Patents

Literature

132results about How to "Easily deteriorated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of fabricating passivation layer for organic devices

InactiveUS20050181535A1Reduce heatEasily deterioratedSolid-state devicesSemiconductor/solid-state device manufacturingOrganic devicesOptoelectronics

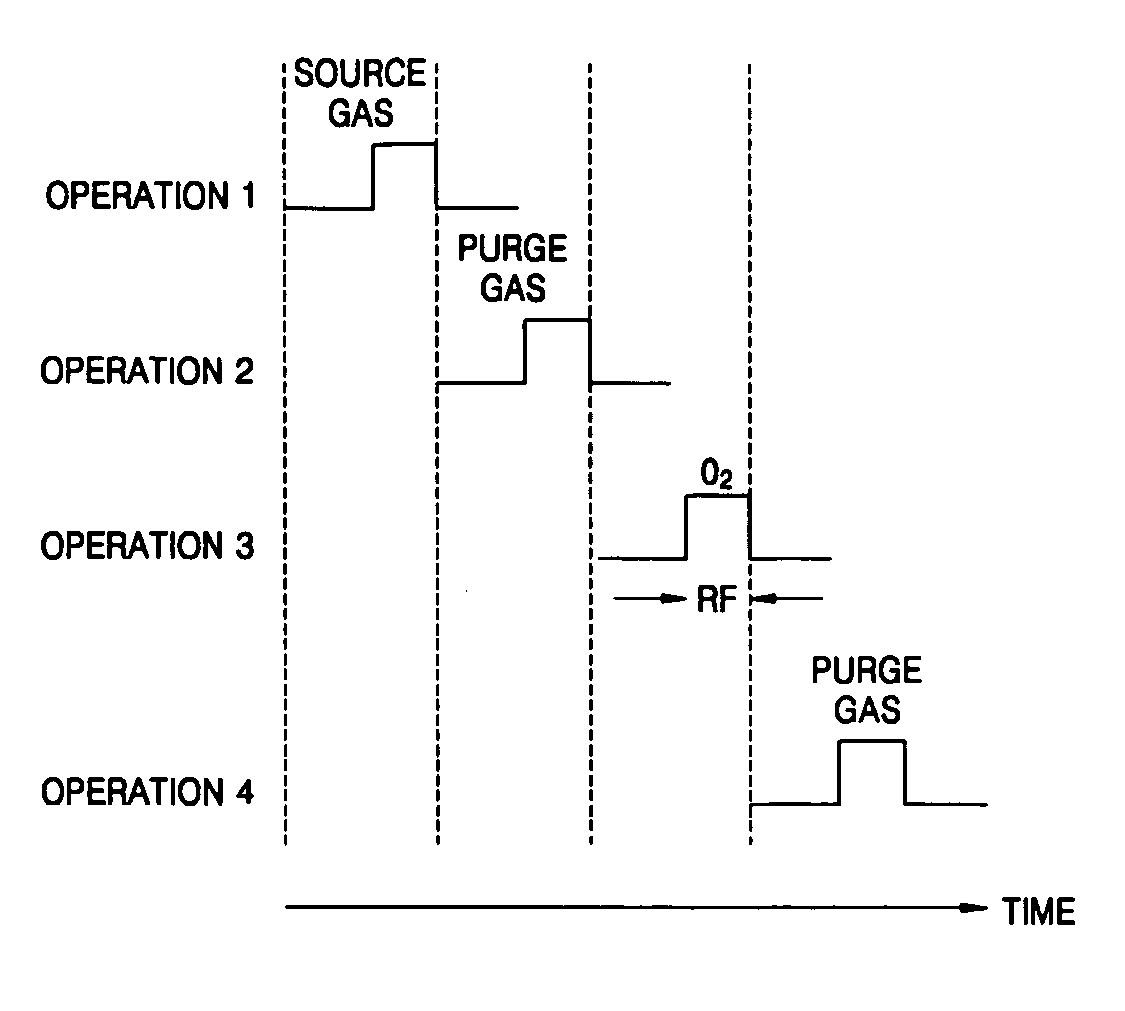

Provided is a method of fabricating a passivation layer for an organic device, including: forming the organic device on a substrate; and forming a passivation layer on the organic device. Here, forming the passivation layer on the organic device includes forming an inorganic thin film by thin film deposition using pulsed plasma.

Owner:ELECTRONICS & TELECOMM RES INST

Display device

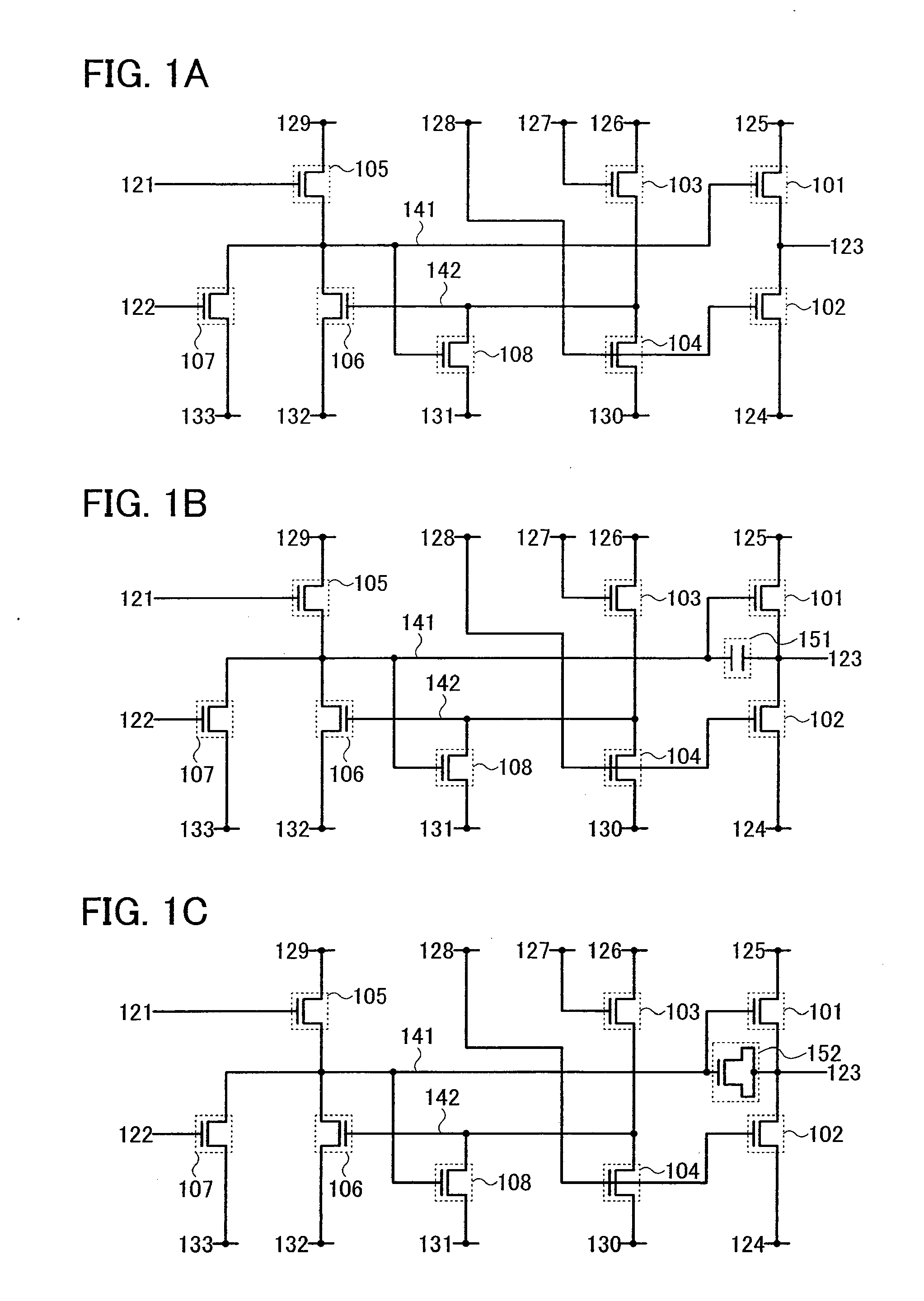

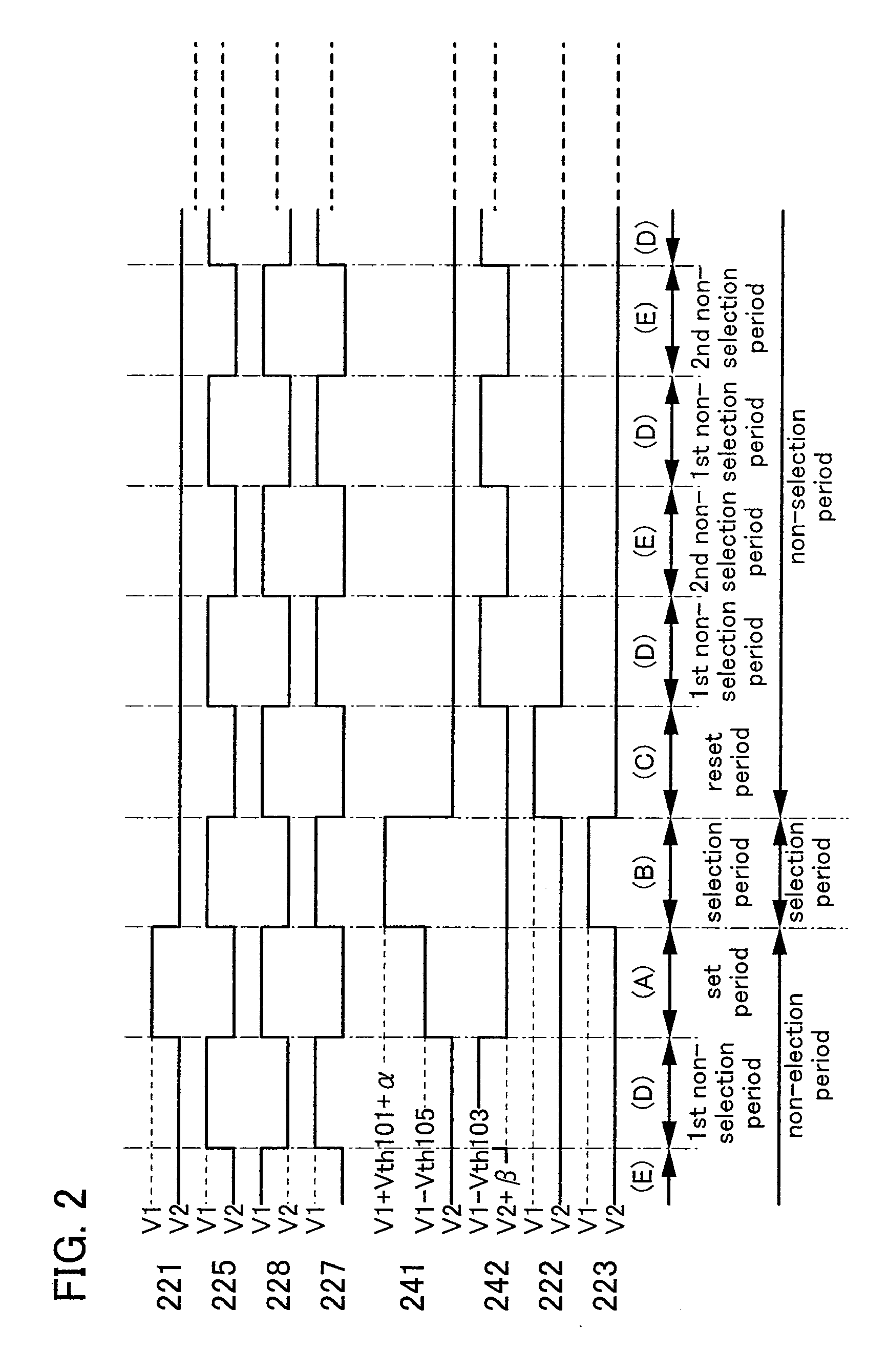

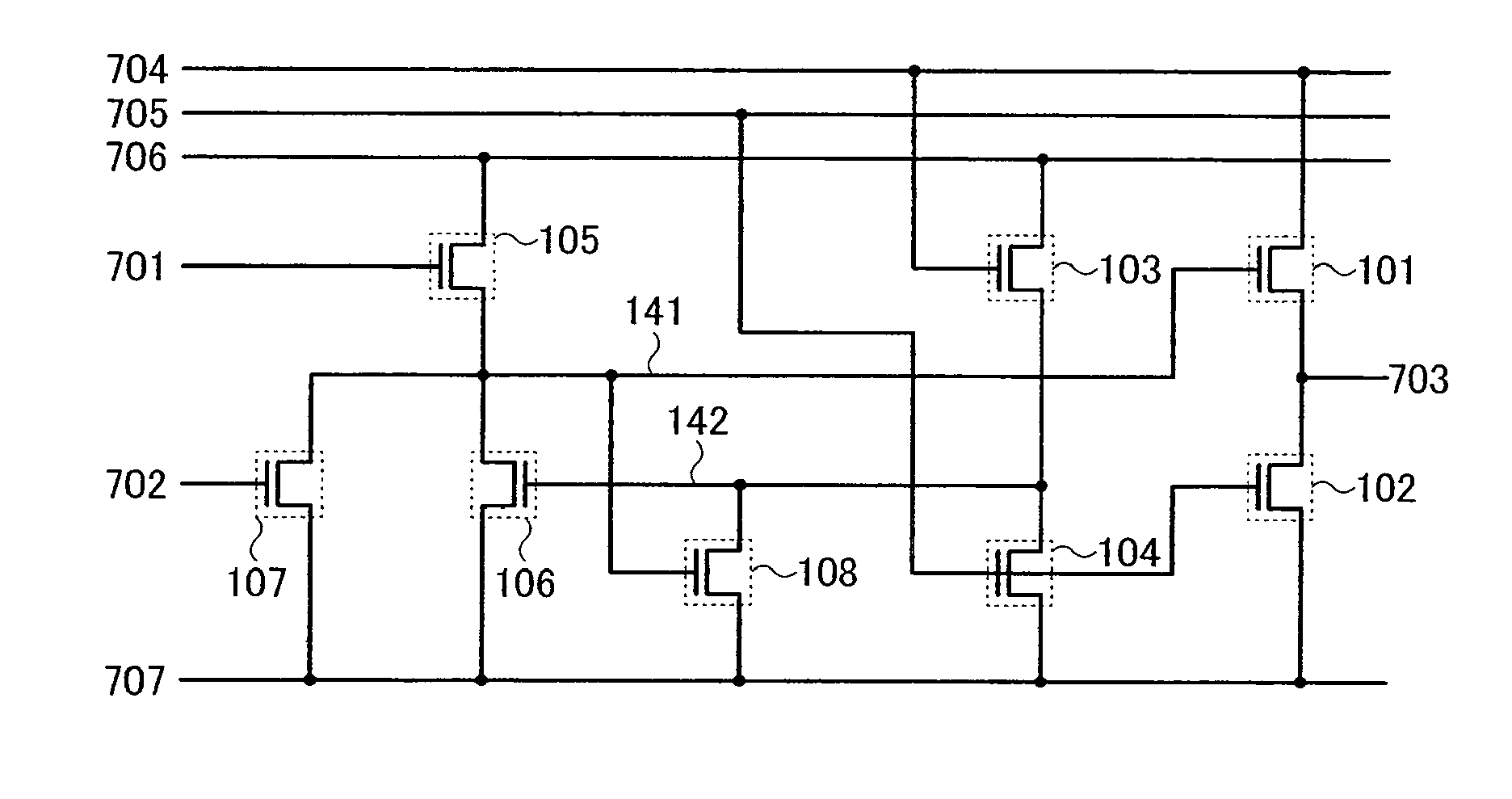

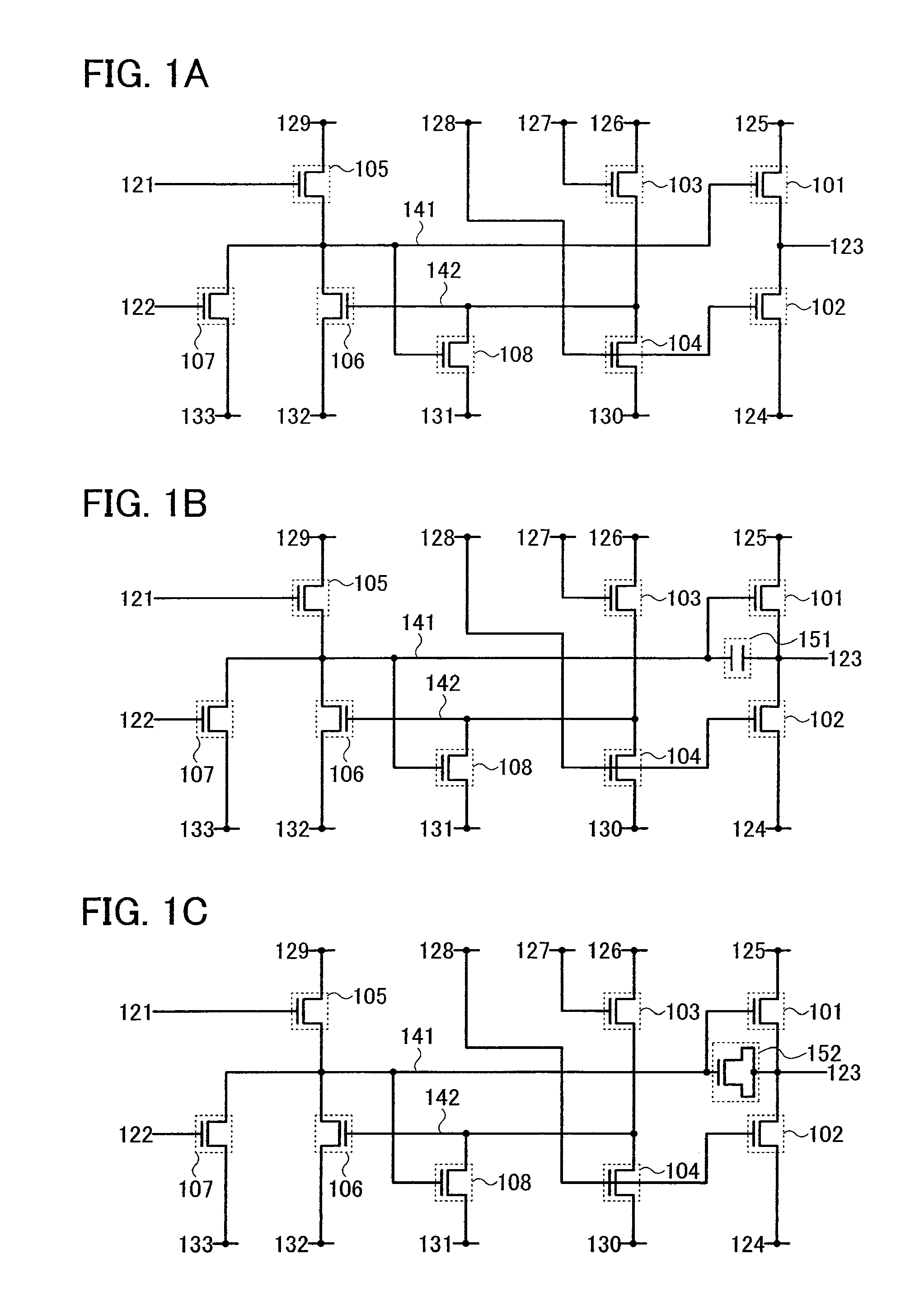

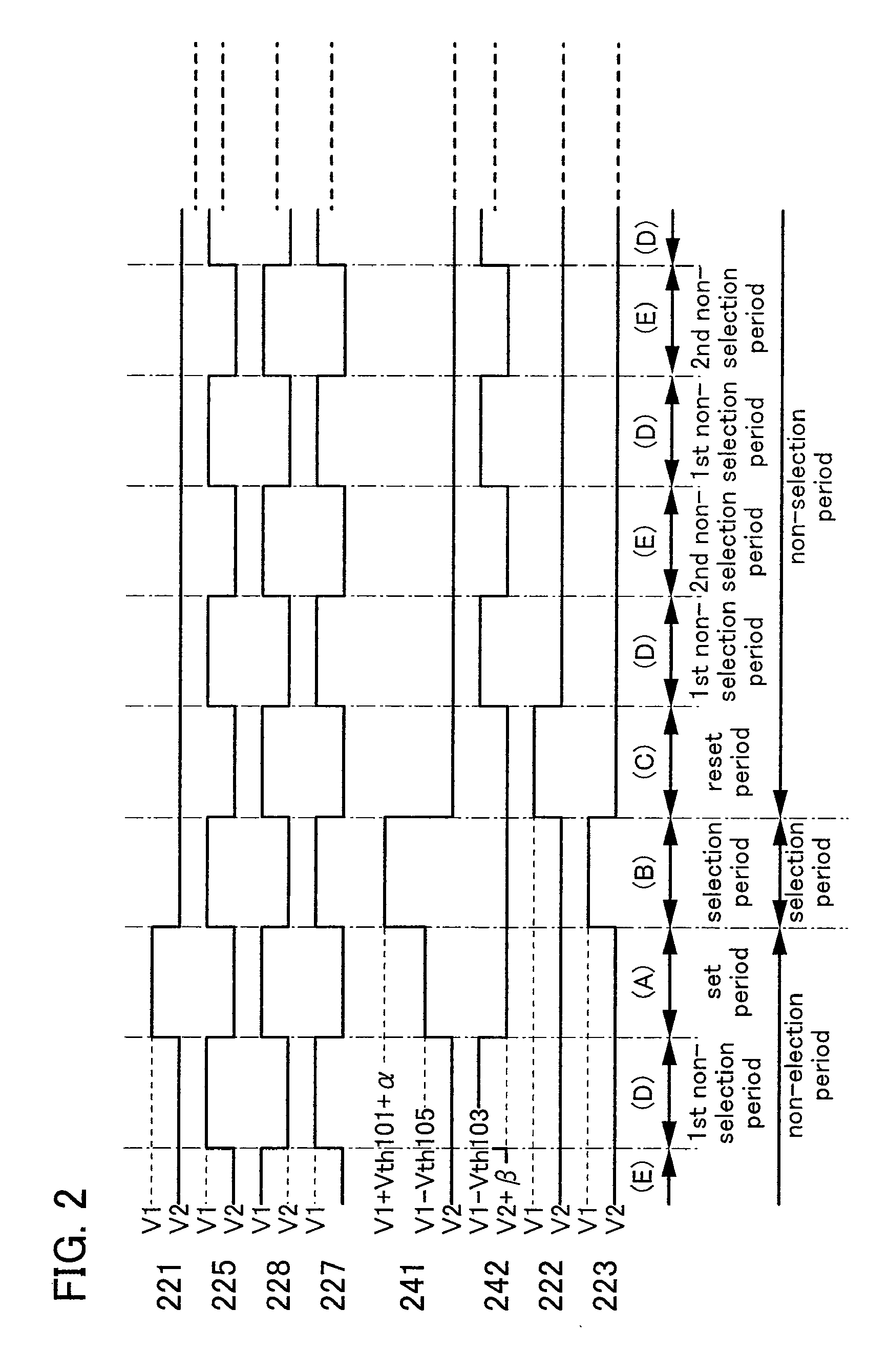

ActiveUS20080079685A1Suppression voltageEasily deterioratedStatic indicating devicesSolid-state devicesDisplay deviceEngineering

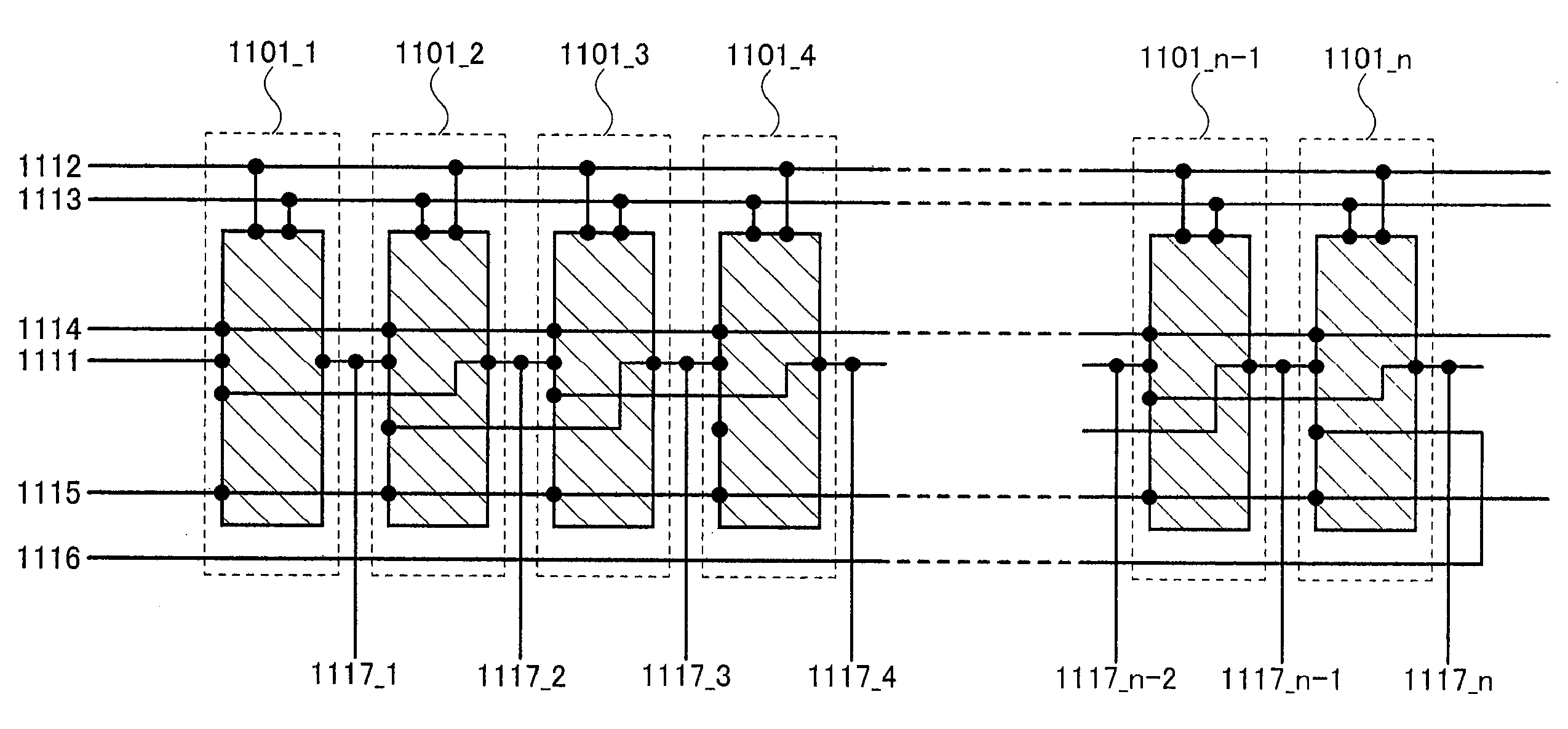

To suppress fluctuation in the threshold voltage of a transistor, to reduce the number of connections of a display panel and a driver IC, to achieve reduction in power consumption of a display device, and to achieve increase in size and high definition of the display device. A gate electrode of a transistor which easily deteriorates is connected to a wiring to which a high potential is supplied through a first switching transistor and a wiring to which a low potential is supplied through a second switching transistor; a clock signal is input to a gate electrode of the first switching transistor; and an inverted clock signal is input to a gate electrode of the second switching transistor. Thus, the high potential and the low potential are alternately applied to the gate electrode of the transistor which easily deteriorates.

Owner:SEMICON ENERGY LAB CO LTD

Display device

ActiveUS8054279B2Suppression voltageEasily deterioratedStatic indicating devicesSolid-state devicesDisplay deviceHigh definition

To suppress fluctuation in the threshold voltage of a transistor, to reduce the number of connections of a display panel and a driver IC, to achieve reduction in power consumption of a display device, and to achieve increase in size and high definition of the display device. A gate electrode of a transistor which easily deteriorates is connected to a wiring to which a high potential is supplied through a first switching transistor and a wiring to which a low potential is supplied through a second switching transistor; a clock signal is input to a gate electrode of the first switching transistor; and an inverted clock signal is input to a gate electrode of the second switching transistor. Thus, the high potential and the low potential are alternately applied to the gate electrode of the transistor which easily deteriorates.

