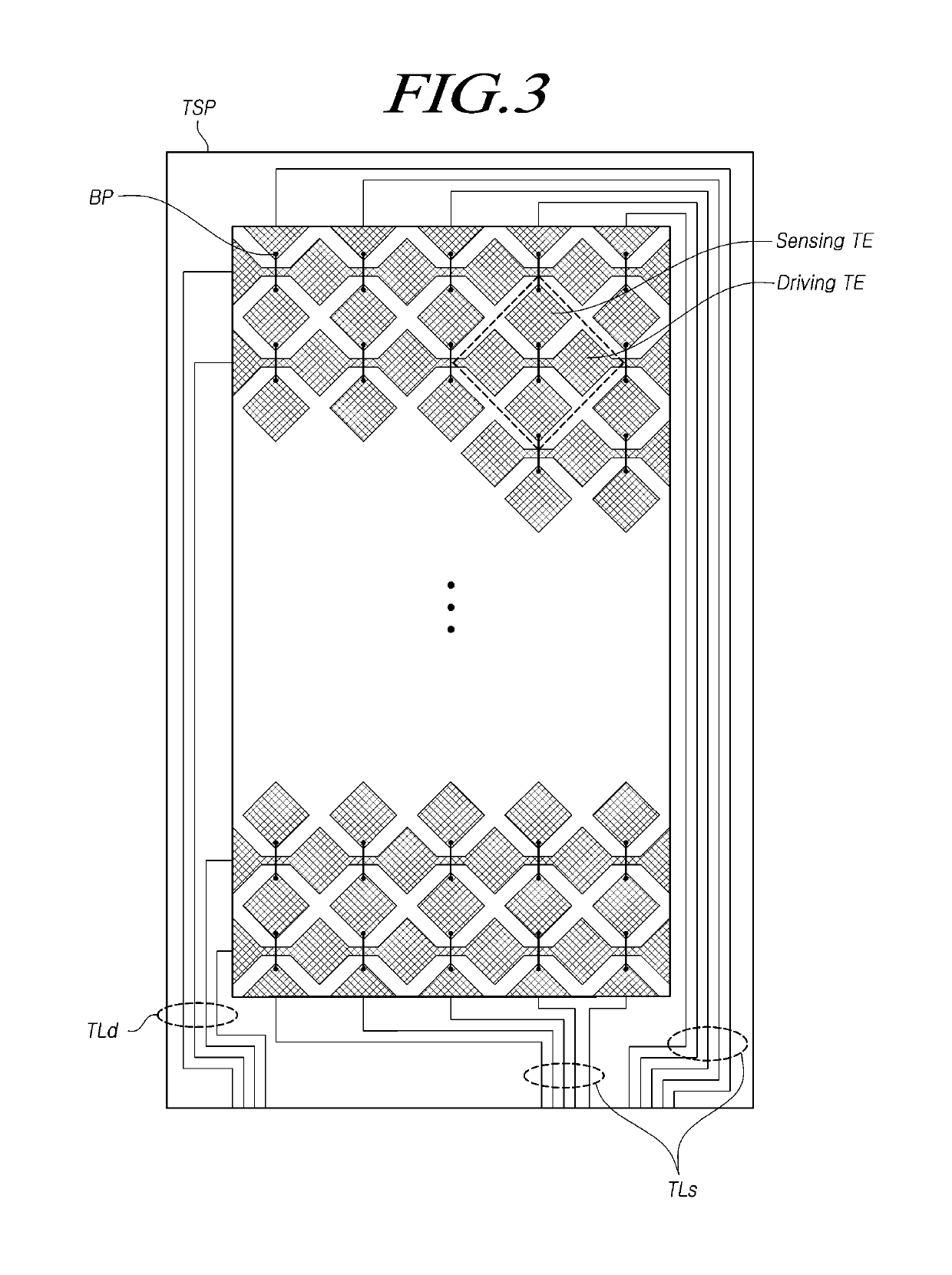

Touch display device and panel

ActiveUS20190121474A1Improve touch sensitivityImprove image qualityStatic indicating devicesSolid-state devicesElectricityTouch Senses

A touch display device can include a panel including a plurality of touch electrodes including a first touch electrode and a second touch electrode, the first touch electrode being adjacent to and electrically isolated from the second touch electrode; a touch sensing circuit configured to drive the panel to sense a touch or a touch position; and at least one external dummy metal disposed in a boundary region between the first touch electrode and the second touch electrode, in which the at least one external dummy metal is spaced apart from and electrically isolated from the first and second touch electrodes.

Owner:LG DISPLAY CO LTD

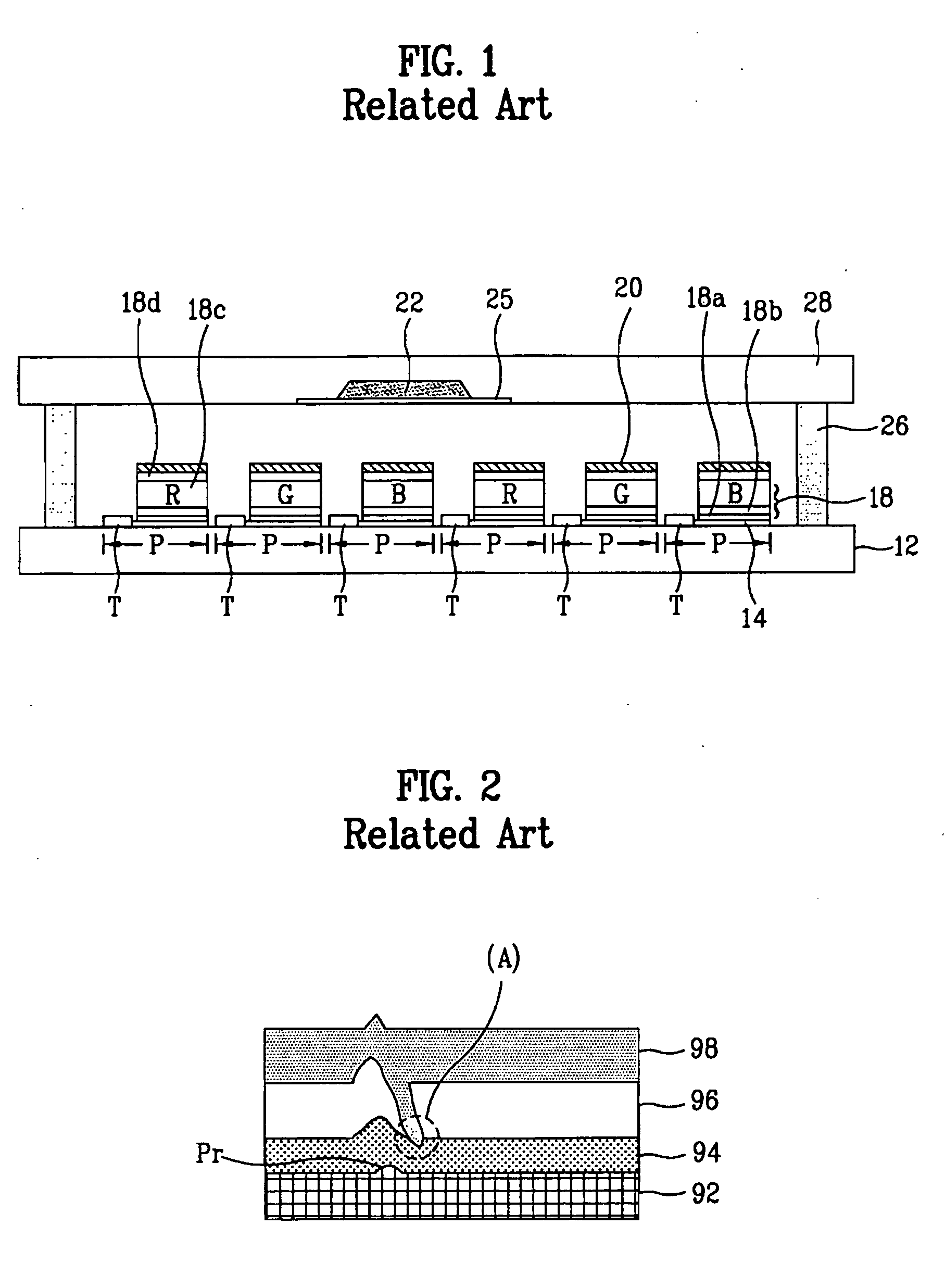

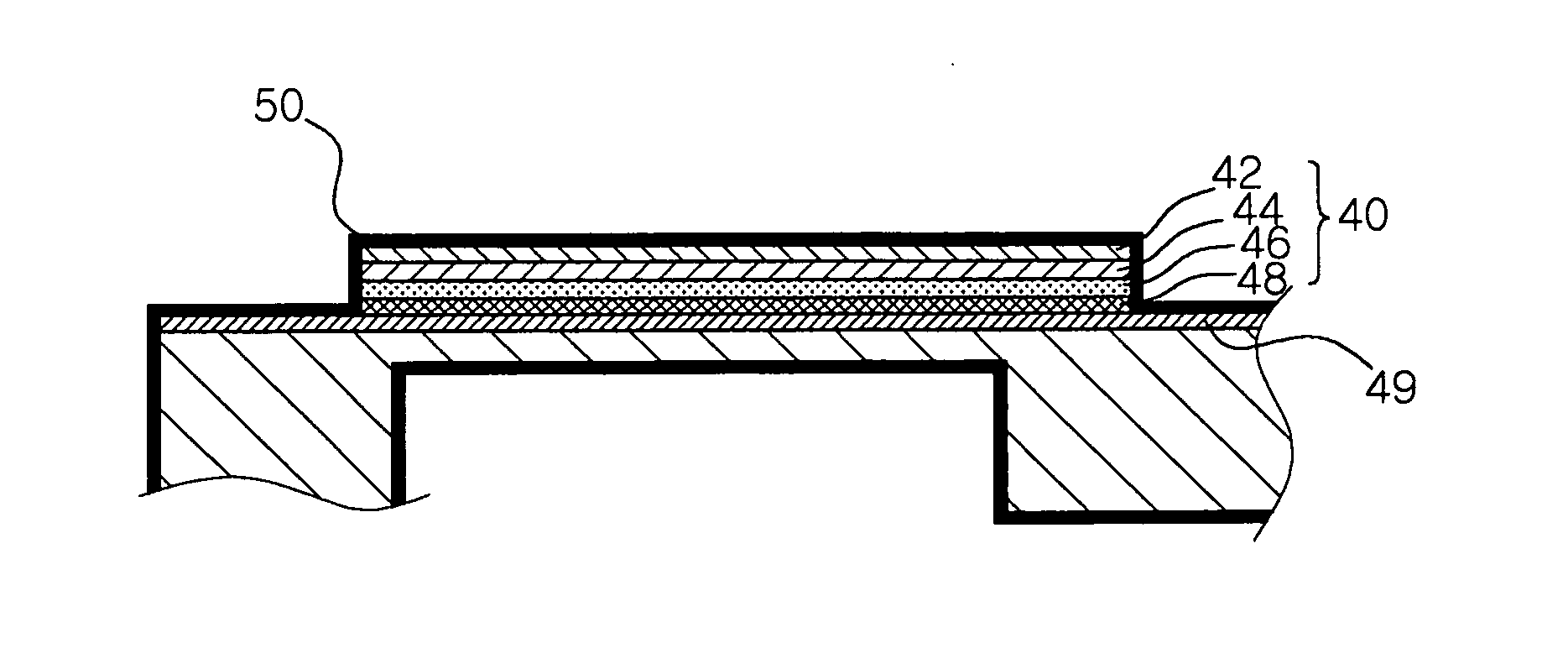

Organic light emitting display device and method for fabricating the same

ActiveUS20090315450A1Easy to shapePreventing a short circuitDischarge tube luminescnet screensLamp detailsDecompositionDisplay device

An OLED device and a method for fabricating the same are disclosed, capable of improving yield and preventing decomposition of organic layers by moisture. An organic passivation layer having excellent morphology is applied to prevent a short circuit between an anode electrode and a cathode electrode. A Ca layer is applied to remove moisture from the inside of the device, thereby increasing the lifespan of the device. Accordingly, generation of dark sports by the short circuit caused by protrusions on a poor-morphology layer can be prevented. In addition, moisture absorbent layers are formed between the passivation layers and the partitions to remove outside moisture and the moisture outgassed from the inside, that is, partitions and organic layers, thereby elongating the lifespan of the OLED device.

Owner:LG DISPLAY CO LTD

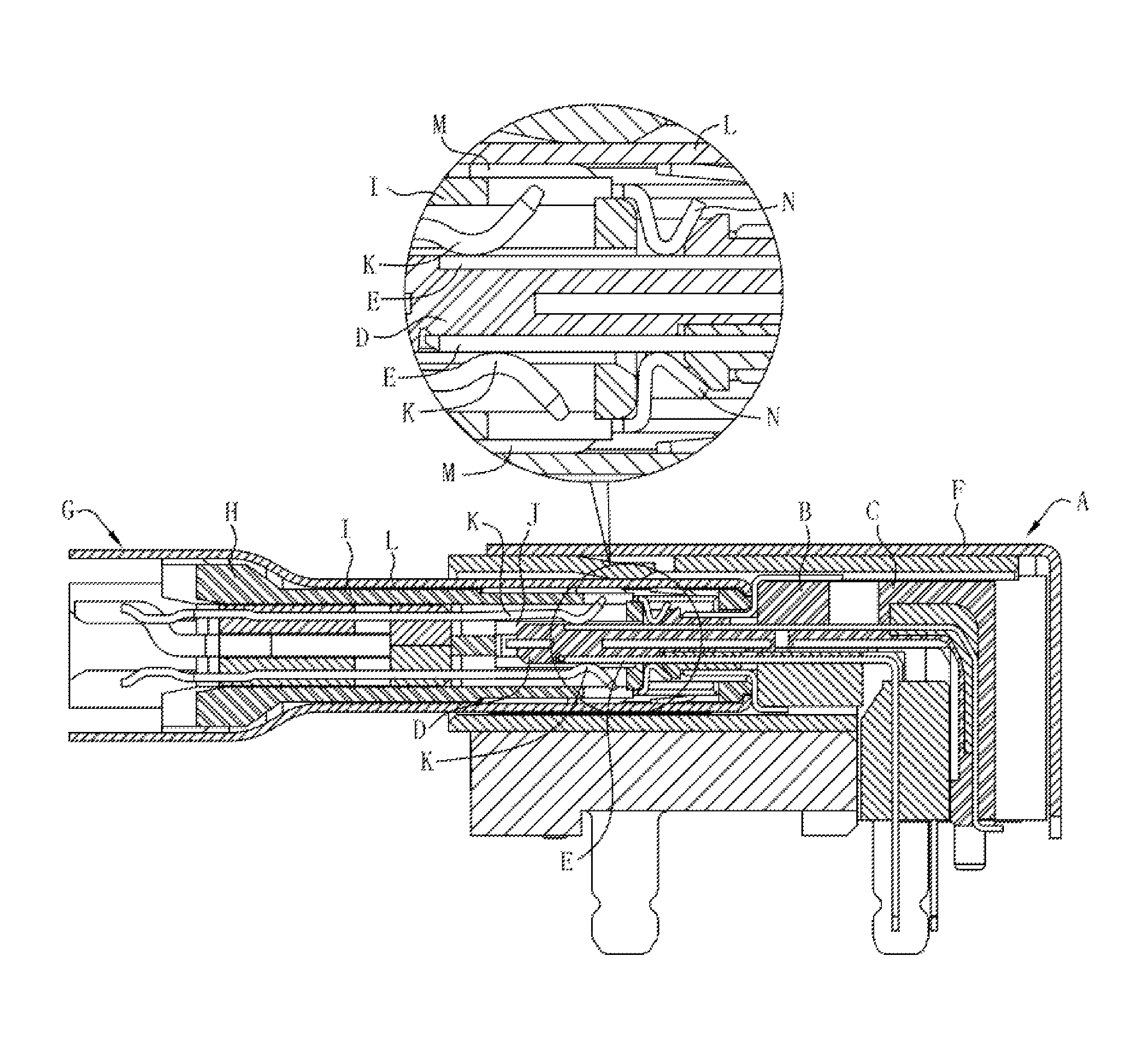

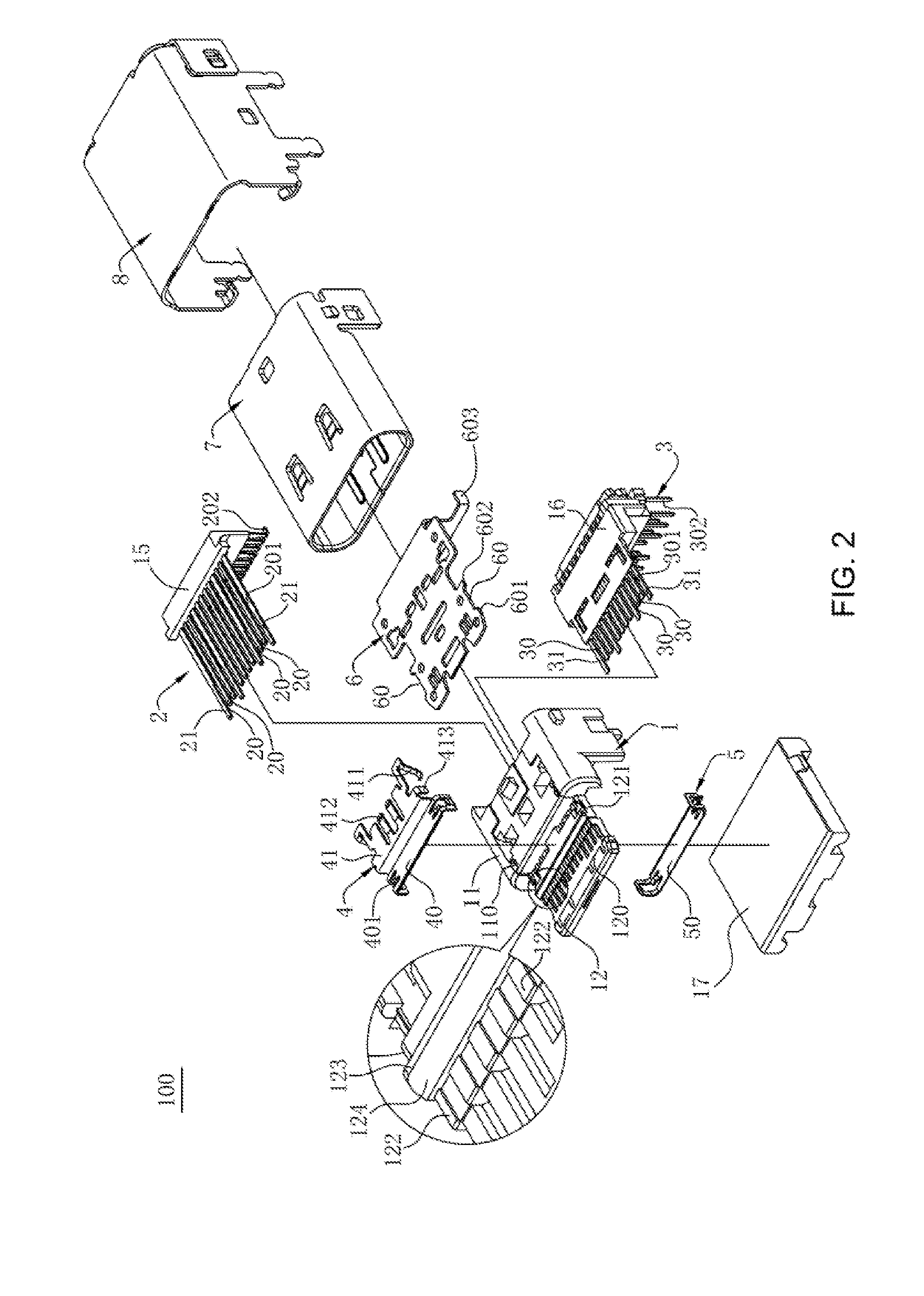

Electrical connector

ActiveUS9590364B1Preventing a short circuitCoupling device detailsTwo-part coupling devicesEngineeringMechanical engineering

An electrical connector including an insulating body, multiple terminals received in the insulating body, and a contact member. The insulating body includes a base and a tongue extending forward from the base. The tongue has a rear segment and a front segment, and the rear segment is higher than the front segment. Each terminal has a mating portion exposed from the front segment. The front segment has an isolation portion close to the rear segment, and the isolation portion is higher than the mating portion and lower than the rear segment. The contact member is disposed at the rear segment, and used for buckling a grounding elastic sheet of a mating connector during mating. The isolation portion is at least partially located on an insertion path of the grounding elastic sheet.

Owner:LOTES

Thin film capacitor and method of manufacturing the same

InactiveUS20050056878A1Preventing a short circuitTransistorThin/thick film capacitorElectrical conductorEngineering

Owner:FUJITSU LTD

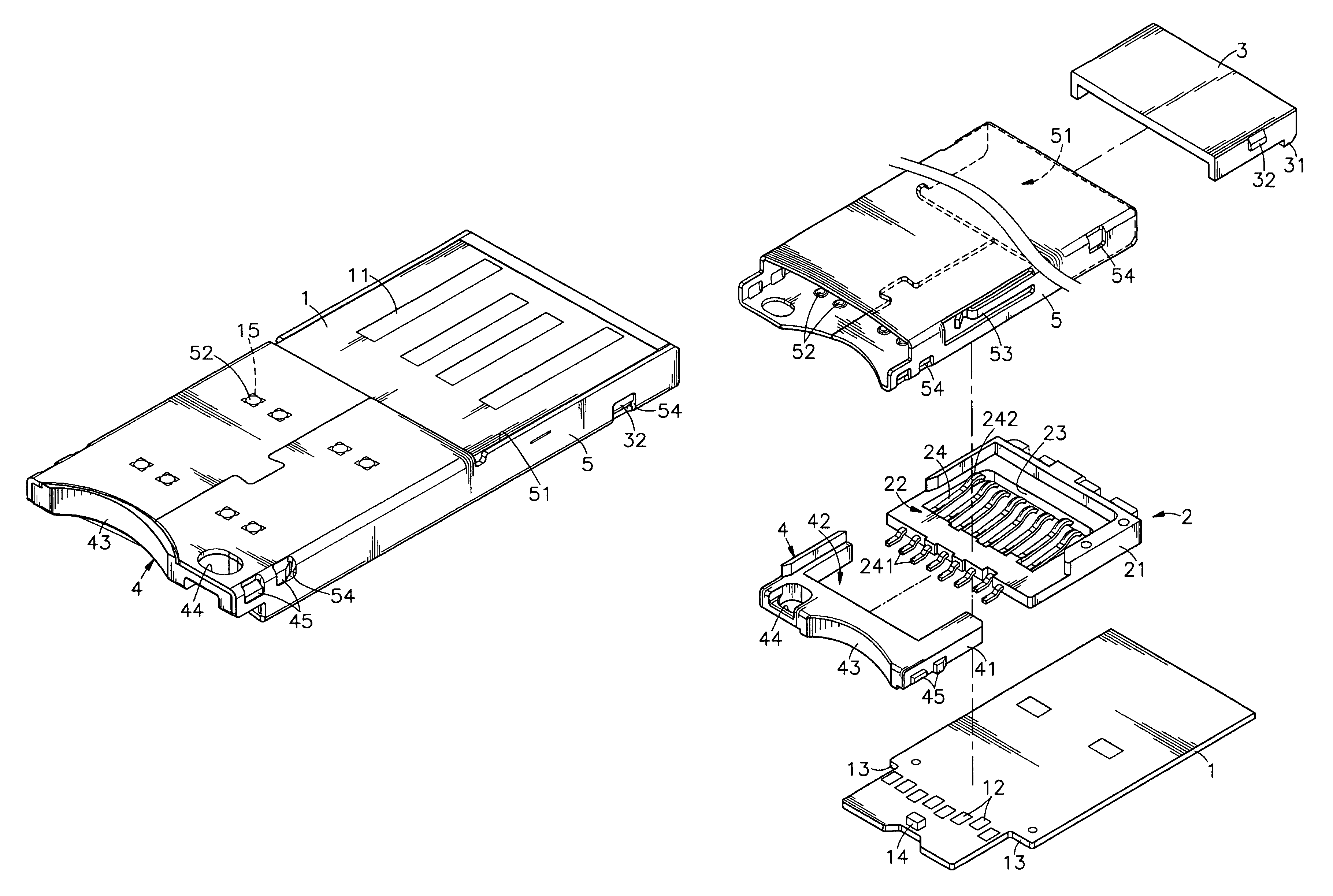

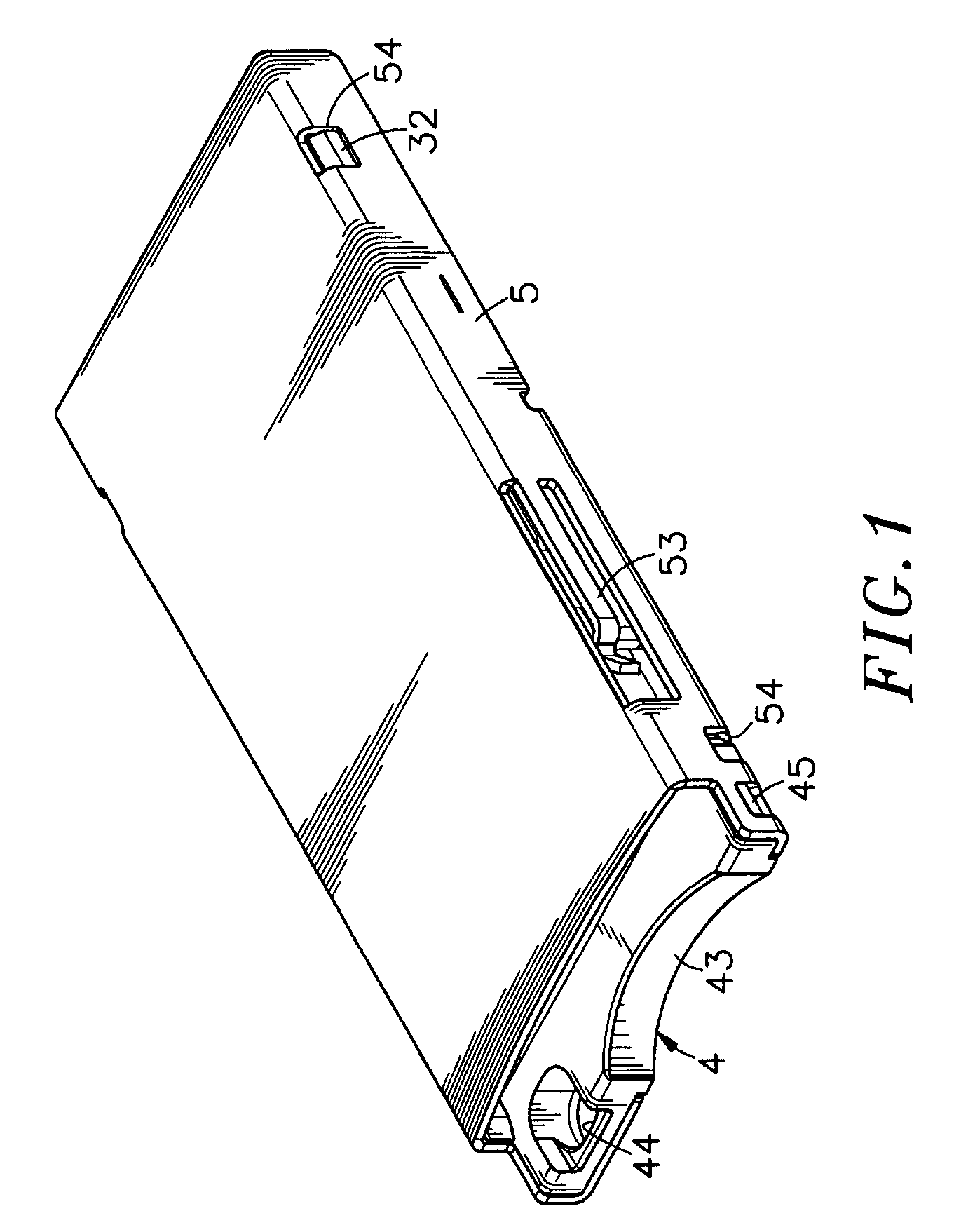

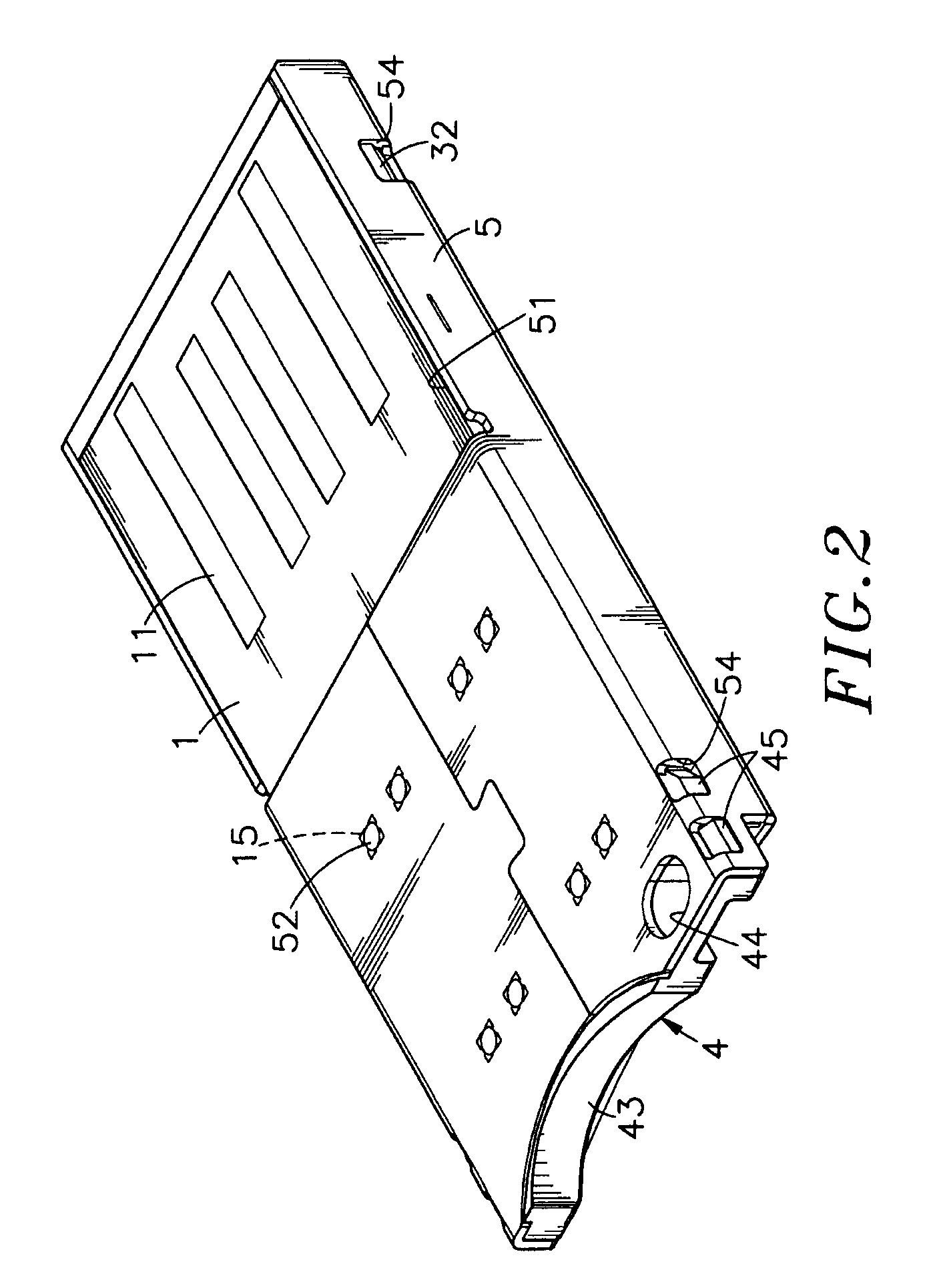

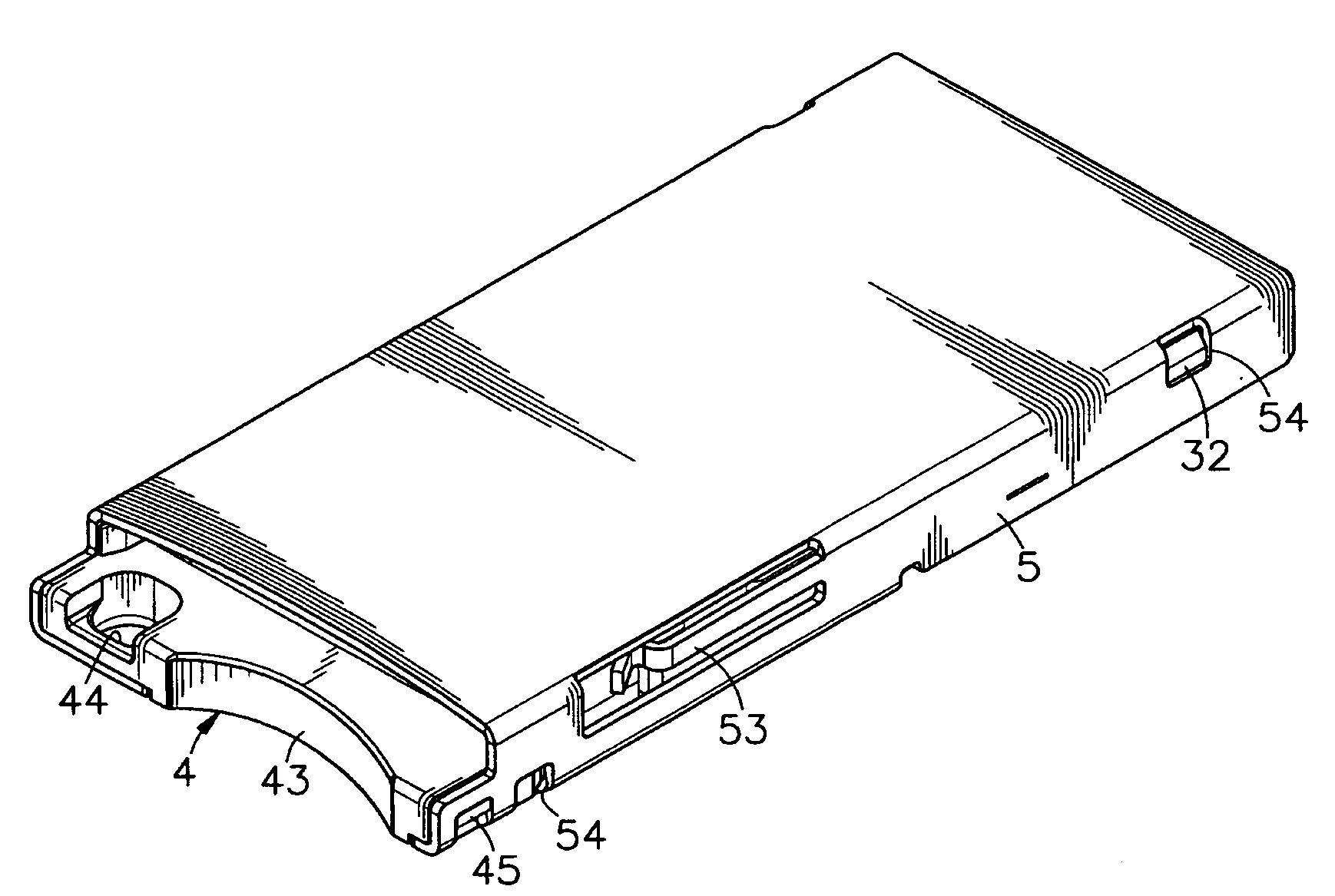

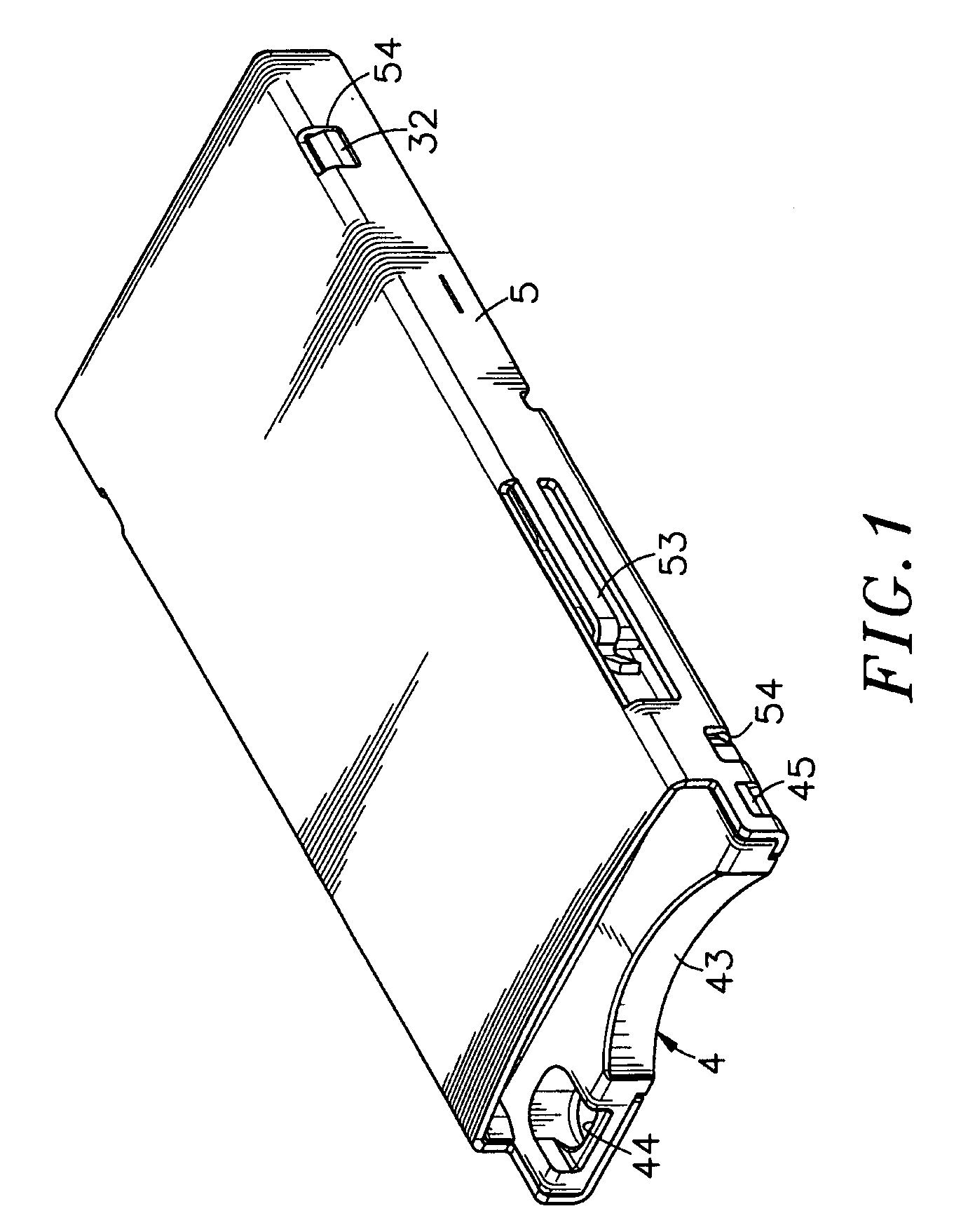

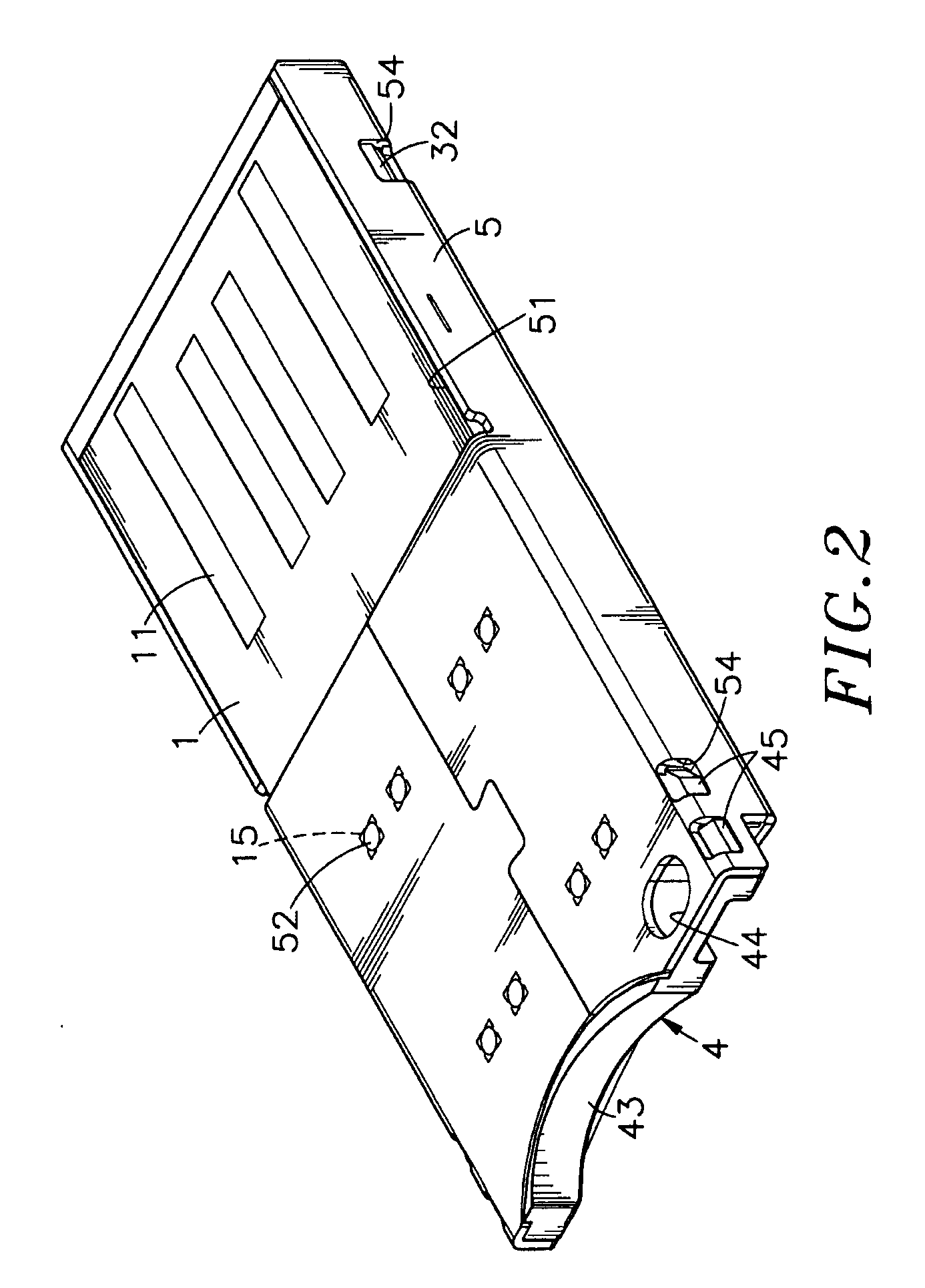

Card reader

InactiveUS7632151B2Low profileAccurate guideIncorrect coupling preventionSecuring/insulating coupling contact membersEngineeringCard reader

A low profile card reader is disclosed to include a circuit board with a USB connection interface at the front part, an electrically insulative inner shell bonded to the circuit board outside the USB connection interface and defining an accommodation space, a card connector mounted in the accommodation space and electrically connected to the circuit board for receiving and reading a memory card and having a receiving space for receiving a memory card, a guide member connected to the circuit board and defining a sliding way disposed in line with the receiving space of the card connector for guiding a memory card into the card connector, and an outer metal shielding shell surrounding the circuit board, the electrically insulative inner shell, the card connector and the guide member for EMI protection with the USB connection interface of the circuit board exposed to the outside for connection to a computer.

Owner:JINN SHYANG PRECISION INDAL +2

Separator For Rechargeable Lithium Battery and Rechargeable Lithium Battery Including Same

ActiveUS20160141576A1Improve securitySuppress feverLi-accumulatorsCell component detailsInorganic materialsInorganic layer

A separator for a rechargeable lithium battery includes a substrate, an organic layer positioned on at least one side of the substrate and including an organic material and an inorganic layer positioned on at least one side of the substrate and including an inorganic material, wherein the organic material includes two or more kinds of organic particles having different particle sizes from each other.