Owner:SEMICON ENERGY LAB CO LTD

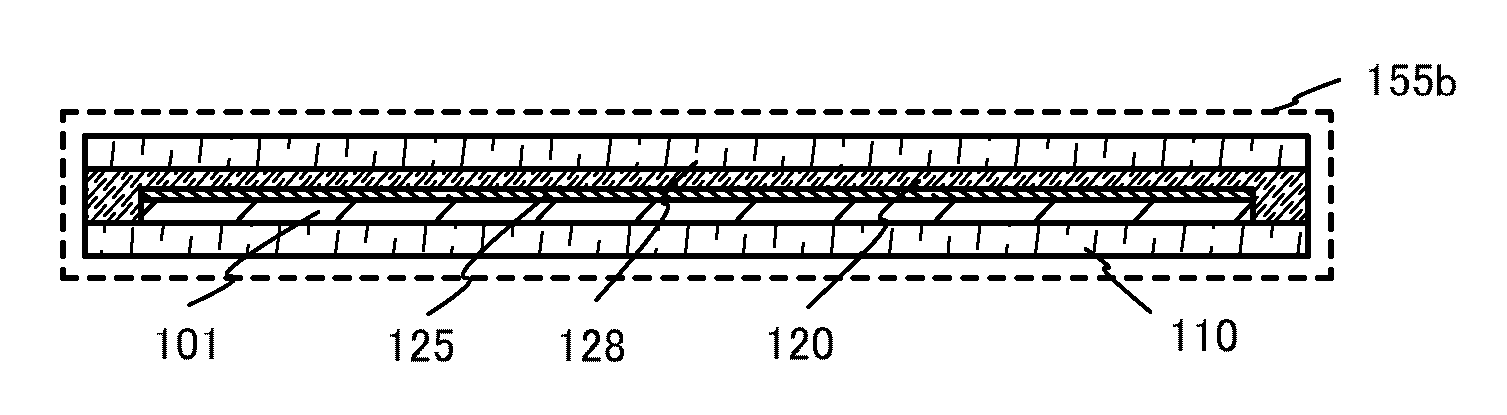

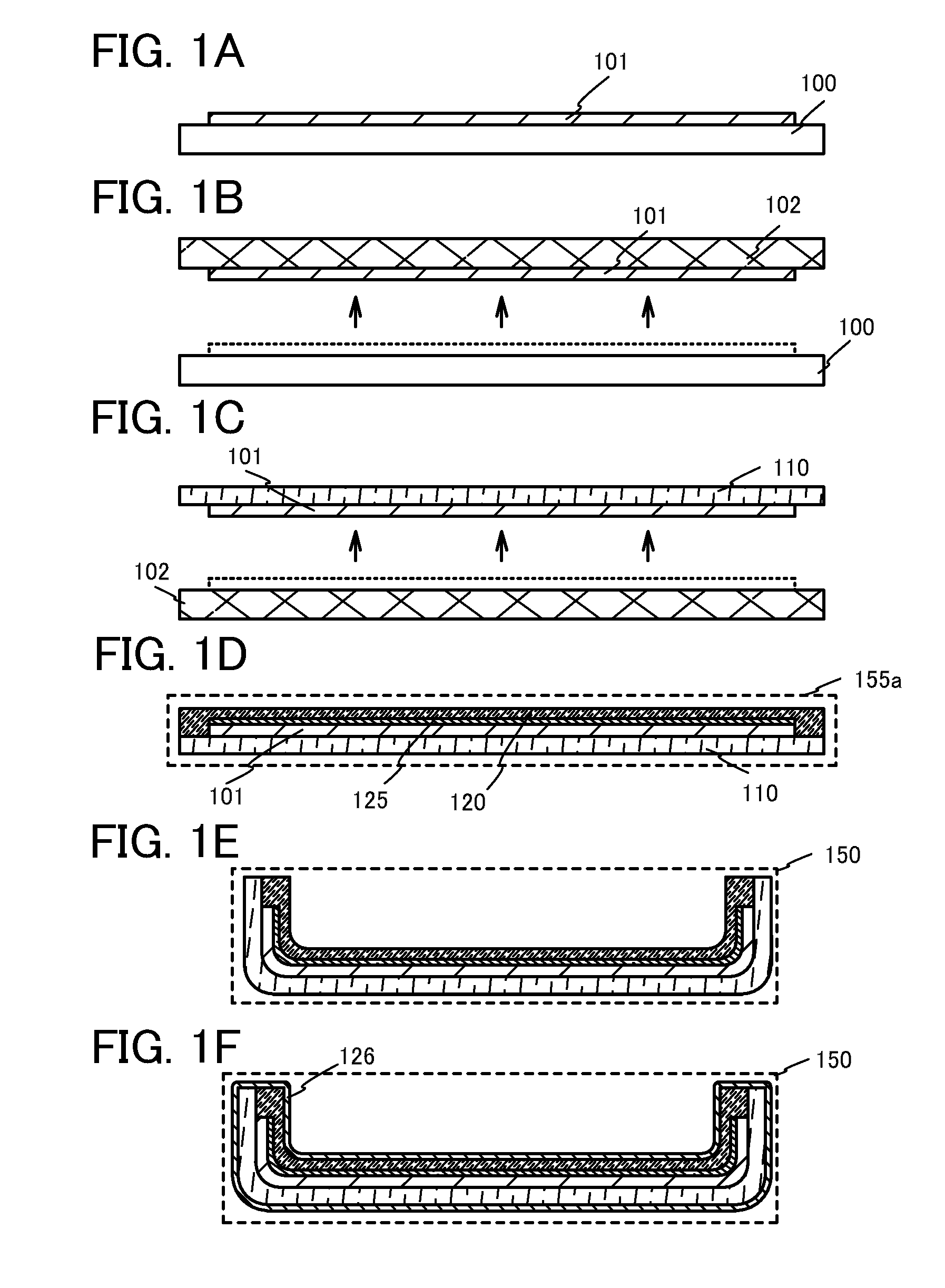

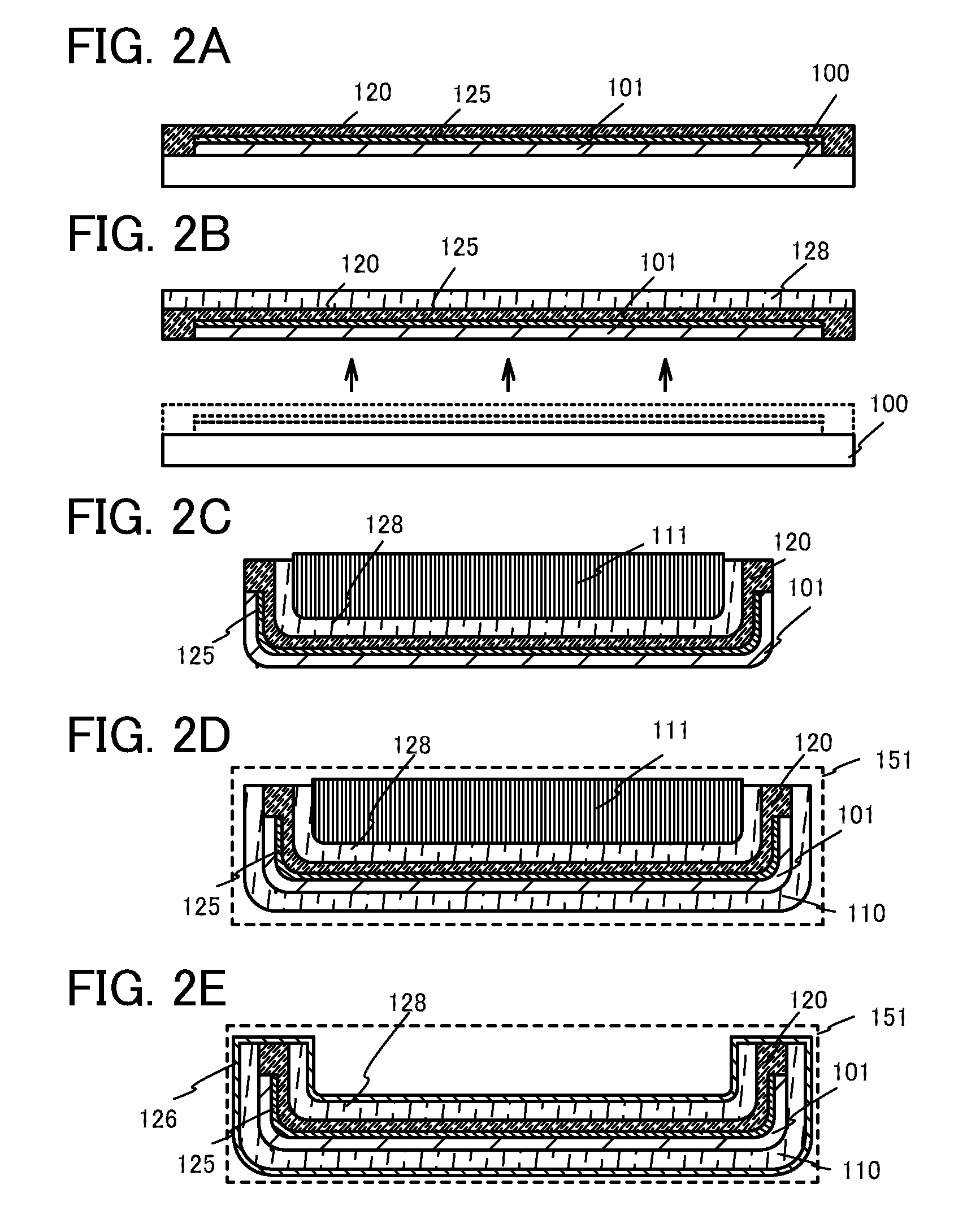

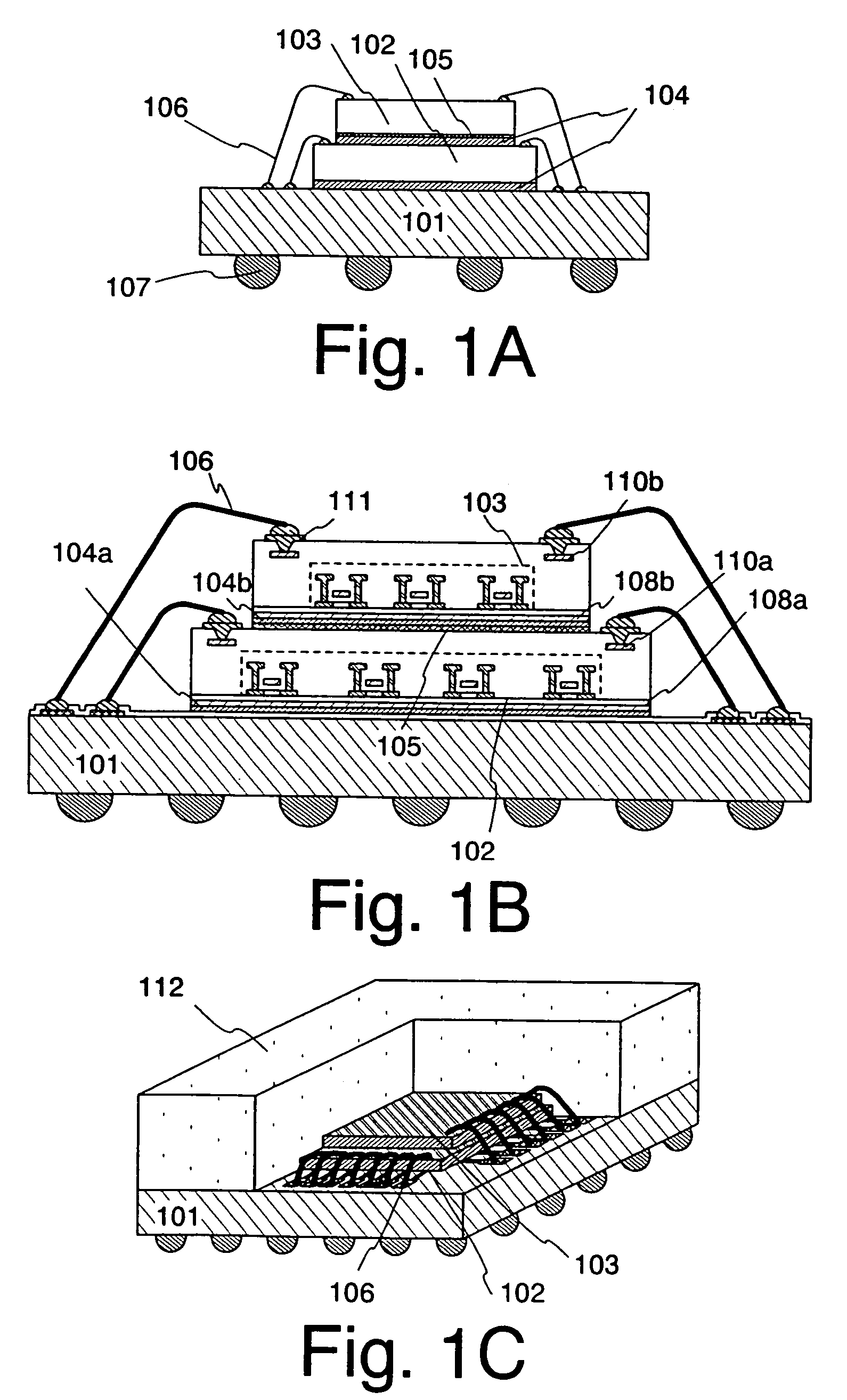

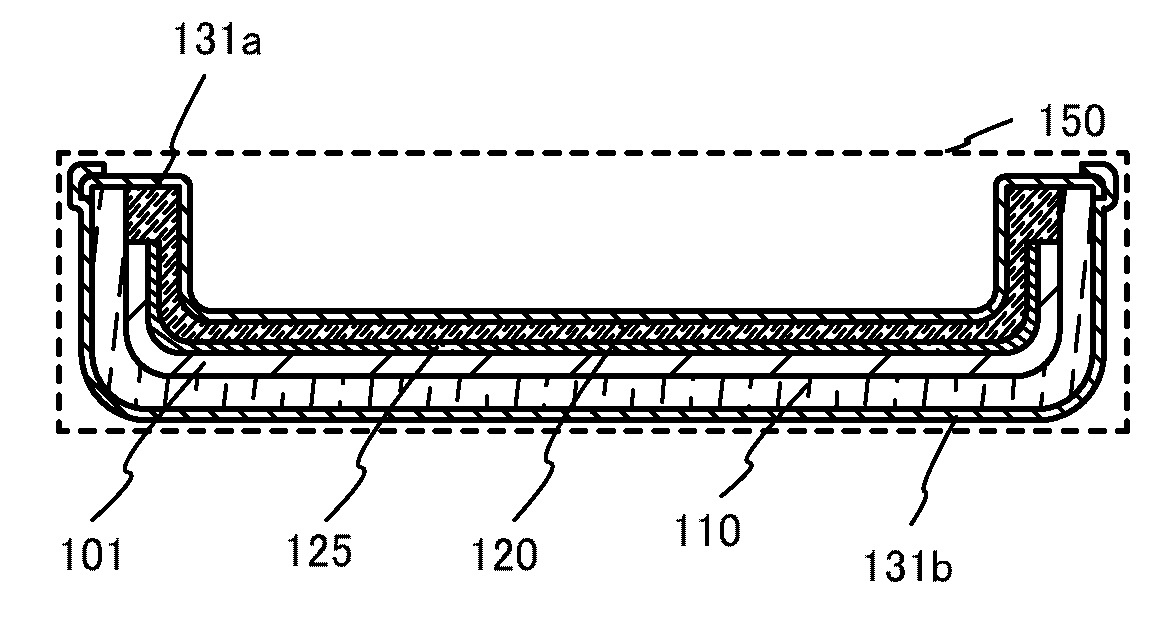

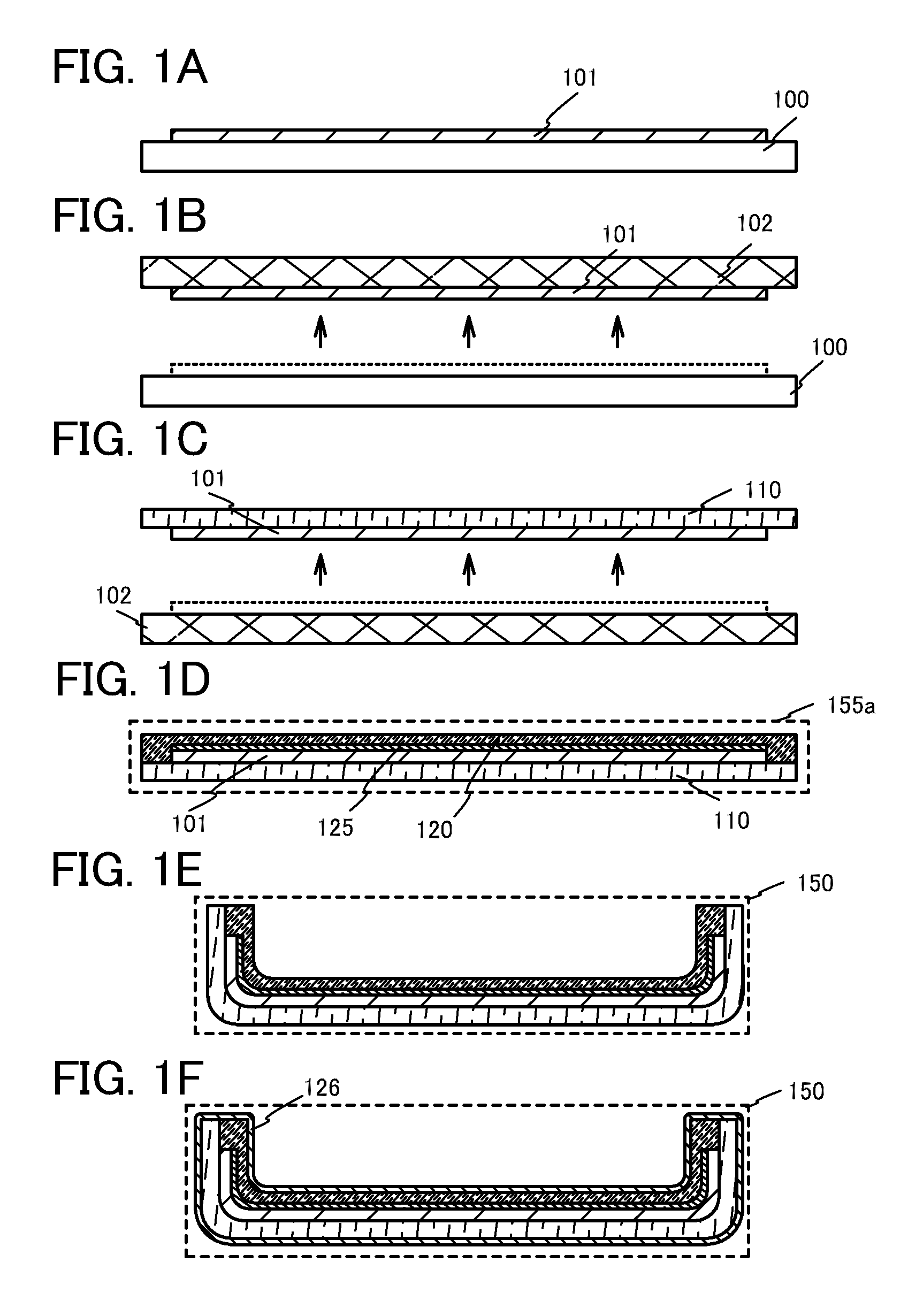

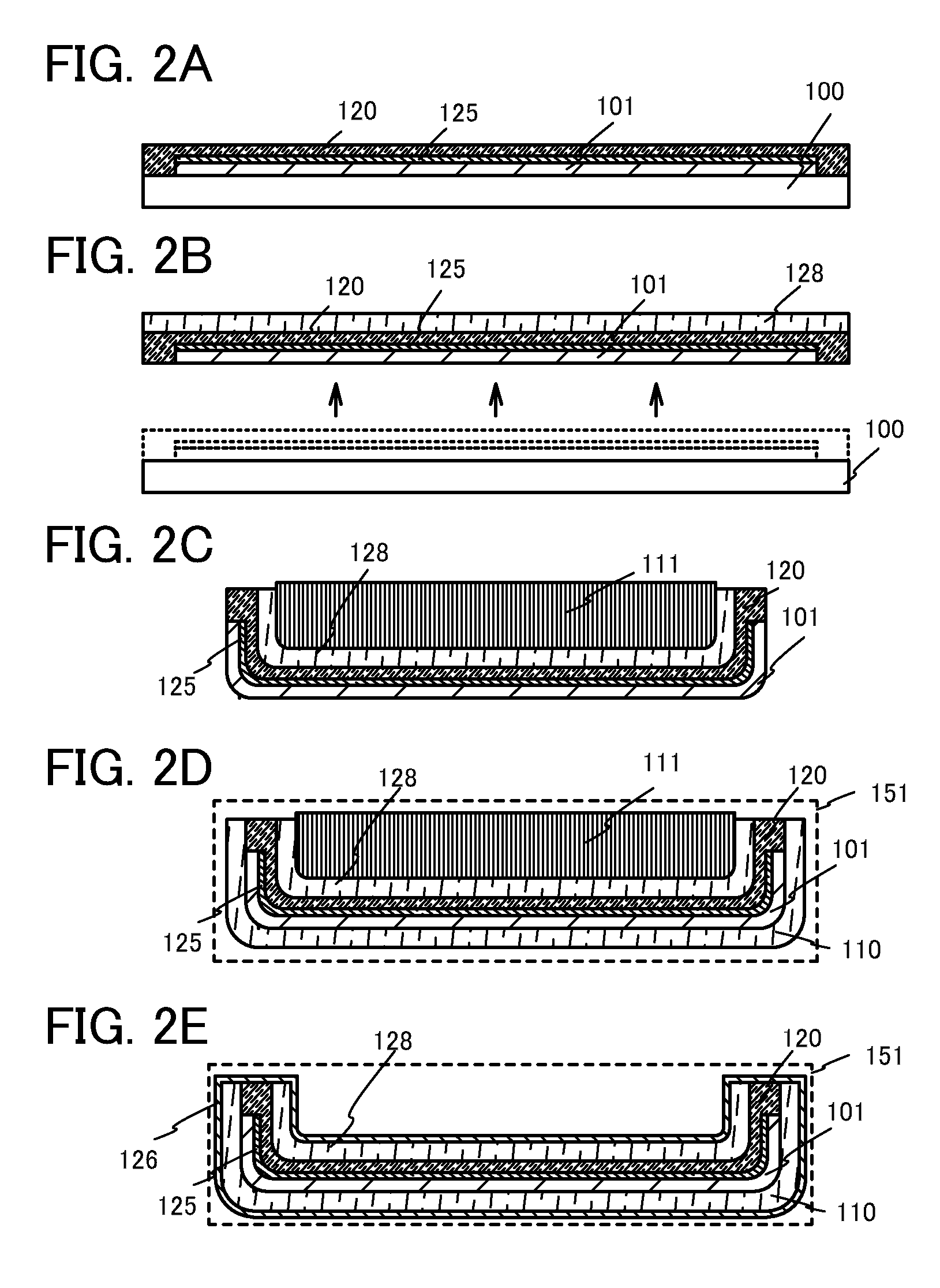

Method for manufacturing light-emitting device

ActiveUS20100293782A1Avoid it happening againAvoid pollutionLine/current collector detailsFinal product manufactureEngineeringLight emitting device

An object of one embodiment of the present invention is to provide a more convenient highly reliable light-emitting device which can be used for a variety of applications. Another object of one embodiment of the present invention is to manufacture, without complicating the process, a highly reliable light-emitting device having a shape suitable for its intended purpose. In a manufacturing process of a light-emitting device, a light-emitting panel is manufactured which is at least partly curved by processing the shape to be molded after the manufacture of an electrode layer and / or an element layer, and a protective film covering a surface of the light-emitting panel which is at least partly curved is formed, so that a light-emitting device using the light-emitting panel has a more useful function and higher reliability.

Owner:SEMICON ENERGY LAB CO LTD

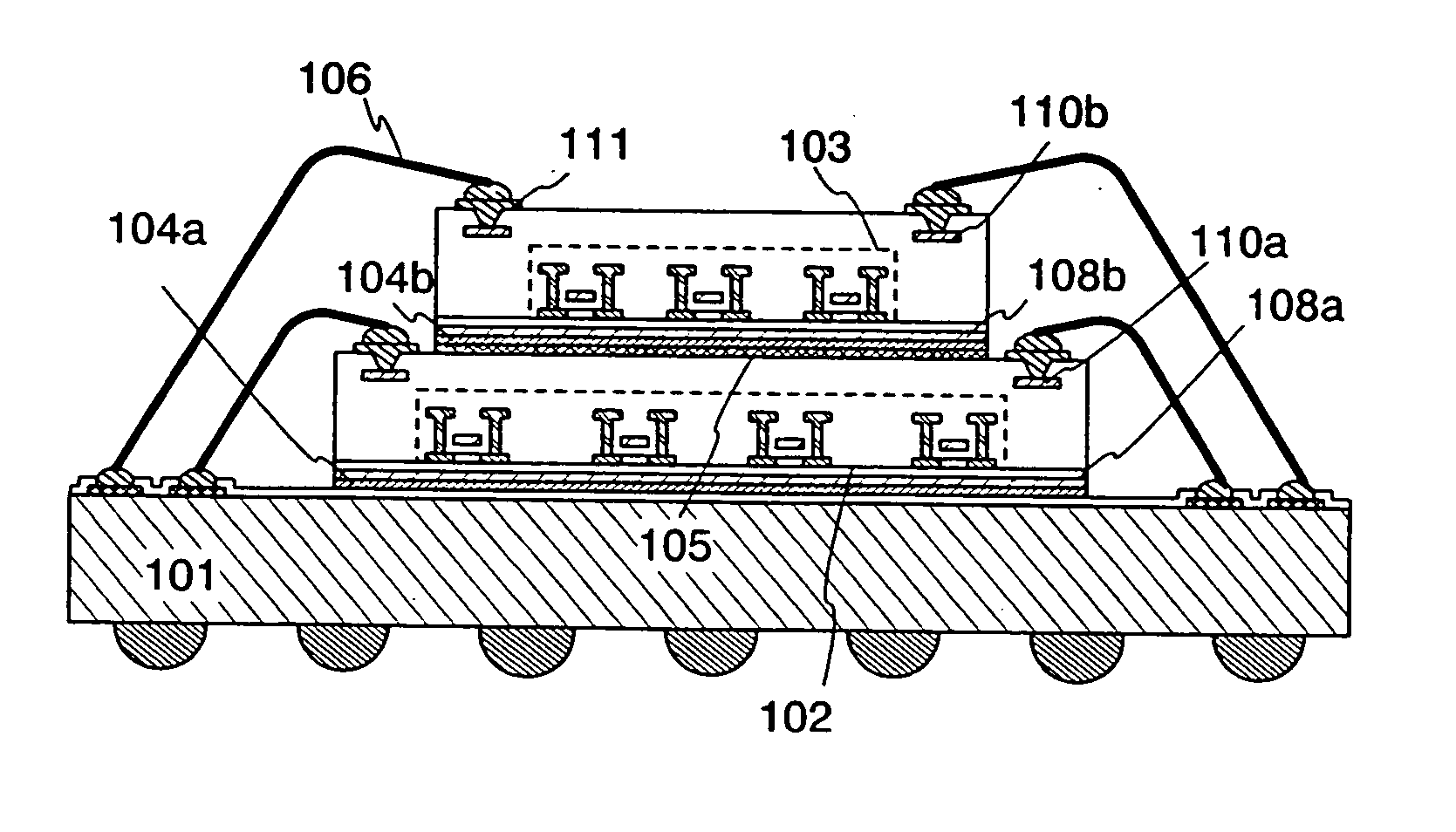

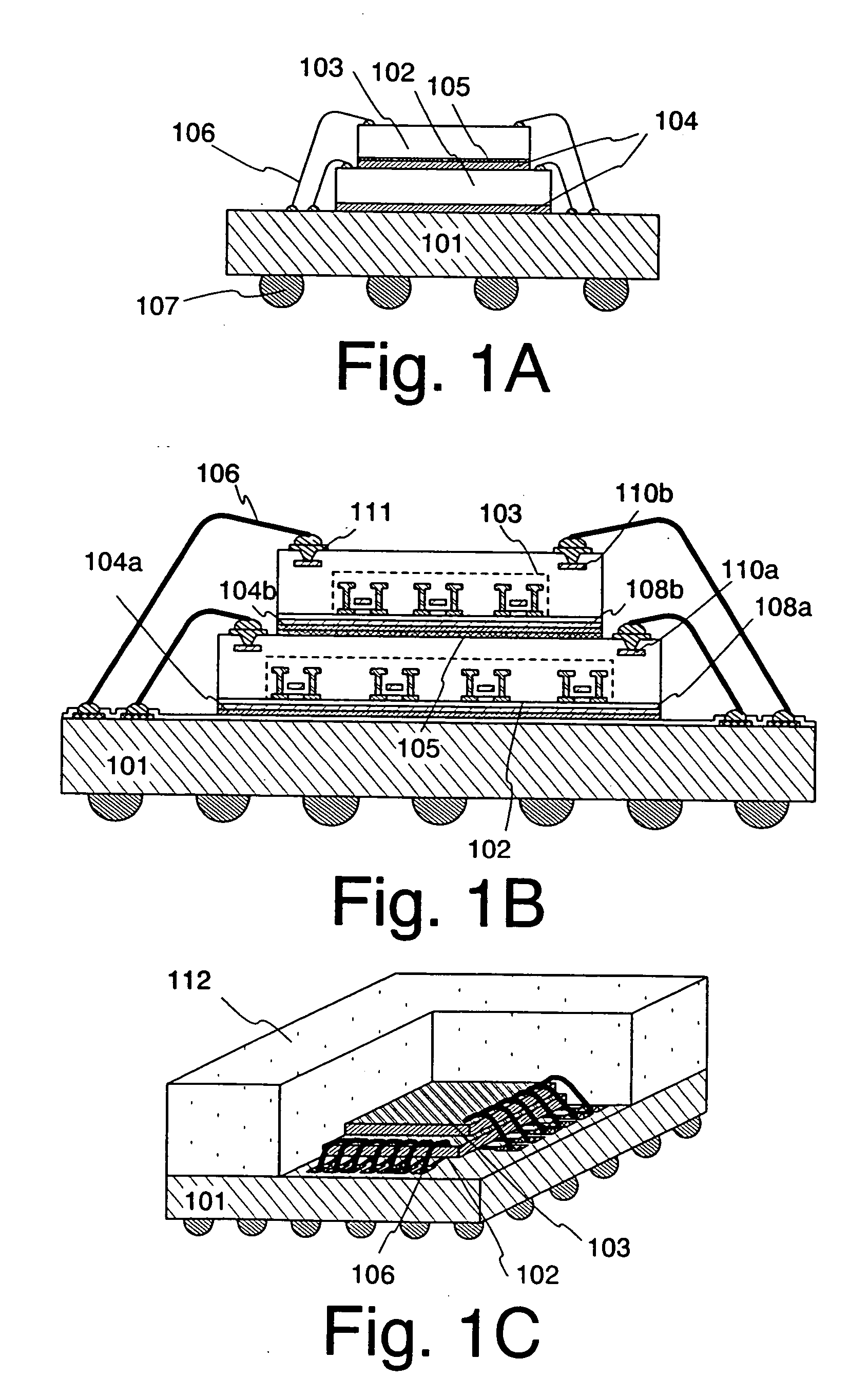

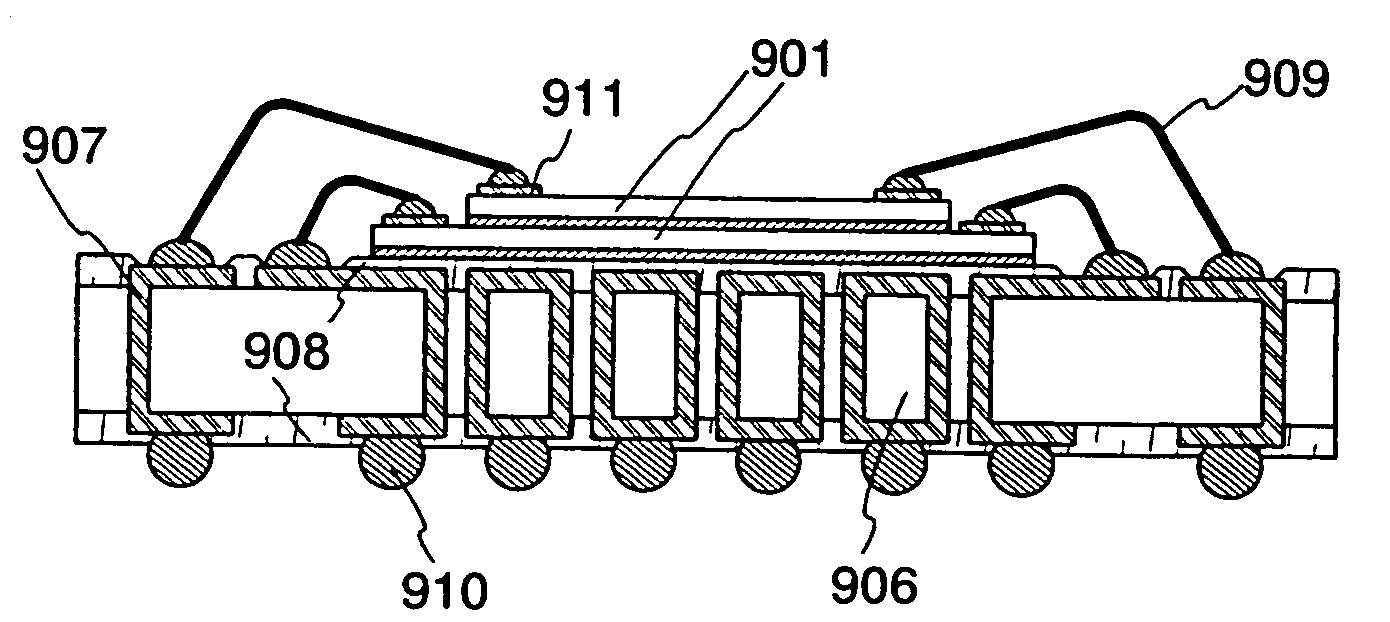

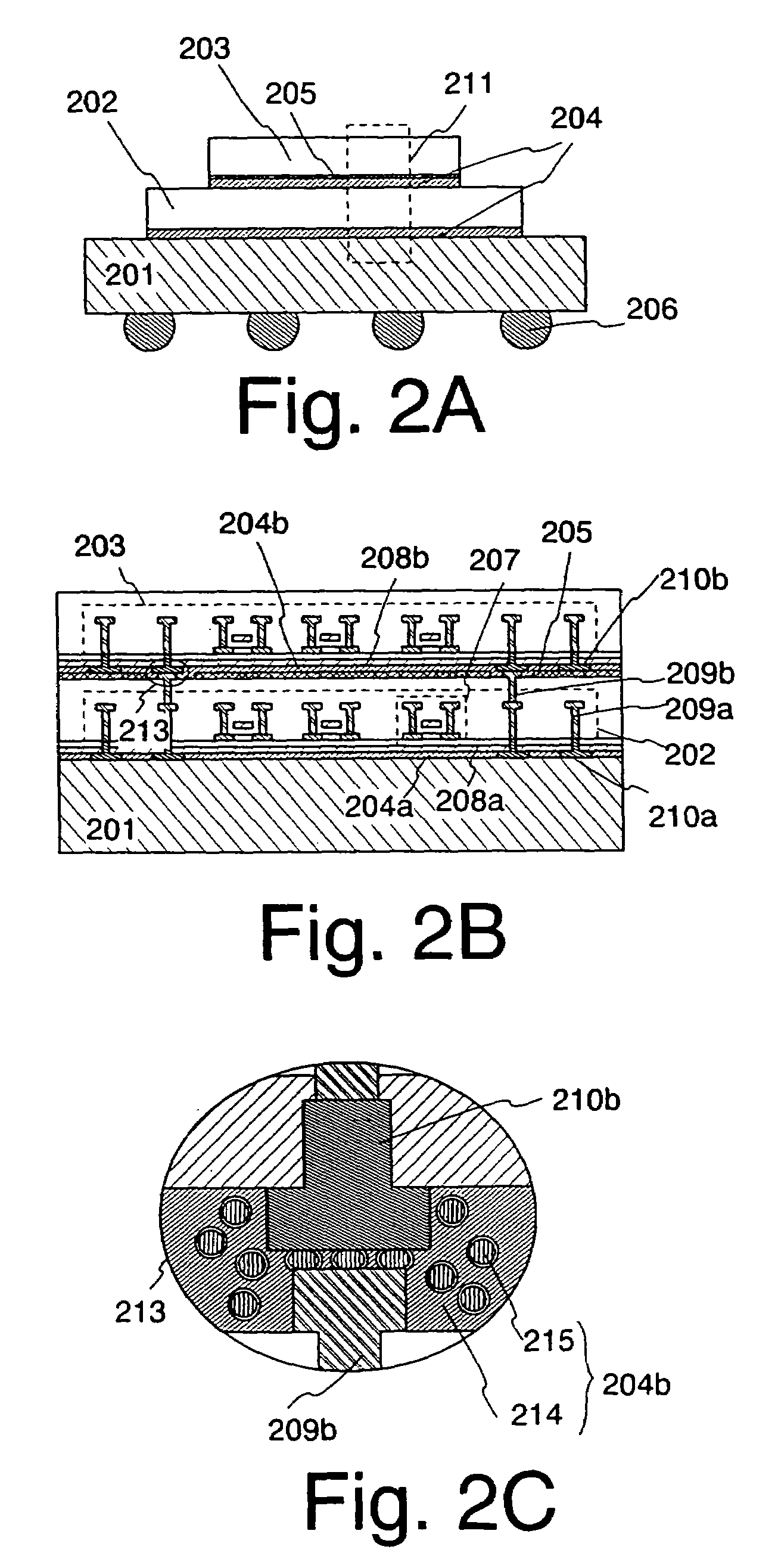

Semiconductor chip and method for manufacturing the same

ActiveUS20040140547A1Prevents each device from deterioratingEasily deterioratedTransistorSemiconductor/solid-state device detailsSemiconductor chip