Owner:SAMSUNG SDI CO LTD

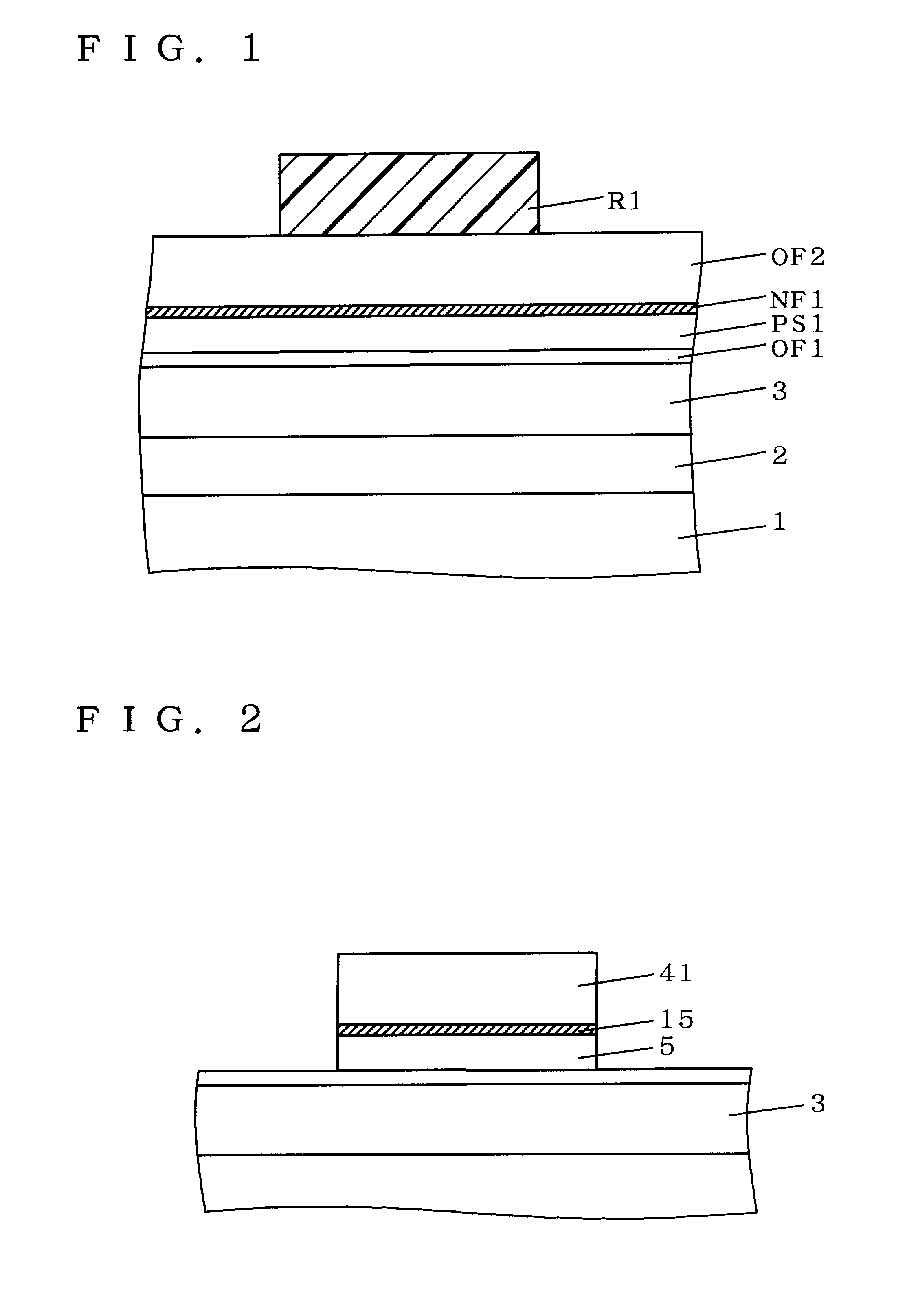

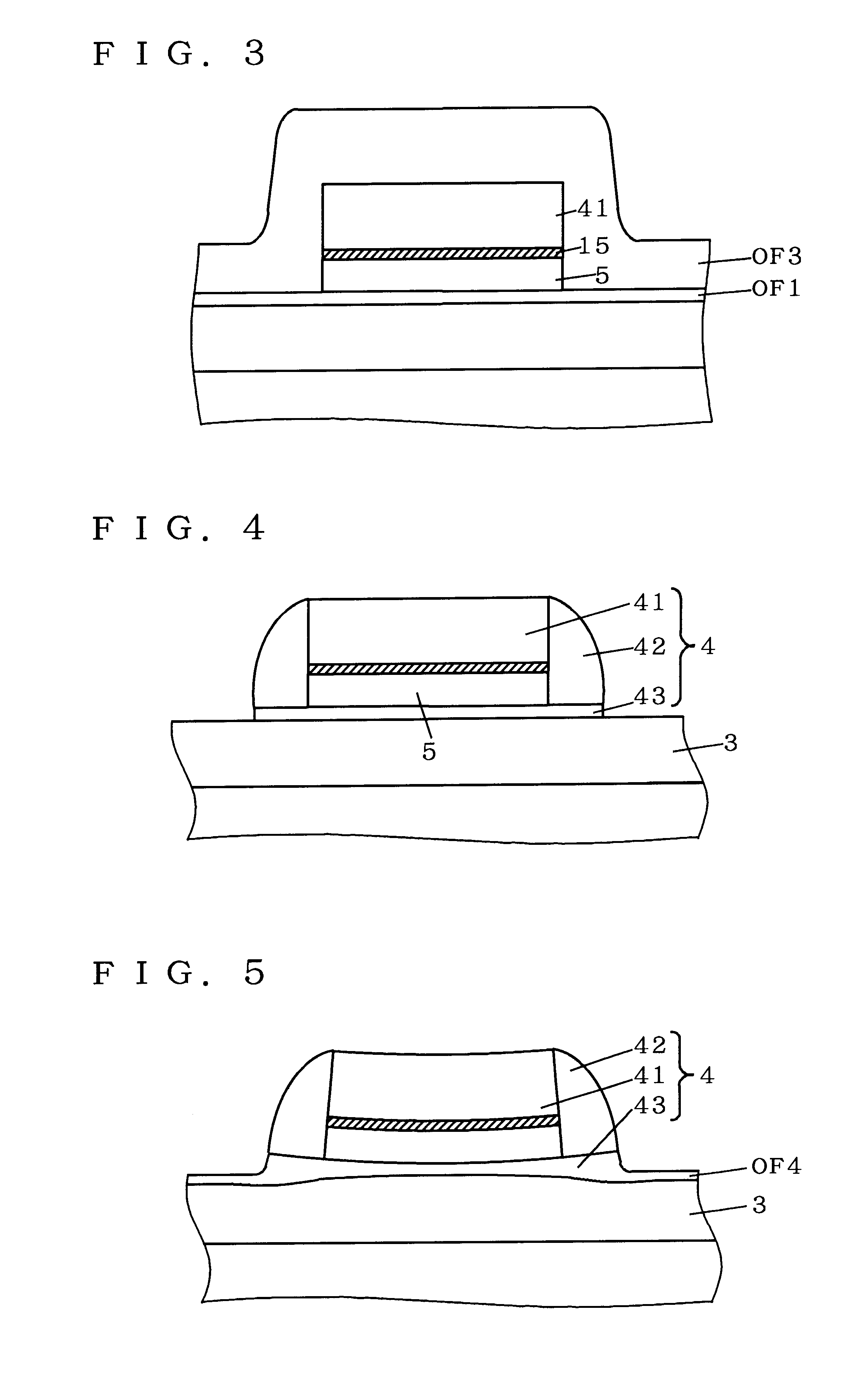

Semiconductor device with field shield electrode

InactiveUS6191450B1Avoid breakingPreventing a short circuitTransistorSolid-state devicesNitrideSemiconductor

An FS upper nitride film (15) is formed on the upper surface of an FS electrode (5). Therefore, the upper surface of the FS electrode (5) is not exposed even when an FS upper oxide film (41) is partially almost removed in the manufacturing process. Thus, a semiconductor device which prevents degradation in operation characteristics and reliability due to existence of an FS insulating layer can be provided.

Owner:MITSUBISHI ELECTRIC CORP

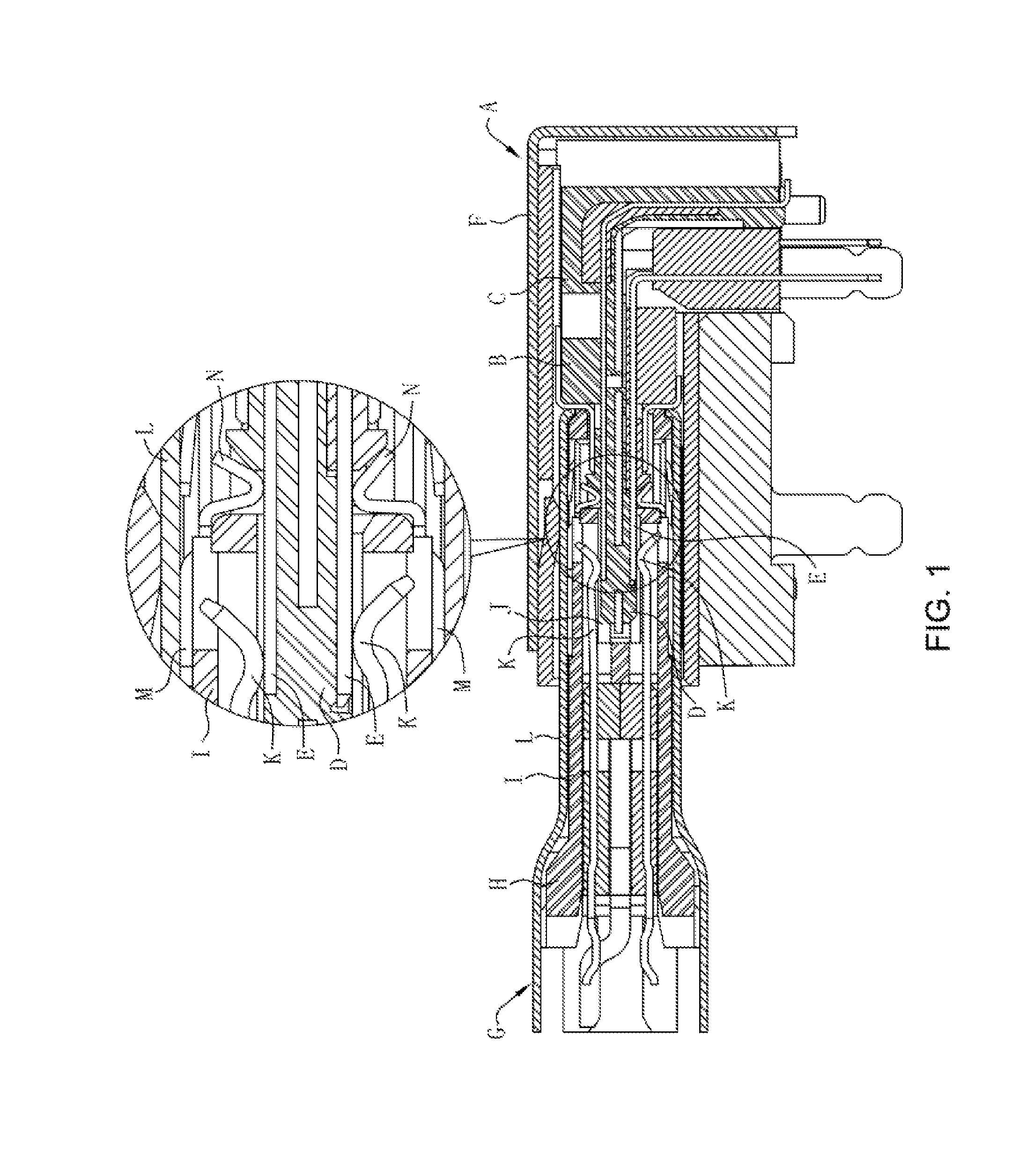

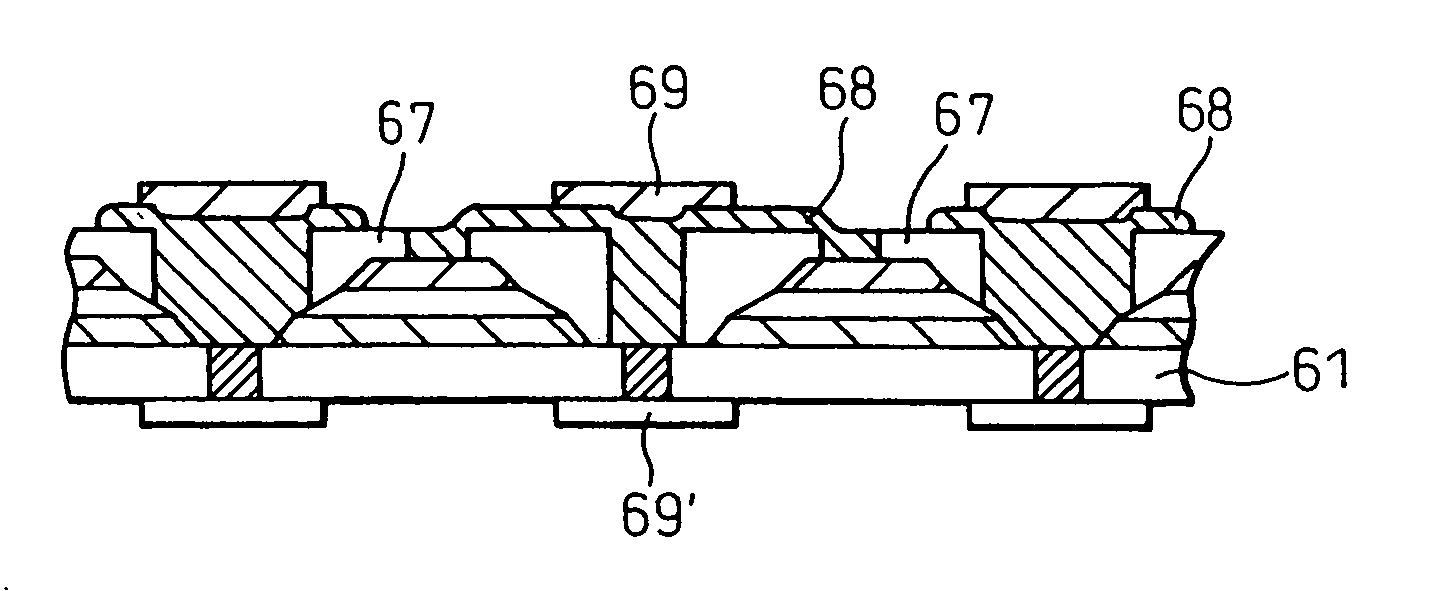

Electrical connector having a space allowing an elastic connecting member to be escaped

InactiveUS7654827B2Improve contact reliabilityPreventing a short circuitCoupling device detailsFixed connectionsEngineeringElectrical connector

In an electrical connector for connecting connection objects to each other in a connecting direction, a holding member has an accommodating portion between a first and a second surface to which the connection objects are opposed, respectively, when connected to said electrical connector. A connecting member has elasticity and is placed in the accommodating portion. The holding member includes a first and a second wall which define the accommodating portion therebetween. At least one of the first and the second walls includes a restraining portion defining a space which allows a portion of the connecting member to elastically move in a predetermined direction crossing the connecting direction.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

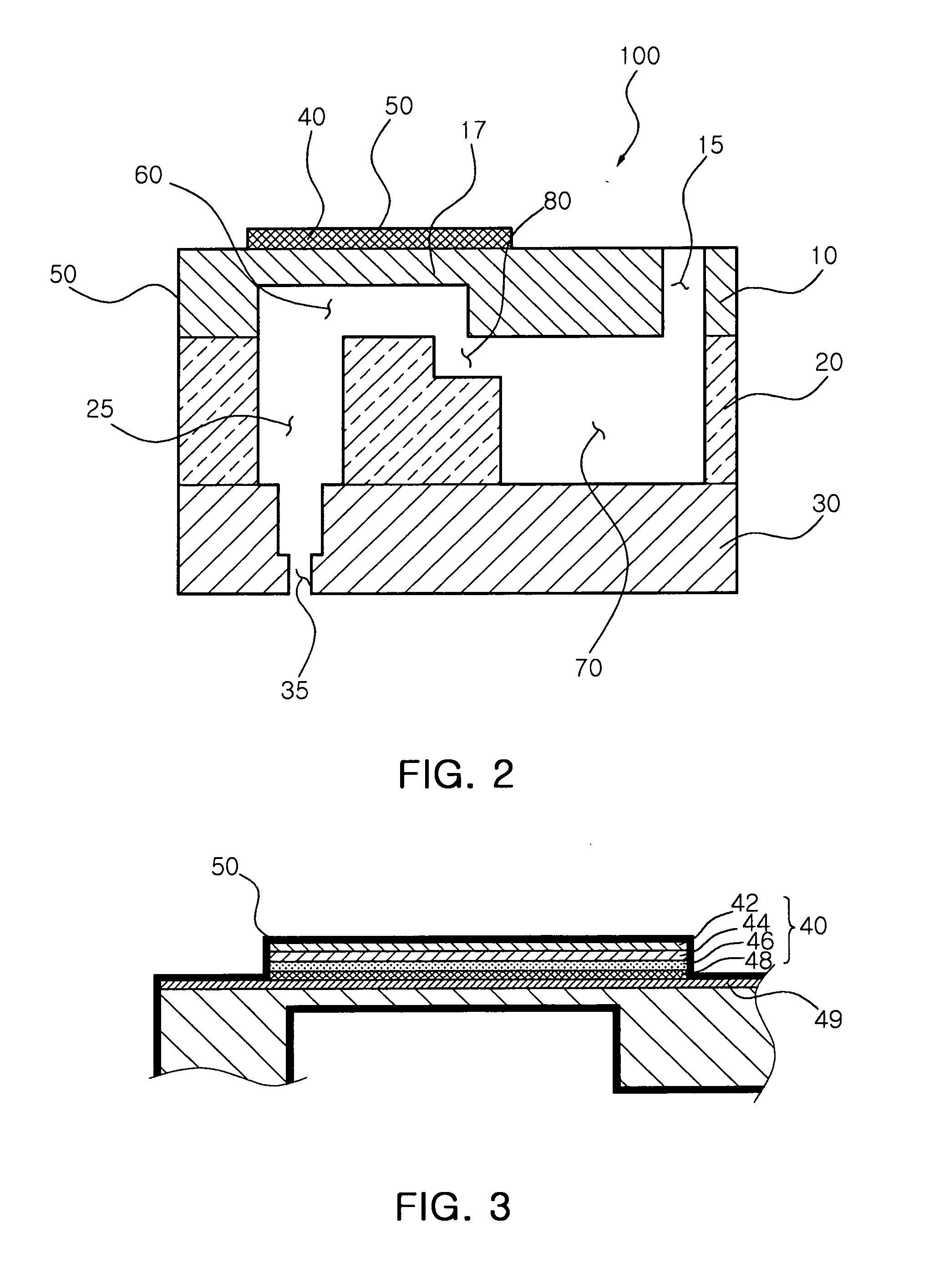

Zinc secondary battery

ActiveUS9293791B2Improve reliabilityPreventing a short circuitSilver accumulatorsSolid electrolytesElectrolyteIon

Provide is a zinc secondary battery capable of preventing a short circuit between the positive and negative electrodes caused by zinc dendrites. The zinc secondary battery of the present invention comprises a positive electrode; a negative electrode containing zinc; an electrolytic solution in which the positive electrode and the negative electrode are immersed or with which the positive electrode and the negative electrode are in contact, wherein the electrolytic solution is an aqueous solution containing an alkali metal hydroxide; and a separator being placed between the positive electrode and the negative electrode and separating the positive electrode and the negative electrode from each other, wherein the separator comprises an inorganic solid electrolyte body having hydroxide ion conductivity.