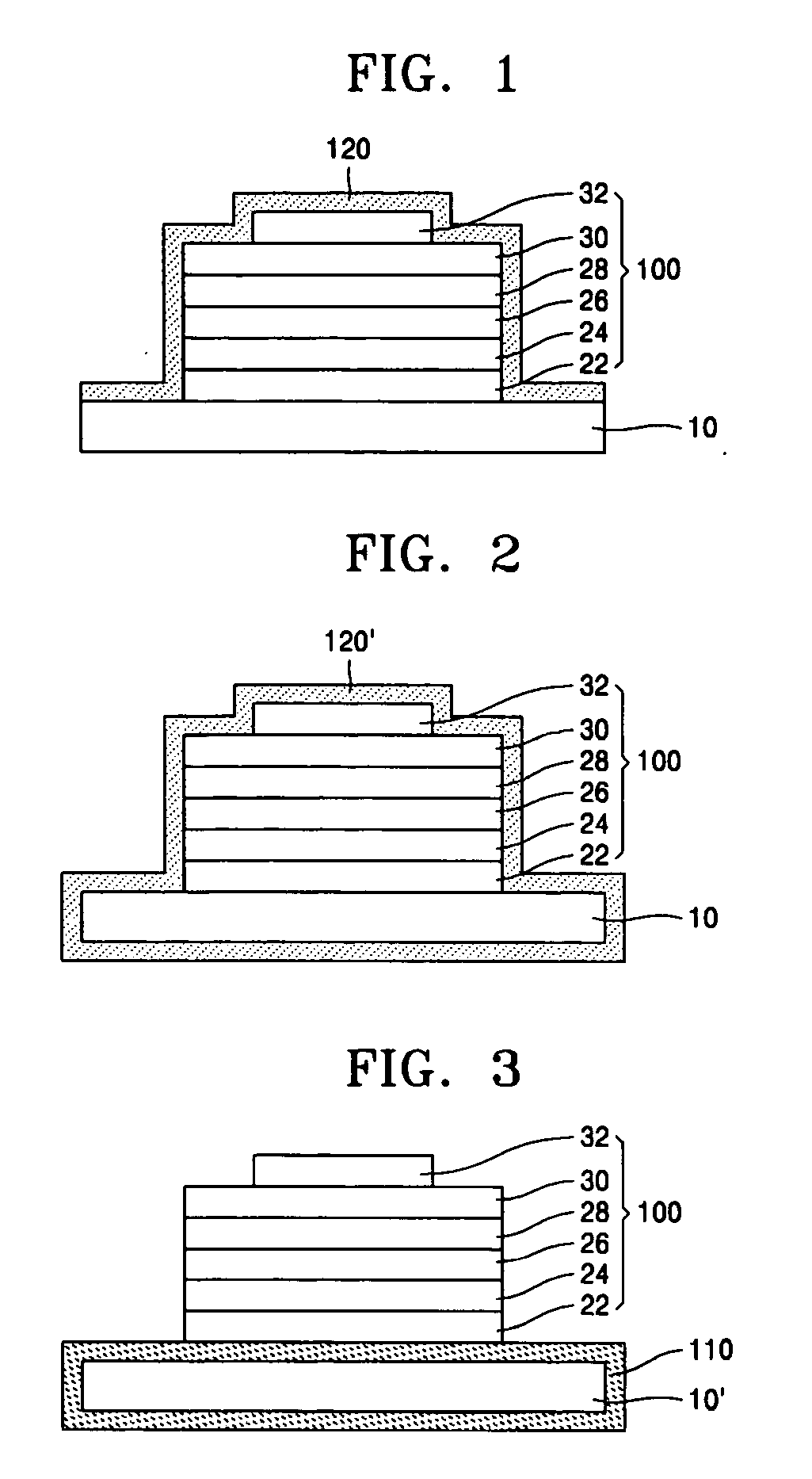

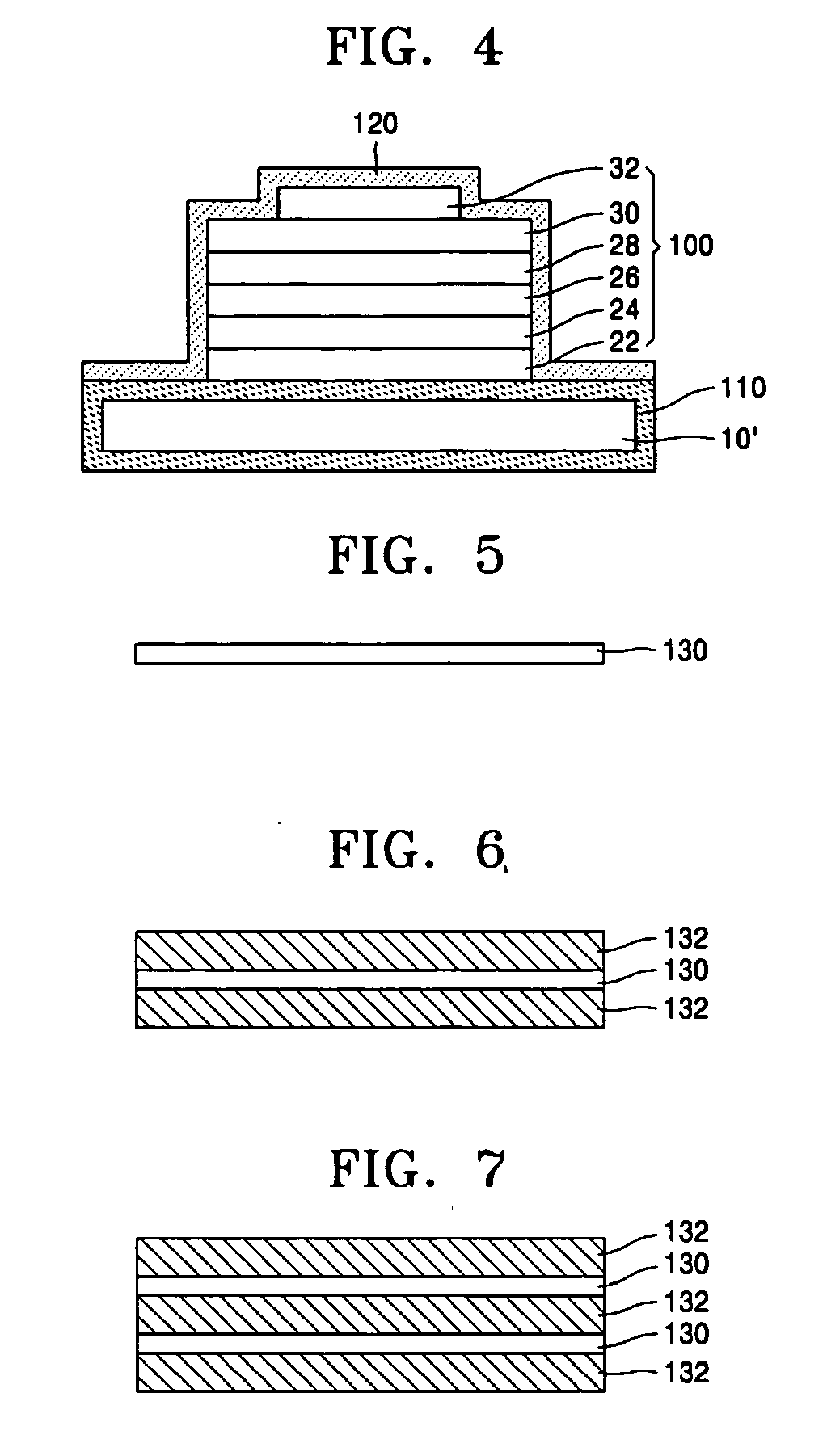

A semiconductor chip having a plurality of device formative layers that are formed into an integrated thin film is provided by a technique for transferring. According to the present invention, a semiconductor chip that is formed into a thin film and that is highly integrated can be manufactured by transferring a device formative layer with a thickness of at most 50 mum which is separated from a substrate into another substrate by a technique for transferring, and transferring another device formative layer with a thickness of at most 50 mum which is separated from another substrate to the above device formative layer, and, repeating such transferring process.