Owner:NGK INSULATORS LTD

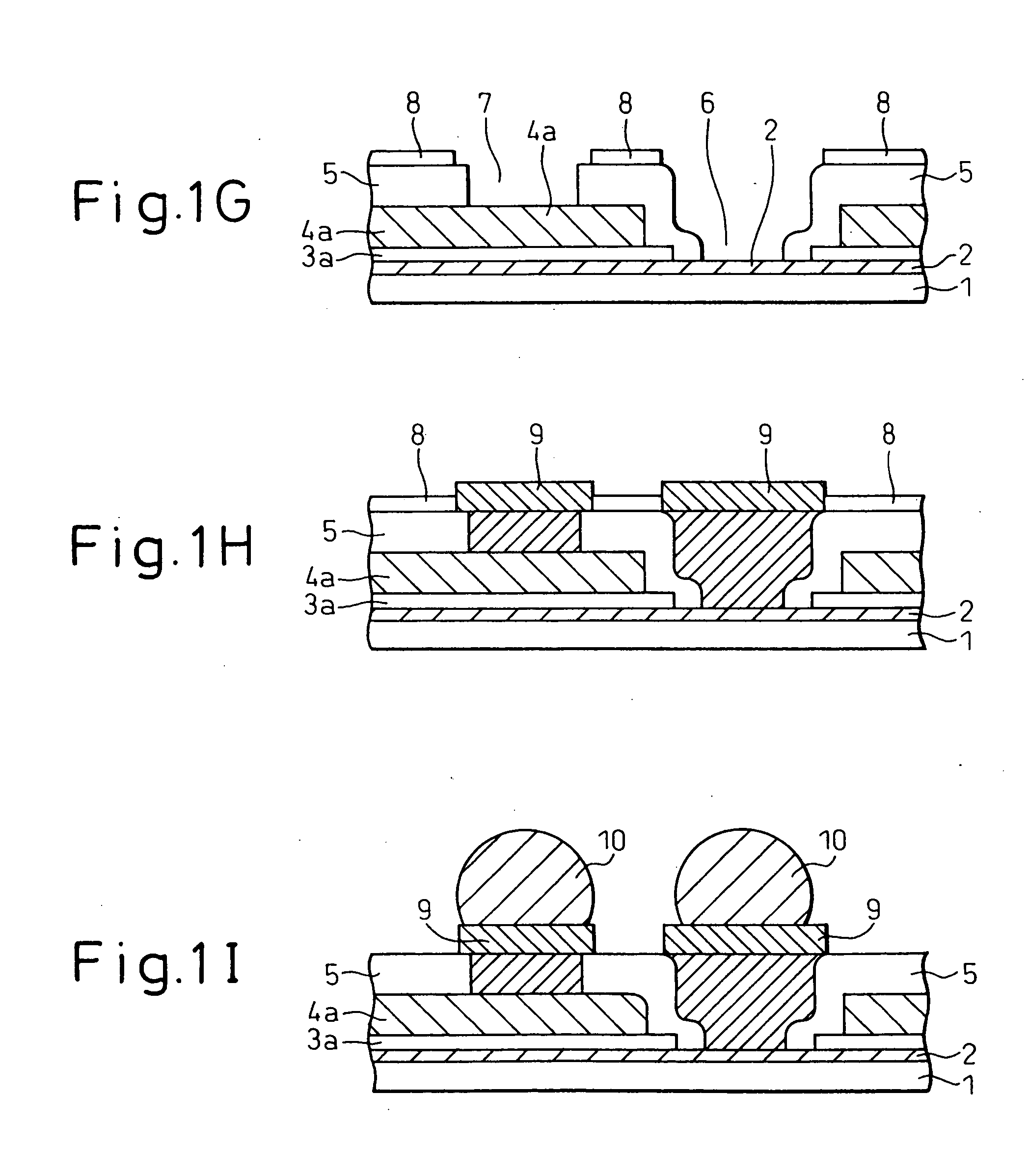

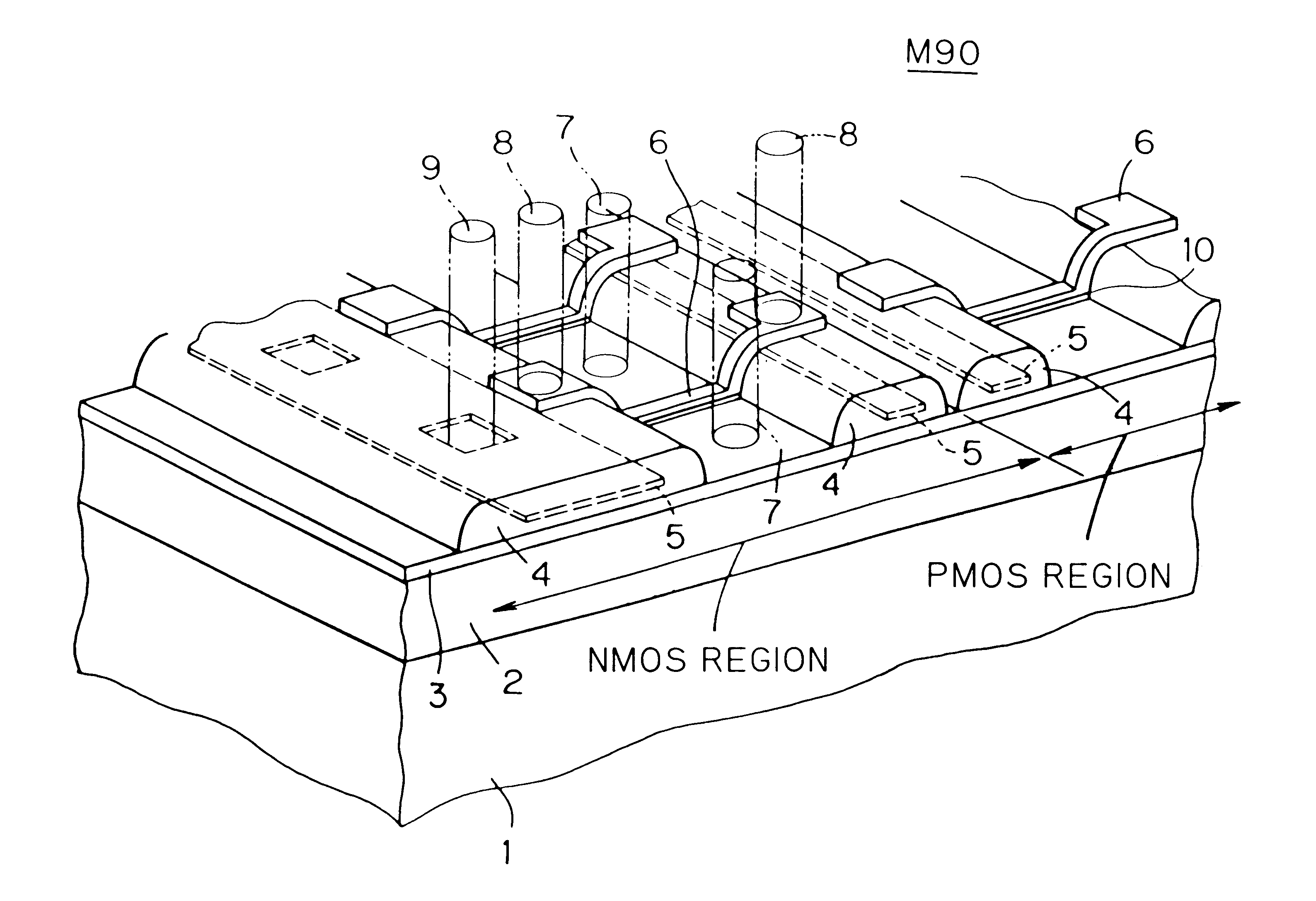

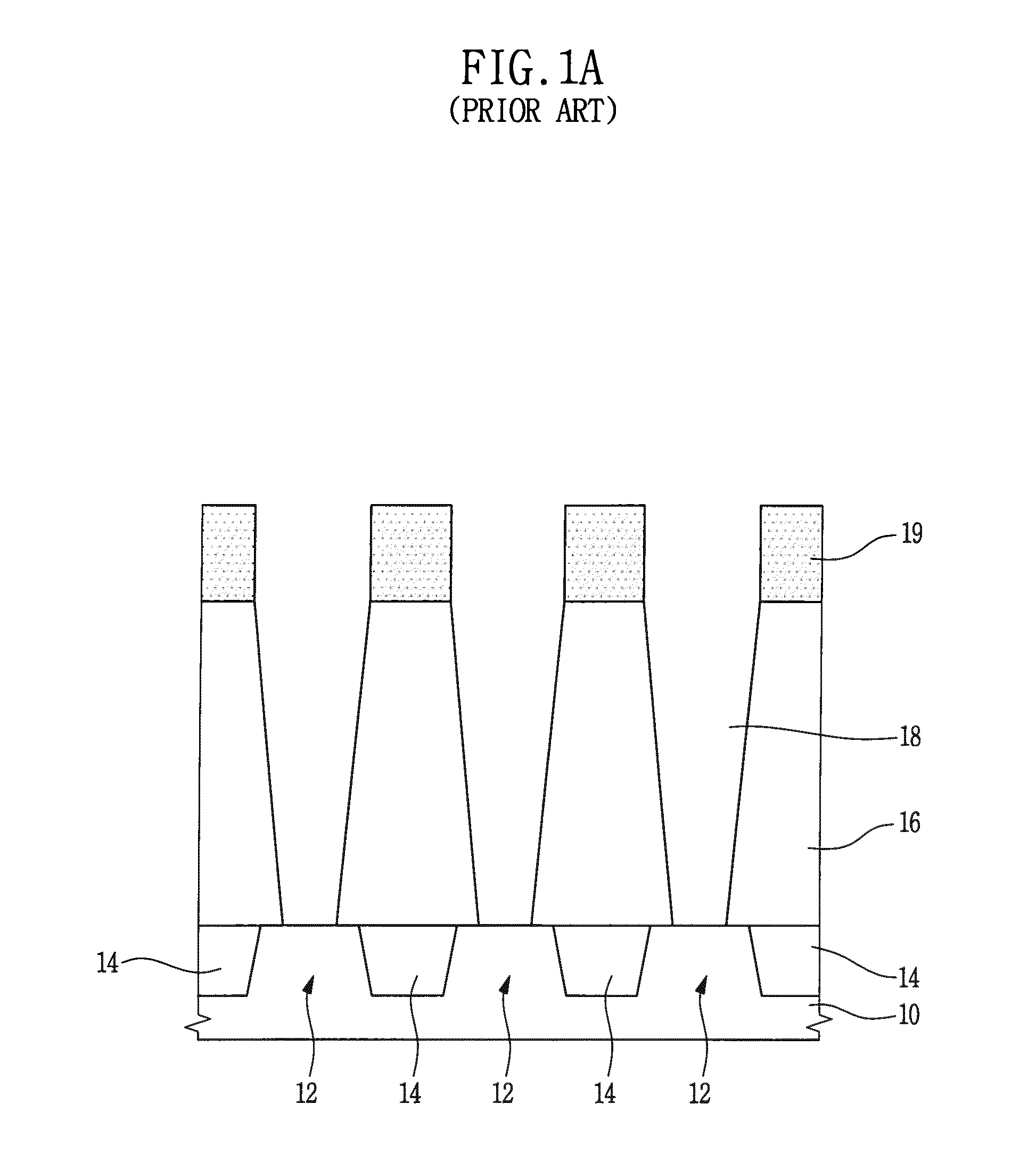

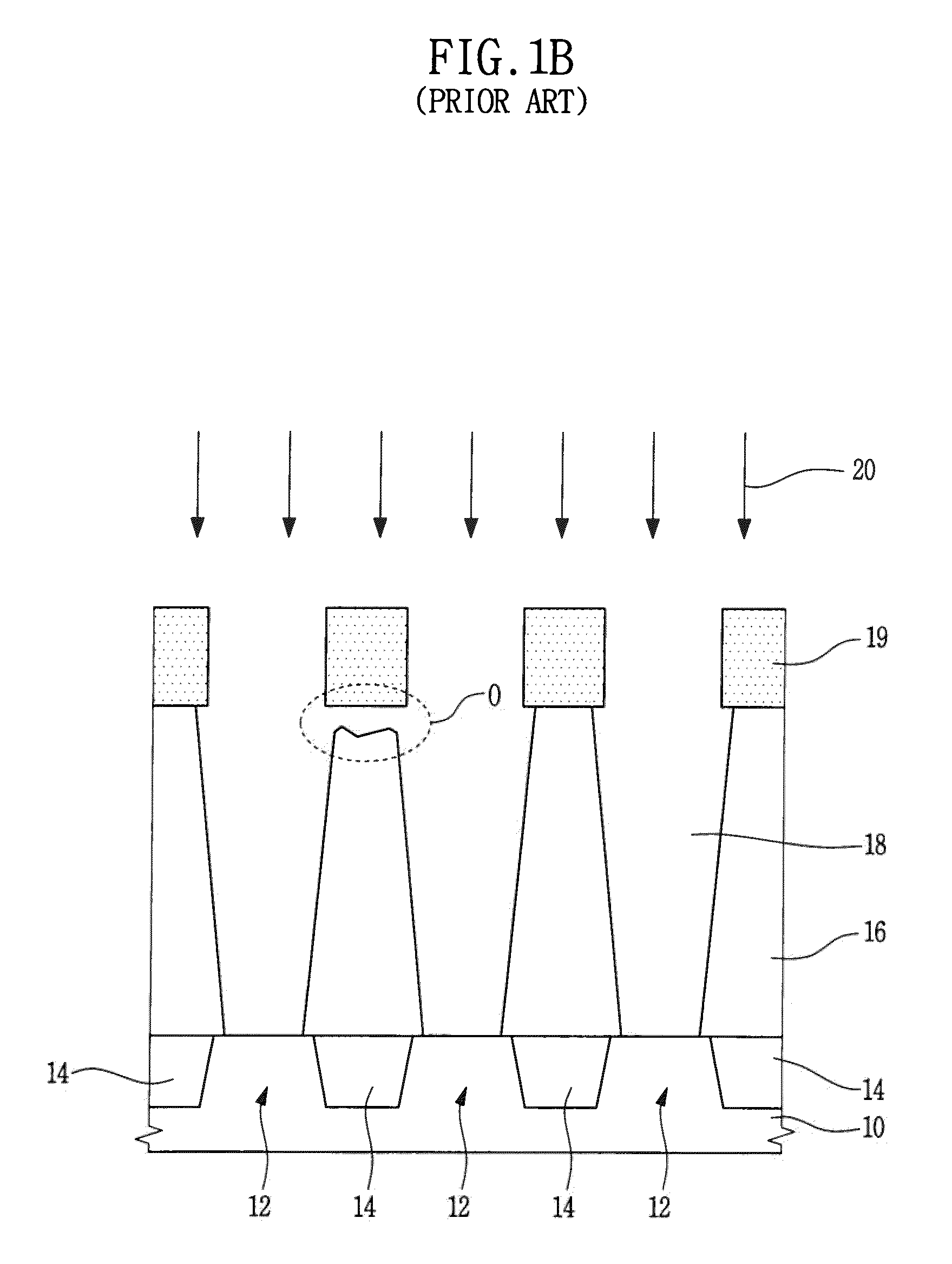

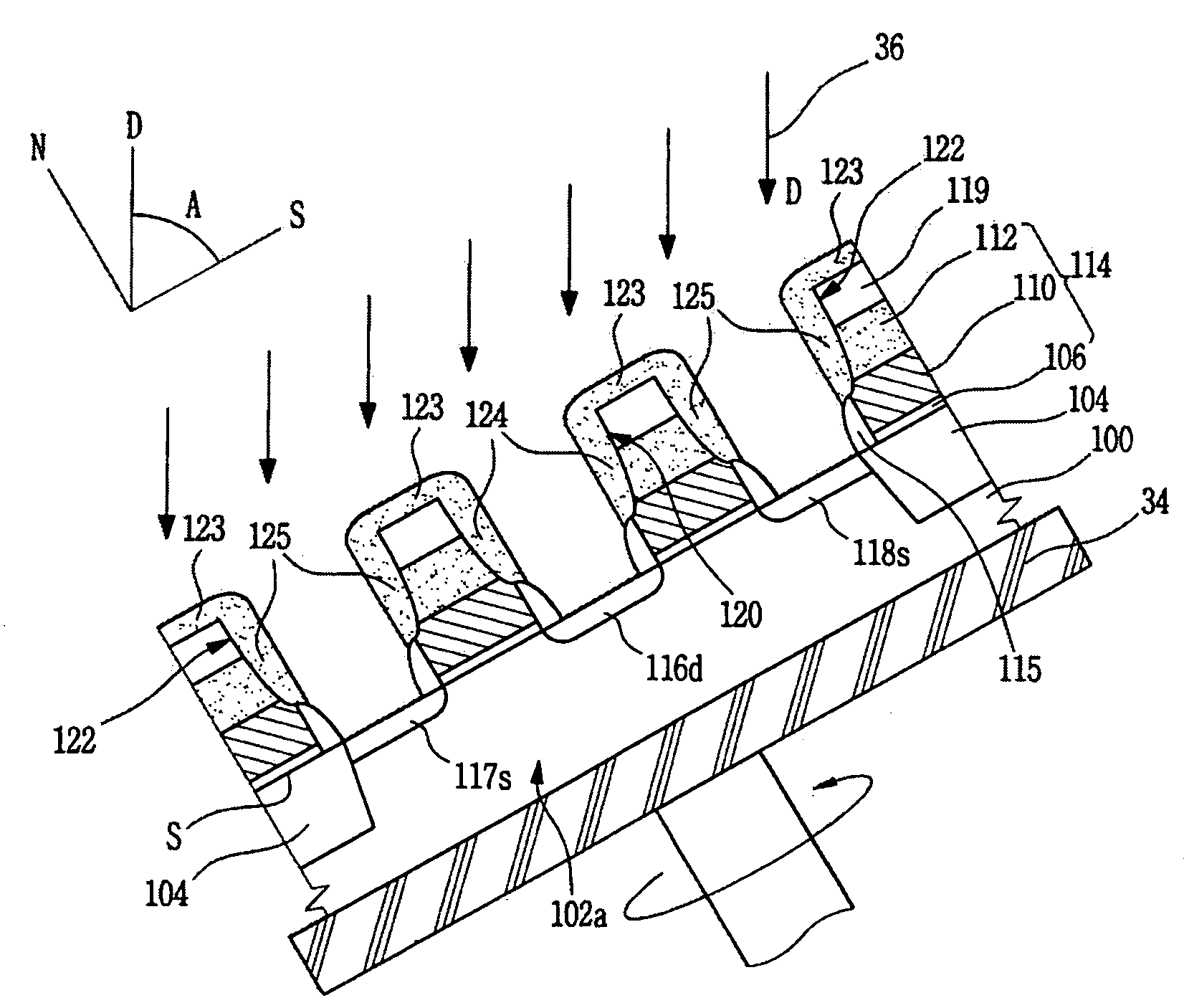

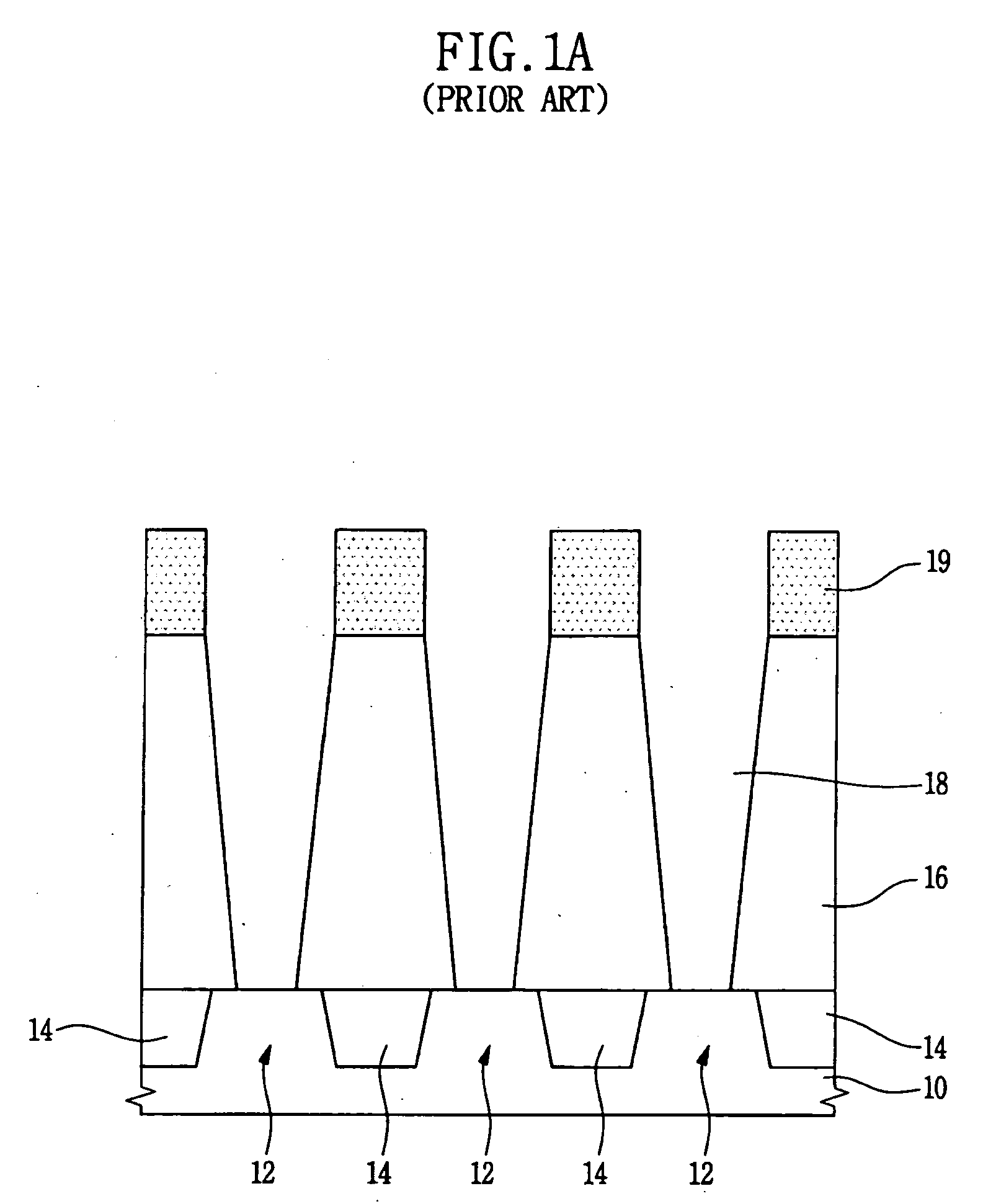

Method of forming contact structure with contact spacer and method of fabricating semiconductor device using the same

InactiveUS7884014B2Improve reliabilityPreventing a short circuitSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A method of forming a contact structure with a contact spacer and a method of fabricating a semiconductor device using the same. In the method of forming a contact structure, an interlayer dielectric layer is formed on a semiconductor substrate. The interlayer dielectric layer is patterned, thereby forming a contact hole for exposing a predetermined region of the semiconductor substrate. A contact spacer is formed on a sidewall of the contact hole using a deposition method having an inclined deposition direction with respect to a main surface of the semiconductor substrate. The deposition direction may be set between the main surface and a normal with respect to the main surface. Further, there is provided a method of fabricating a semiconductor device using the method of forming the contact structure.

Owner:SAMSUNG ELECTRONICS CO LTD

Card reader

InactiveUS20090130905A1Low profileAccurate guideIncorrect coupling preventionSecuring/insulating coupling contact membersEngineeringCard reader

A low profile card reader is disclosed to include a circuit board with a USB connection interface at the front part, an electrically insulative inner shell bonded to the circuit board outside the USB connection interface and defining an accommodation space, a card connector mounted in the accommodation space and electrically connected to the circuit board for receiving and reading a memory card and having a receiving space for receiving a memory card, a guide member connected to the circuit board and defining a sliding way disposed in line with the receiving space of the card connector for guiding a memory card into the card connector, and an outer metal shielding shell surrounding the circuit board, the electrically insulative inner shell, the card connector and the guide member for EMI protection with the USB connection interface of the circuit board exposed to the outside for connection to a computer.