Owner:SEMICON ENERGY LAB CO LTD

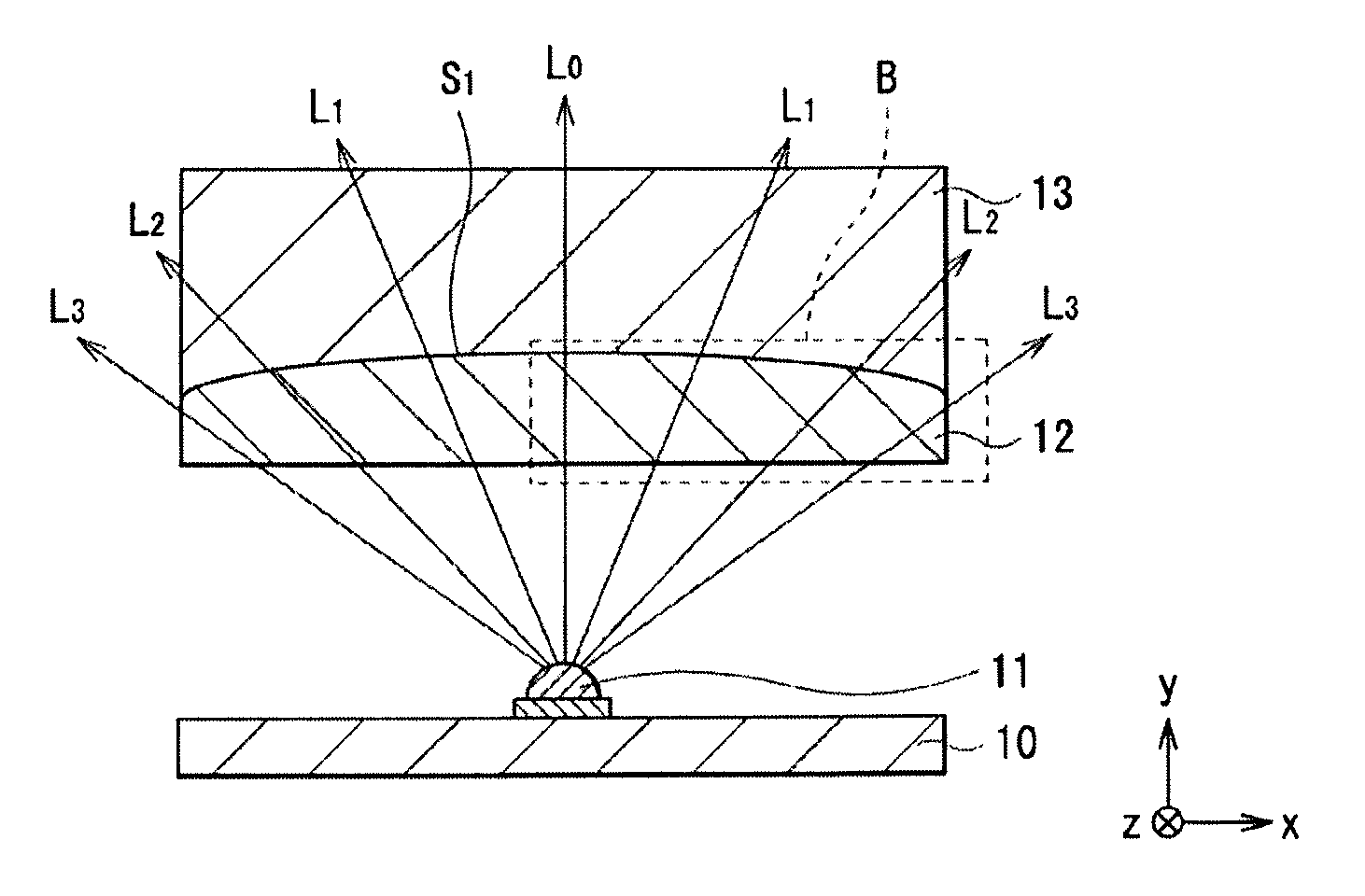

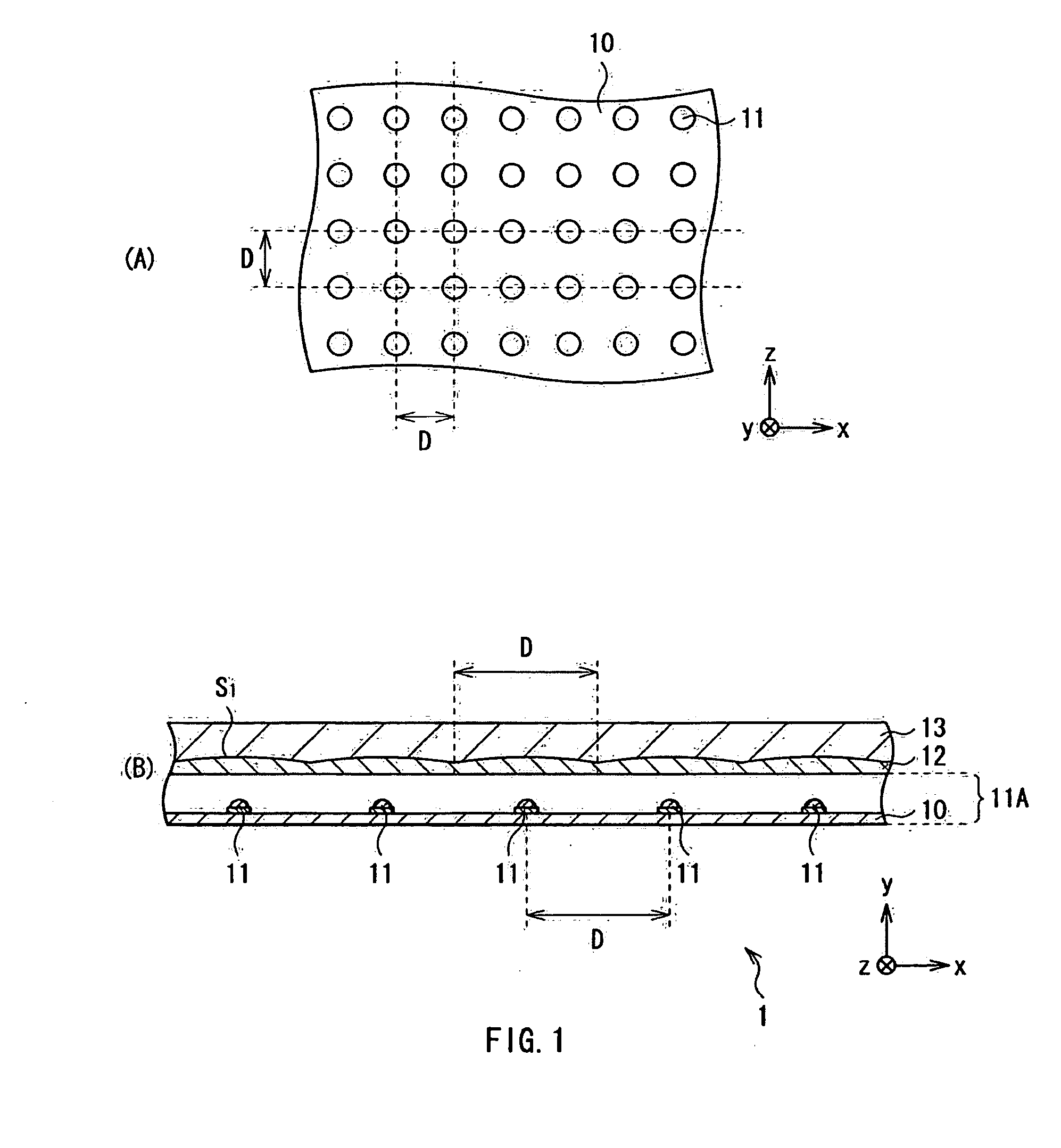

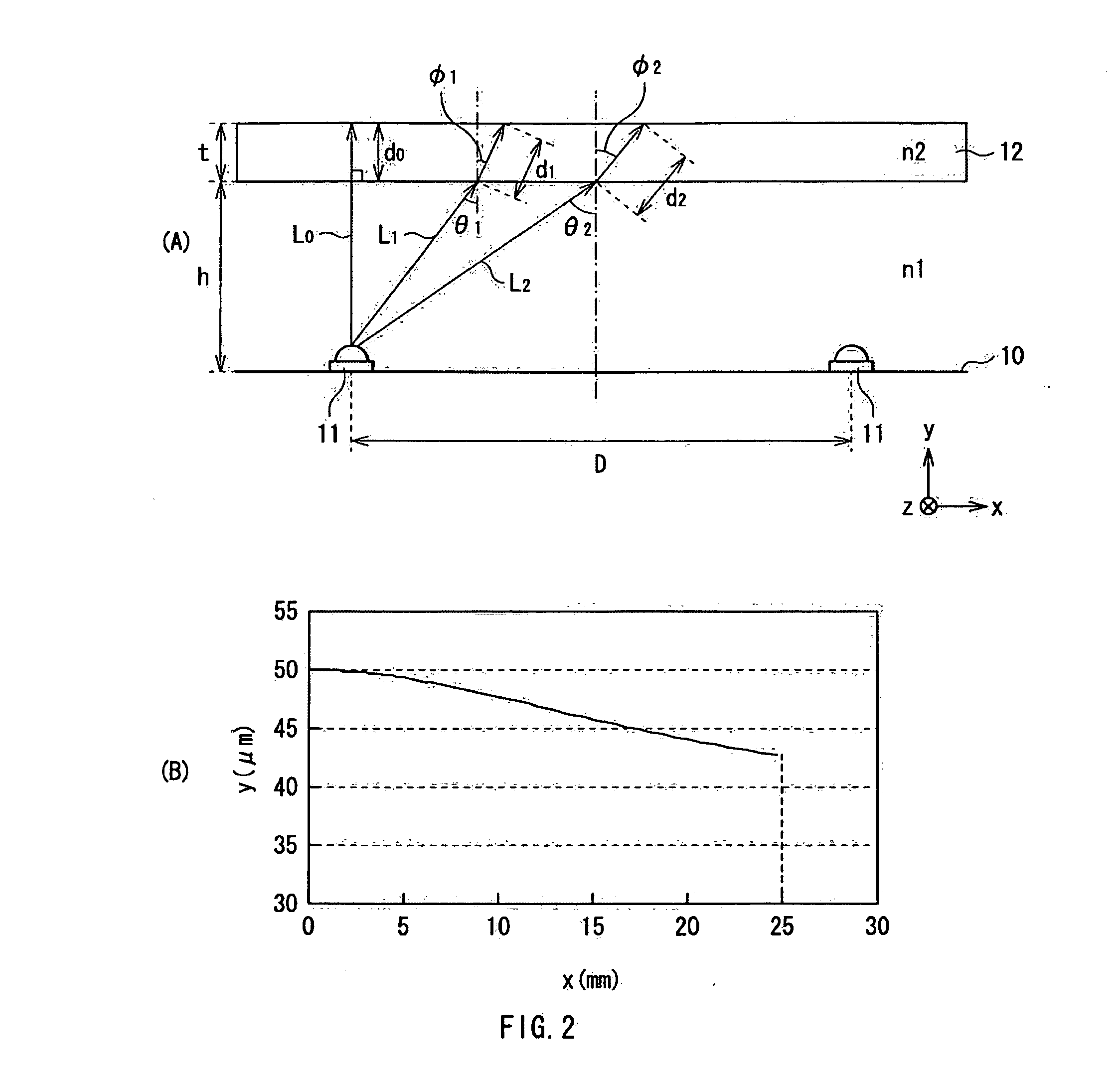

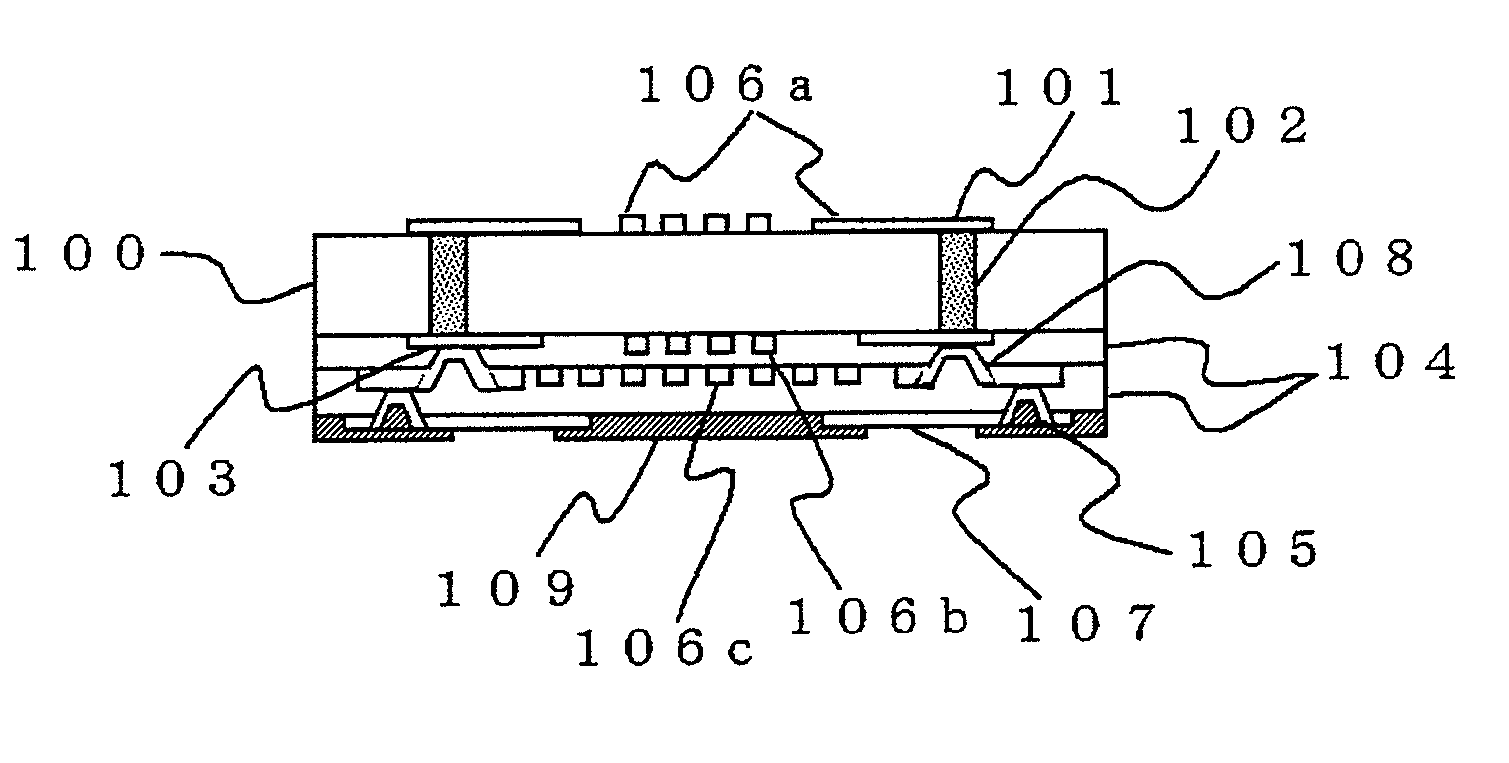

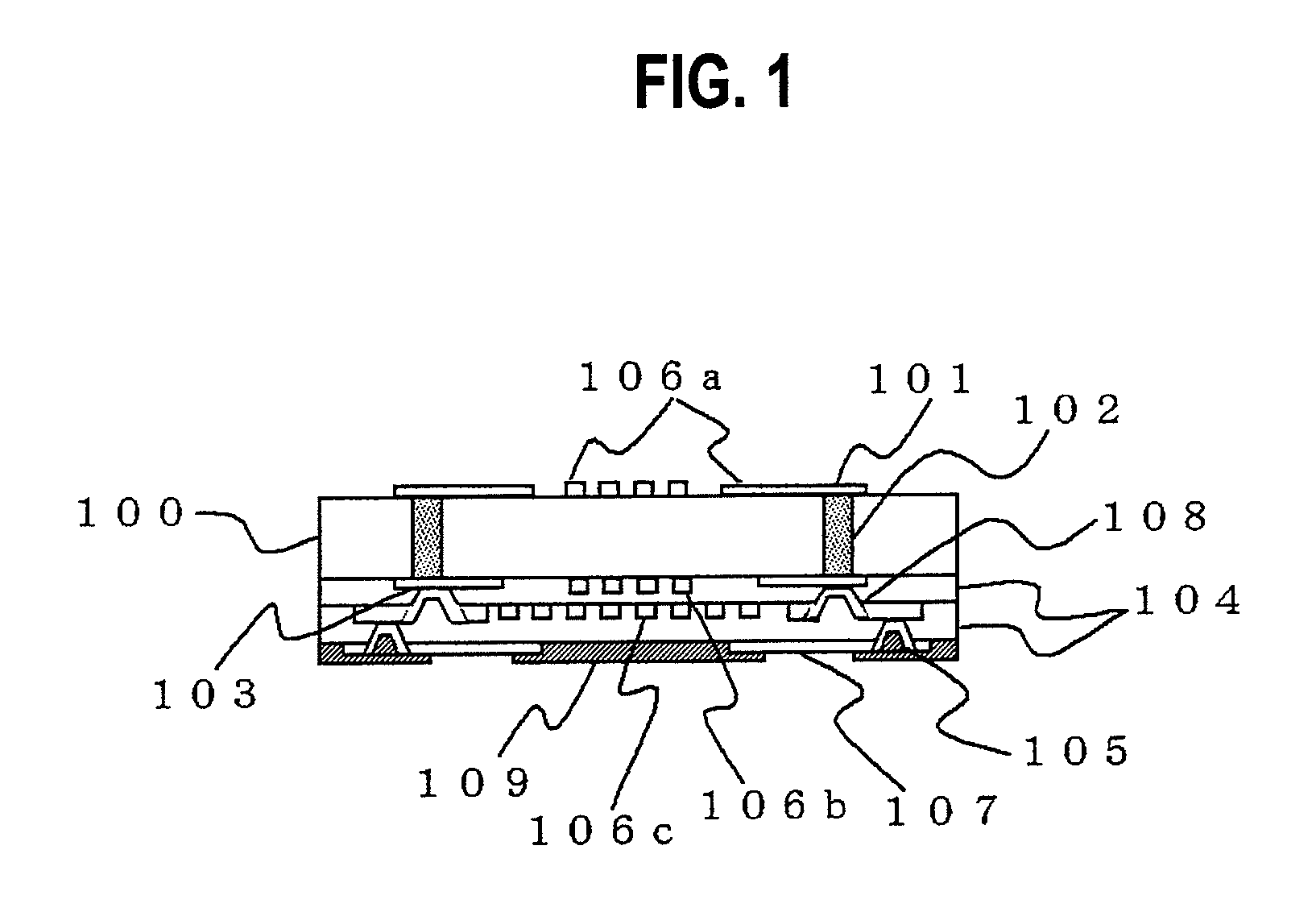

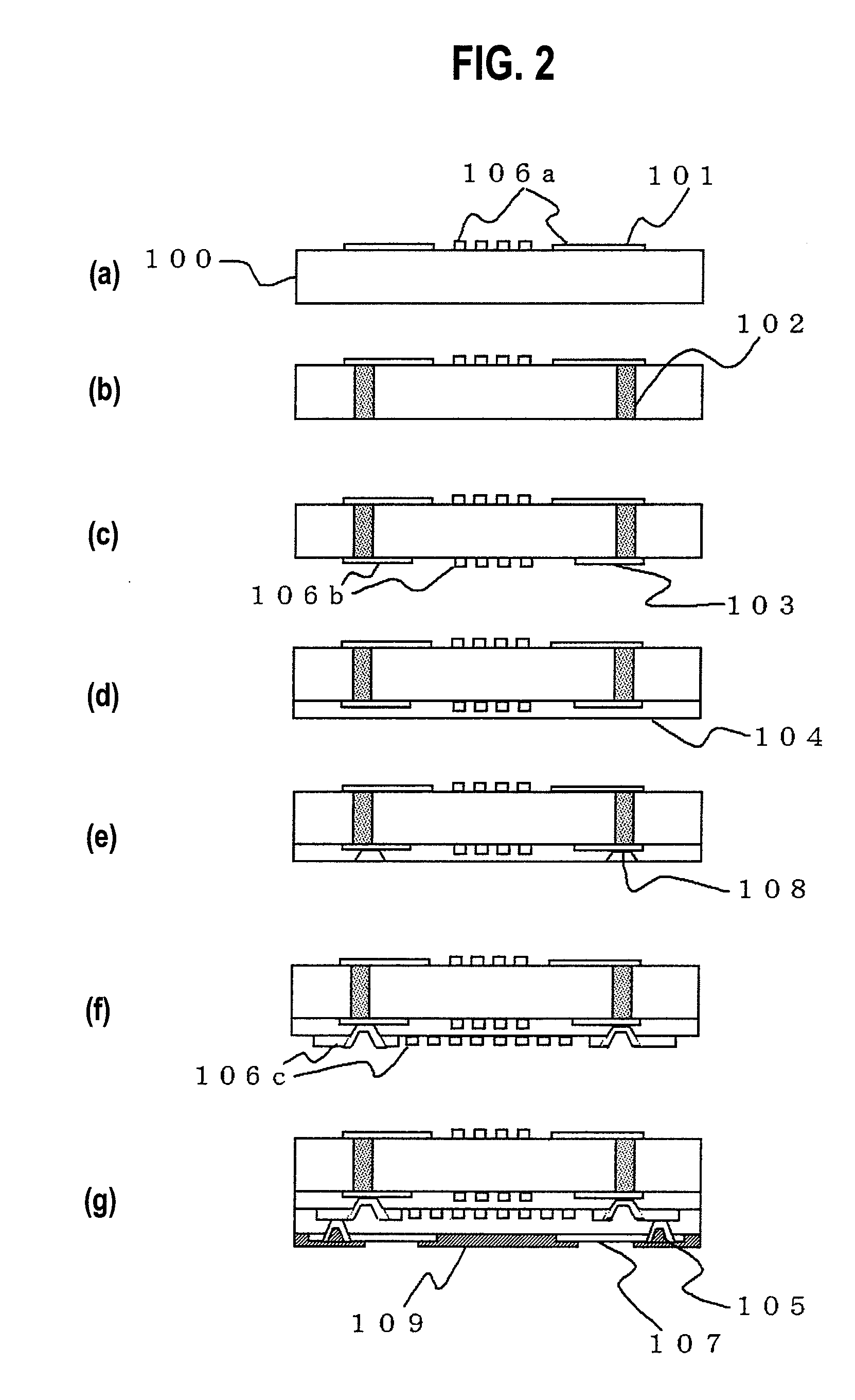

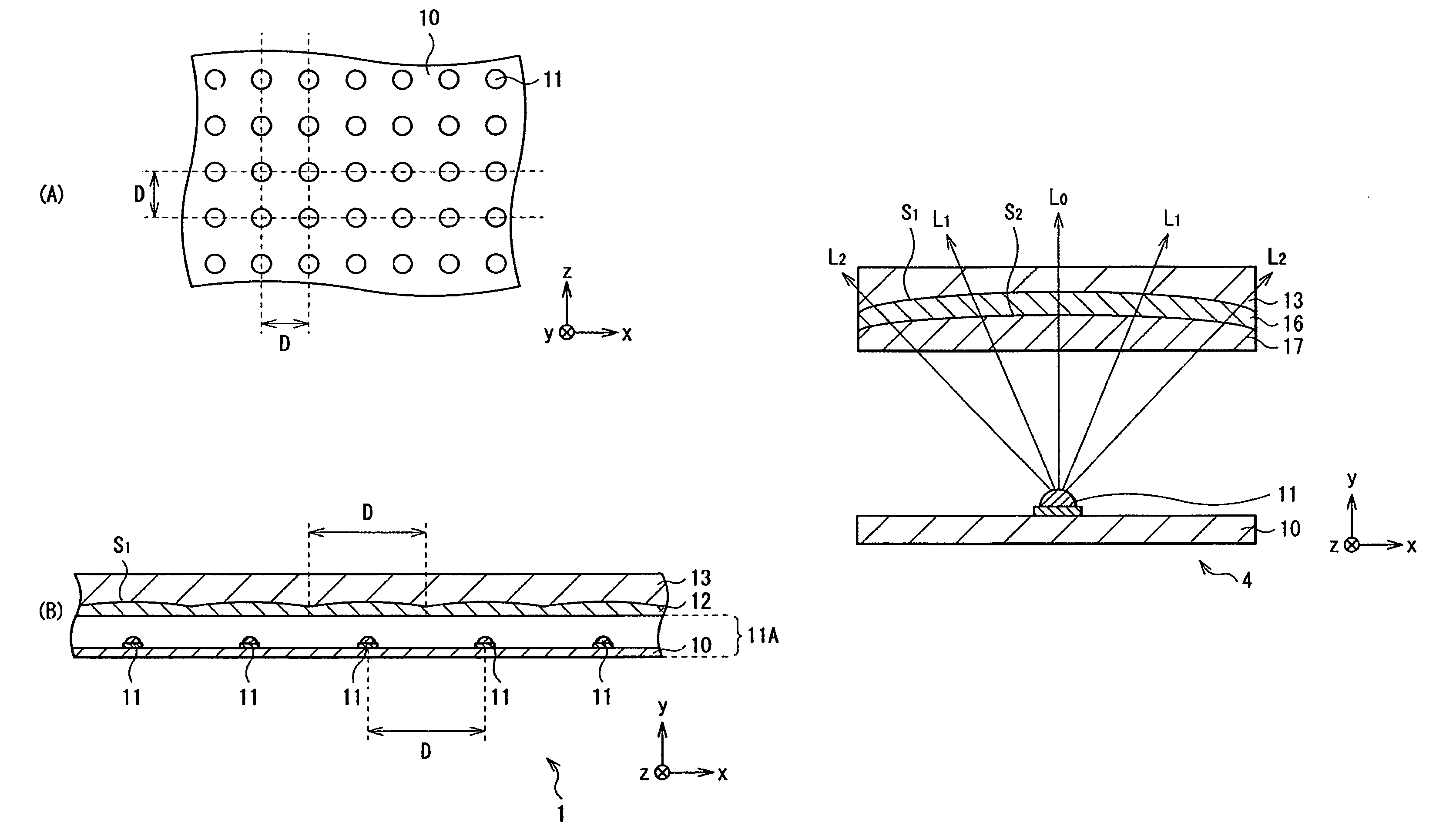

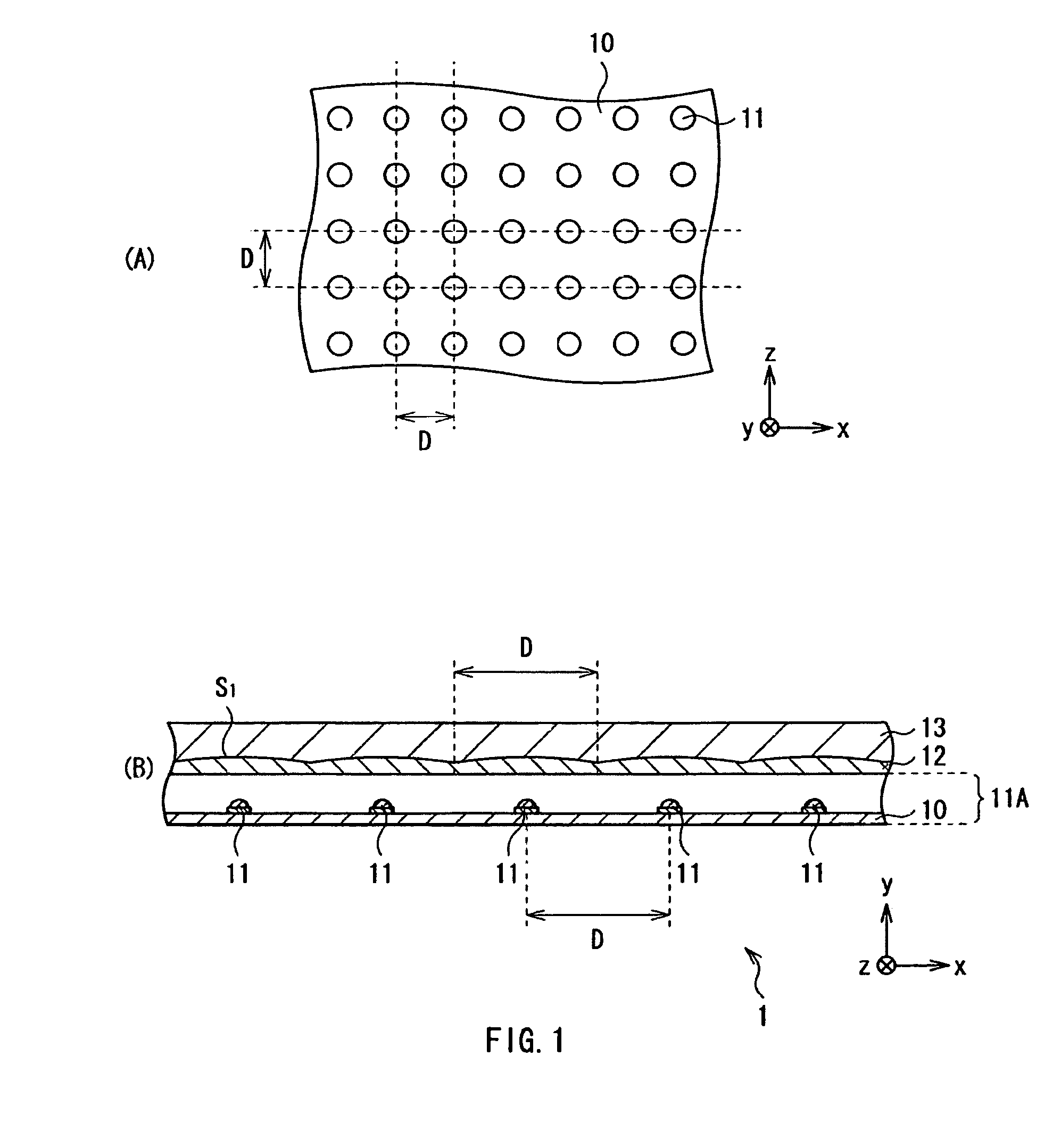

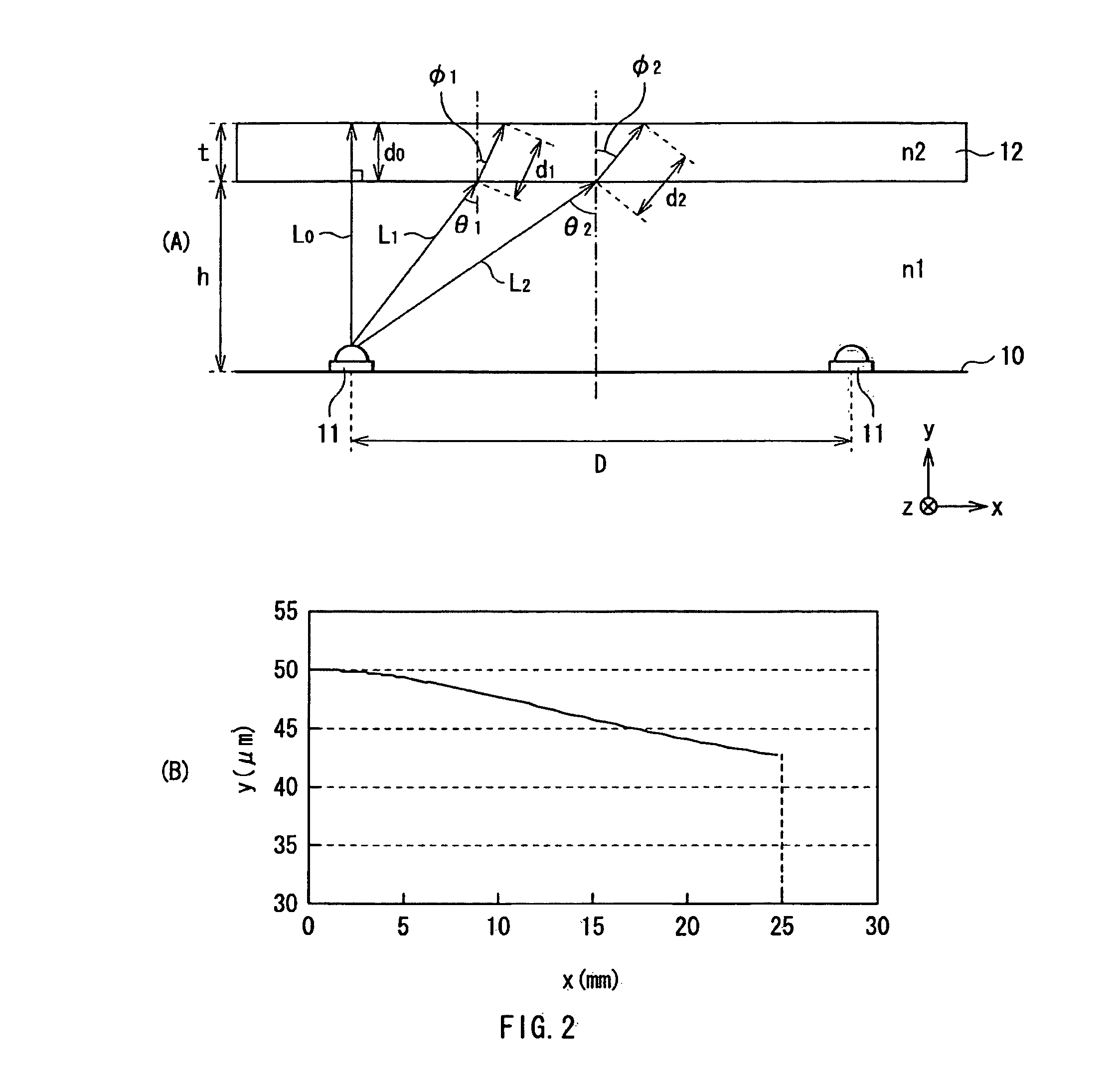

Light source device and display device

ActiveUS20100315320A1Suppress fluctuation of intensitySuppress generationNon-electric lightingPoint-like light sourcePhosphorDisplay device

A light source device capable of suppressing generation of color unevenness, and a display device using the same are provided. The light source device 1 is provided with a plurality of excitation light sources 11 which are arranged at prescribed intervals D on a substrate 10 and emit blue light, and a phosphor layer 12 which converts part of the blue light emitted from the excitation light sources into red light and green light and arranged at a distance from the excitation light sources 11 to oppose the substrate 10. Fluctuation of intensity of each color light due to nonuniform application of the phosphor layer is difficult to occur as compared with a configuration in the past where the phosphor layer is formed adjacent to each excitation light source.

Owner:DEXERIALS CORP

Semiconductor chip and method for manufacturing the same

InactiveUS7067926B2Prevents each device from deterioratingEasily deterioratedTransistorSemiconductor/solid-state device detailsSemiconductor chipEngineering

A semiconductor chip having a plurality of device formative layers that are formed into an integrated thin film is provided by a technique for transferring. According to the present invention, a semiconductor chip that is formed into a thin film and that is highly integrated can be manufactured by transferring a device formative layer with a thickness of at most 50 μm which is separated from a substrate into another substrate by a technique for transferring, and transferring another device formative layer with a thickness of at most 50 μm which is separated from another substrate to the above device formative layer, and, repeating such transferring process.

Owner:SEMICON ENERGY LAB CO LTD

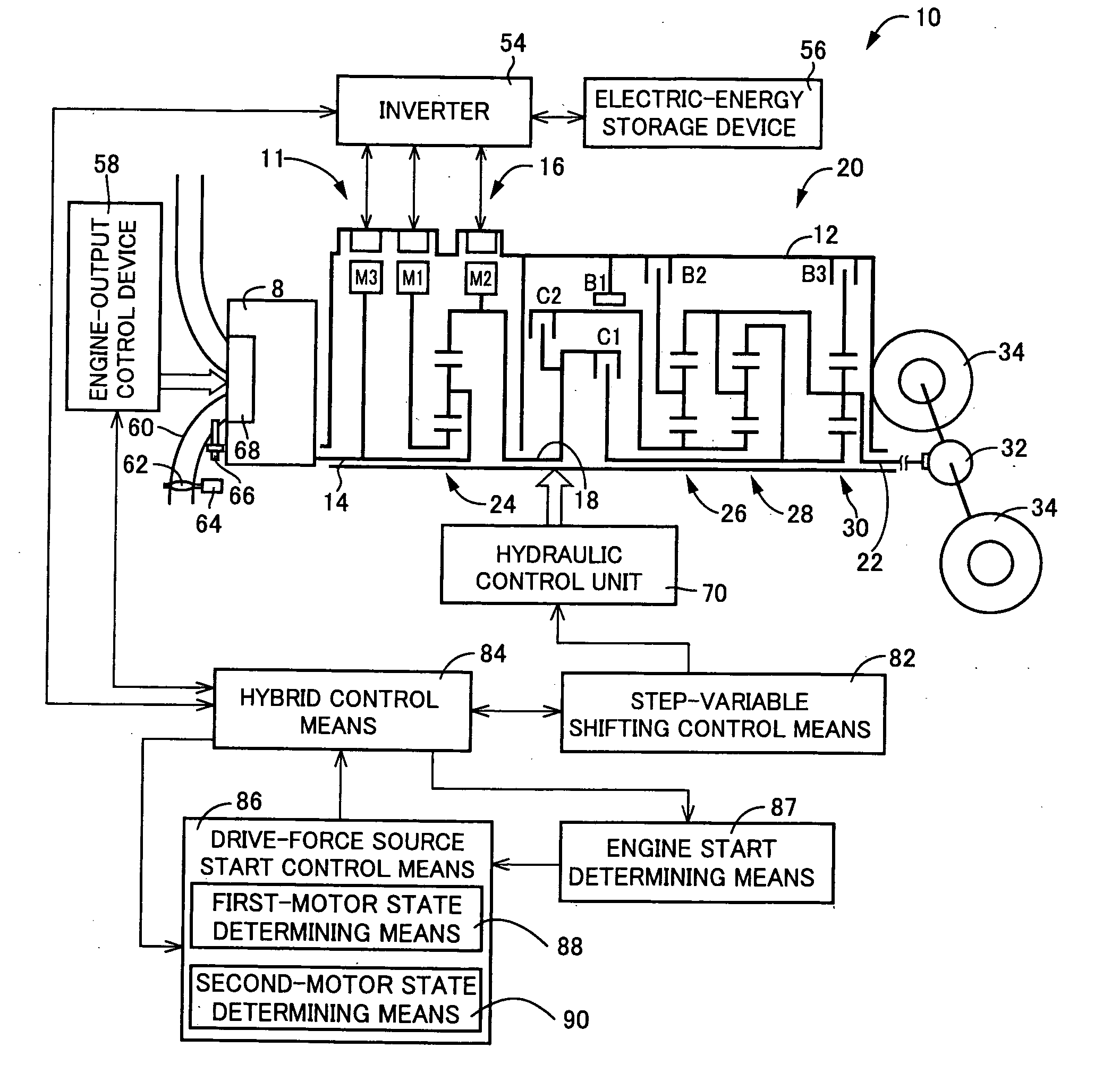

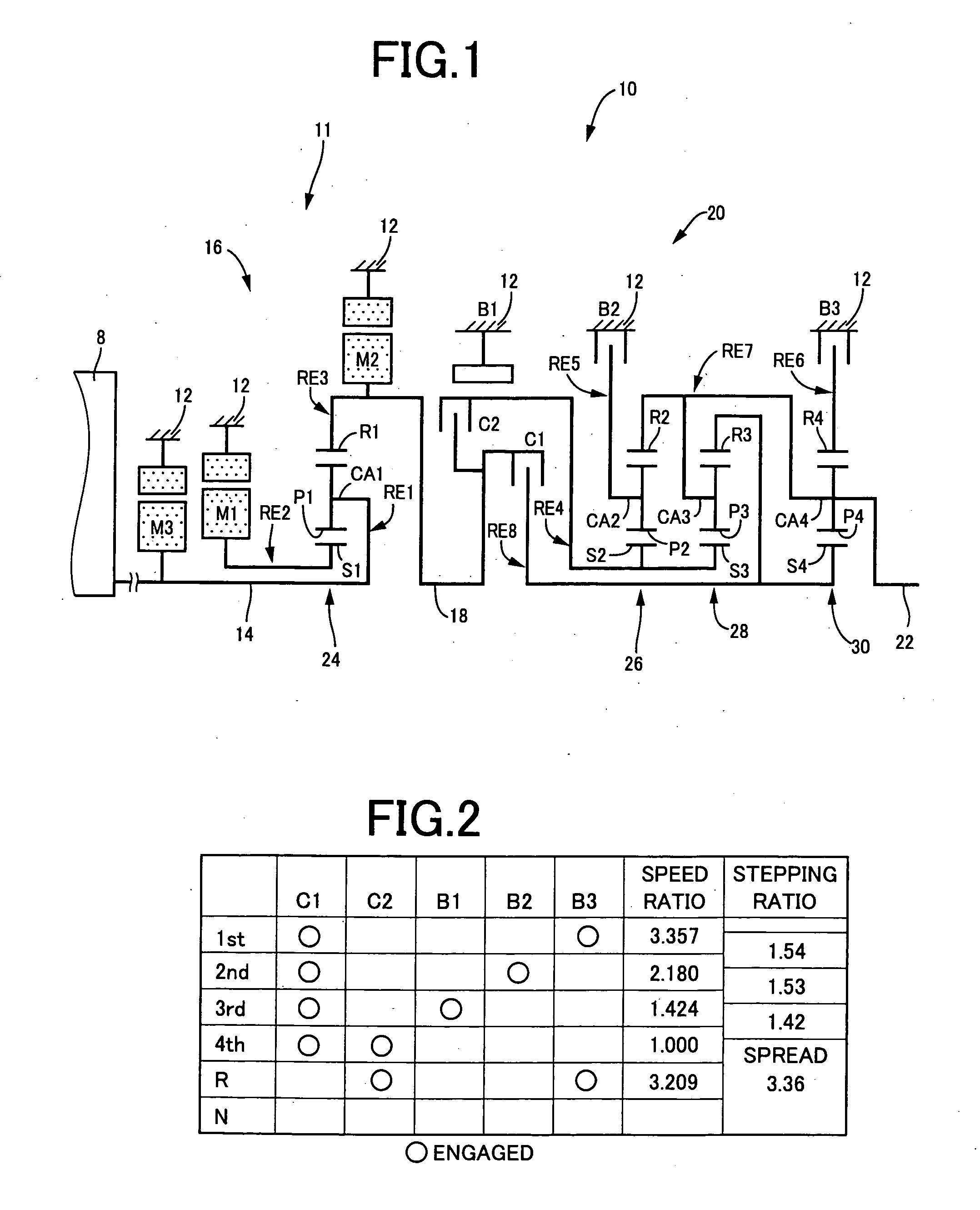

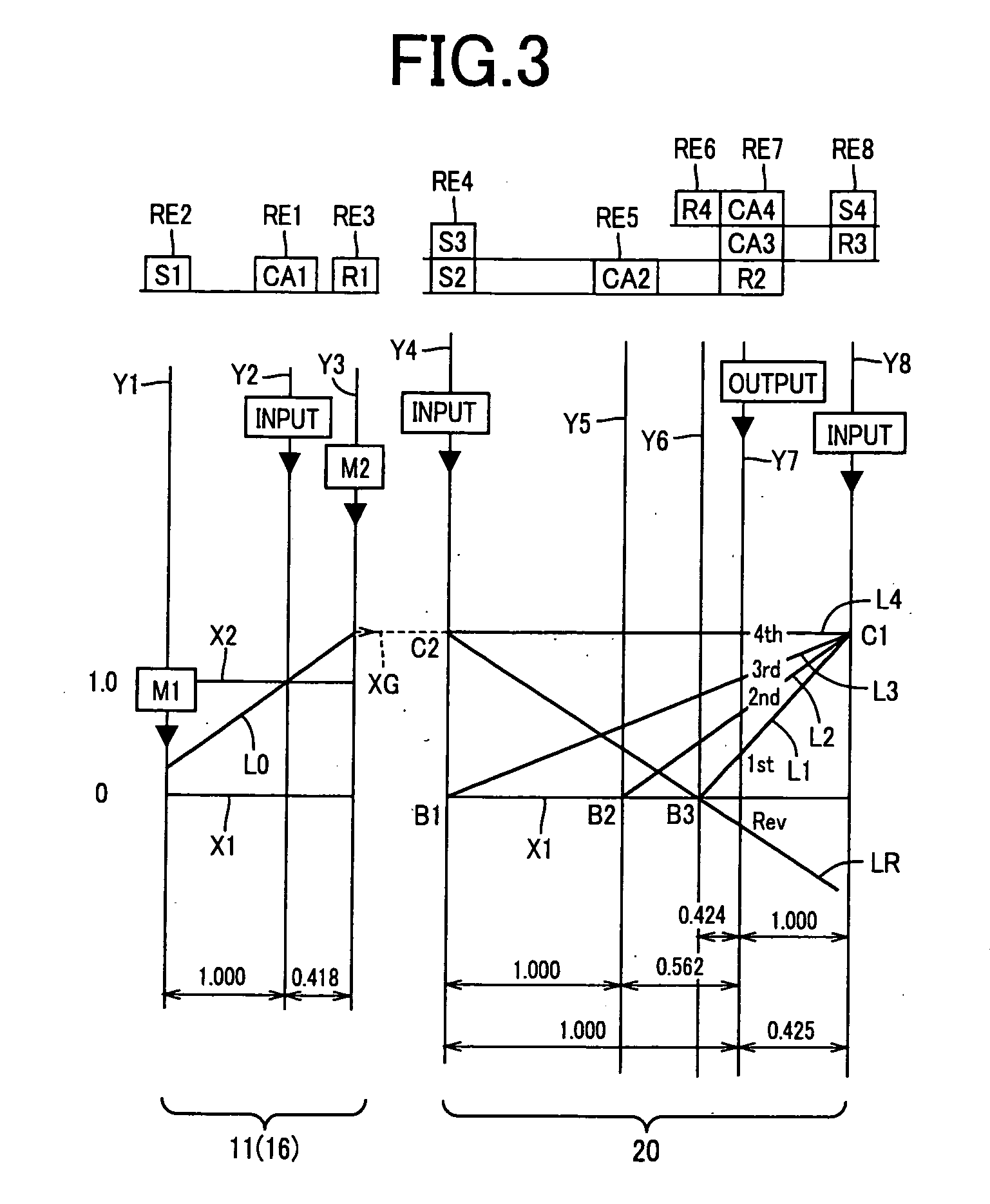

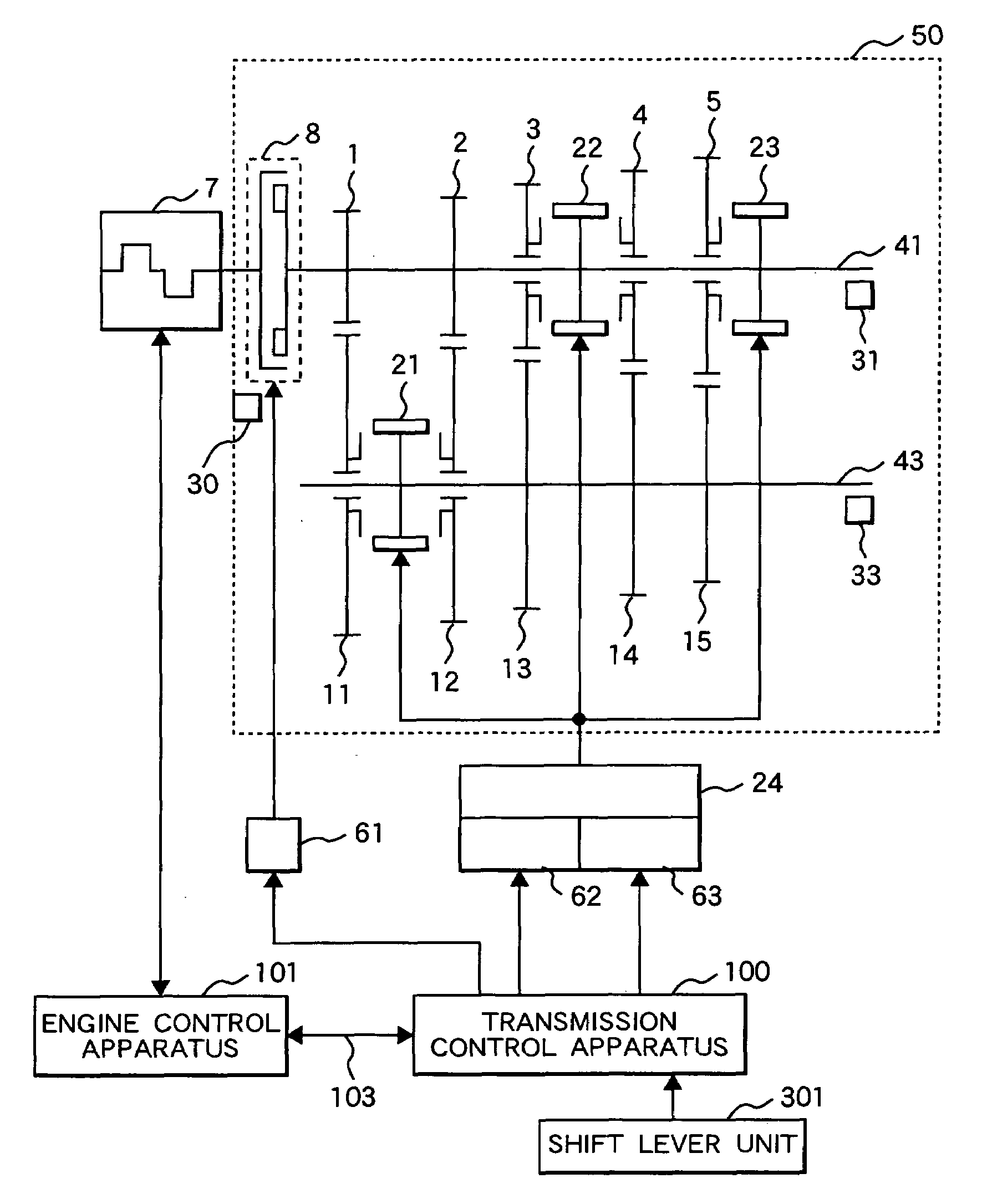

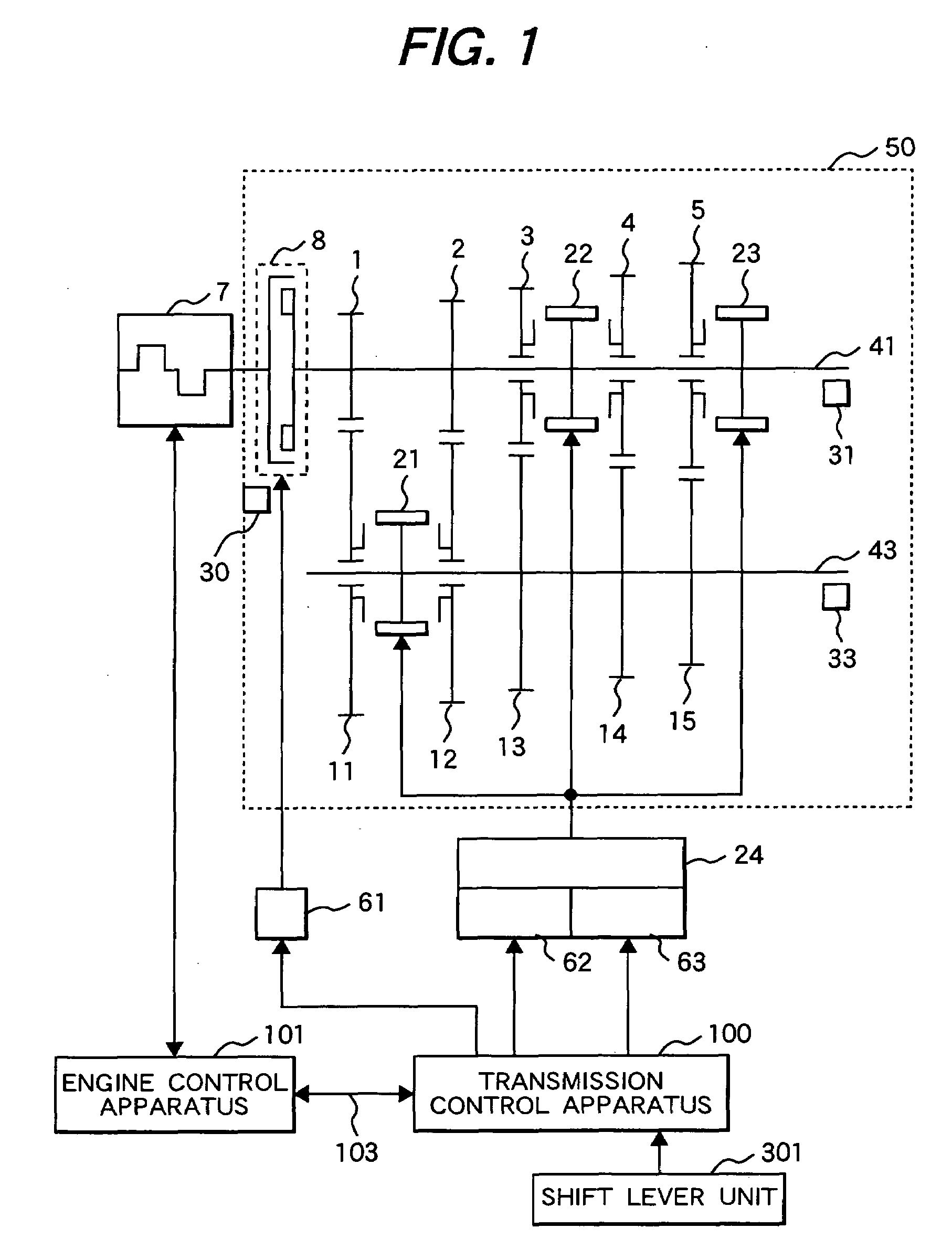

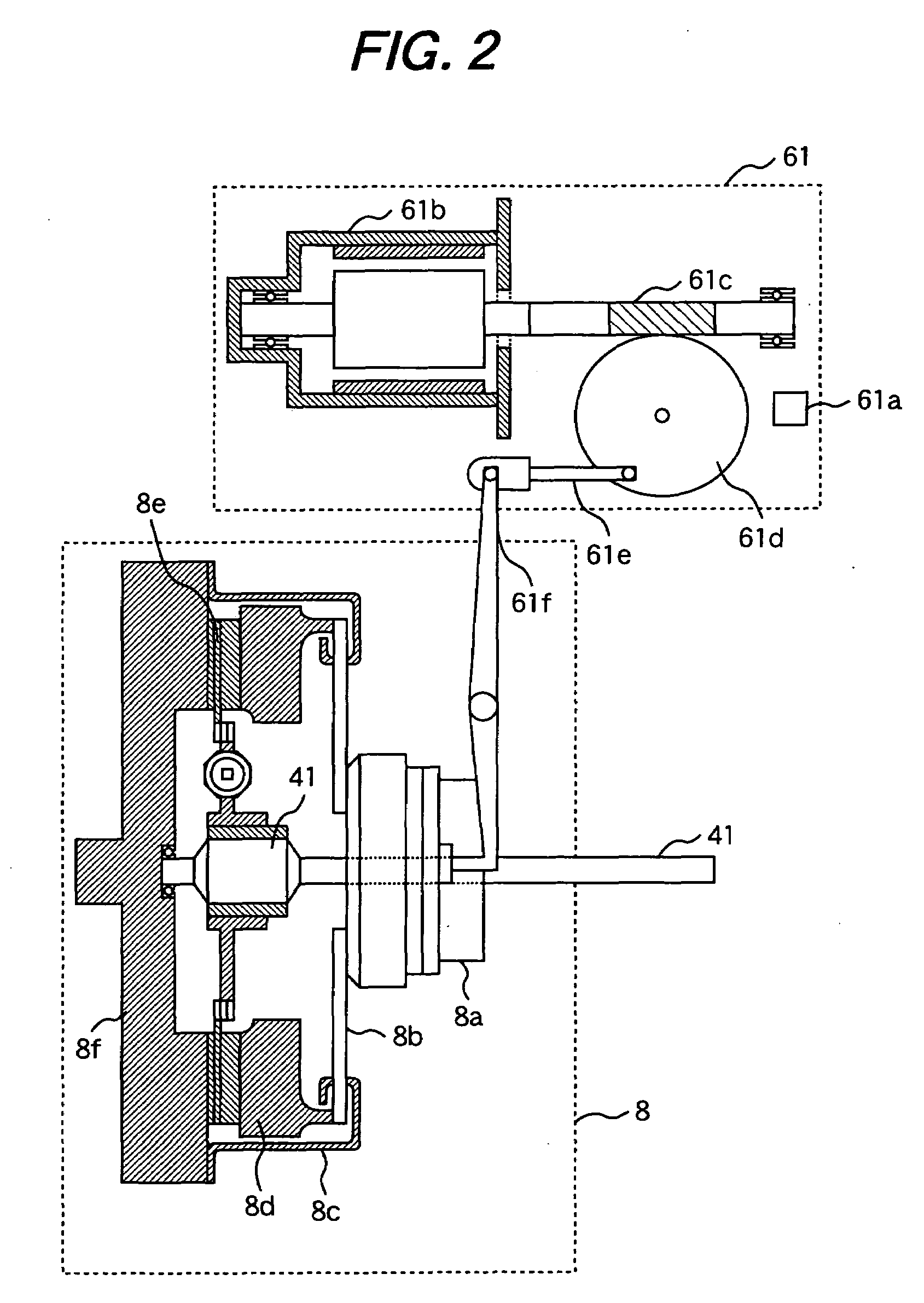

Control device for vehicular power transmitting apparatus

ActiveUS20100125019A1Inhibition of contractionAvoid reductionHybrid vehiclesDC motor speed/torque controlStart timeElectric control

In a vehicular power transmitting apparatus provided with an electrically-controlled differential portion in which controlling an operating state of an electric motor controls a differential state of a differential mechanism, a control device for starting up a drive force source in an appropriate mode depending on a vehicle condition can be provided. The control device includes drive-force source start control means 86 for switching start modes of an engine 8 depending on a vehicle condition to achieve an appropriate start mode for the engine 8 depending on the vehicle condition, so that for instance a contracted drive range by a second electric motor can be avoided.

Owner:TOYOTA JIDOSHA KK

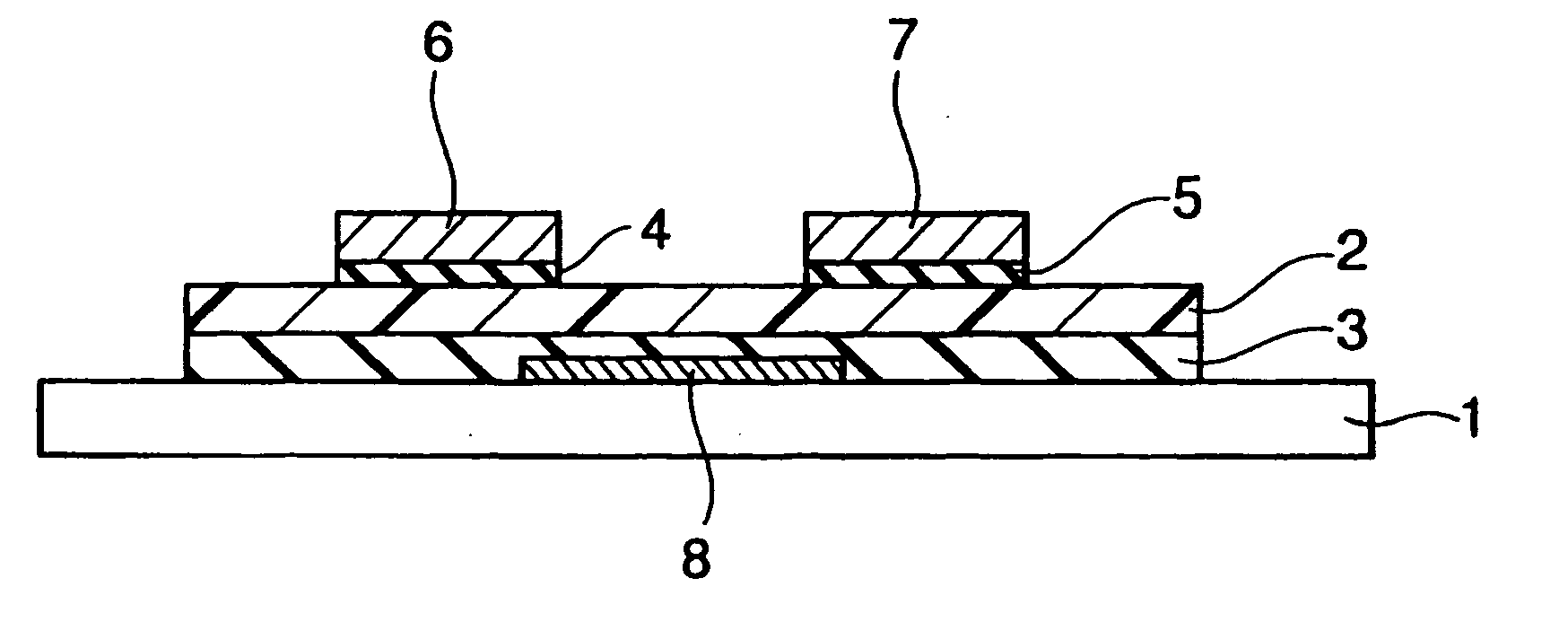

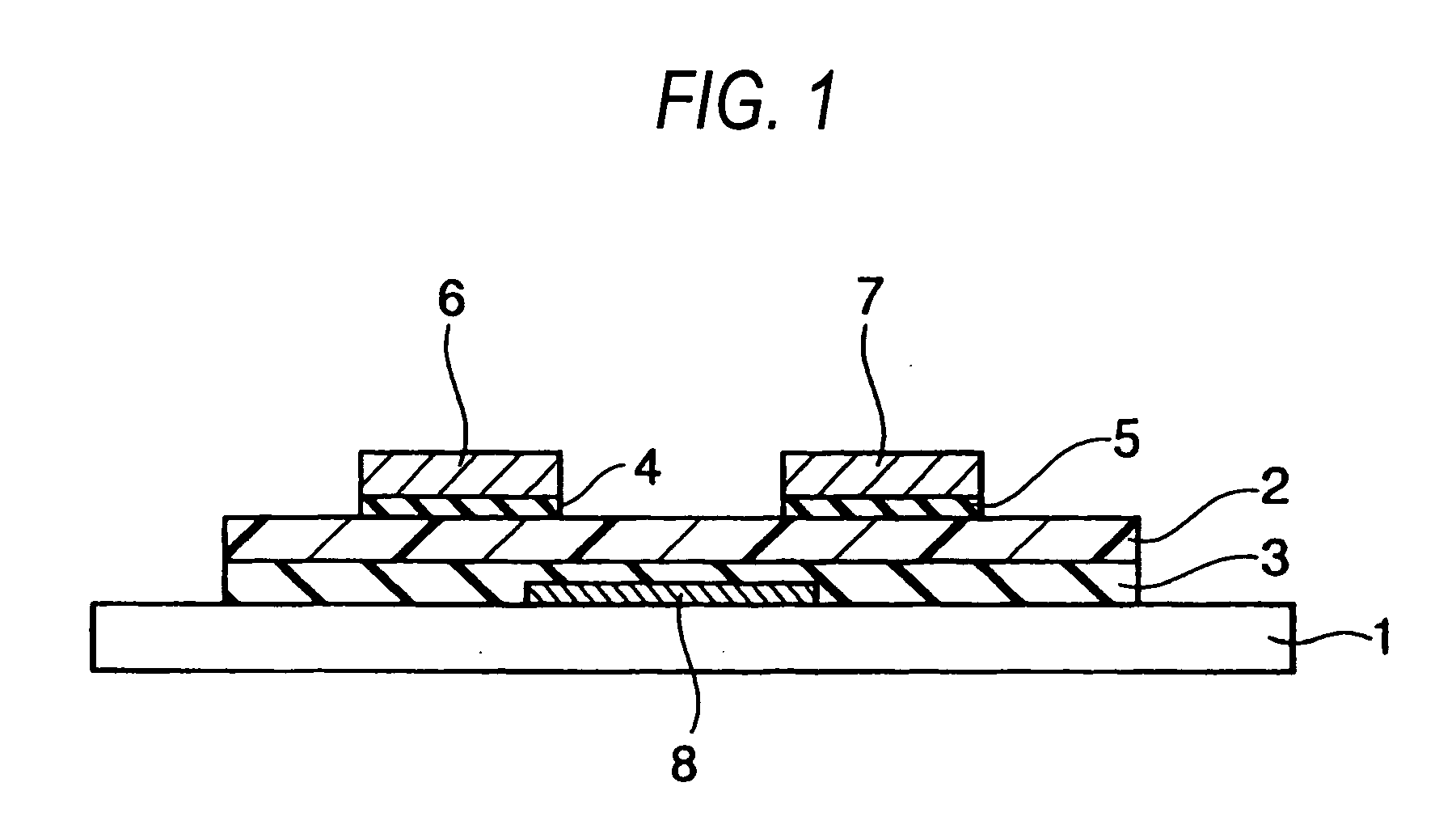

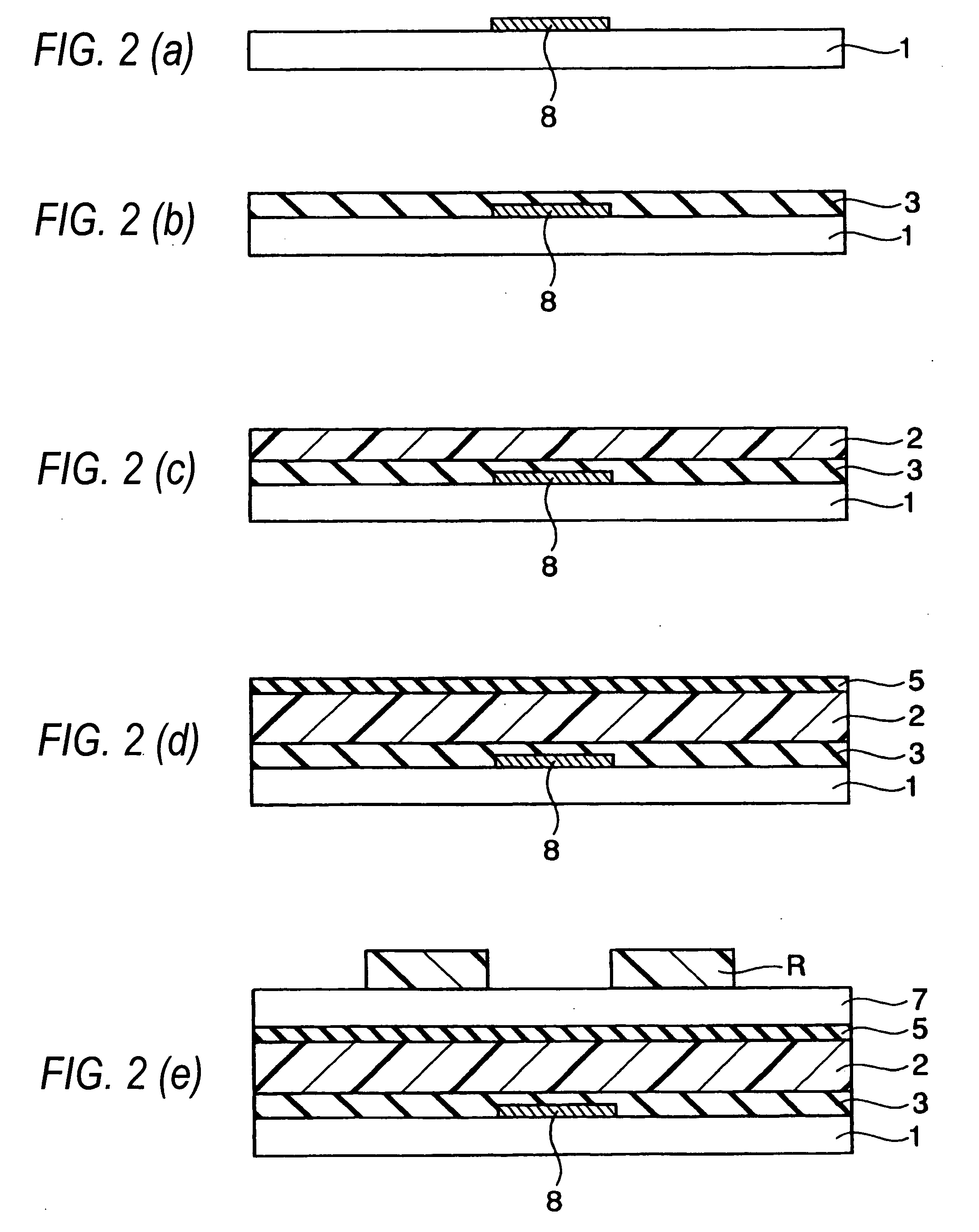

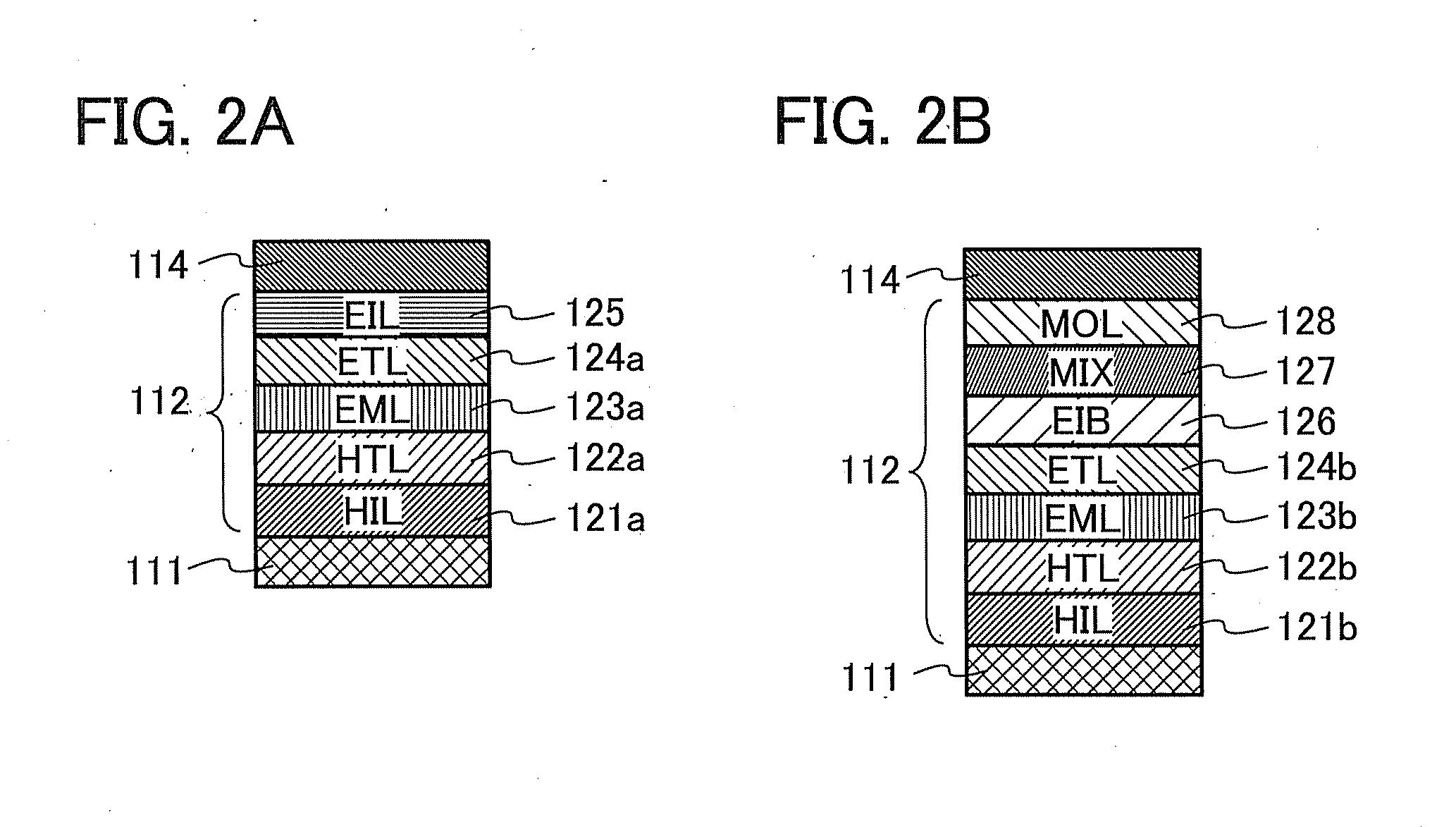

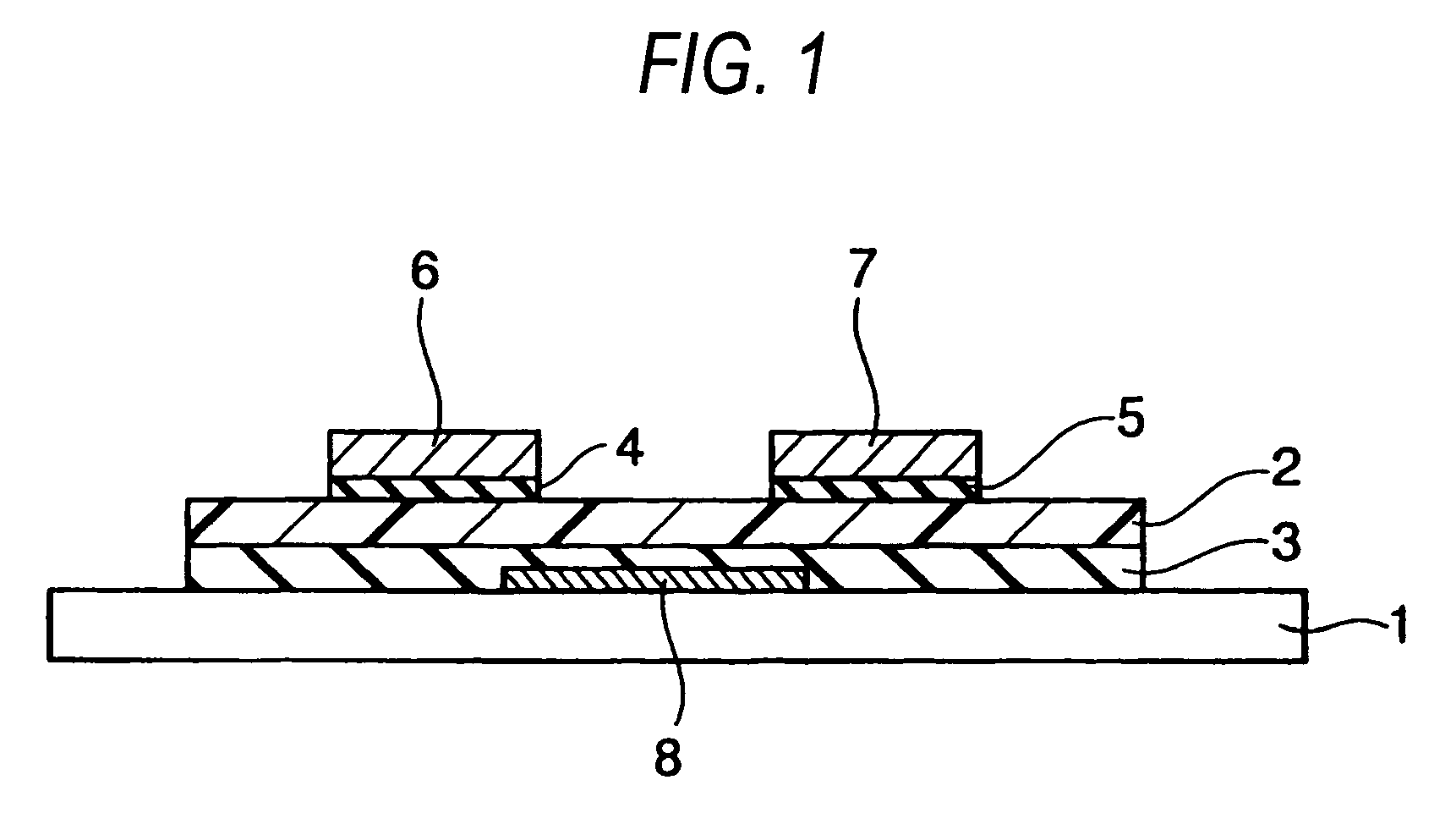

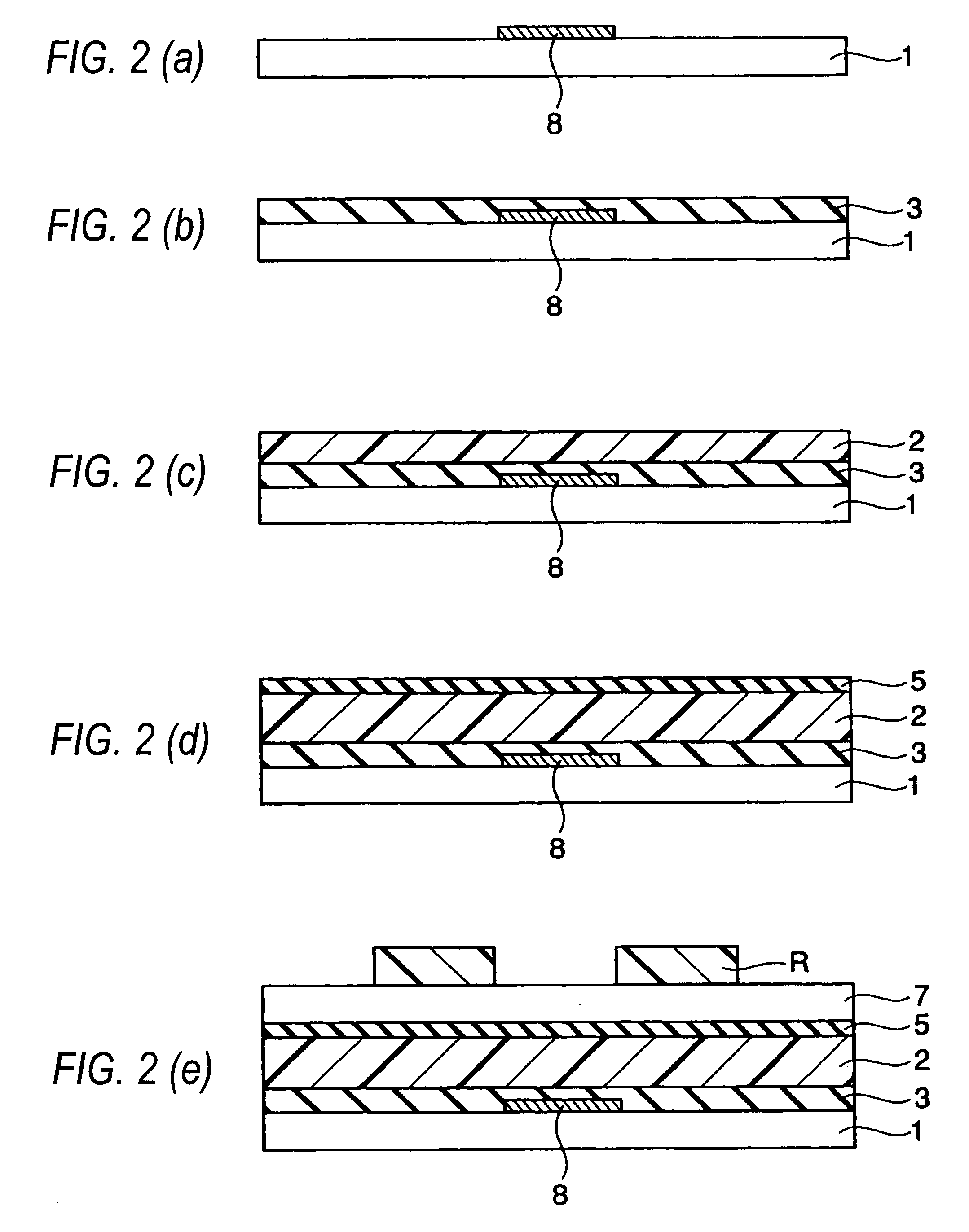

Organic field effect transistor and method of manufacturing the same

InactiveUS20050263756A1Characteristic changeExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingCharge injectionContact formation

To provide an organic field effect transistor with stable characteristics and a long life span, an organic field effect transistor includes a gate electrode 8 formed on an organic semiconductor film 2 made of an organic semiconductor material with a gate insulating film 3 interposed therebetween; and a source electrode 6 and a drain electrode 7 provided so as to come in contacts with the organic semiconductor film with the gate electrode 8 interposed therebetween. At least one of the source electrode 6 and the drain electrode 7 is formed in contact with the organic semiconductor film 2 with charge injection layers 4 and 5 made of an inorganic material interposed therebetween.