Owner:JINN SHYANG PRECISION INDAL +2

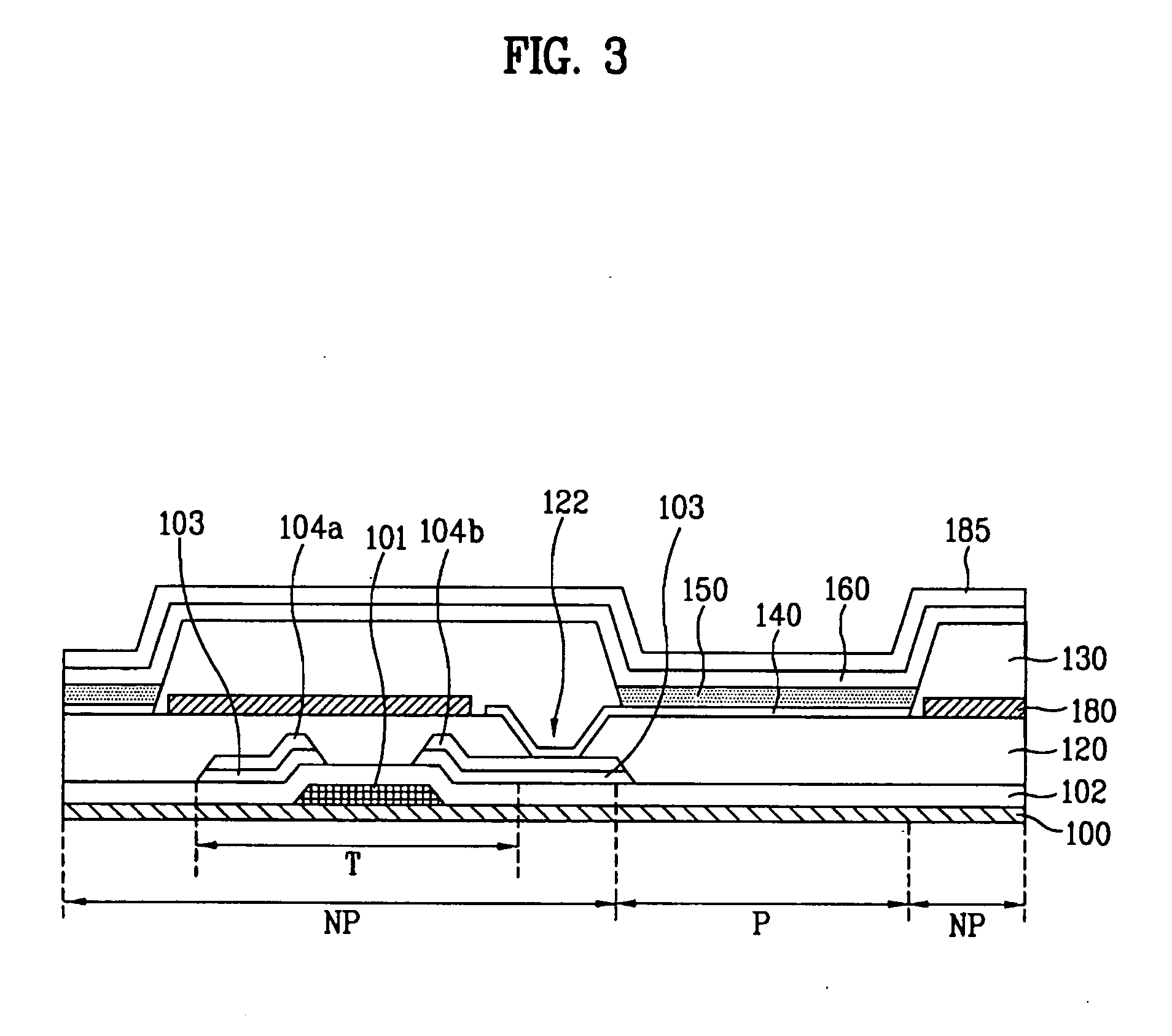

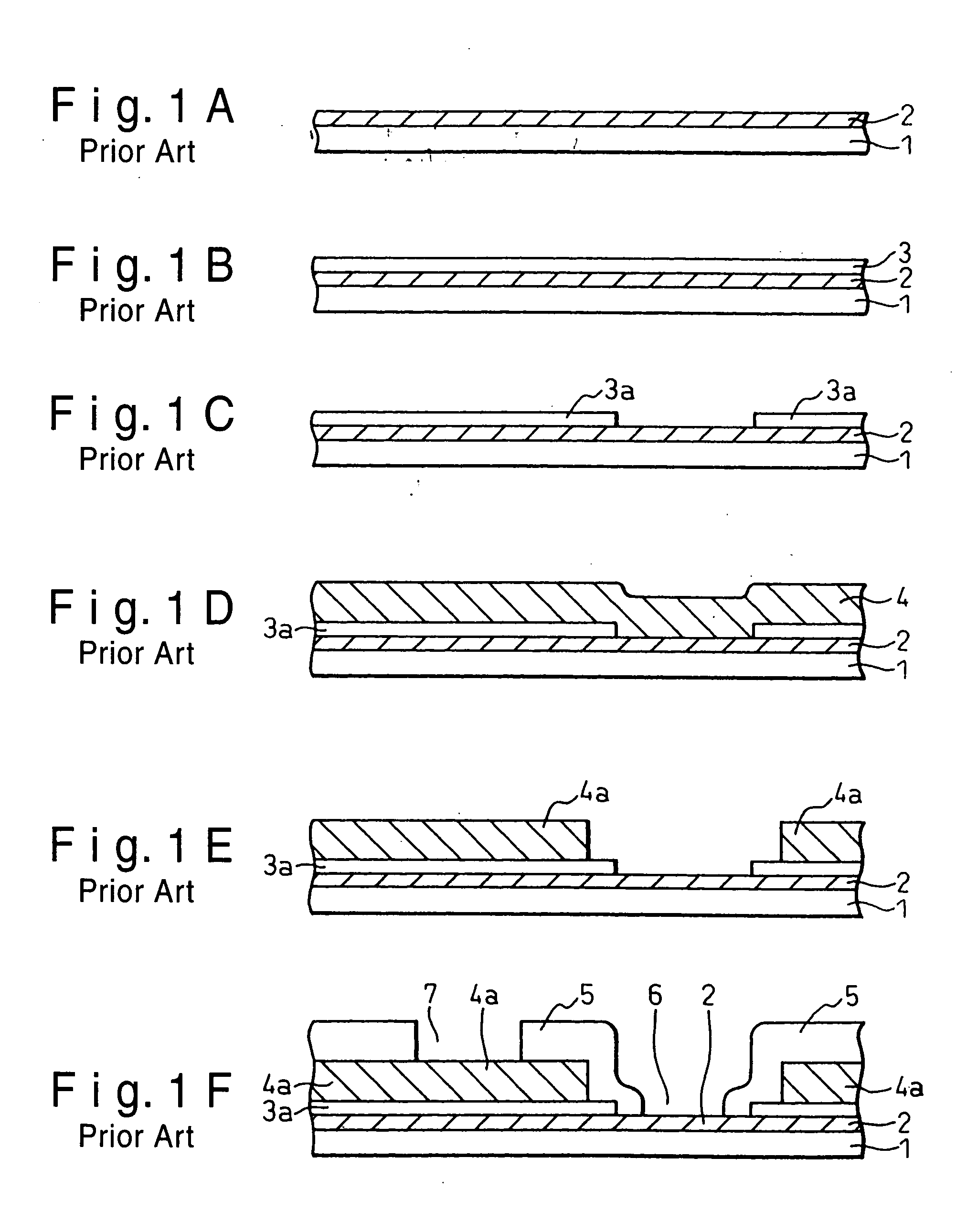

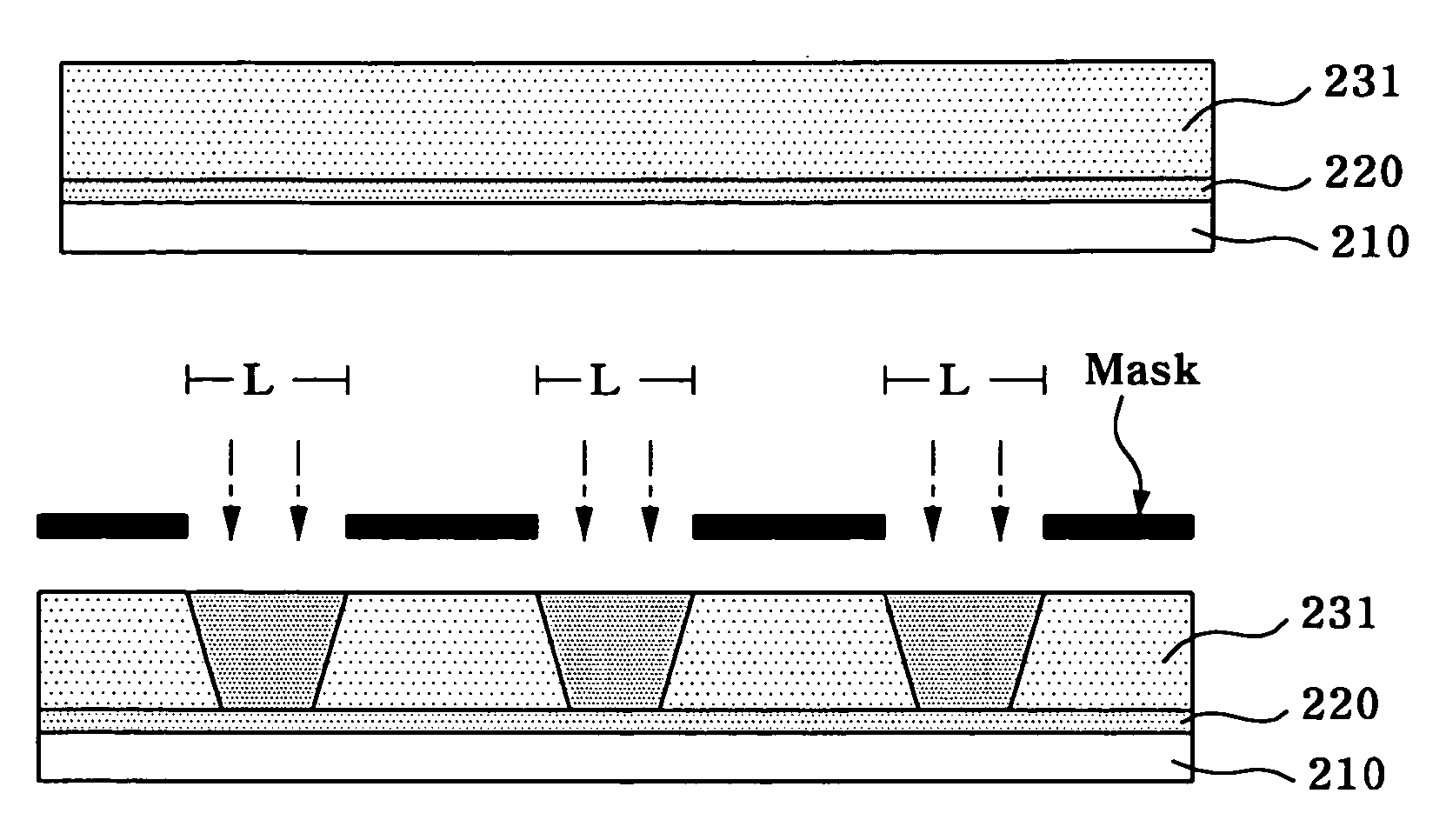

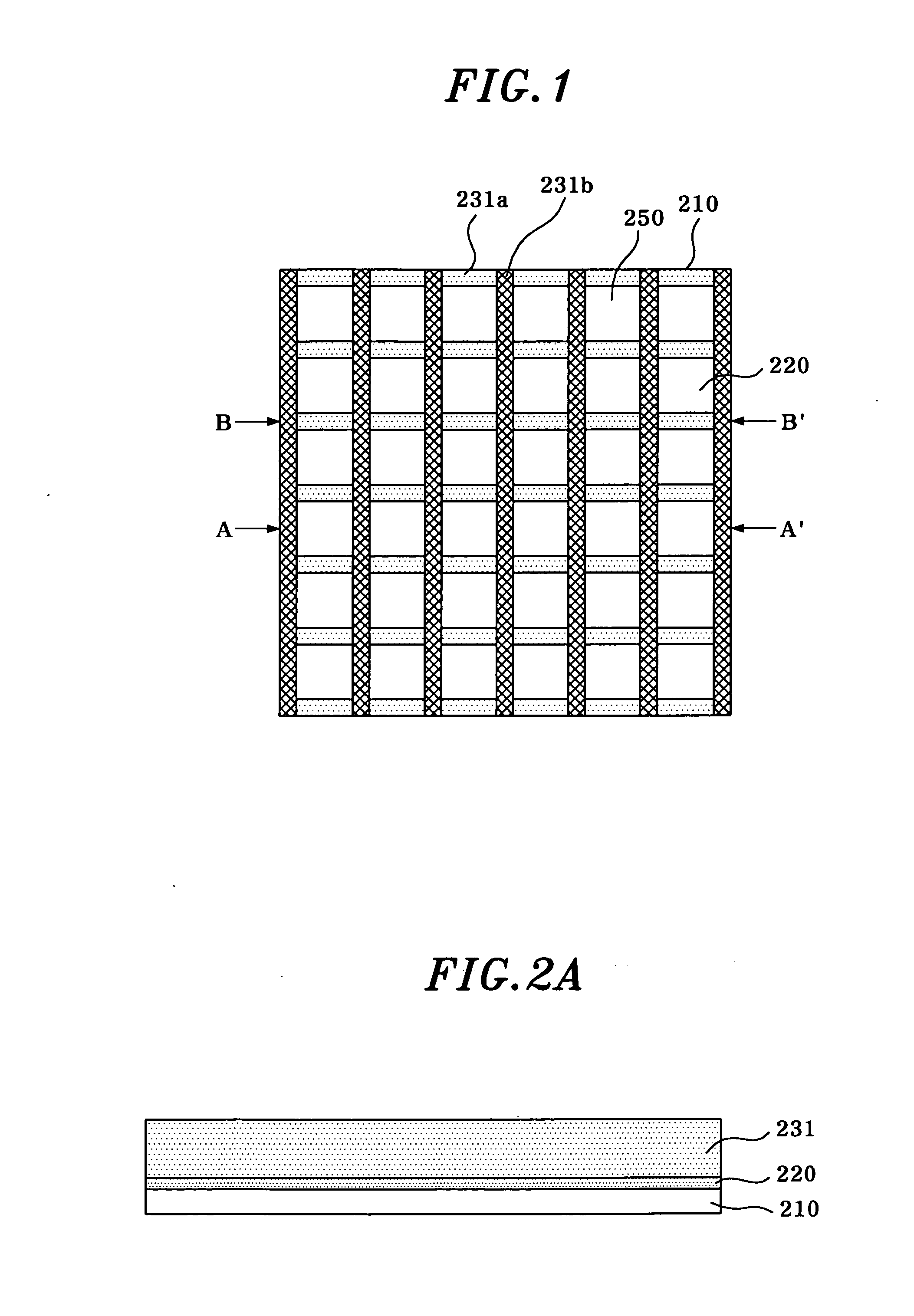

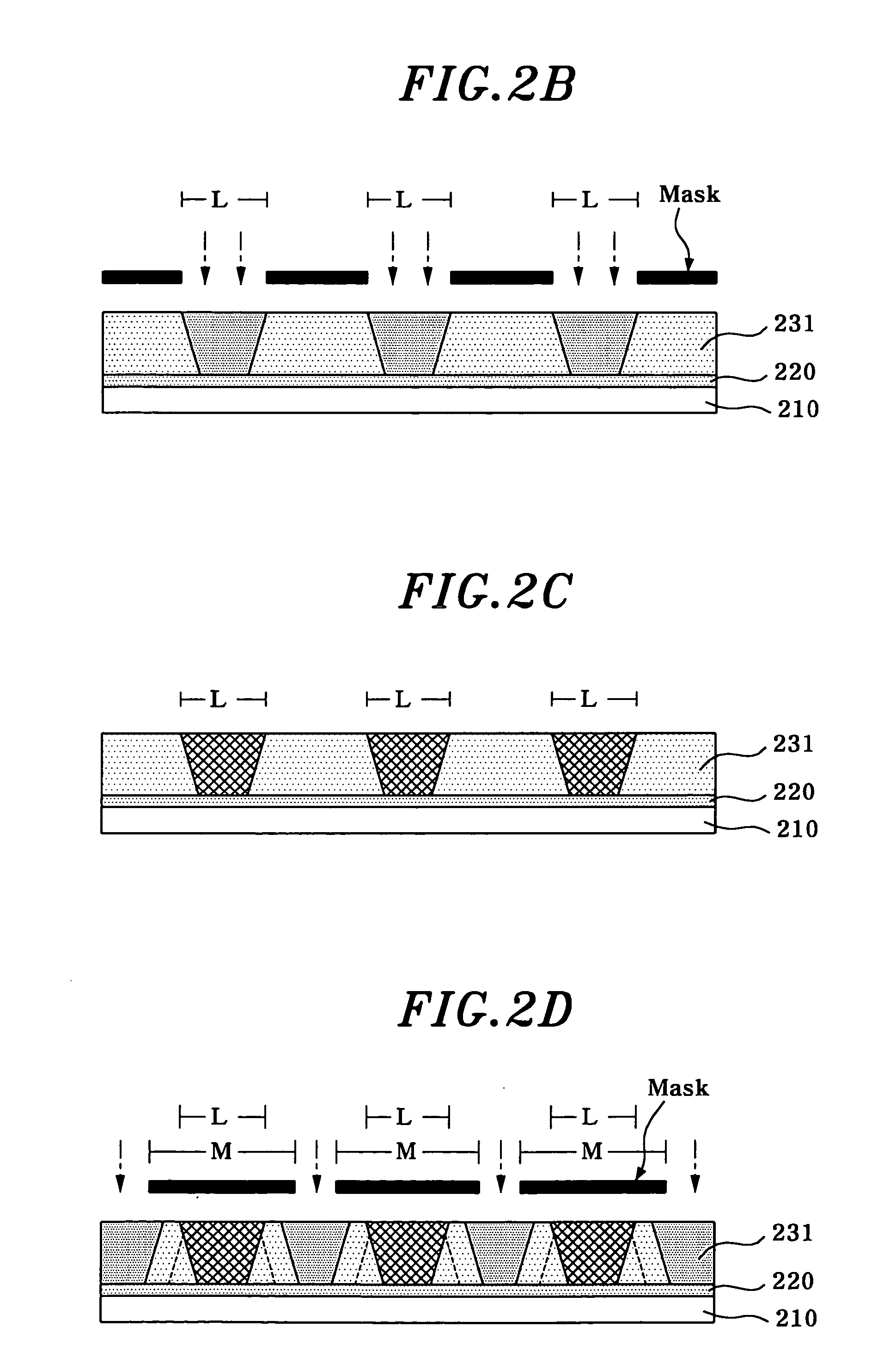

Method for manufacturing organic electroluminescence display

InactiveUS20060204903A1Simple manufacturing processPreventing a short circuitElectroluminescent light sourcesSolid-state devicesOrganic electroluminescencePhotoresist

A method for manufacturing an organic electroluminescence display includes forming a plurality of first electrodes on a substrate in a shape of stripe; forming a photoresist layer on an entire surface of the substrate; performing a first exposure of a first area on the photoresist layer crossing the first electrodes; carrying out an image reversal of the first exposed photoresist layer; performing a second exposure of a remaining area on the photoresist layer except a second area crossing the first electrodes and a third area between the first electrodes; performing a third exposure of the entire surface of the photoresist layer; and developing the second exposed photoresist layer and the third exposed photoresist layer.

Owner:DAEWOO ELECTRONICS CO LTD

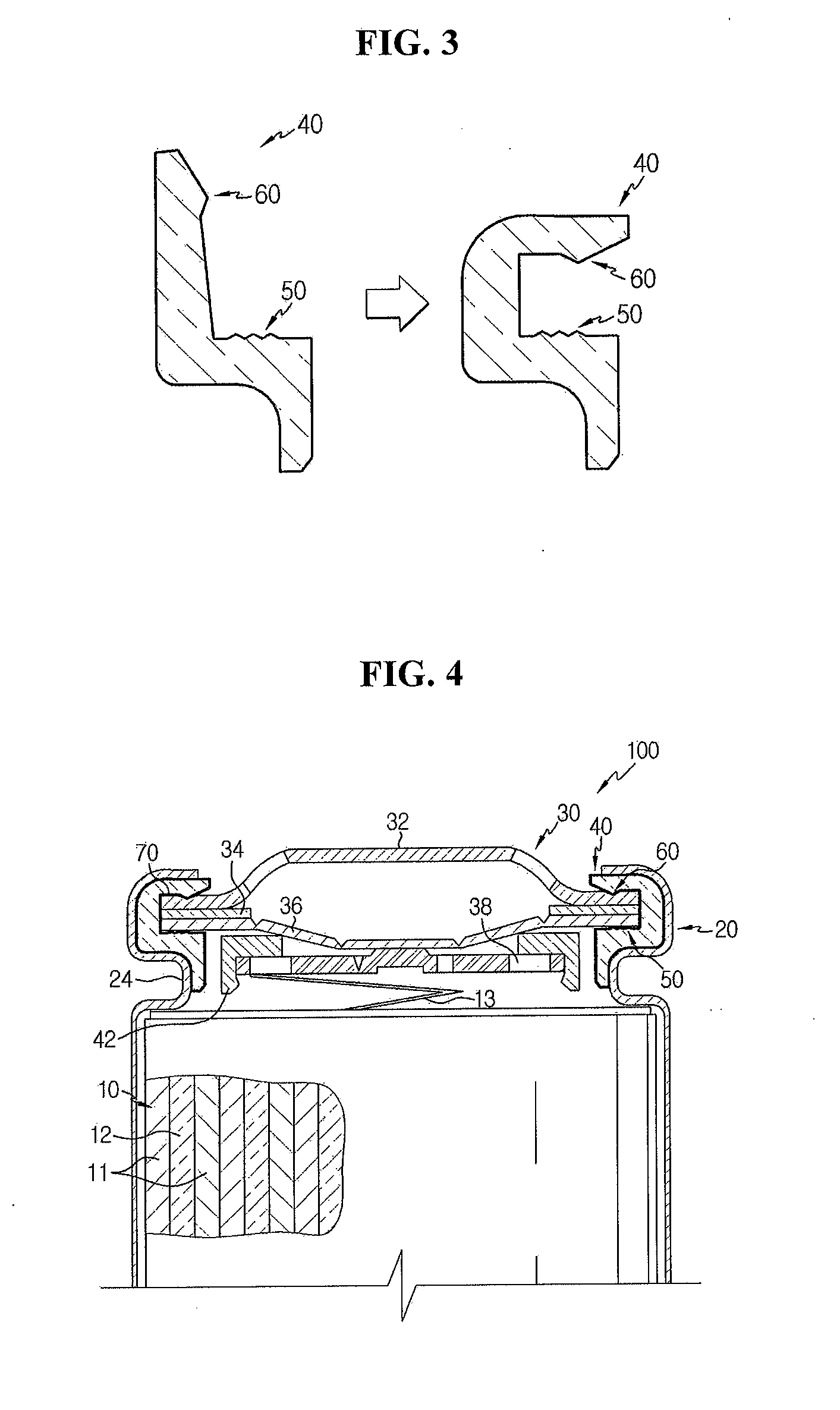

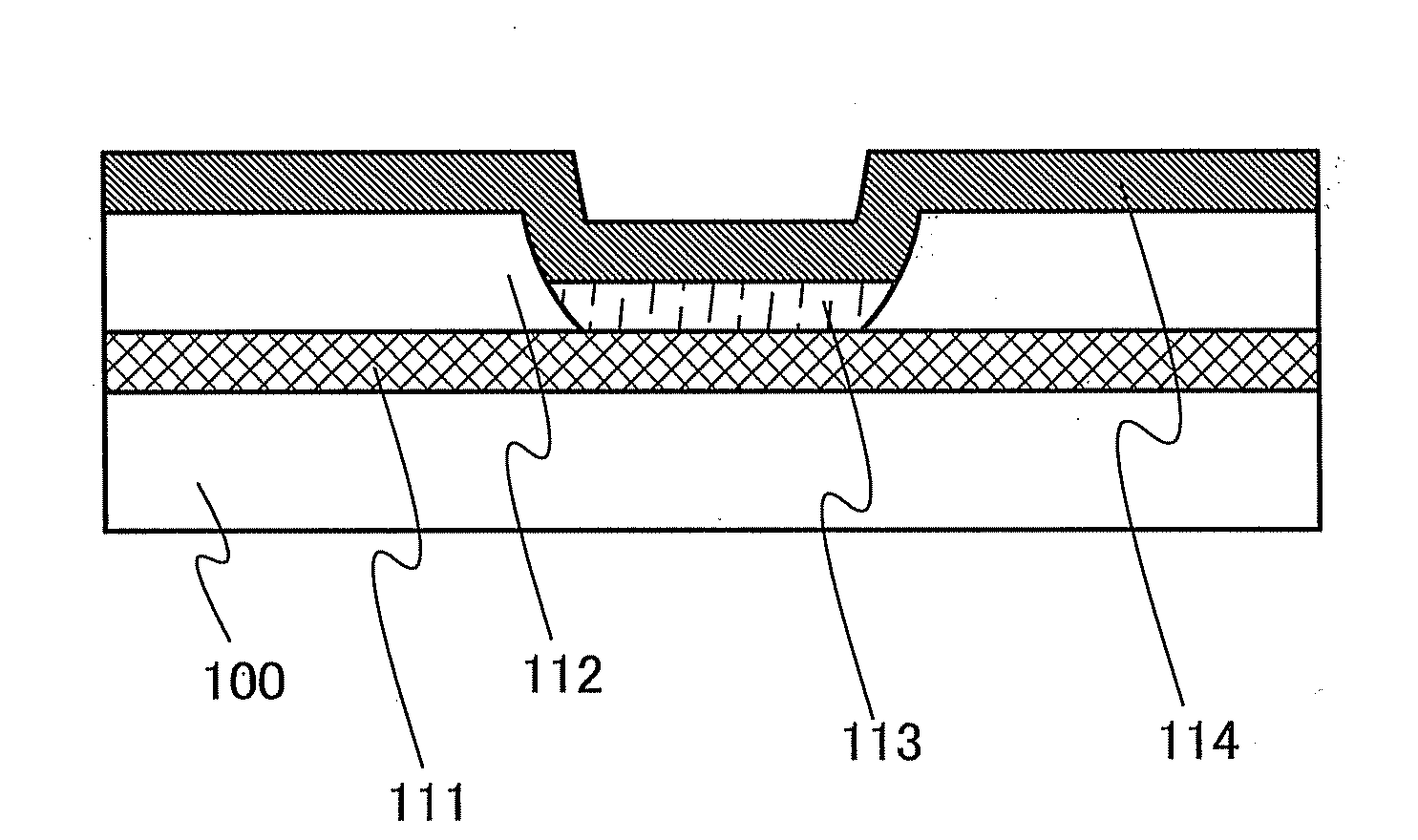

Method of forming contact structure with contact spacer and method of fabricating semiconductor device using the same

InactiveUS20090017629A1Improve reliabilityPreventing a short circuitSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A method of forming a contact structure with a contact spacer and a method of fabricating a semiconductor device using the same. In the method of forming a contact structure, an interlayer dielectric layer is formed on a semiconductor substrate. The interlayer dielectric layer is patterned, thereby forming a contact hole for exposing a predetermined region of the semiconductor substrate. A contact spacer is formed on a sidewall of the contact hole using a deposition method having an inclined deposition direction with respect to a main surface of the semiconductor substrate. The deposition direction may be set between the main surface and a normal with respect to the main surface. Further, there is provided a method of fabricating a semiconductor device using the method of forming the contact structure.

Owner:SAMSUNG ELECTRONICS CO LTD

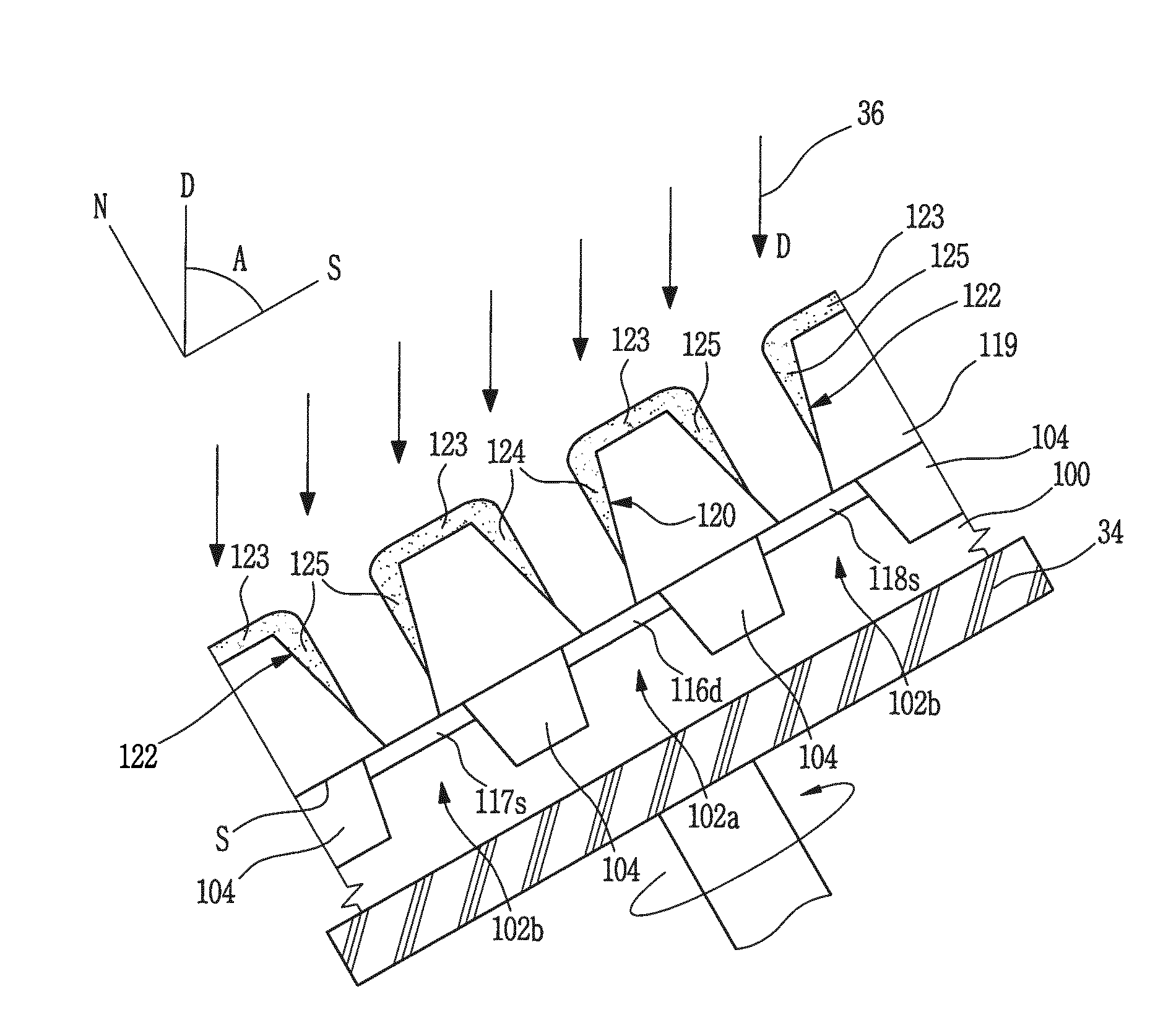

Inkjet head

InactiveUS20110134196A1Prevent oxidationPreventing a short circuitInking apparatusParylenePiezoelectric actuators

There is provided an inkjet head including: a flow path plate having a plurality of ink chambers; a nozzle plate having a plurality of nozzles connected to the respective ink chambers in order to eject ink in the ink chambers to the outside; a piezoelectric actuator provided above the ink chambers and controlling pressure of the ink chambers; and a parylene protective film provided in order to prevent oxidization of the piezoelectric actuator.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Semiconductor device and manufacturing method thereof

InactiveUS20100244188A1Reducing eddy-current lossPreventing a short circuitSemiconductor/solid-state device detailsSolid-state devicesEngineeringInductor

Disclosed is a semiconductor device comprising: a semiconductor substrate in which an integrated circuit is formed; a first resin film provided over the semiconductor substrate; a second resin film provided over an upper surface of the first resin film except at least a peripheral portion of the first resin film; and a thin film inductor provided over the second resin film.