Owner:PANASONIC CORP

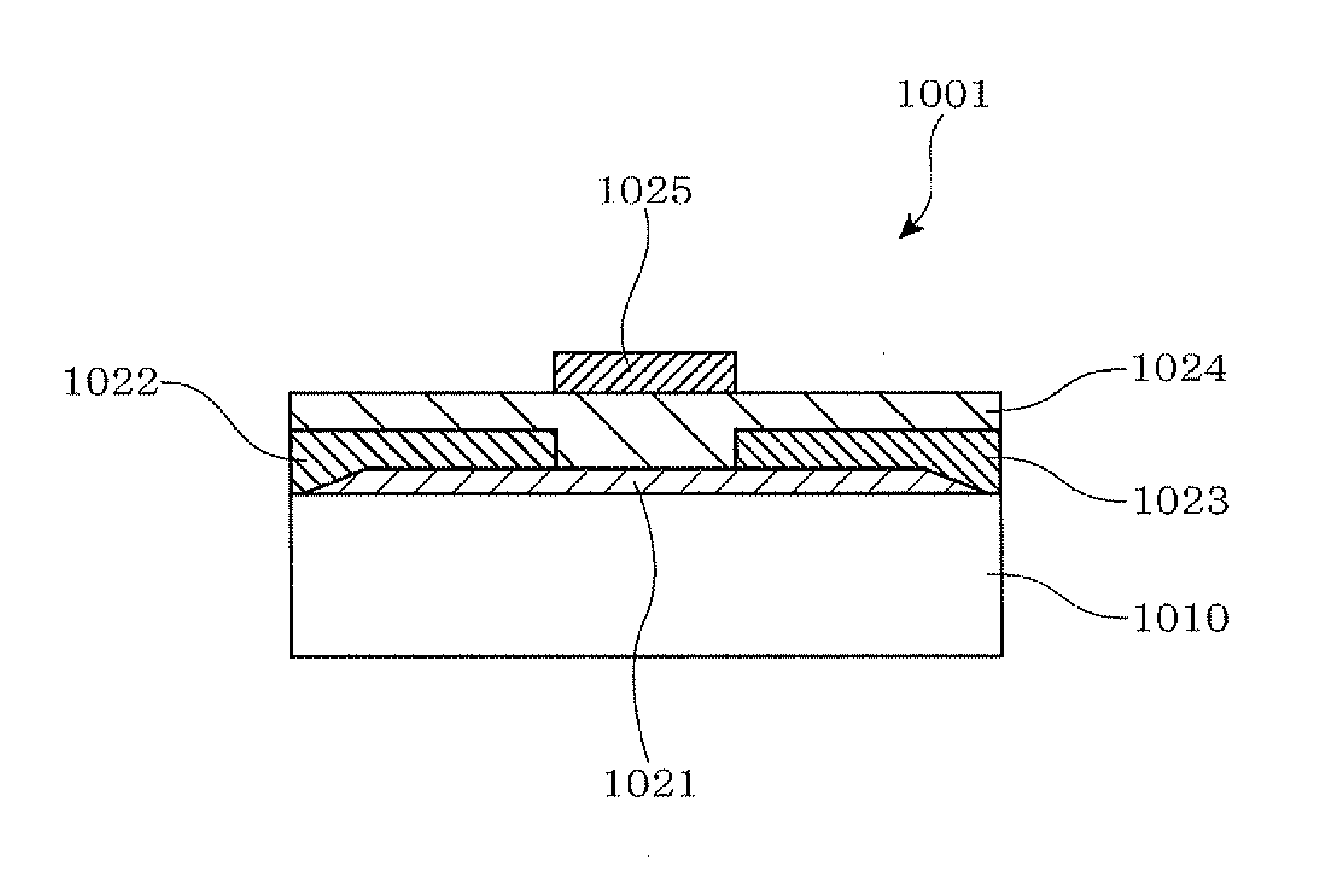

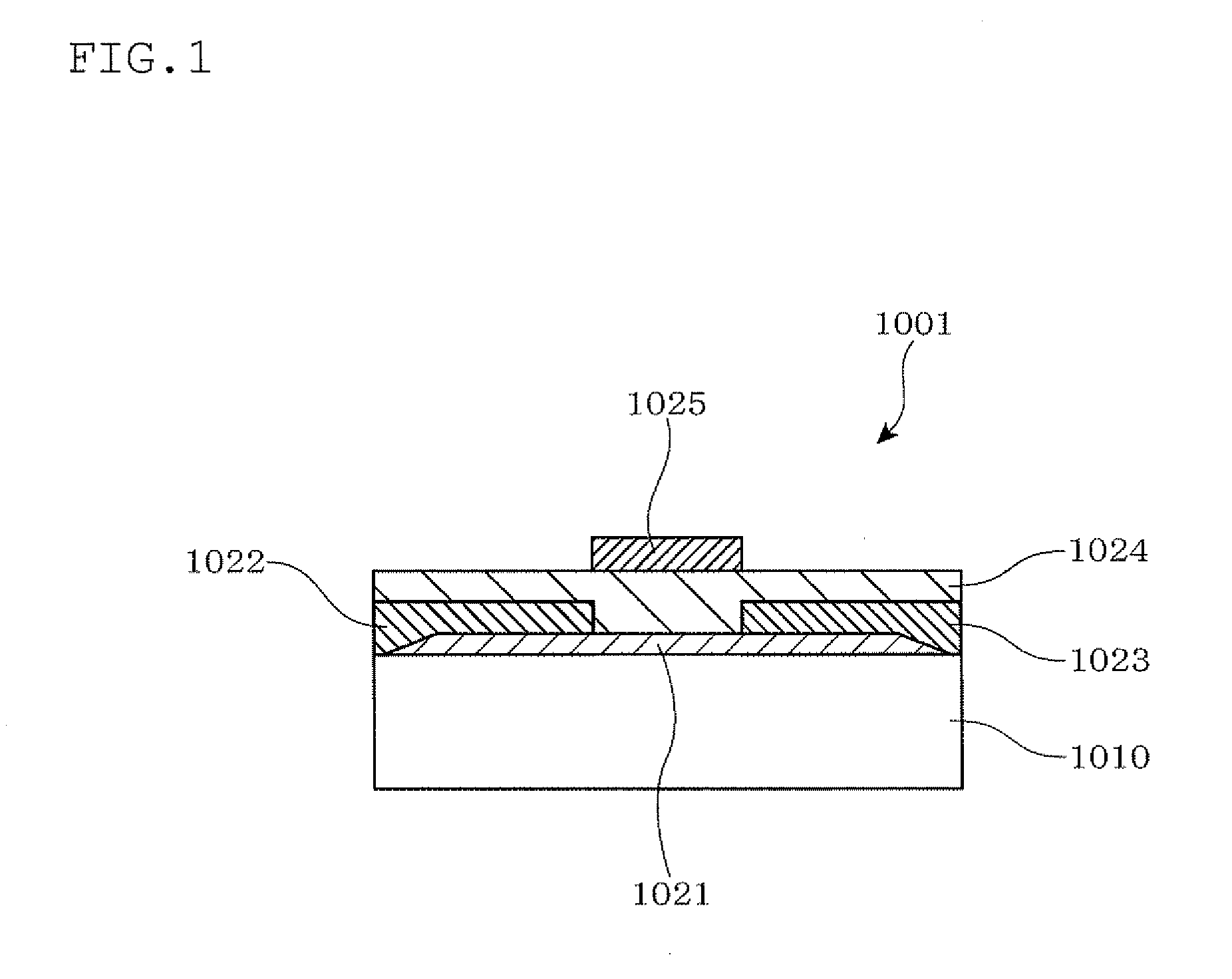

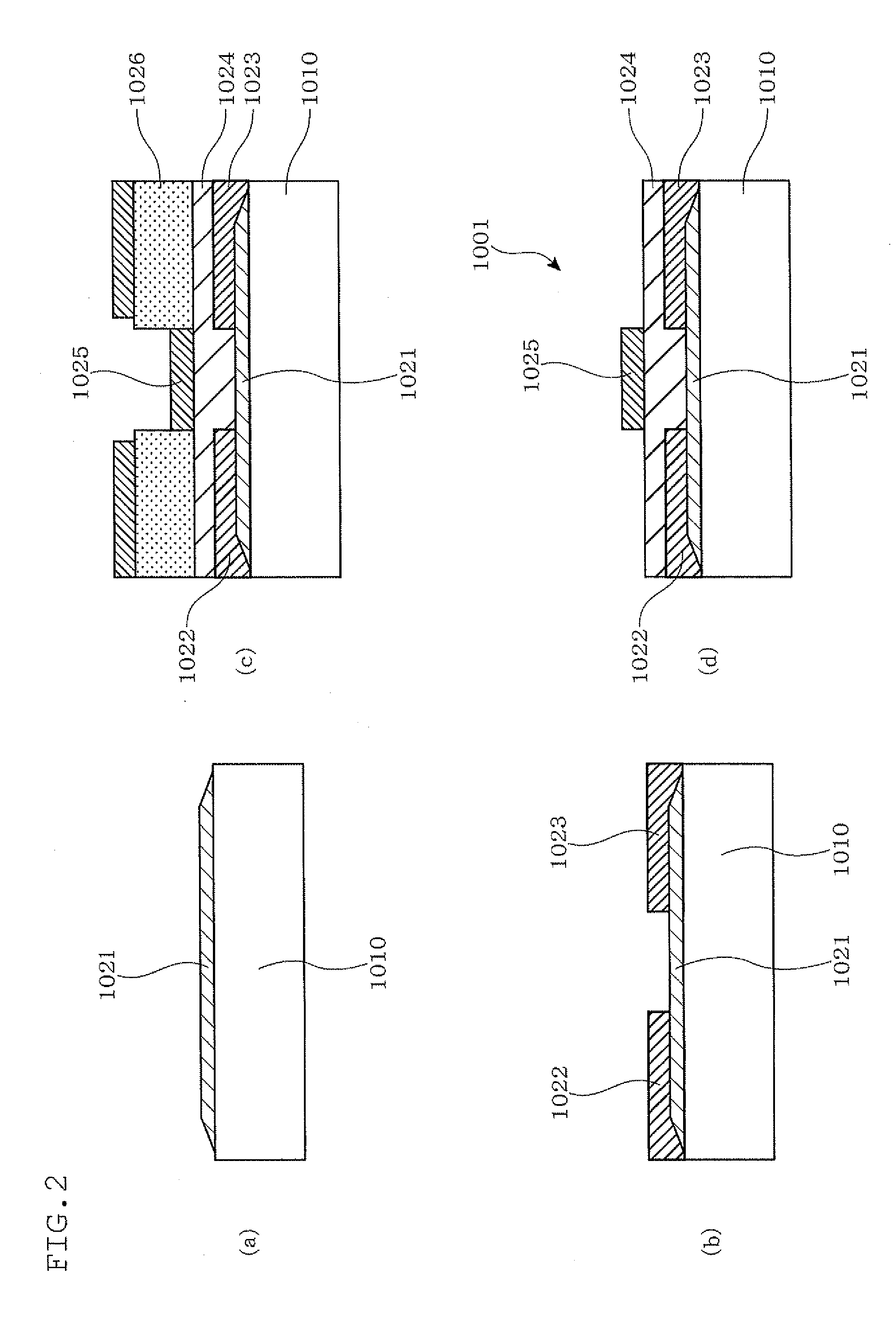

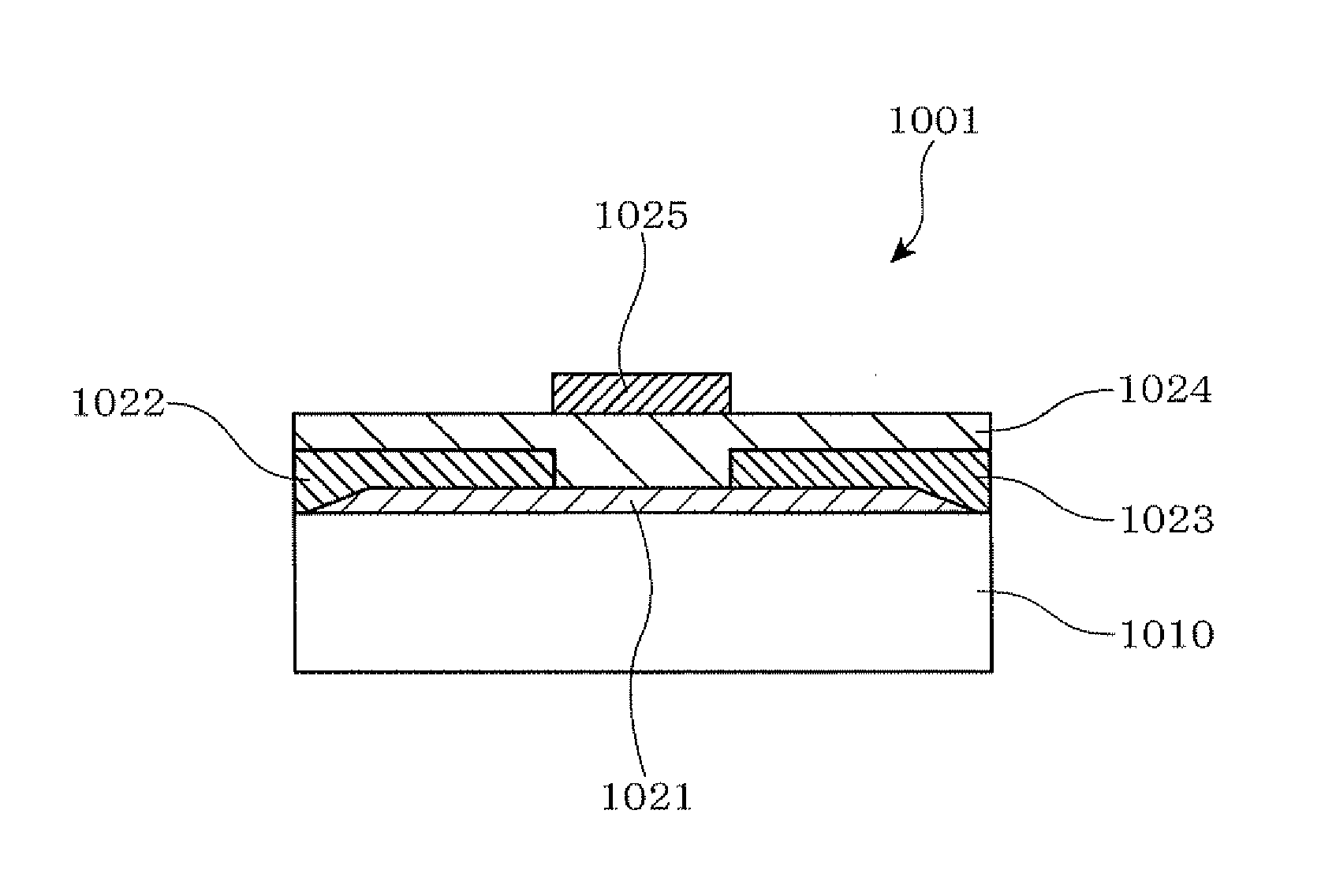

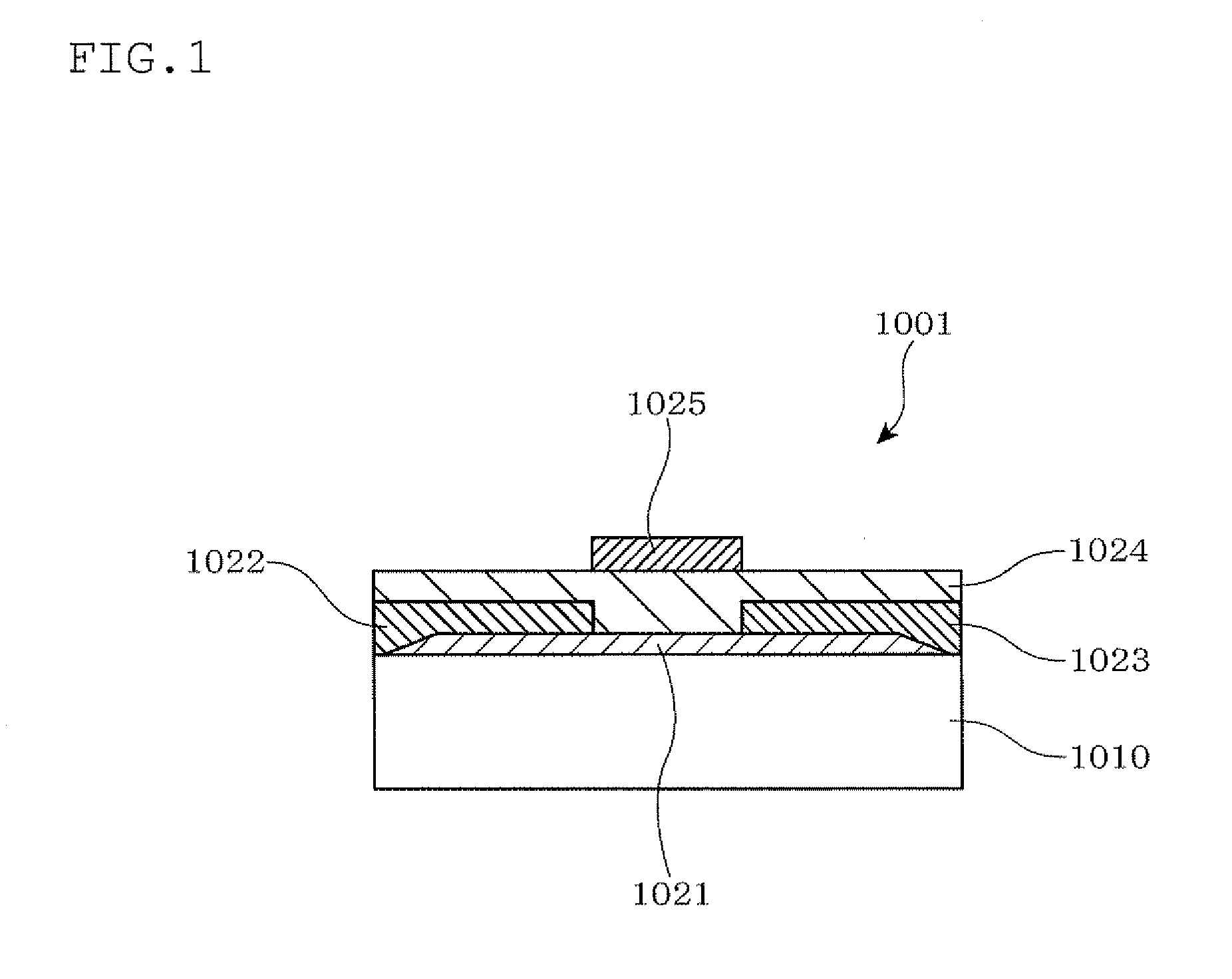

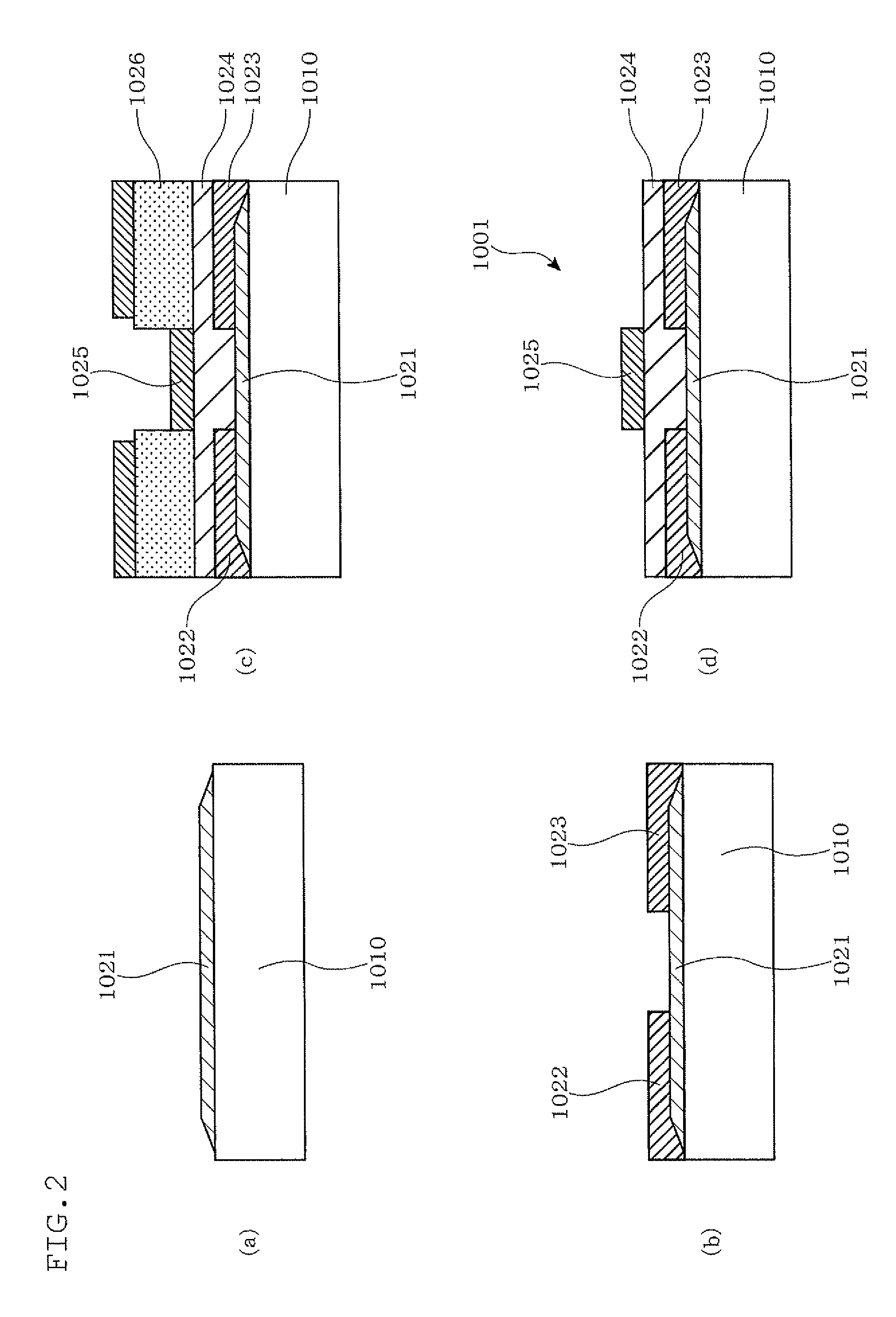

Field-effect transistor, and process for producing field-effect transistor

ActiveUS20100117071A1Increase freedomEfficient productionTransistorSemiconductor/solid-state device manufacturingCrystalline oxideIndium

To provide a field-effect transistor improved in transparency, electrical properties, stability, uniformity, reproducibility, heat resistance and durability, and as a reduced overlap capacity between electrodes.A field-effect thin film transistor 1001 includes a gate electrode 1025, an active layer, a source electrode 1022 and a drain electrode 1023, wherein a crystalline oxide 1021 containing indium and having an electron carrier concentration of less than 1018 / cm3 is used as the active layer, and the gate electrode 1025 is in self-alignment with the source electrode 1022 and the drain electrode 1023. The crystalline oxide 1021 contains a positive trivalent element different from a positive divalent element or indium.