Owner:TERAMIKROS INC

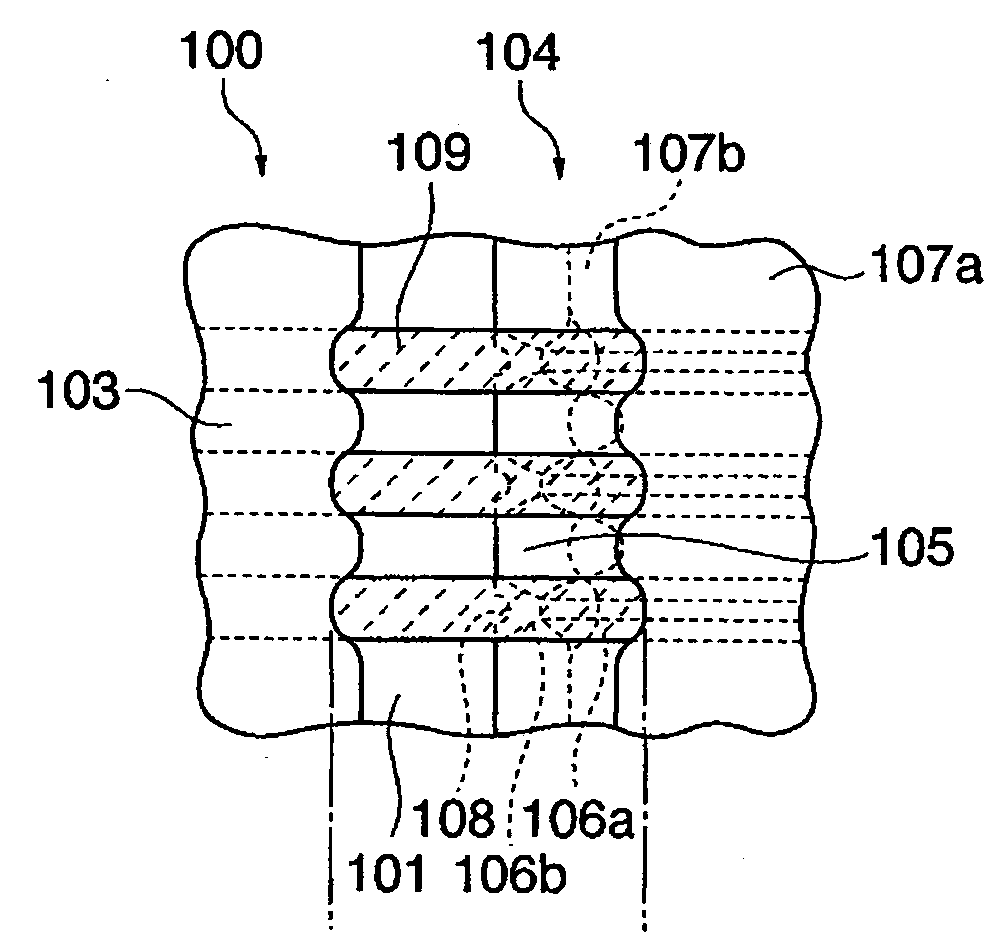

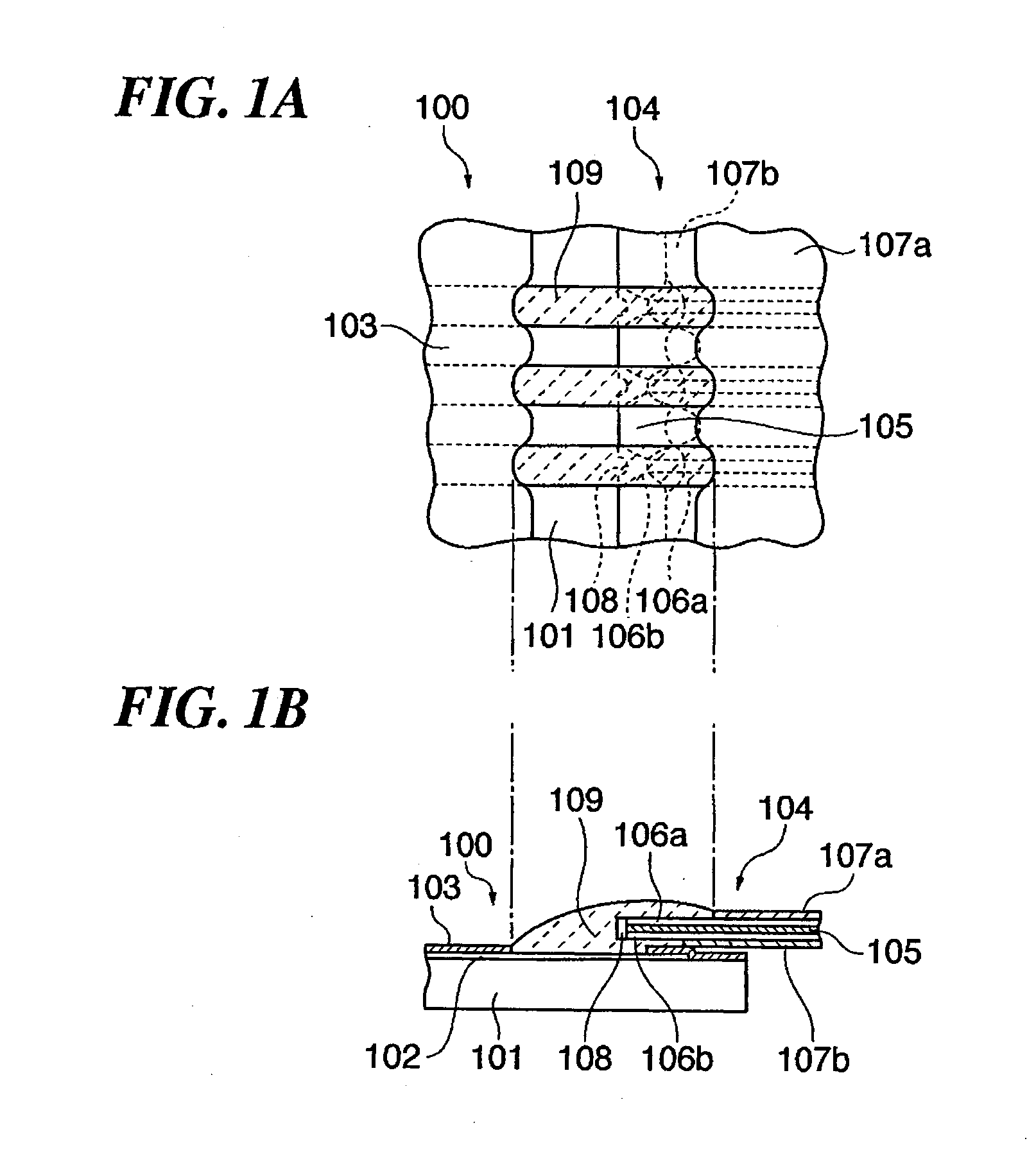

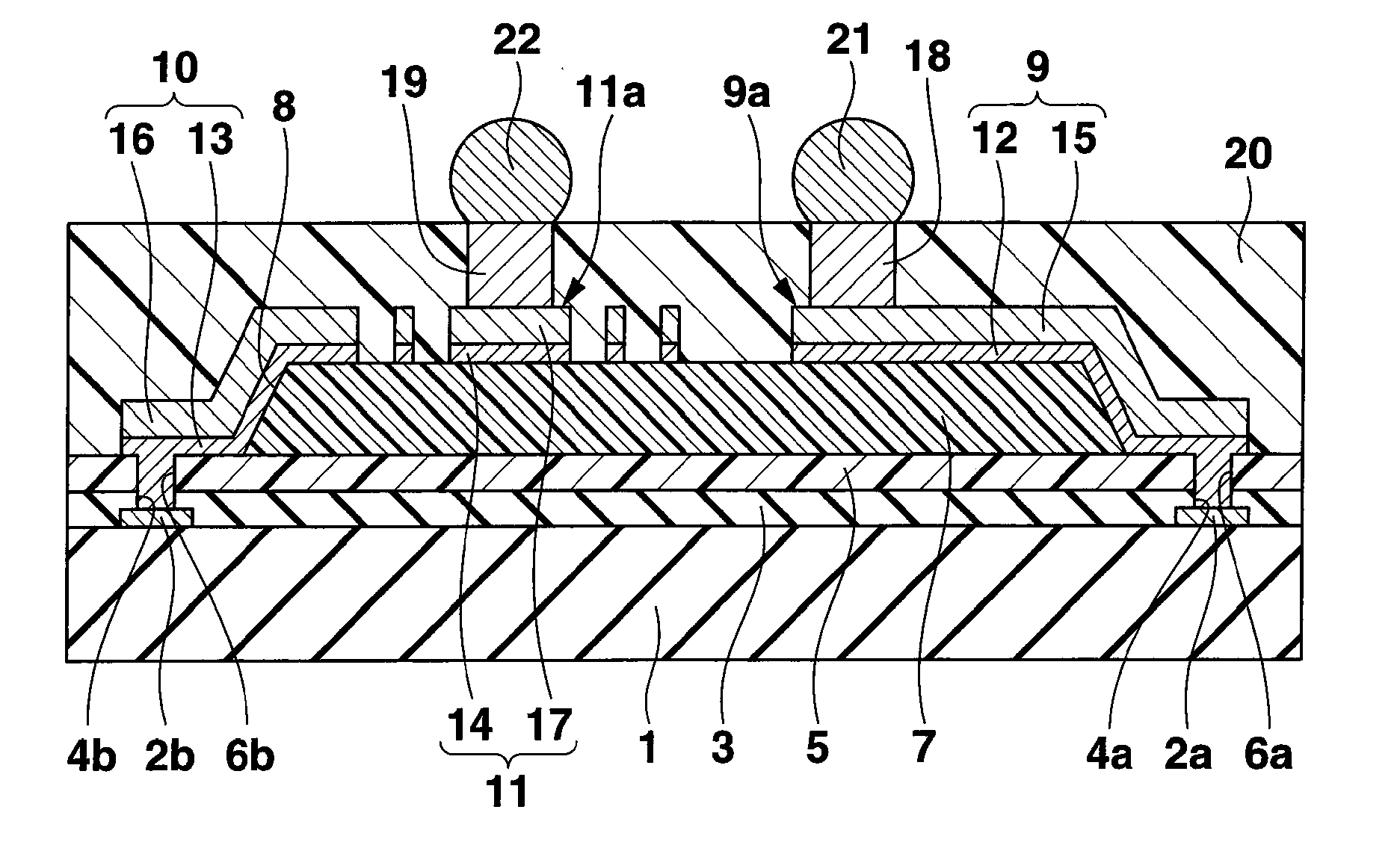

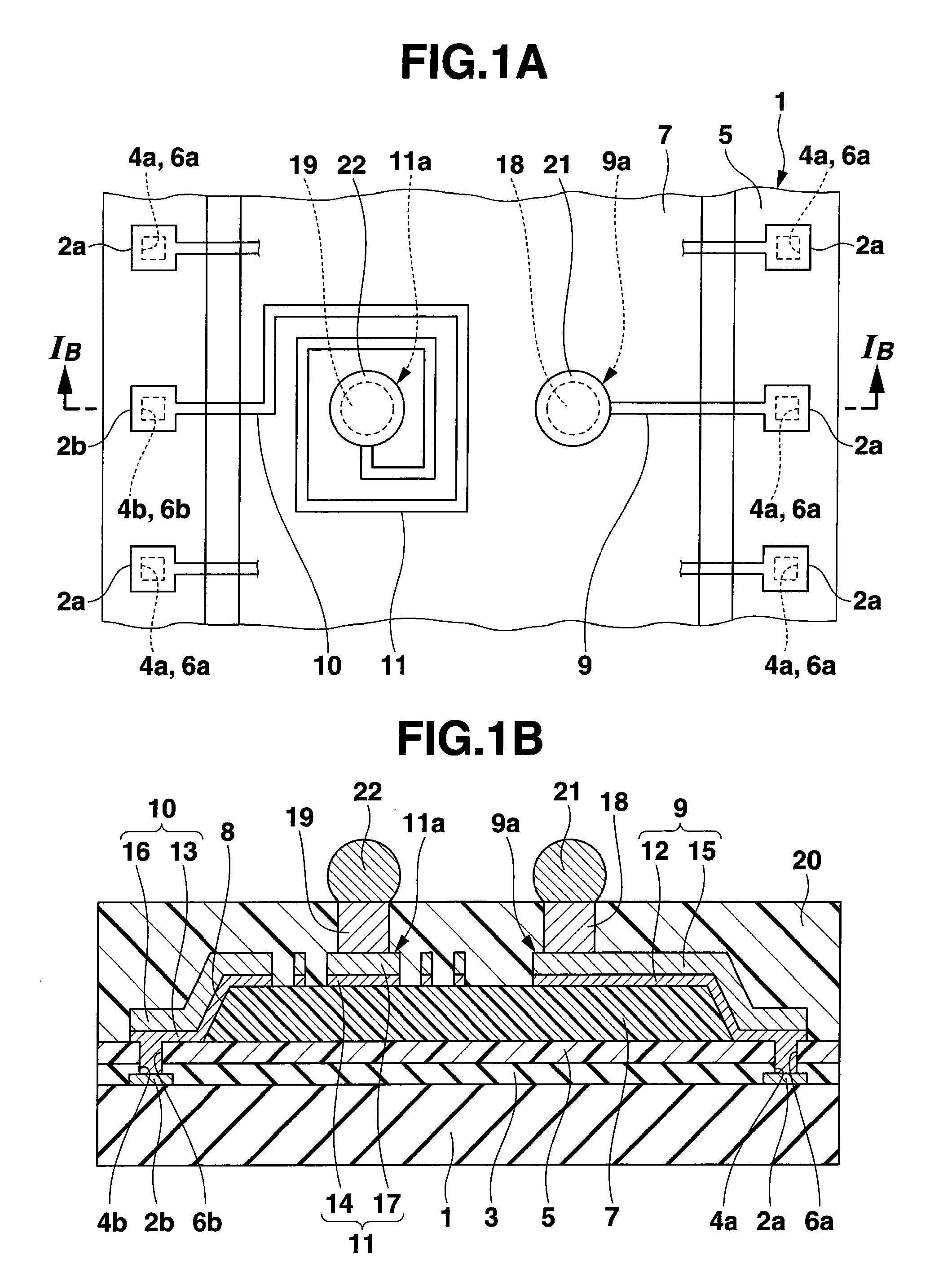

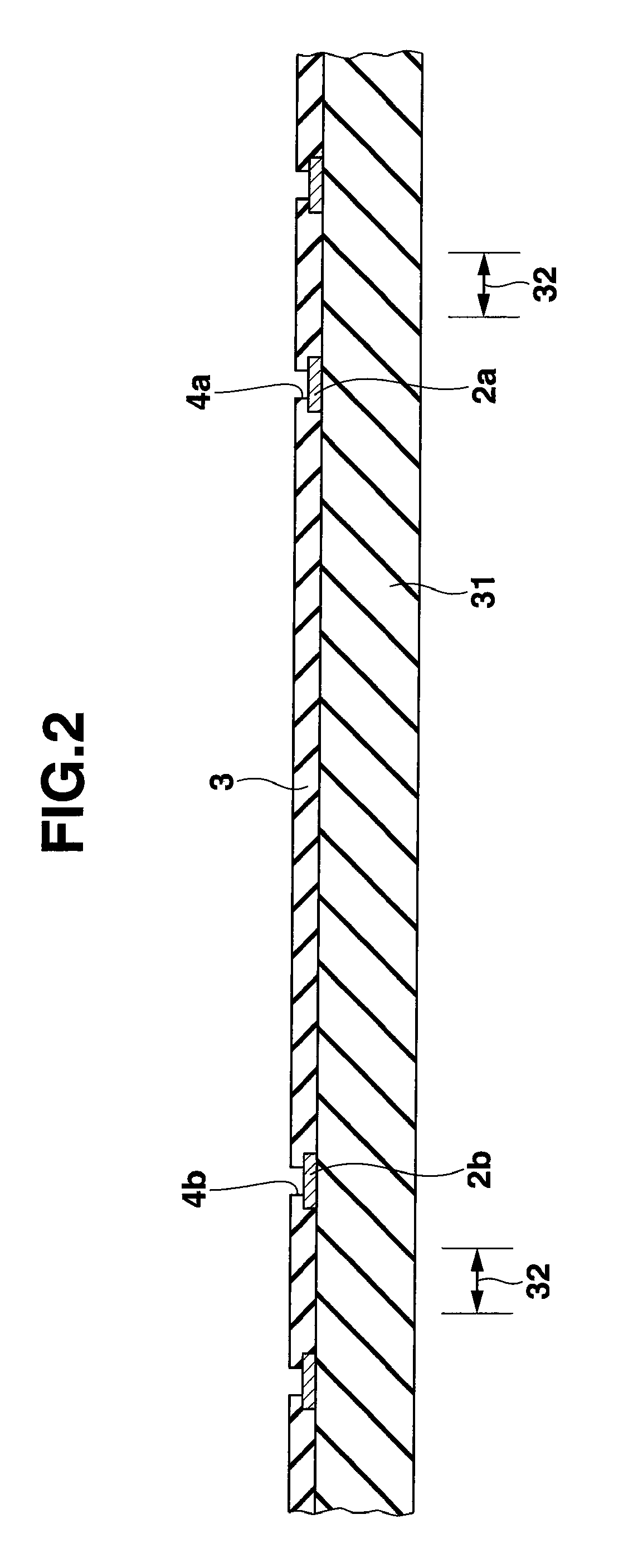

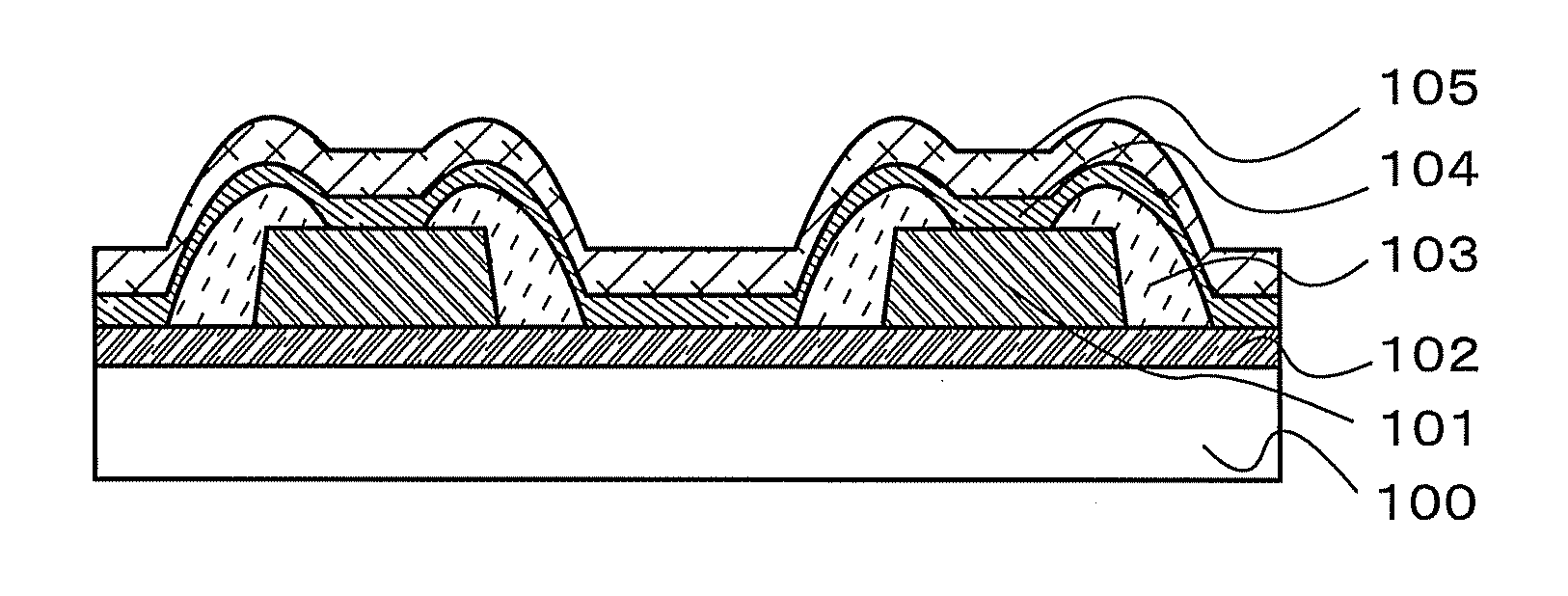

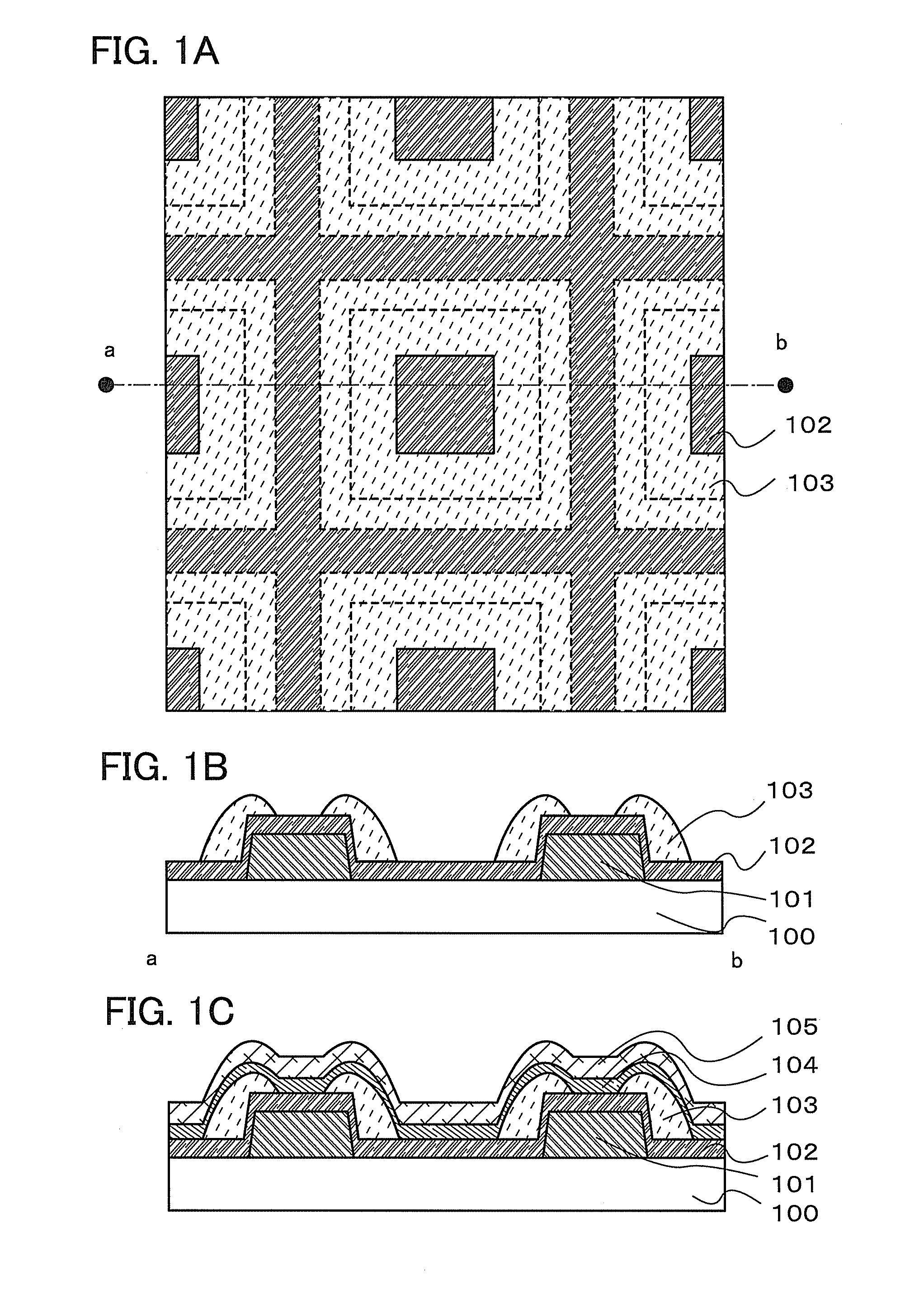

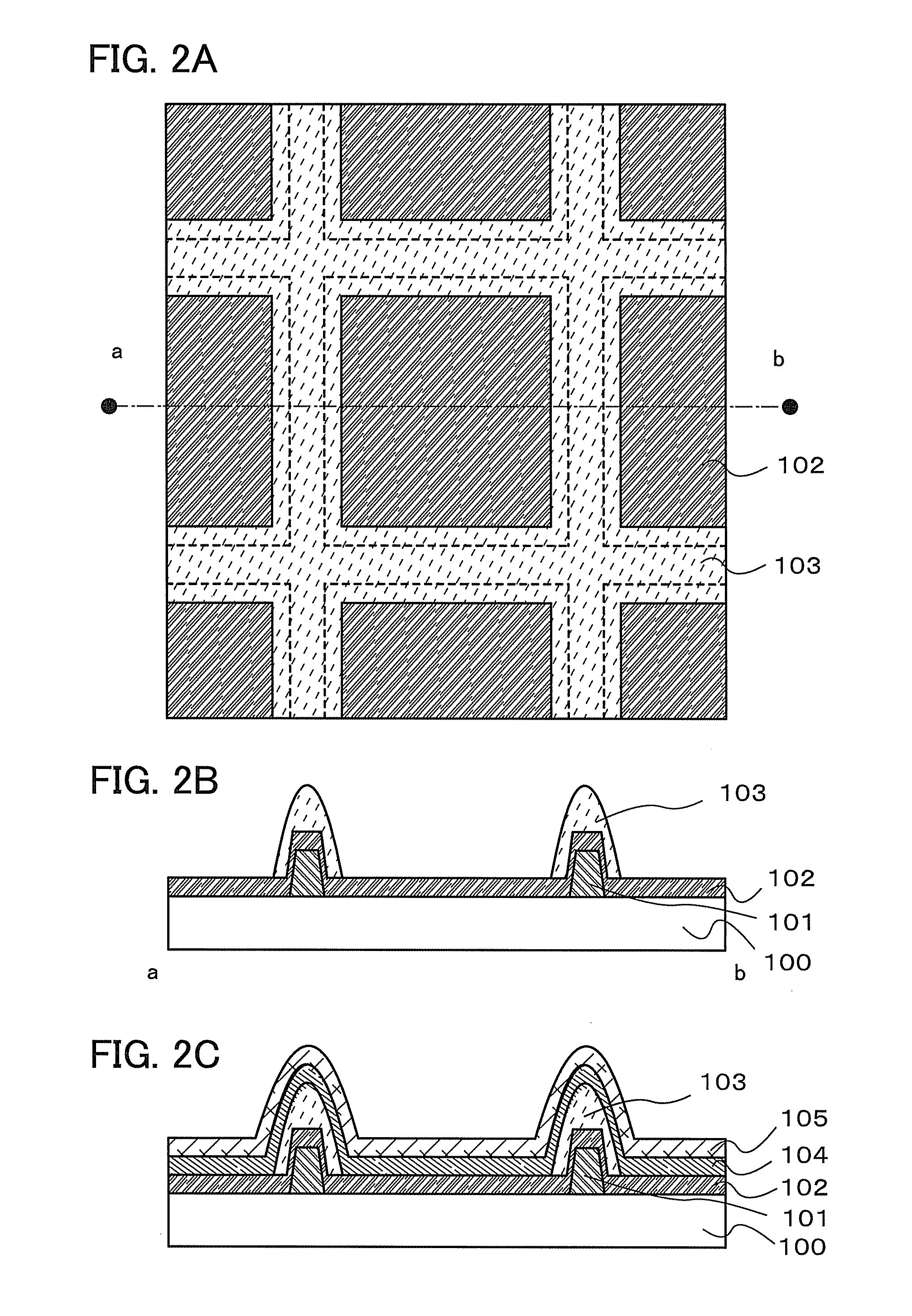

Light-Emitting Device and Lighting Device

ActiveUS20110284913A1Improve reliabilityLight evenlyPlanar light sourcesSolid-state devicesEffect lightEngineering

To provide a light-emitting device from which uniform light emission can be obtained by providing an auxiliary wiring; a light-emitting device in which a short circuit between electrodes or between an electrode and an auxiliary wiring, which is attributed to a step caused by the auxiliary wiring, hardly occurs; and a light-emitting device which has high reliability by preventing a short circuit. In an EL light-emitting device including an auxiliary wiring, by covering a step caused by the auxiliary wiring is covered with an insulator, a short circuit between electrodes or between an electrode and the auxiliary wiring, which is attributed to the step caused by the auxiliary wiring, is prevented. Thus, the above objects are achieved.

Owner:SEMICON ENERGY LAB CO LTD

Anisotropic conductive adhesive

InactiveUS7452923B2Minimizes its contractionPreventing a short circuitImpression capsConductive materialAnisotropic conductive adhesivePolymerization

The present invention discloses an anisotropic conductive adhesive comprising an insulating adhesive component and a number of conductive particles dispersed in the insulating adhesive component, wherein the insulating adhesive component contains a crosslinked rubber resin. The anisotropic conductive adhesive of the present invention prevents exfoliation of an adhesive or reduction in adhesive strength of circuit by minimizing its the heat-contraction occurring in the process of a polymerization or a hardening reaction when connecting micro-circuits, whereby a short circuit between adjacent electrodes can be prevented when connecting the circuits, and excellent connection reliability according to a long-term use is achieved.

Owner:H&S HIGH TECH +1

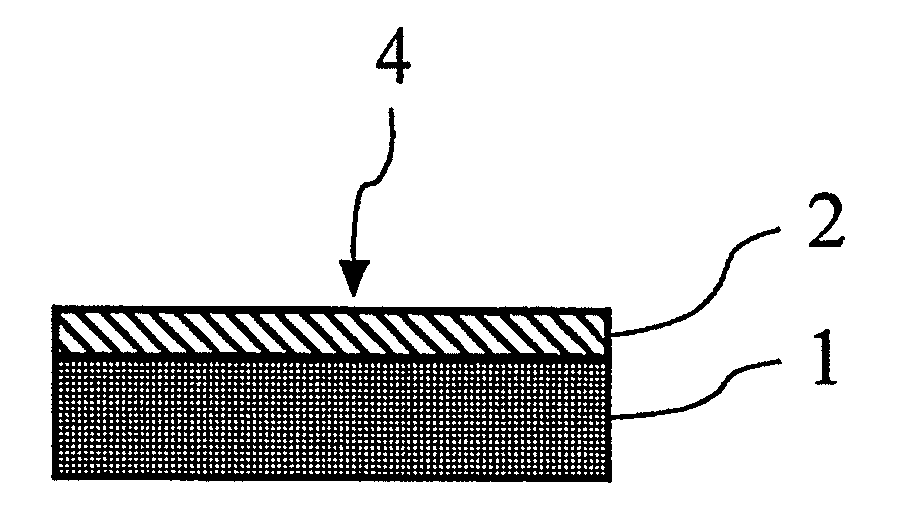

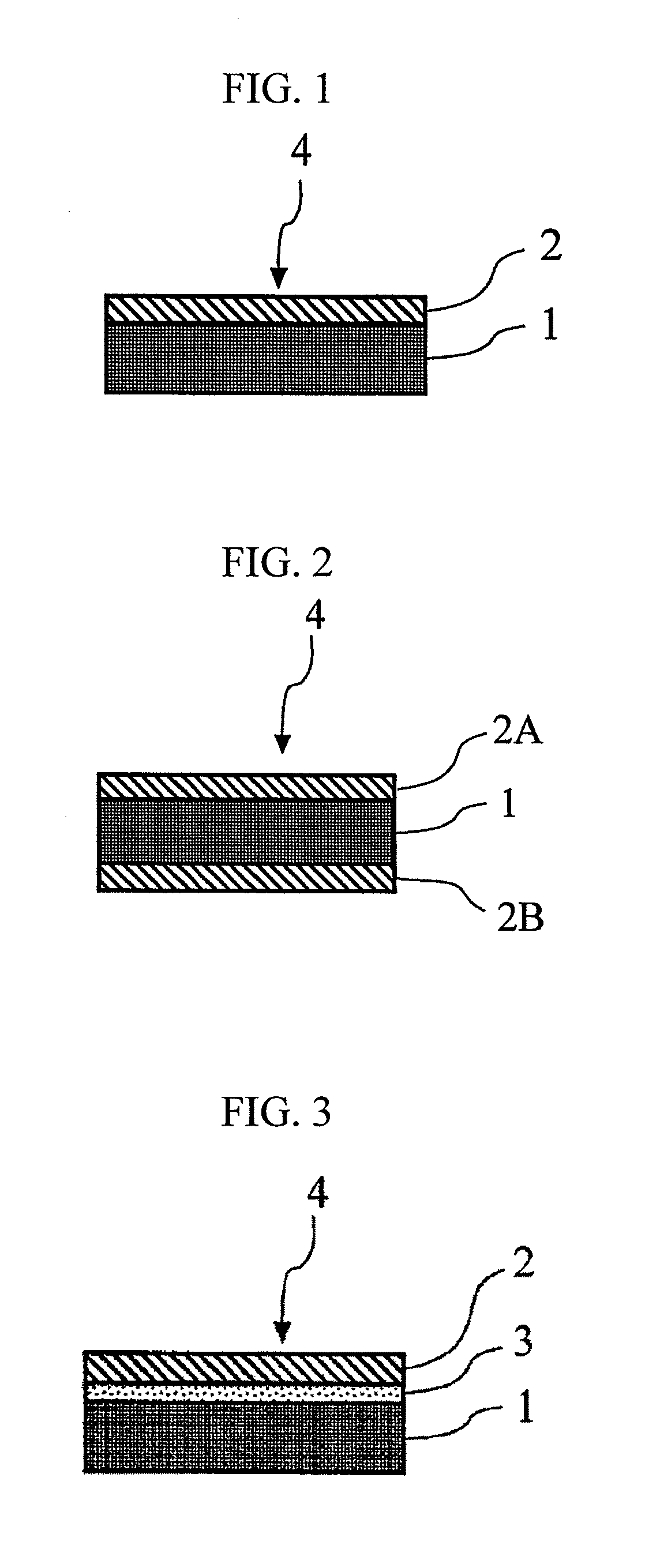

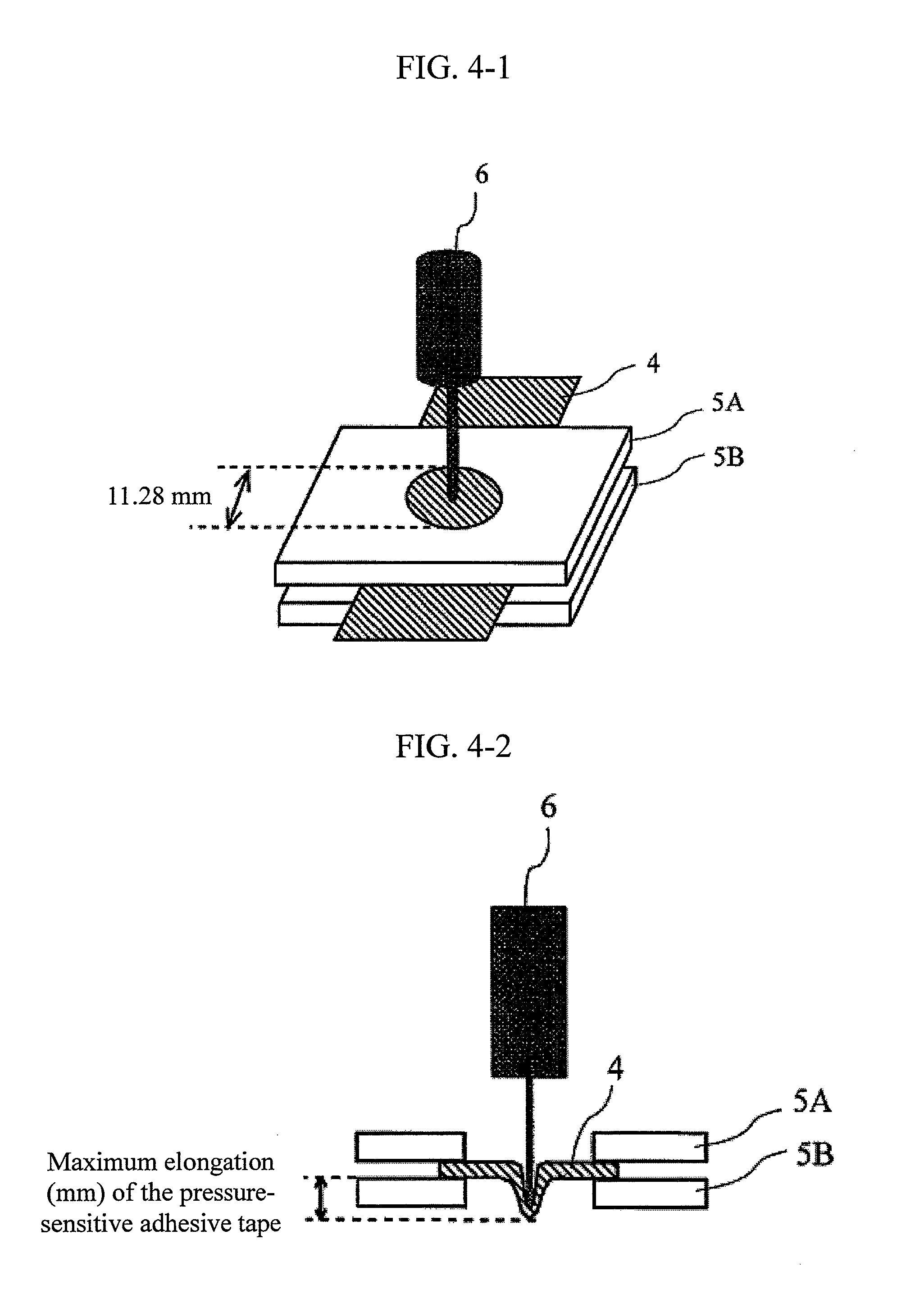