Owner:IDEMITSU KOSAN CO LTD

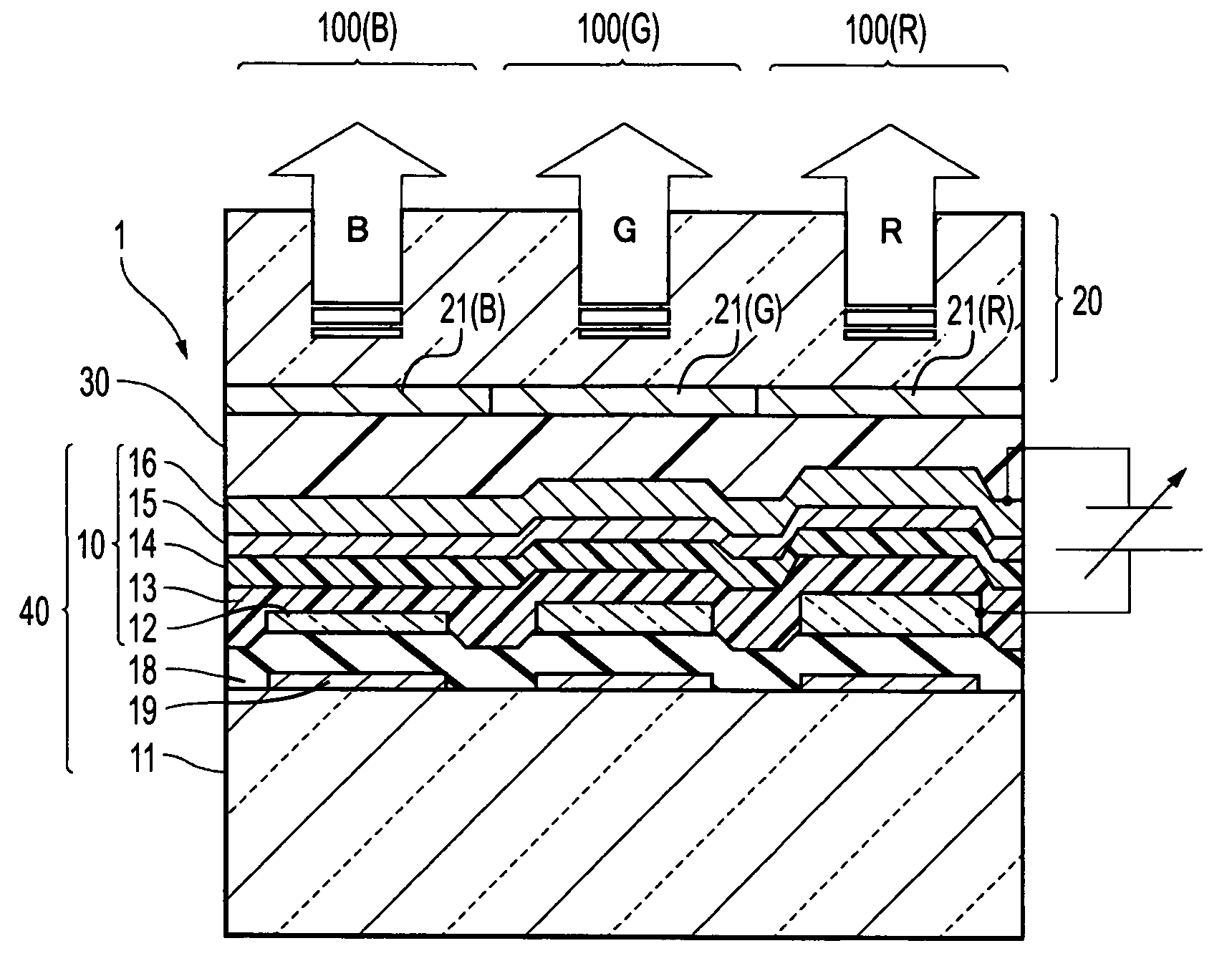

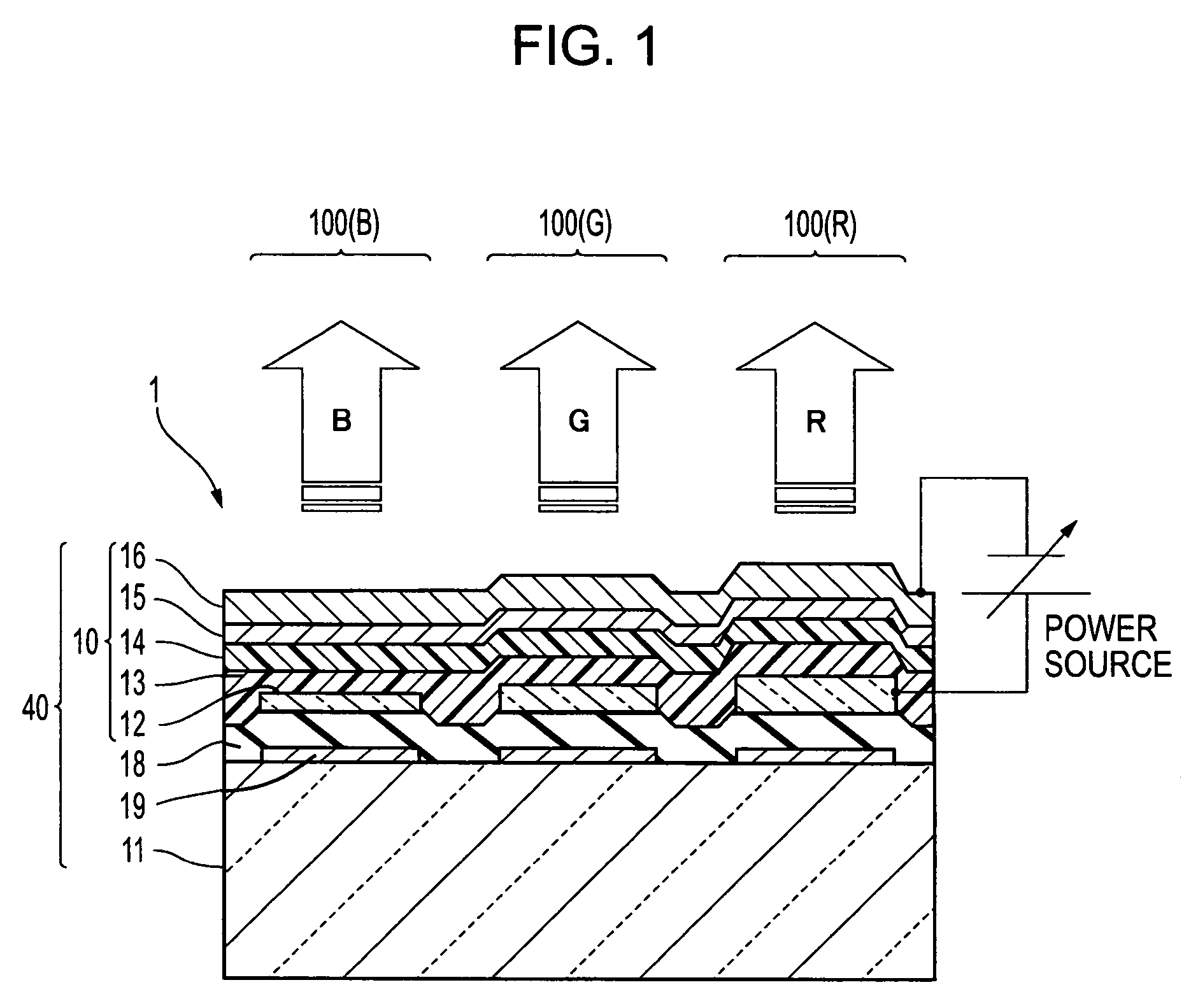

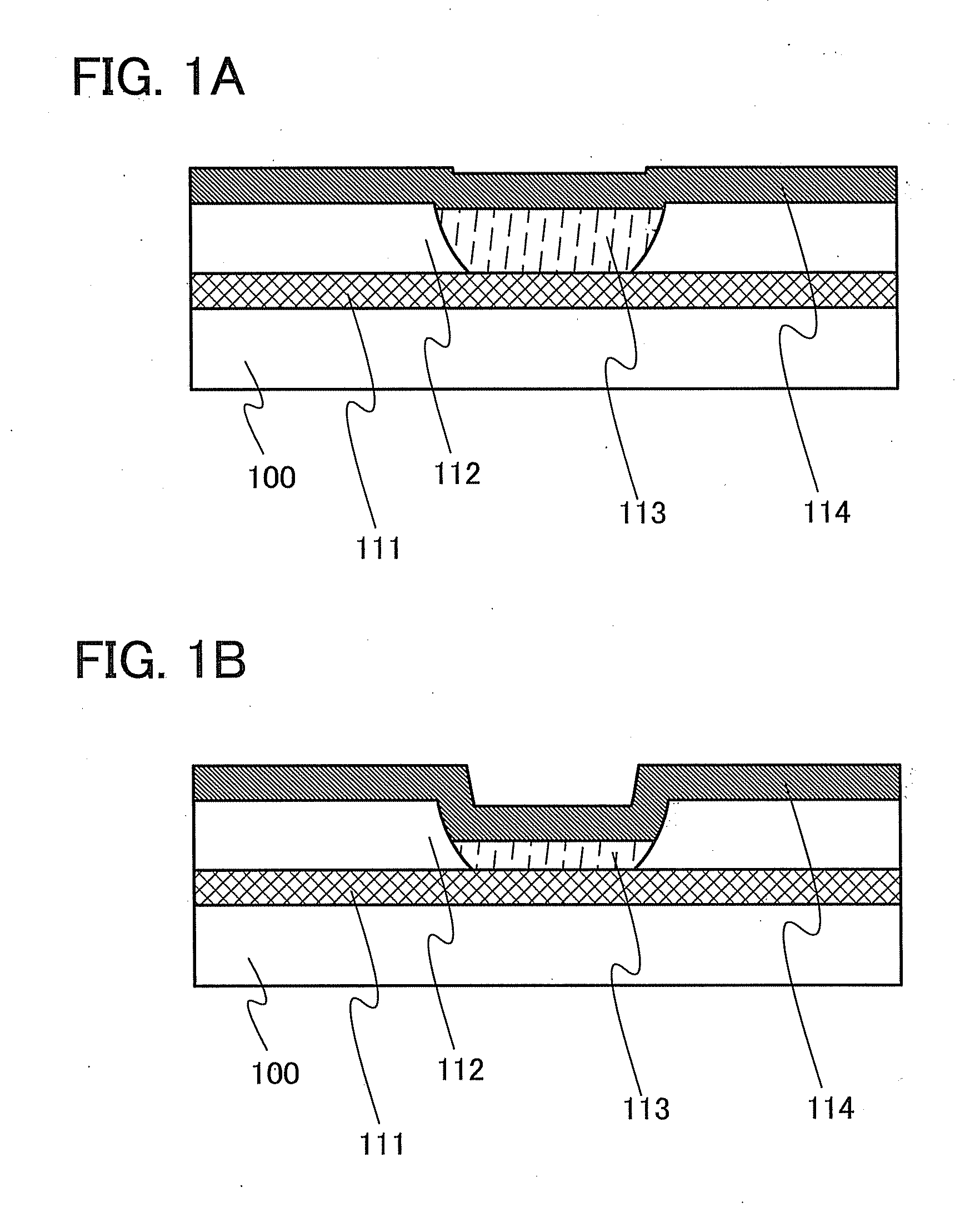

Light emitting apparatus

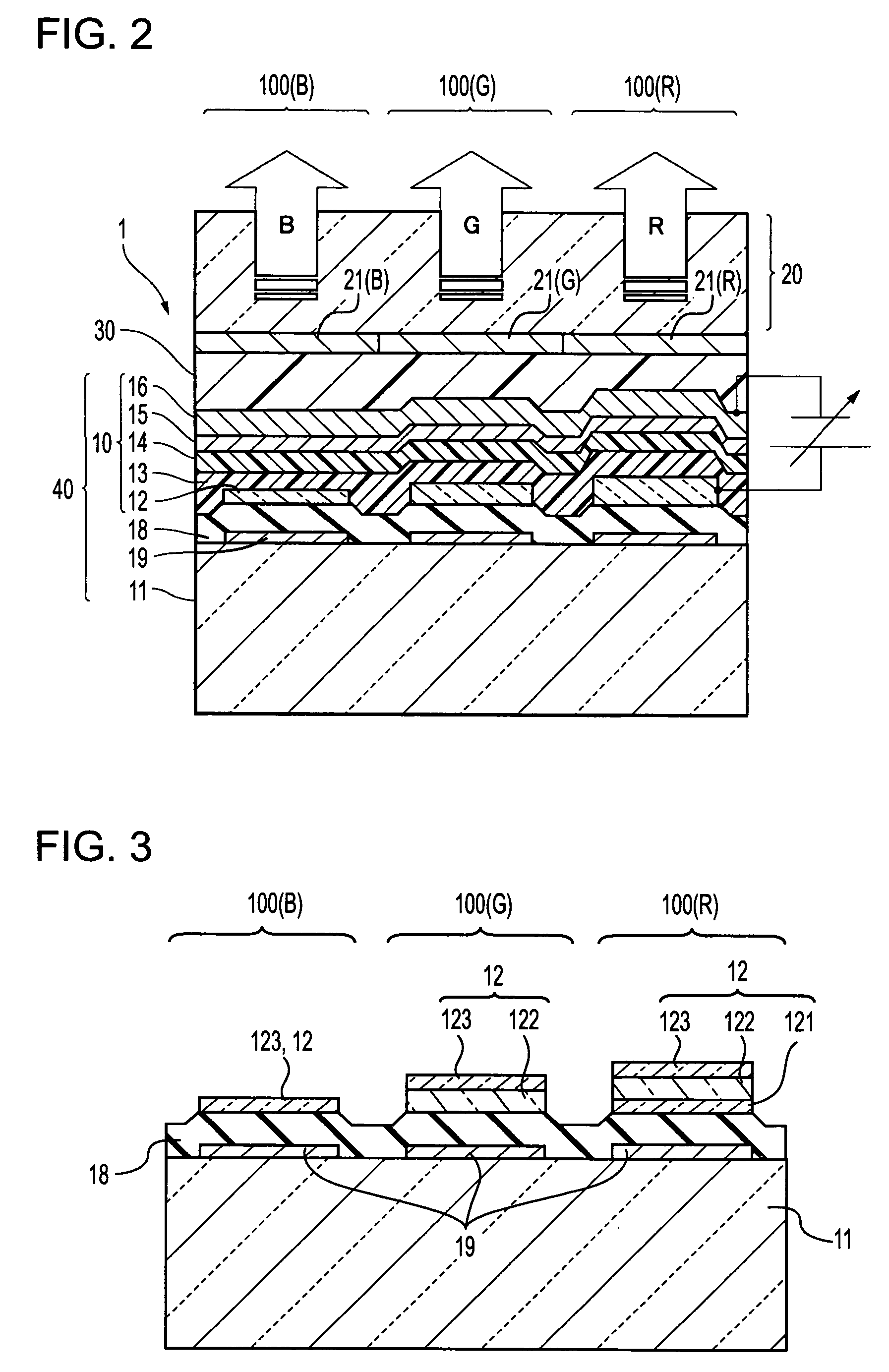

ActiveUS20060214573A1Easily deterioratedImprove productivityPipe supportsDischarge tube luminescnet screensPhysicsResonator

A light emitting apparatus having light emitting devices having a stack of a light-transmitting anode, a functional layer including at least a light emitting layer, and a cathode for a plurality of pixels corresponding to red, green, and blue colors on a substrate, wherein an optical resonator having a lower-layer-side reflecting layer at a lower-layer side of the anode is formed in the light emitting device, wherein a plurality of the pixels include pixels which correspond to different thicknesses of a anode, and wherein a light-transmitting insulating protective film is formed between the anode and the lower-layer-side reflecting layer to cover the lower-layer-side reflecting layer.

Owner:SEIKO EPSON CORP

Method Of Treating The Surface Of Copper And Copper

ActiveUS20080096046A1Easily deterioratedVariation in the height of the irregularitiesDecorative surface effectsPrinted circuit aspectsCopperOxidizing agent

A method of treating the surface of copper is provided to ensure adhesive strength between the surface of copper and an insulating layer without forming irregularities exceeding 1 μm on the surface of copper and to improve insulation reliability between wirings. A copper whose surface is treated by the above surface treating method is also provided. The method of treating the surface of copper comprises the surface of copper comprising the steps of: forming a metal nobler than copper discretely on the surface of copper; and subsequently oxidizing the surface of copper by using an alkaline solution containing an oxidant.

Owner:RESONAC CORP

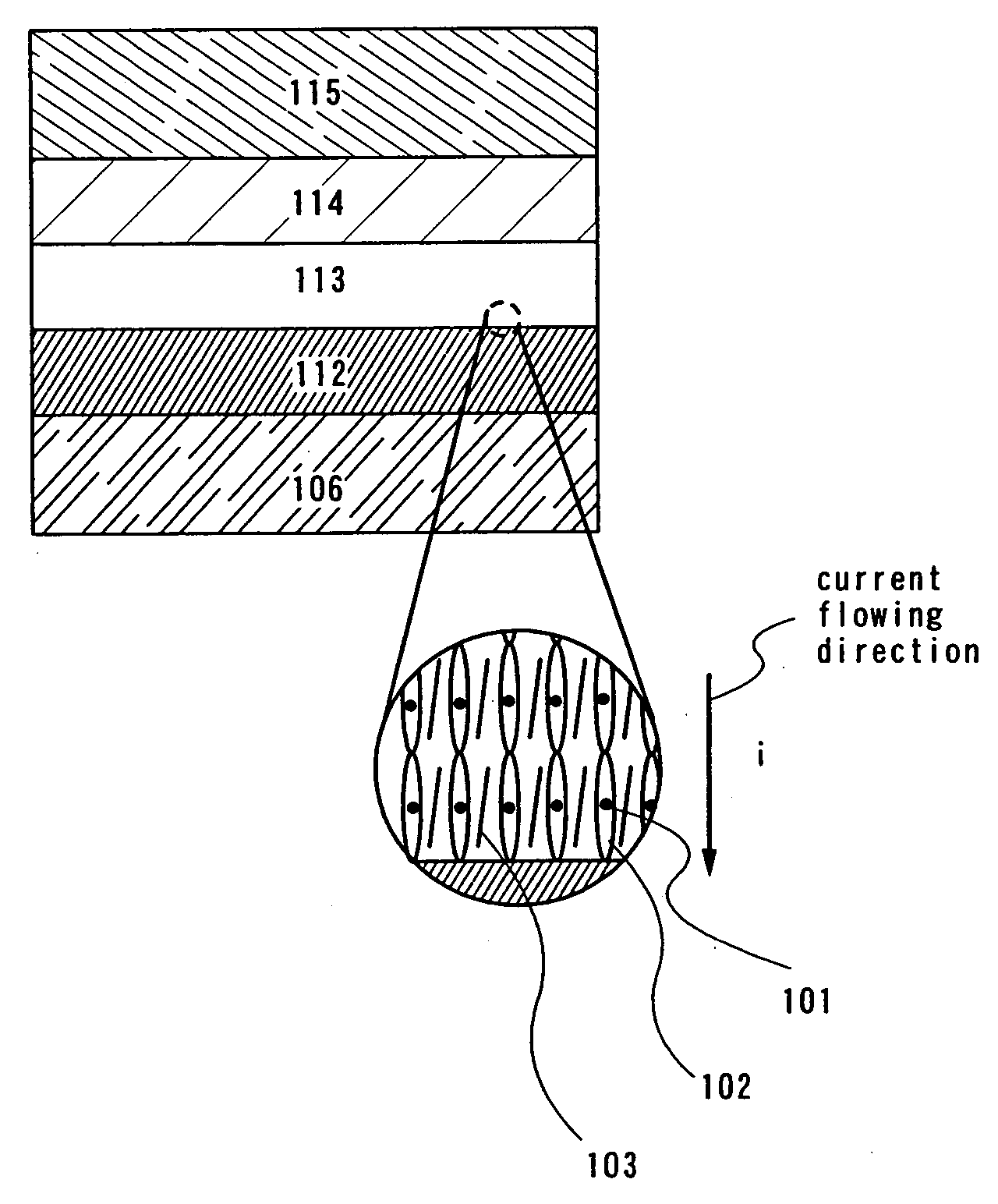

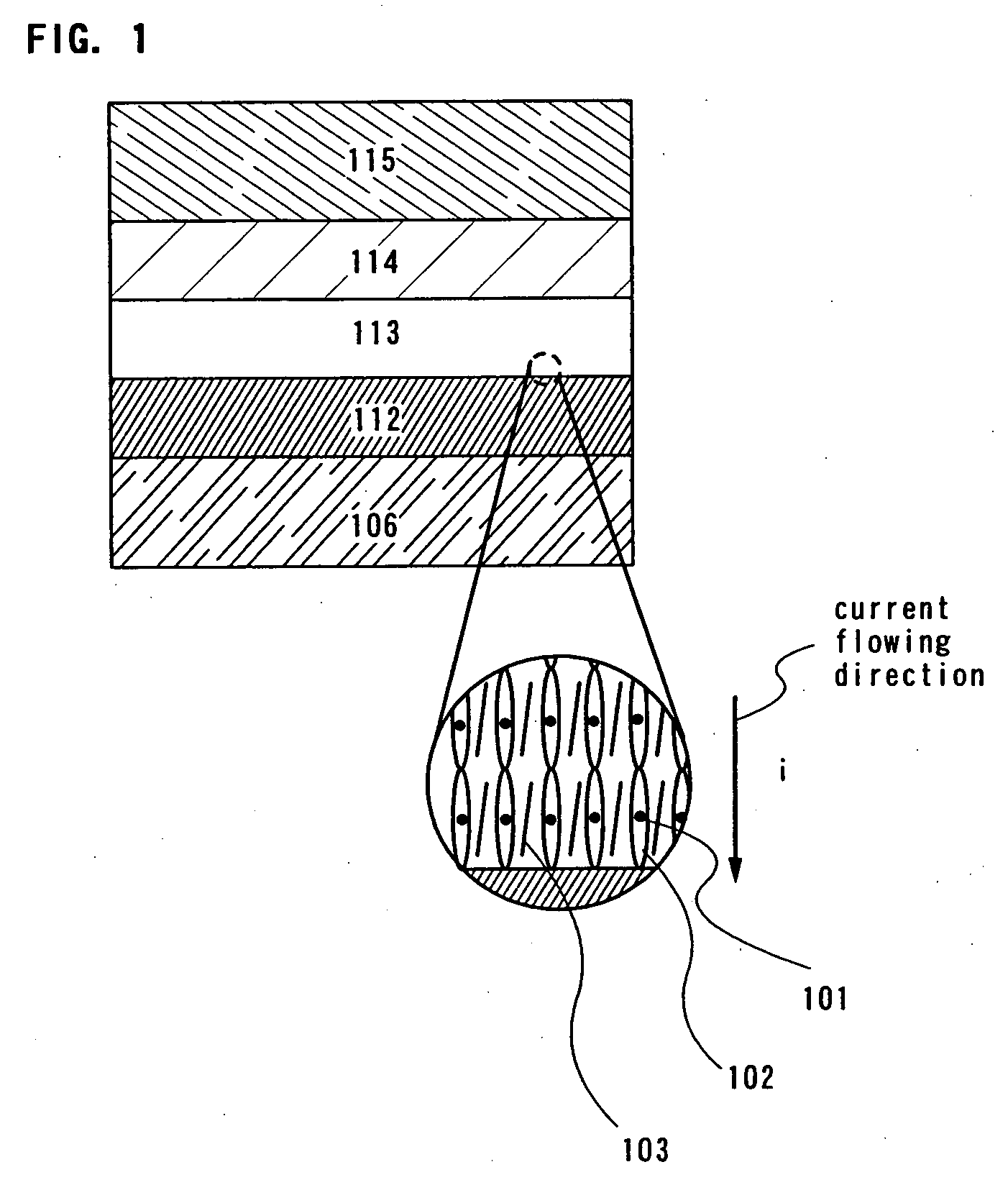

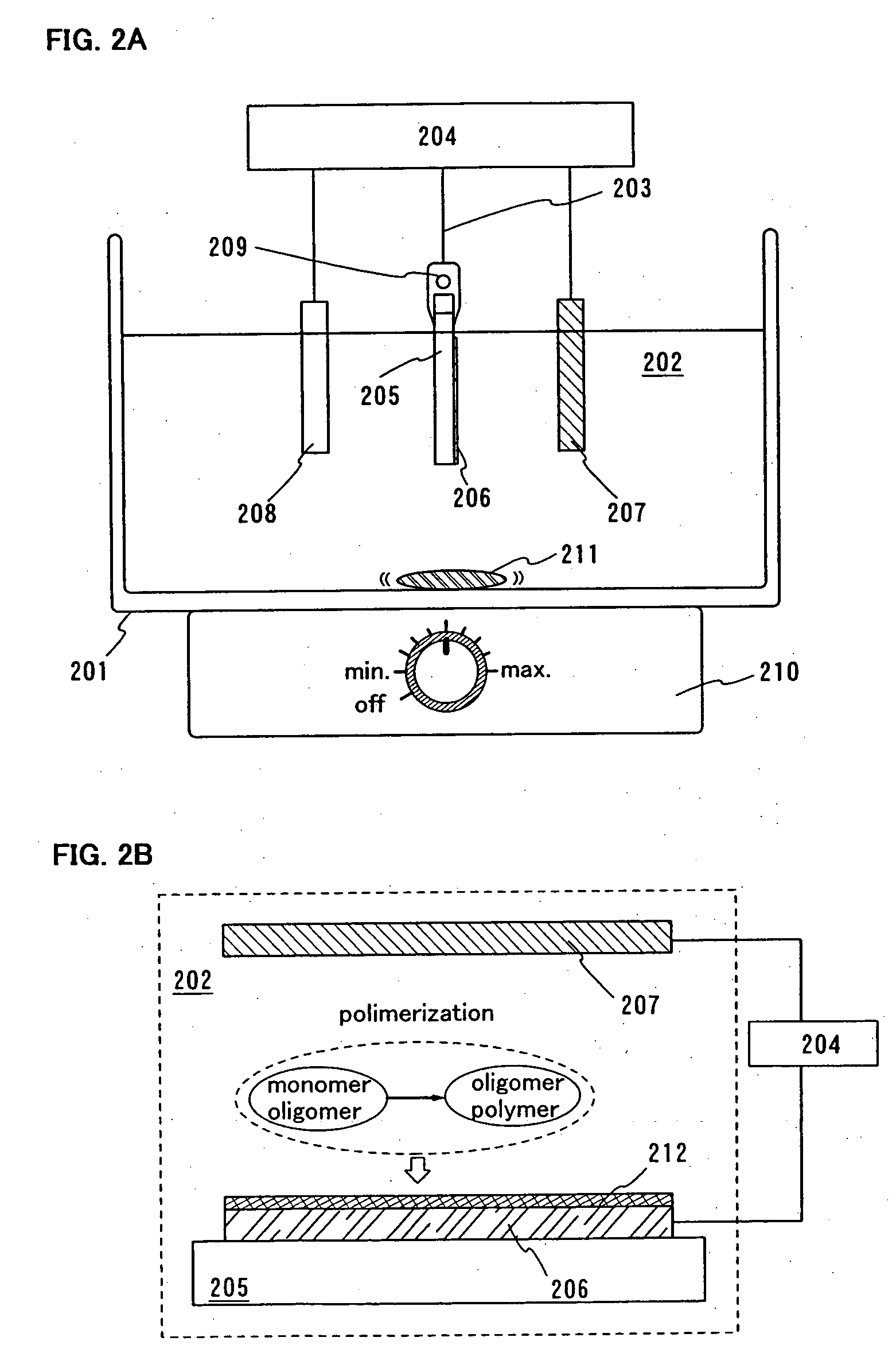

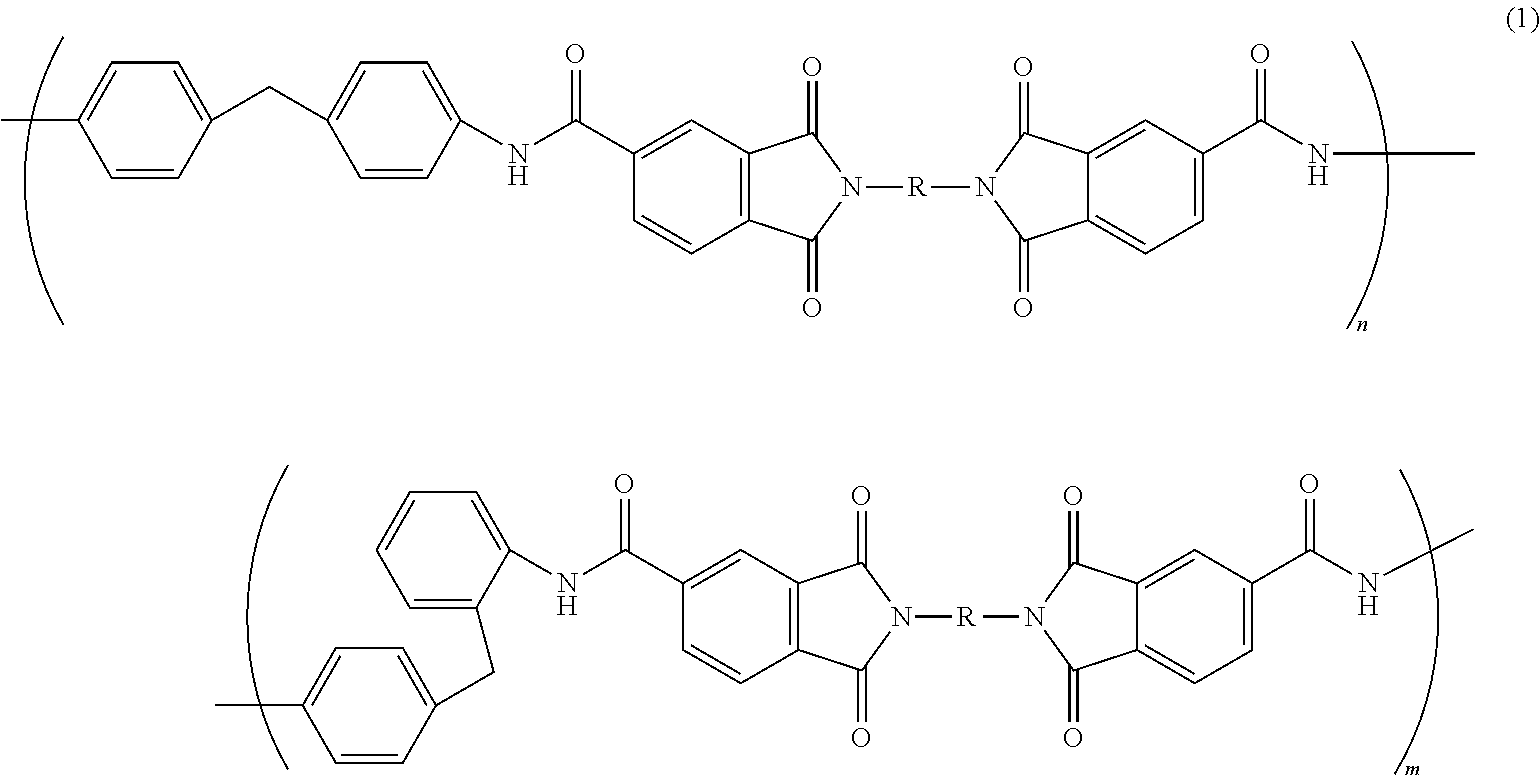

Light emitting device and method for manufacturing the same

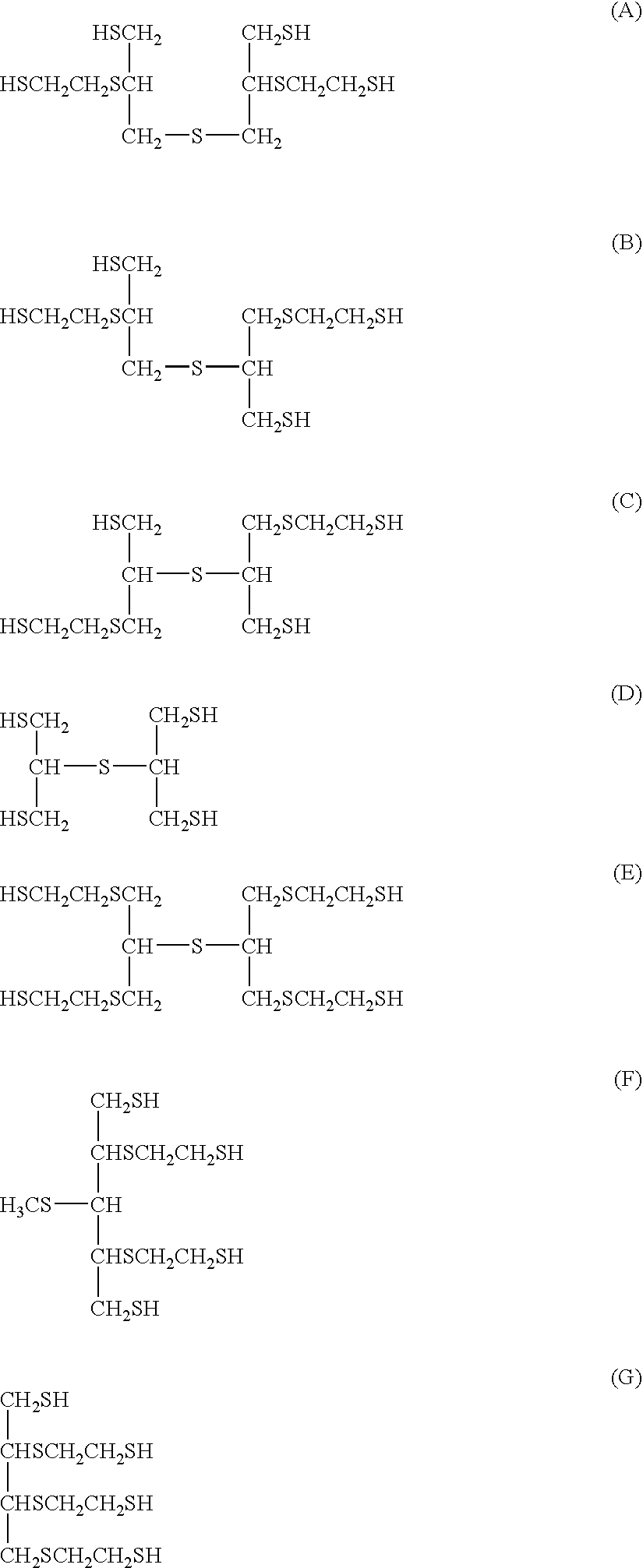

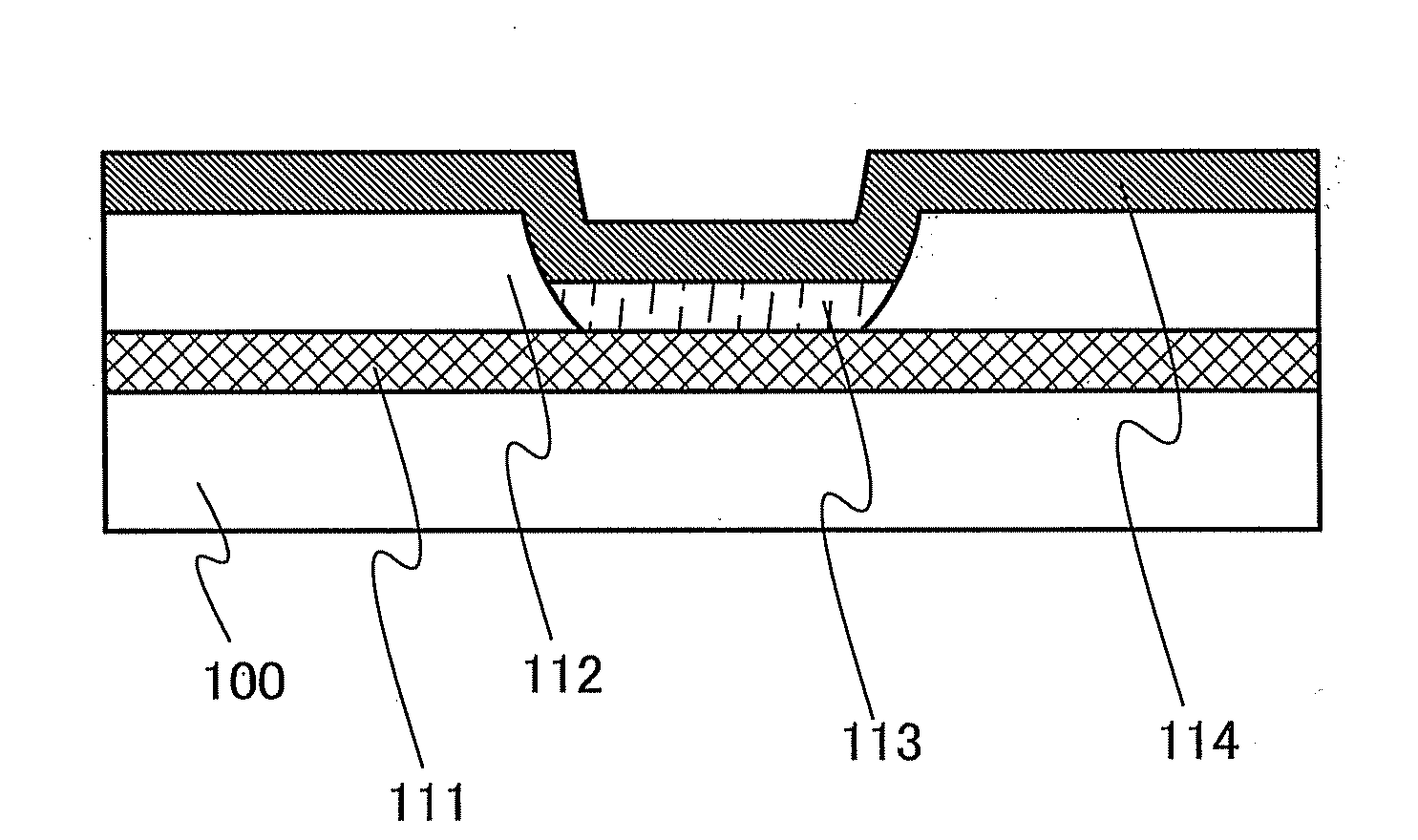

InactiveUS20050001543A1Reduce and eliminate generationEasily deterioratedDischarge tube luminescnet screensElectroluminescent light sourcesSimple Organic CompoundsCompound (substance)

A light emitting element containing an organic compound has a defect that the light emitting element is easily deteriorated by various factors; therefore, it is the biggest issue of the light emitting element that the light emitting element is formed with high reliability (longer lifetime). An objective of the present invention is to reduce or eliminate generation of the above described various defective modes of the light emitting element containing an organic compound. According to the present invention, current efficiency-luminance characteristics can be improved by orienting organic compound molecules in an applying direction of current. In addition, deterioration can be prevented by using a crystallization inhibitor.