Pressure-sensitive adhesive tape for protecting electrode plate

InactiveUS20120052295A1Avoid it happening againImprove reliabilityCell component detailsThin material handlingCalculation methodsRADIUS

The present invention relates to a pressure-sensitive adhesive tape for protecting an electrode plate, containing: a substrate, and a pressure-sensitive adhesive layer provided on at least one side of a the substrate, in which the pressure-sensitive adhesive tape has a piercing resistance, obtained by the following calculation method, of 300 gf·mm or more; and has a heat shrinkage ratio, when heating is performed at 260° C. for 1 hour, of 1.0% or less in both of TD (width) direction and MD (length) direction, and in which the calculation method contains fixing the pressure-sensitive adhesive tape to a fixing plate in which a circular hole having a diameter of 11.28 mm is formed, piercing a needle of which the end of has a curvature radius of 0.5 mm to the pressure-sensitive adhesive tape at a speed of 2 mm / s under condition of 23±2° C., and measuring a maximum load (gf) and a maximum elongation (mm) of the pressure-sensitive adhesive tape when the needle penetrates the pressure-sensitive adhesive tape; and the piercing resistance is calculated by the following equation (1):Piercing resistance=[Maximum load (gf)]×[Maximum elongation (mm) of the pressure-sensitive adhesive tape]×½ (1).

Owner:NITTO DENKO CORP

Electrical connector having a space allowing an elastic connecting member to be escaped

InactiveUS20080057757A1Improve reliabilityImprove contact reliabilityCoupling device detailsPrinted circuitsEngineeringMechanical engineering

In an electrical connector for connecting connection objects to each other in a connecting direction, a holding member has an accommodating portion between a first and a second surface to which the connection objects are opposed, respectively, when connected to said electrical connector. A connecting member has elasticity and is placed in the accommodating portion. The holding member includes a first and a second wall which define the accommodating portion therebetween. At least one of the first and the second walls includes a restraining portion defining a space which allows a portion of the connecting member to elastically move in a predetermined direction crossing the connecting direction.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

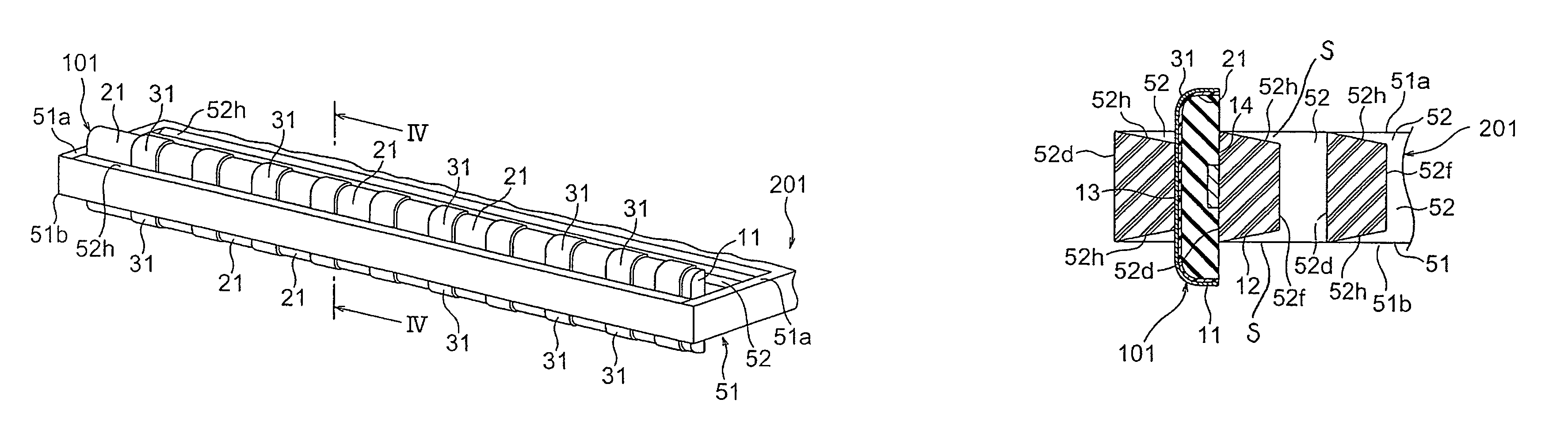

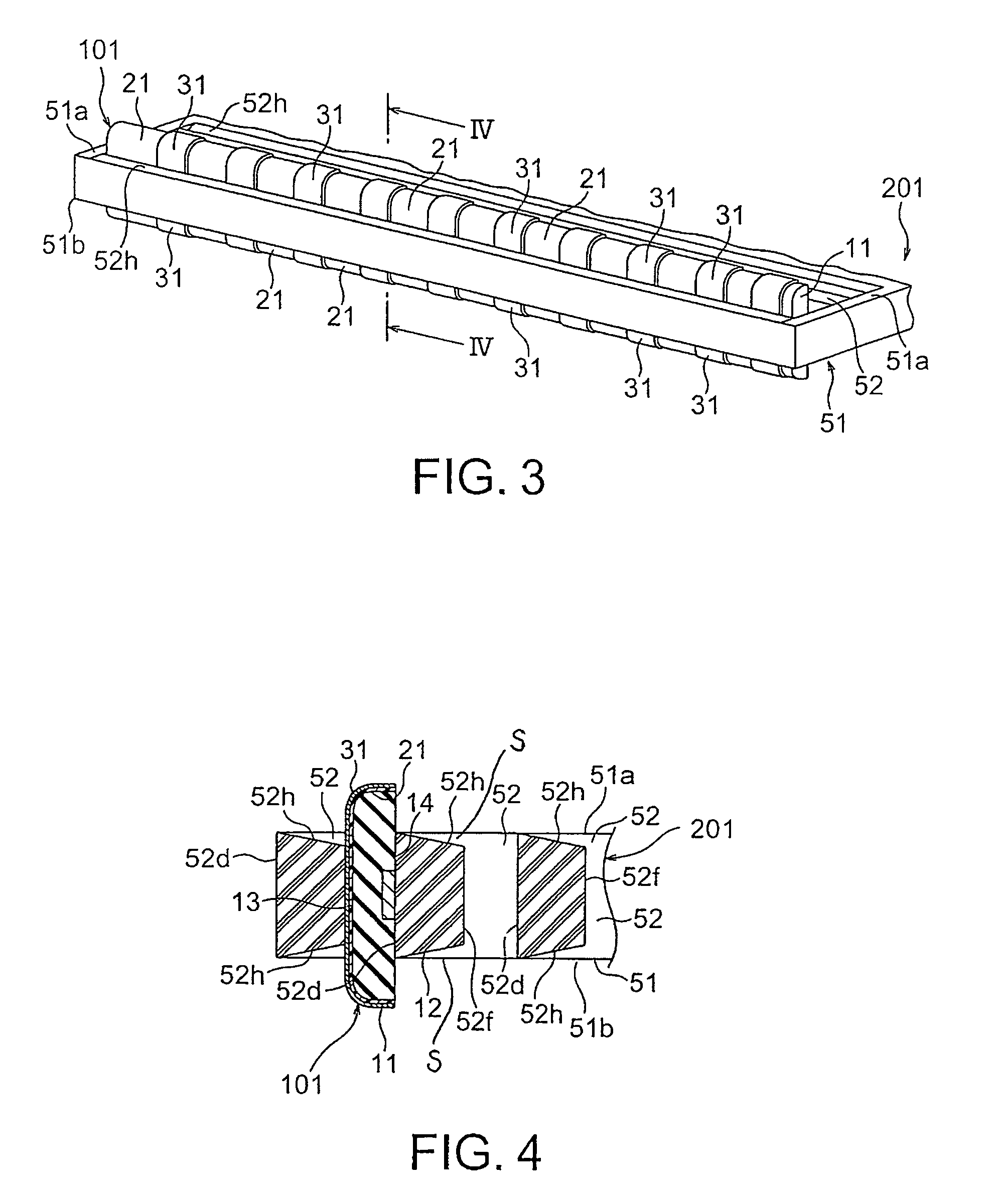

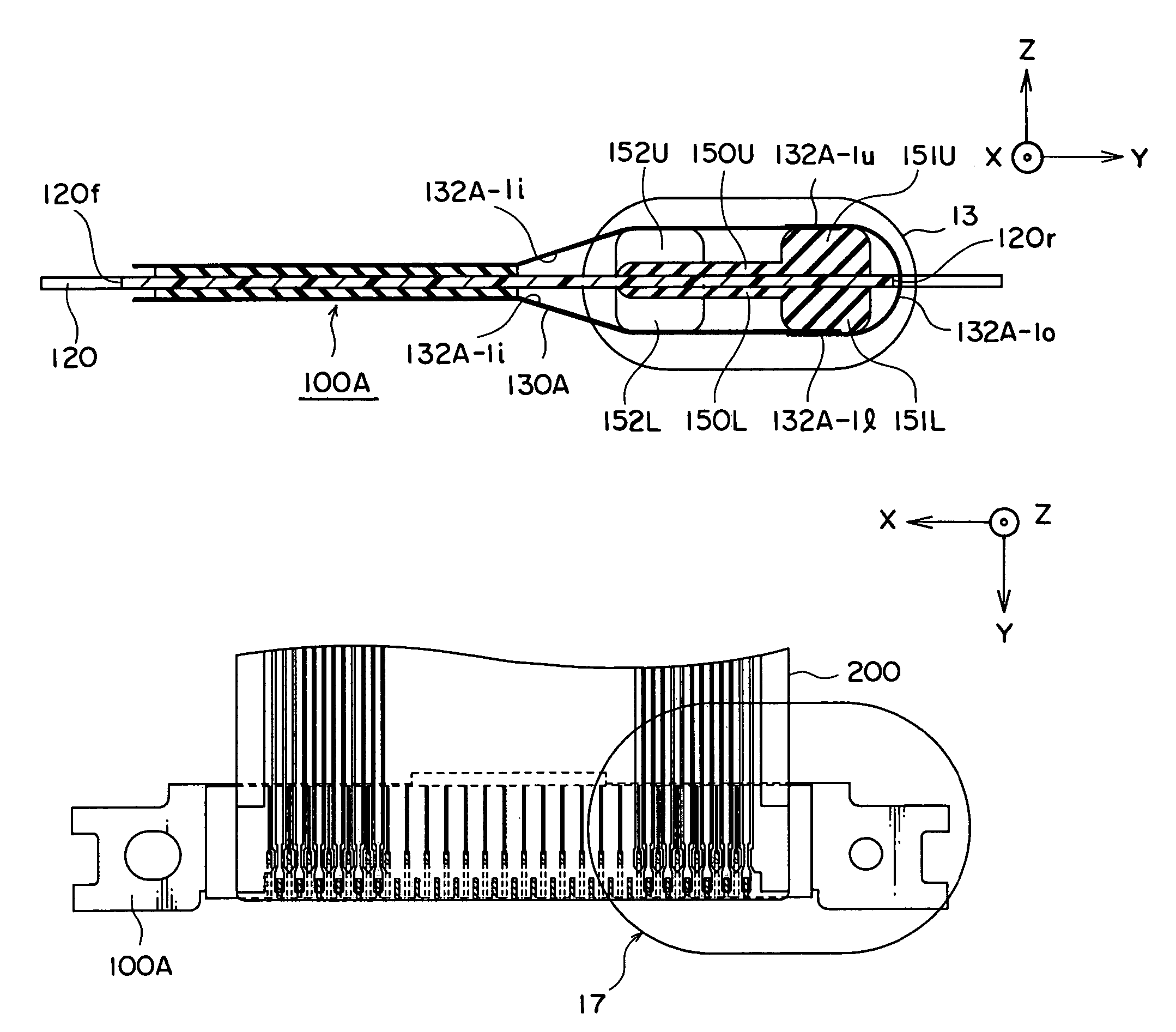

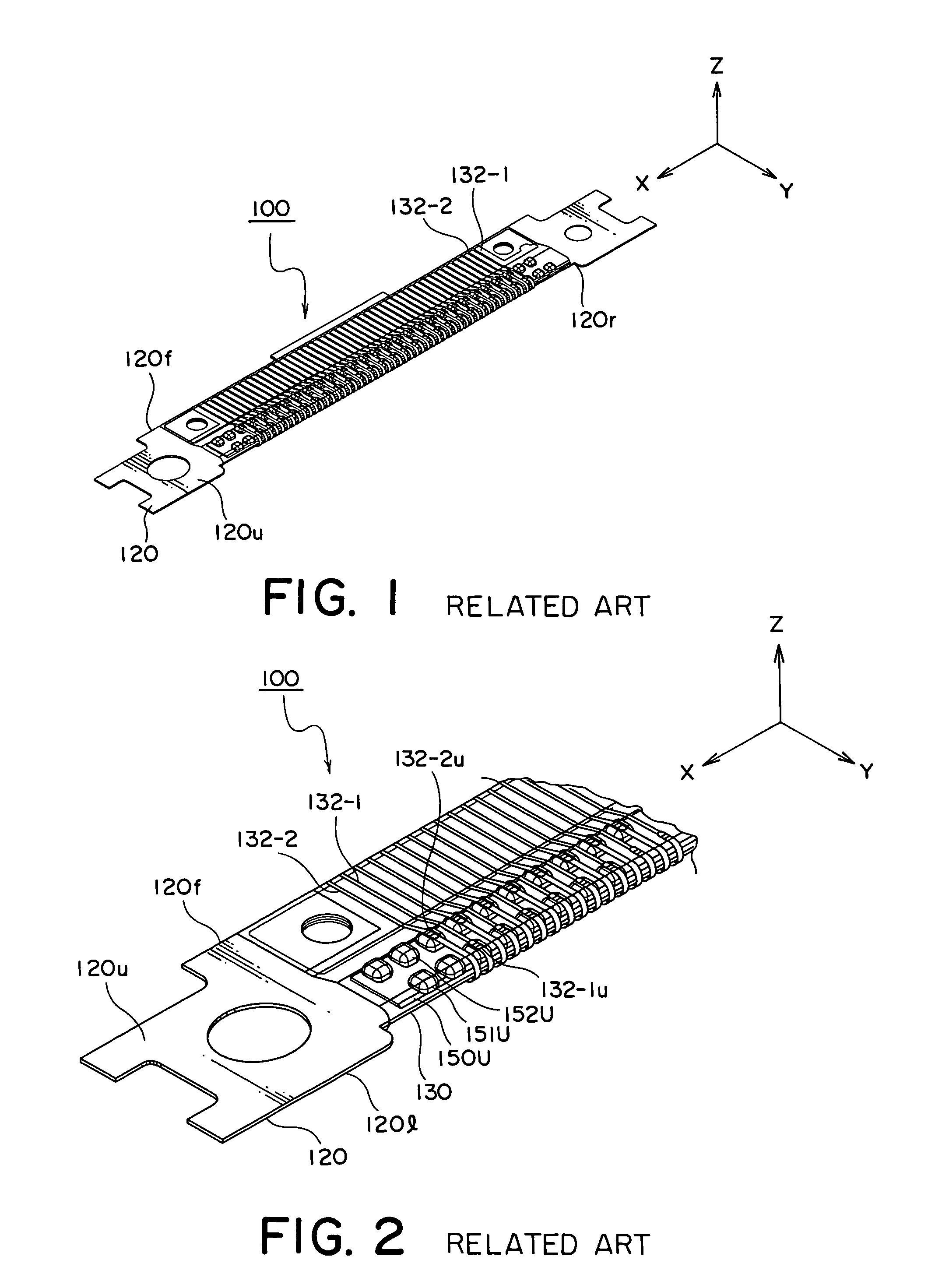

Intermediate connector

InactiveUS7367838B2Preventing a short circuitDecrease pitchCoupling device connectionsElectrolysis componentsEngineeringElectrical connector

In an electrical connector adapted to be interposed between two connection objects to electrically connect the connection objects to each other, a flexible conductive film, mounted on a base member, includes a flexible insulating film having an outer surface and an inner surface. The flexible insulating film is folded near a rear edge of the base member into a generally U shape with the outer surface kept on the outside. The flexible conductive film has a film conductive pattern formed not only the outer surface of the flexible insulating film but also on the inner surface of the flexible insulating film.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

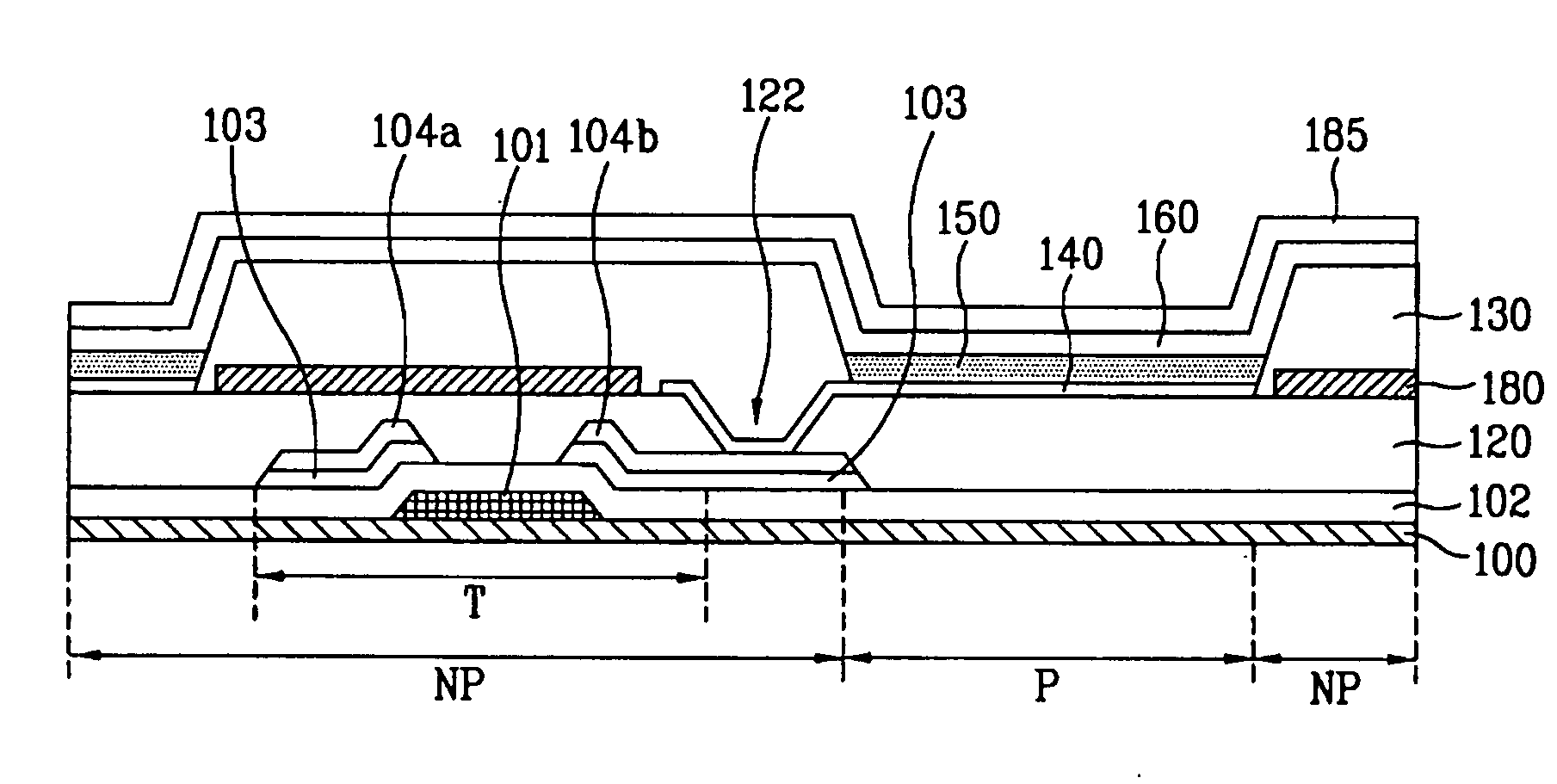

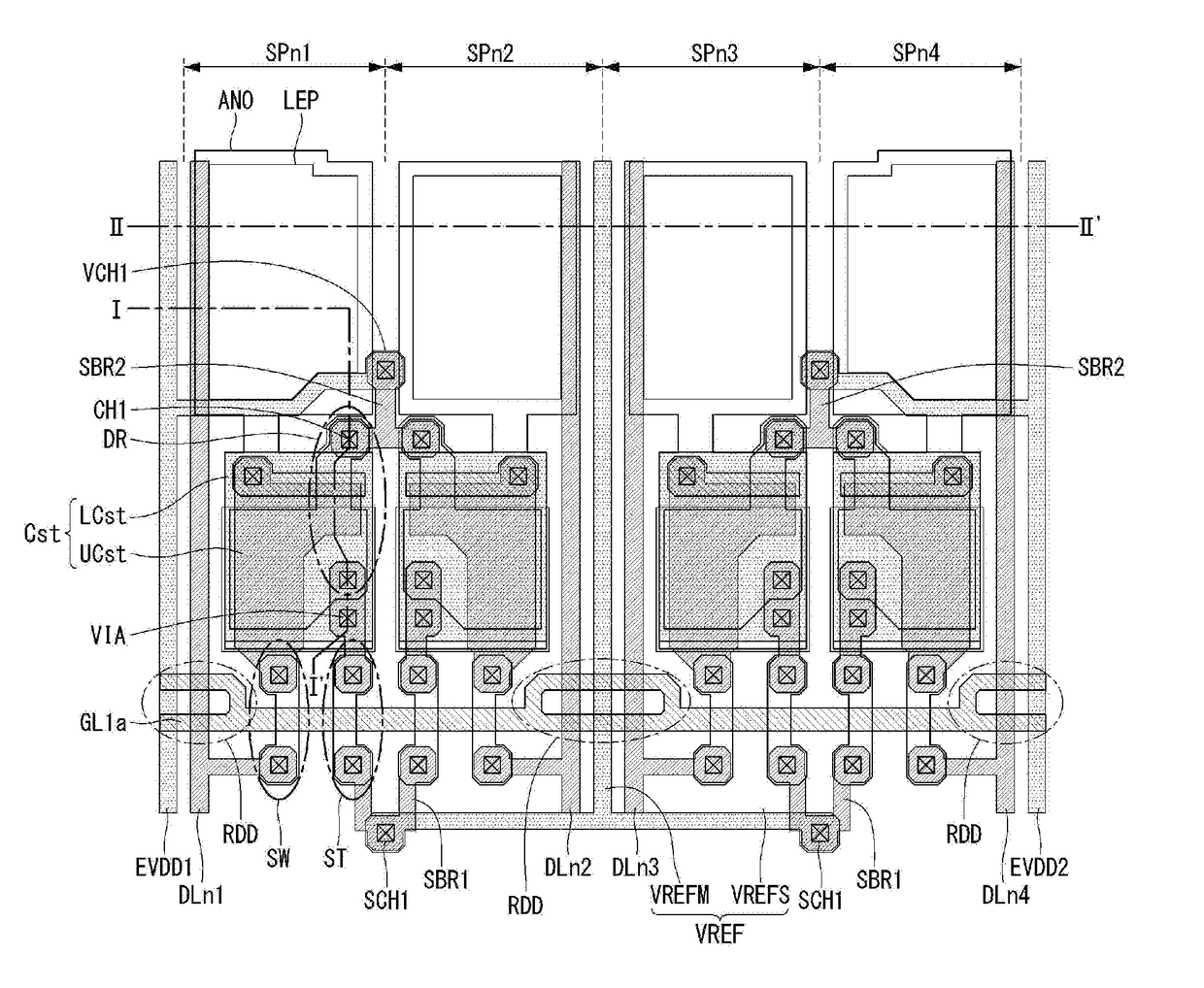

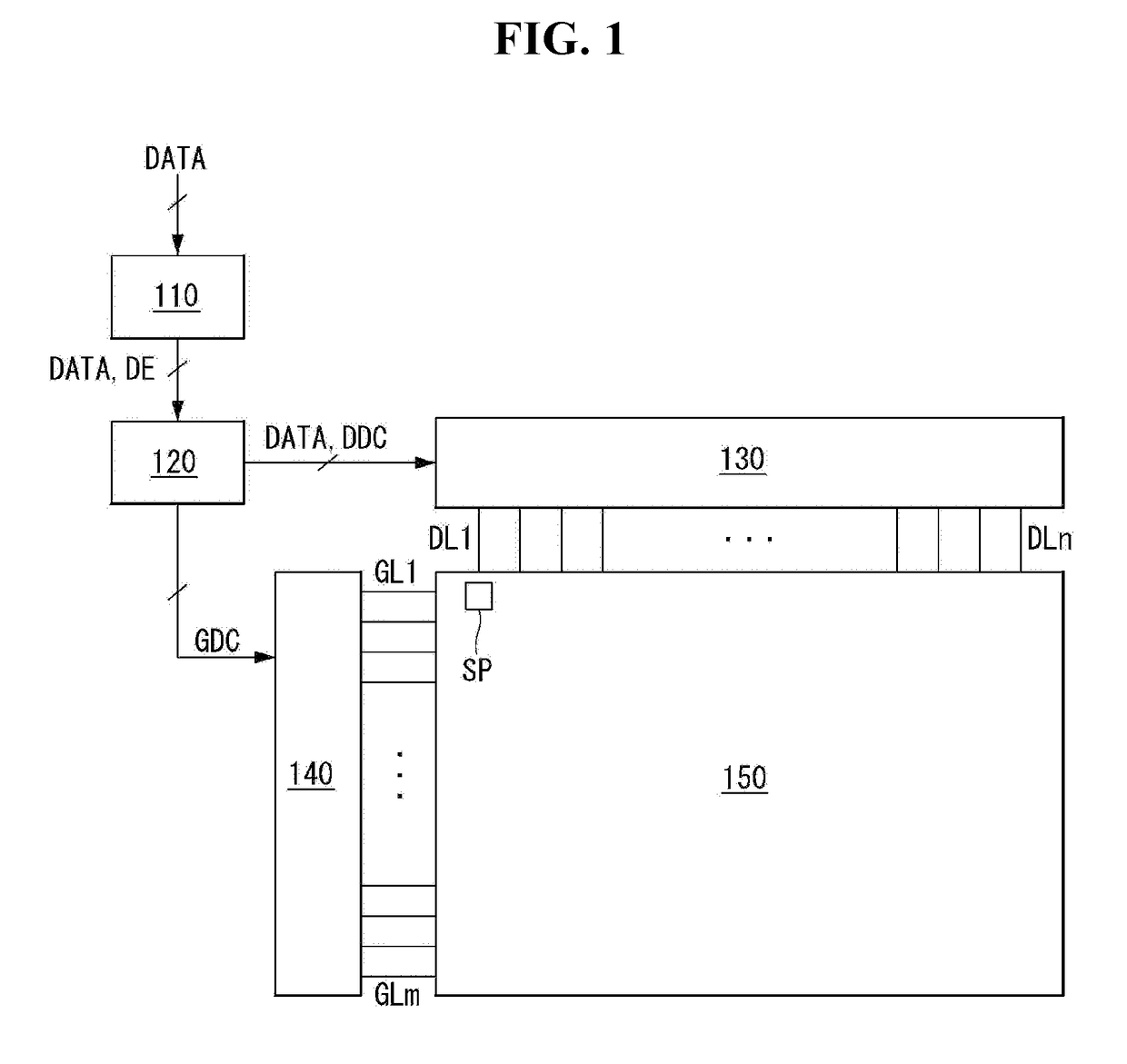

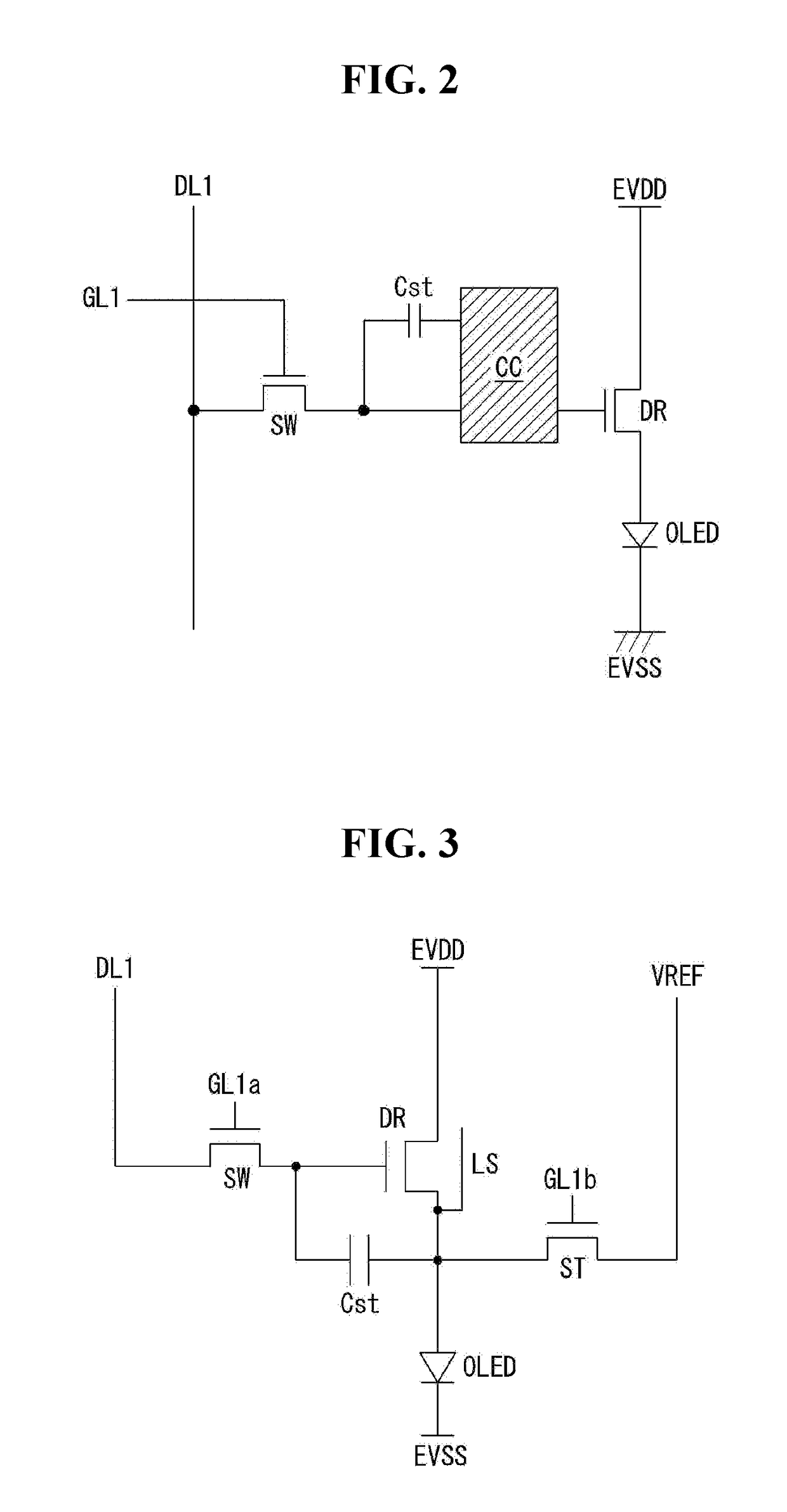

Display device

A display device, includes a substrate; first to fourth subpixels sequentially arranged on the substrate; a first power line on a left side of the first subpixel and shared by the first and second subpixels; a sensing line between the second subpixel and the third subpixel and shared by the first to fourth subpixels; a second power line on a right side of the fourth subpixel and shared by the third and fourth subpixels; and a first data line on the left side of the first subpixel, a second data line on a right side of the second subpixel, a third data line on a left side of the third subpixel, and a fourth data line on the right side of the fourth subpixel. The first and second power lines and the sensing line are disposed on a layer different from the first to fourth data lines.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com