Owner:SEMICON ENERGY LAB CO LTD

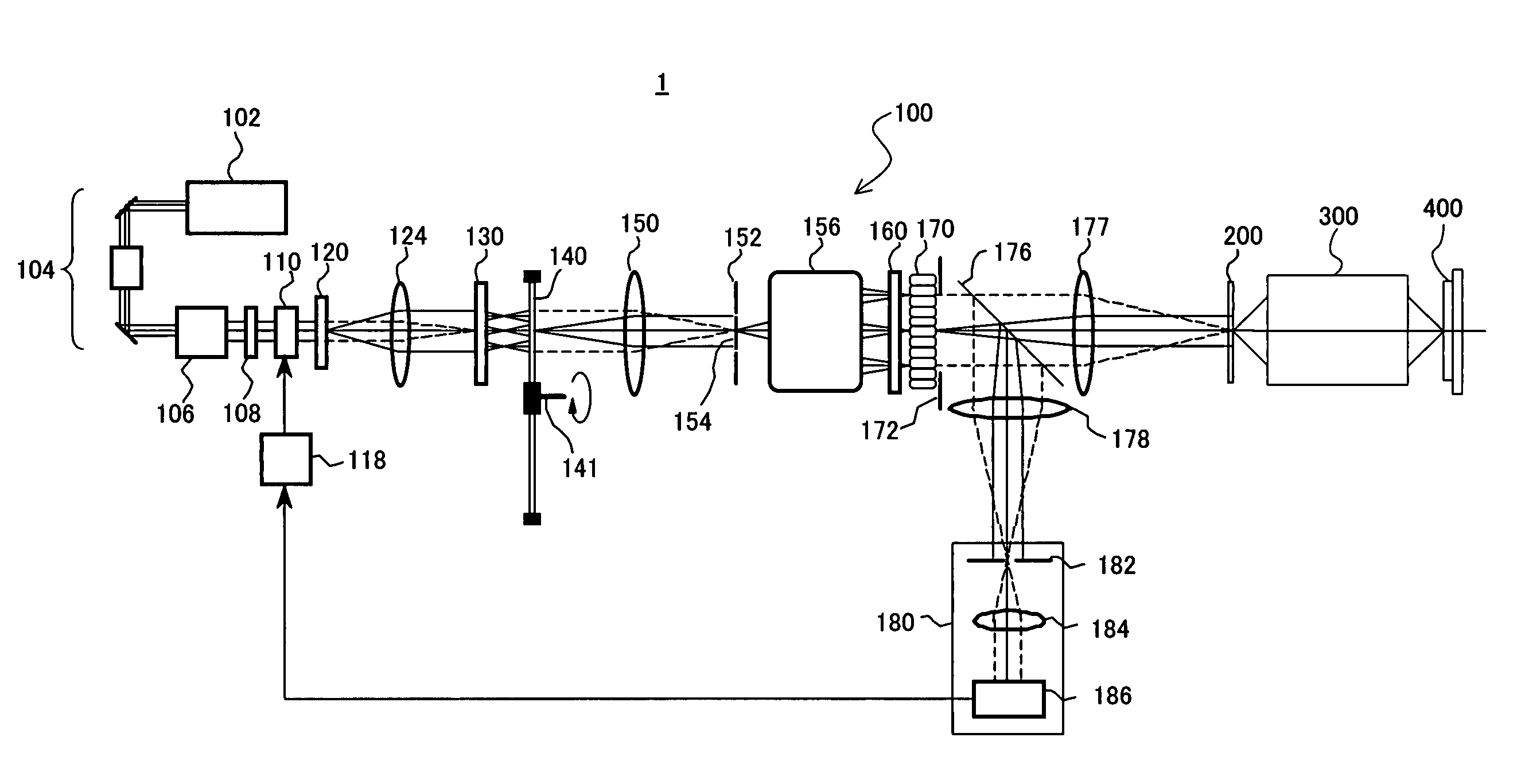

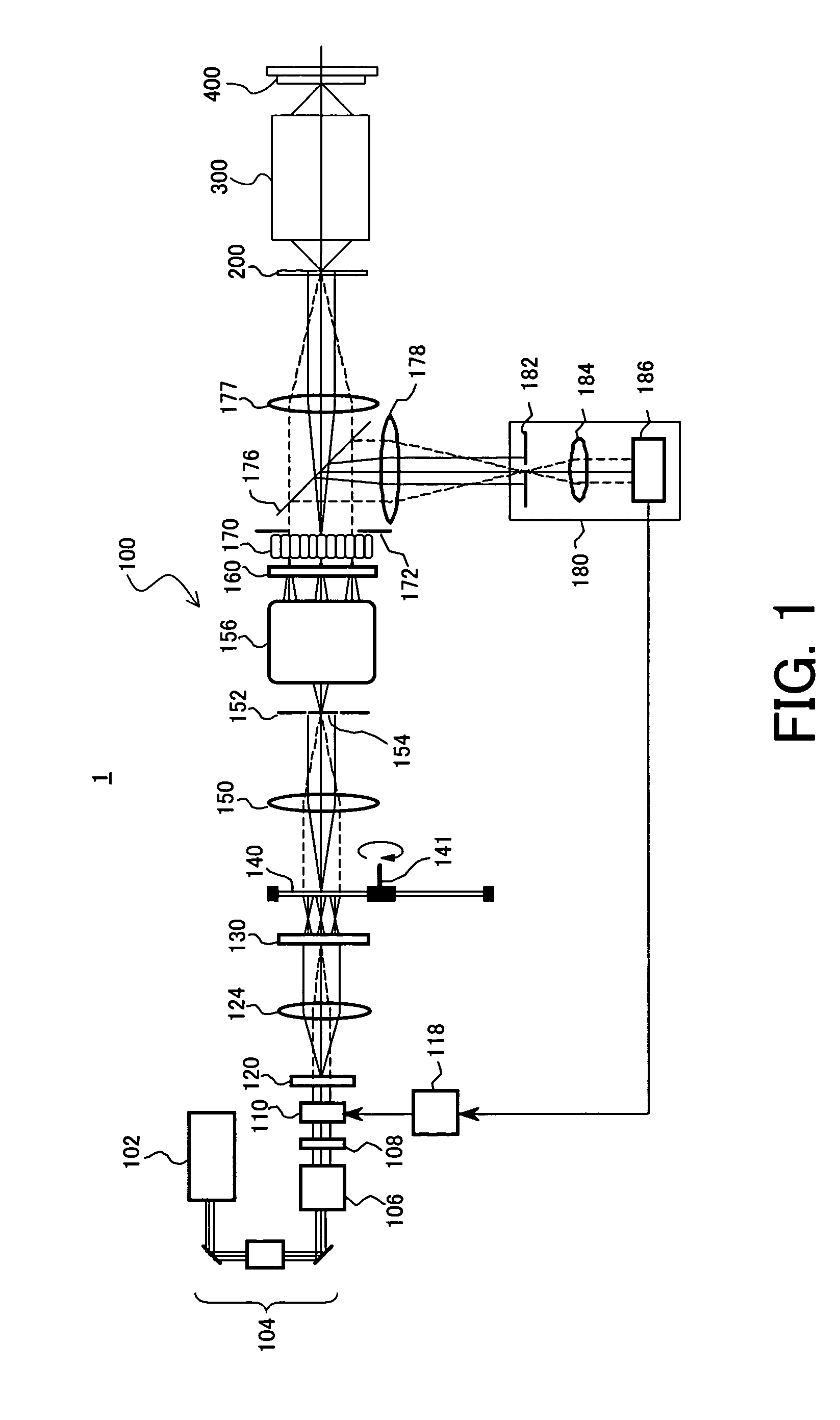

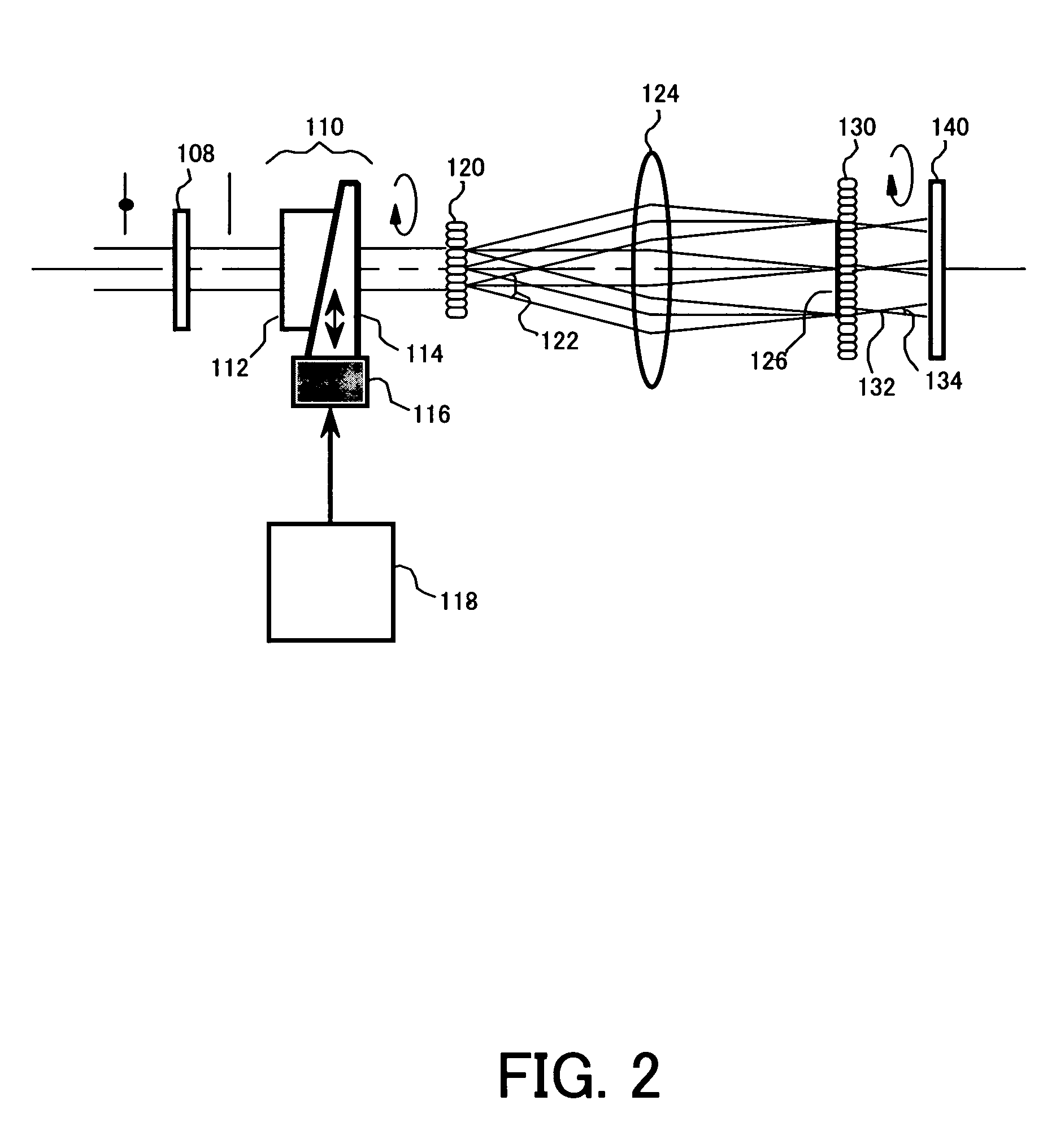

Illumination apparatus, exposure apparatus and device manufacturing method

InactiveUS7130025B2Without lowering illumination efficiencyEasily deterioratedConstructionsSemiconductor/solid-state device manufacturingOptoelectronicsPhysics

An illumination apparatus for illuminating a mask having a pattern, using light from a light source, includes a generating section for generating an effective light source distribution for a modified illumination to the mask, a polarization setting section for setting a predetermined polarization state in plural areas in the effective light source distribution, and an adjusting section for commonly controlling a polarization state of each area.

Owner:CANON KK

Method for manufacturing light-emitting device

ActiveUS8911653B2Low reliabilityEasily deterioratedFinal product manufactureSolid-state devicesEngineeringLight emitting device

Owner:SEMICON ENERGY LAB CO LTD

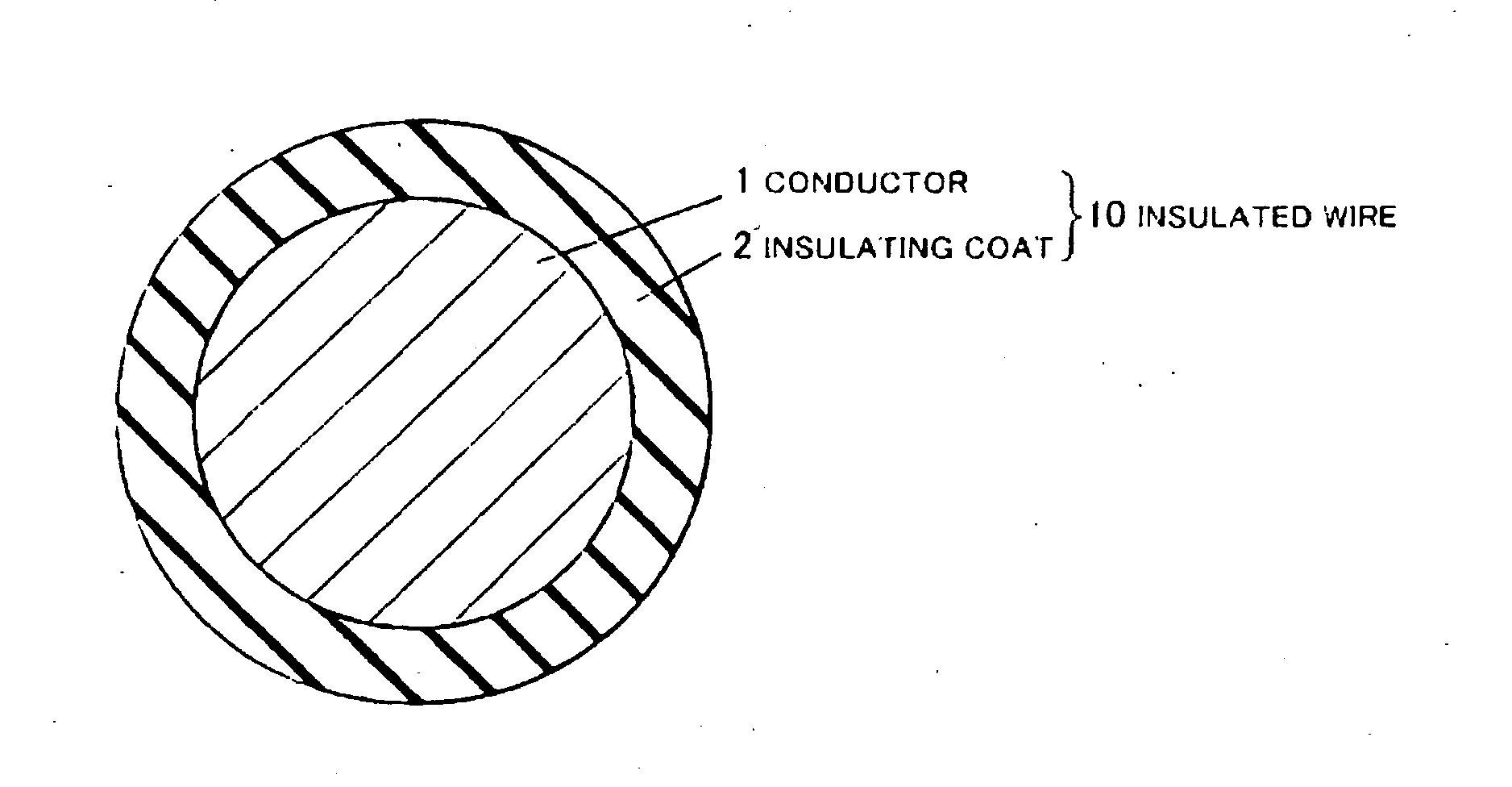

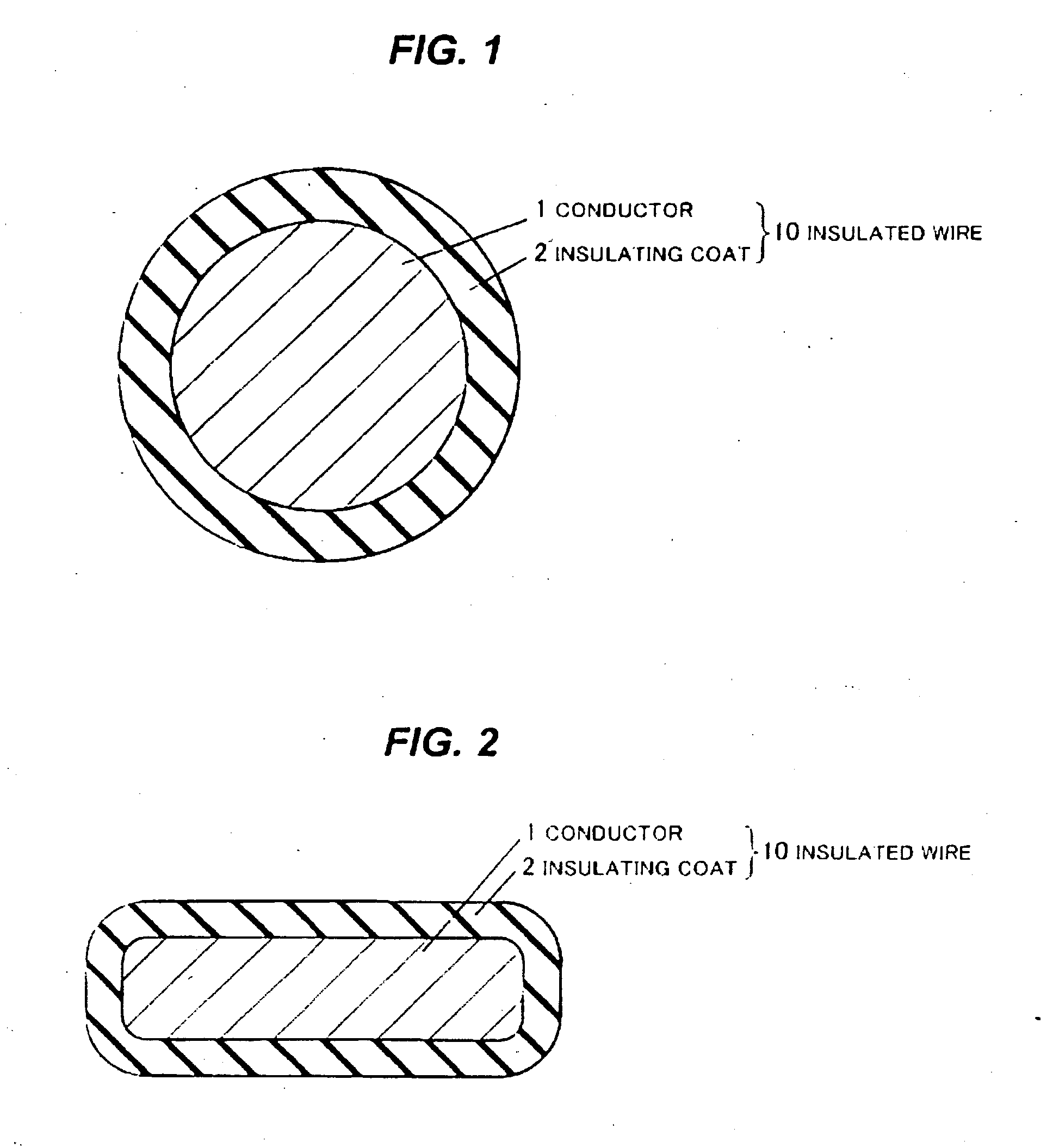

Insulating varnish and insulated wire formed by using the same

InactiveUS20110290528A1Improve compatibilityHigh partial discharge inception voltagePlastic/resin/waxes insulatorsInsulated cablesPolyamide-imideVarnish

An insulating varnish includes a polyamide-imide resin varnish including a solvent and a polyamide-imide resin, and an organosol. The polyamide-imide resin varnish is obtained by a synthesis reaction between a resin component (X) and an isocyanate component (Y). The resin component (X) is obtained by a synthesis reaction between a diamine component and an acid component in presence of an azeotropic medium. The diamine component includes aromatic diamines including a divalent aromatic group having three or more aromatic rings. The isocyanate component (Y) includes a diisocyanate (Y1) a molecule of which includes a bend structure.

Owner:HITACHI CABLE

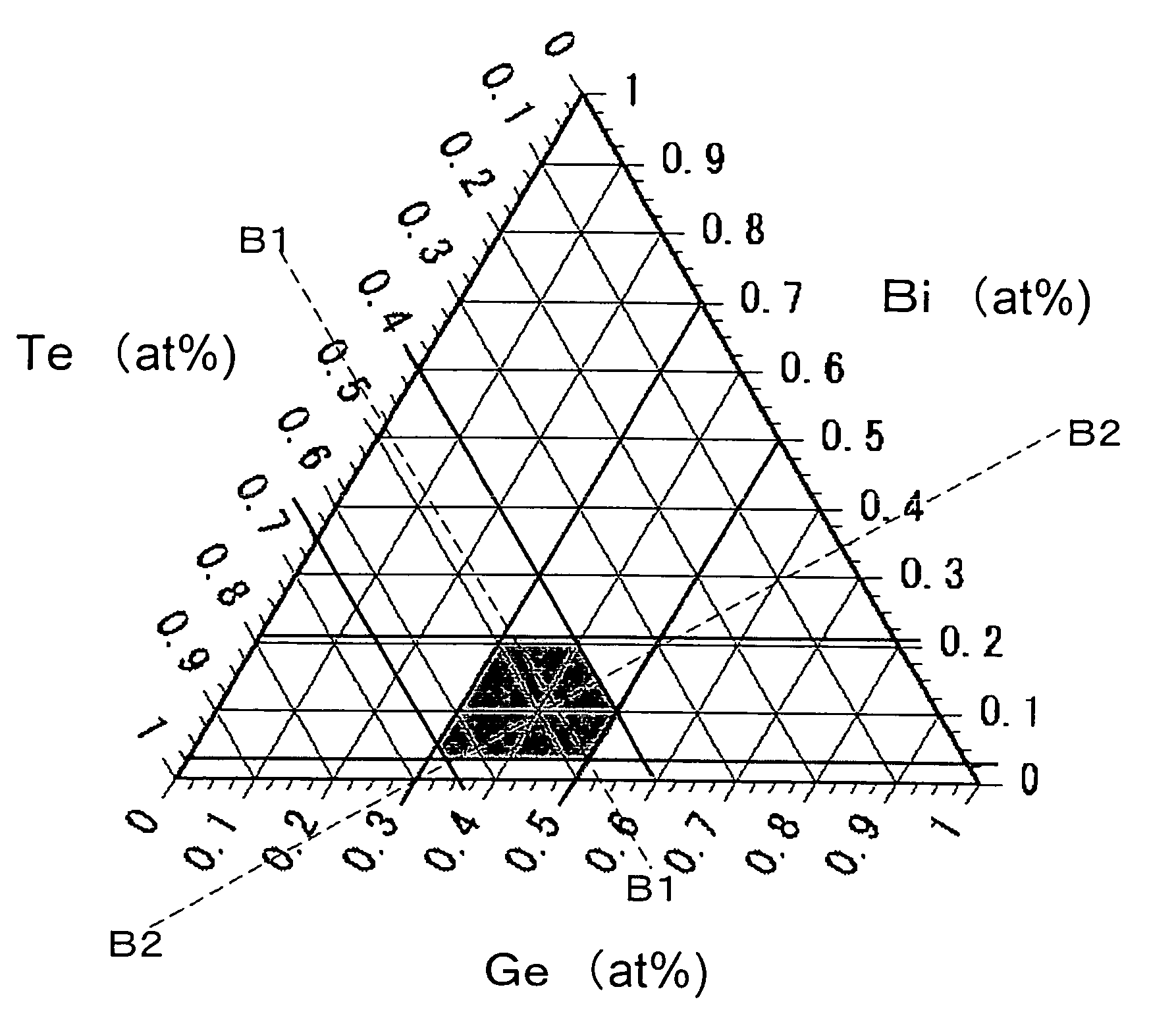

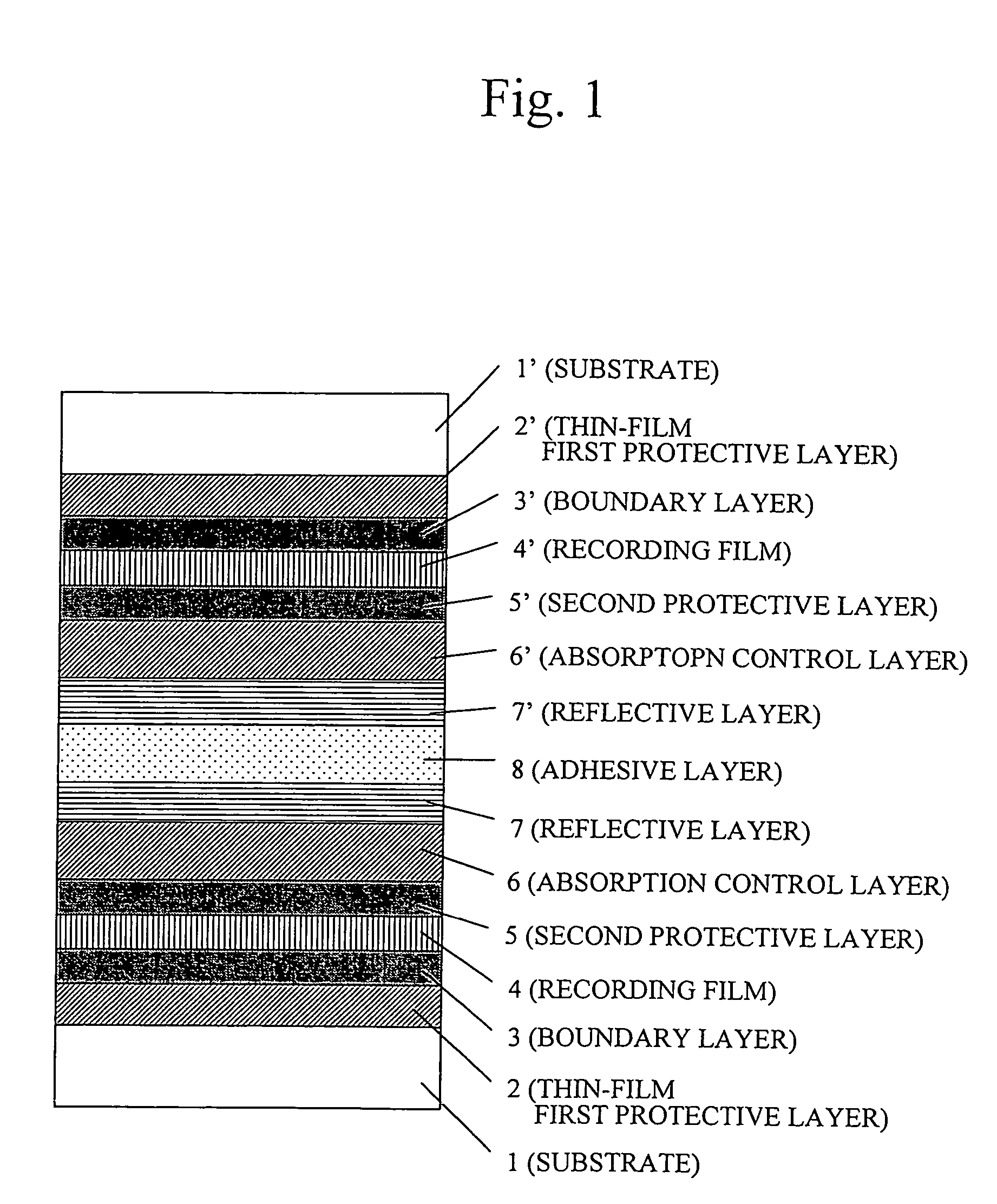

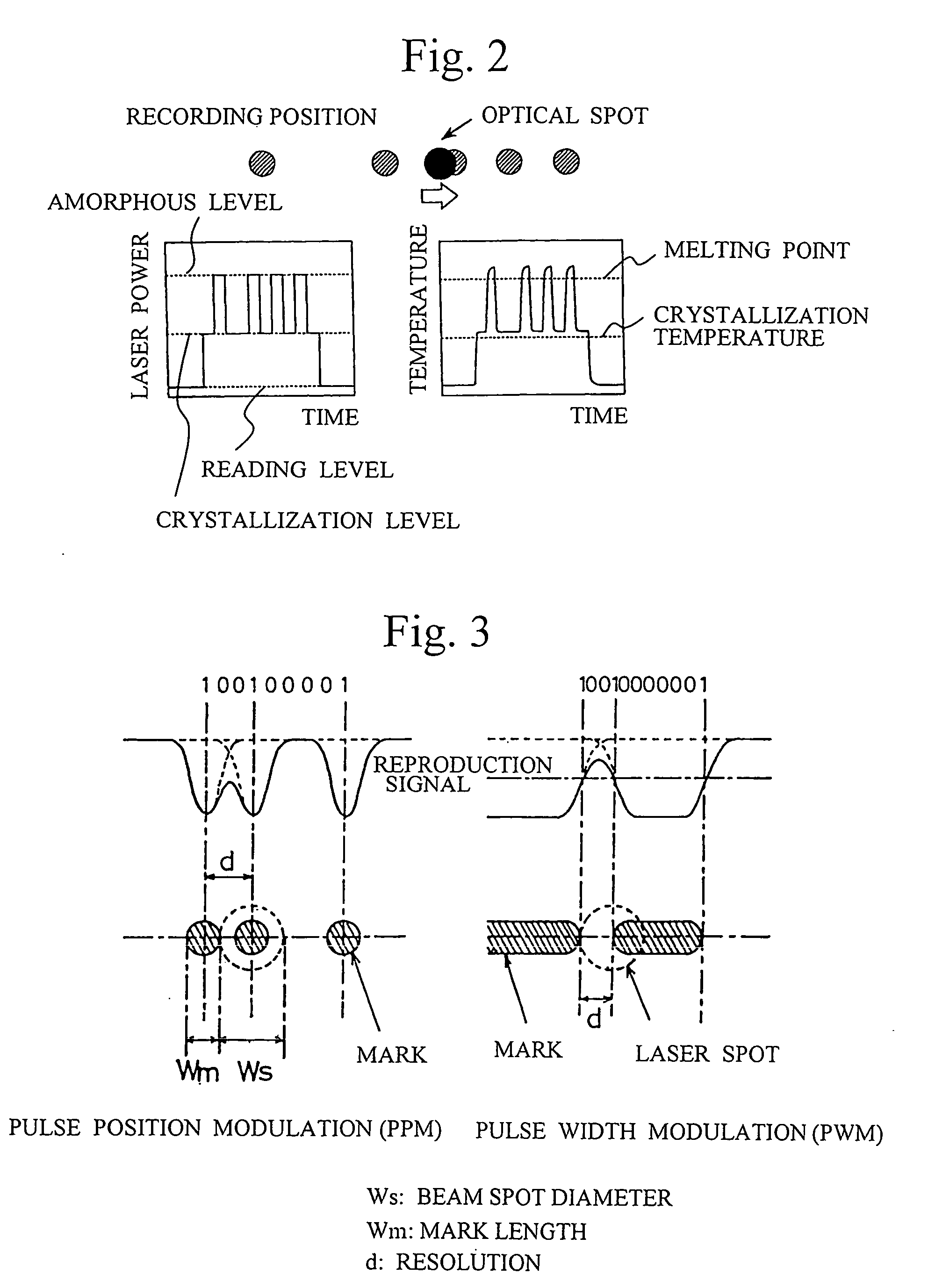

Information recording medium

InactiveUS20050064334A1Large thicknessExtension of timeLayered productsPhotomechanical apparatusHigh densityReflective layer

An information recording medium for high-density recording and reproduction that is low-cost and that has good rewrite characteristics. The information recording medium, in which recording is performed as an atomic arrangement is changed by optical irradiation, is capable of a number of rewrites. The information recording medium comprises a substrate on which a first protective layer with a thickness in the range from 18 to 65 nm, a recording film, a second protective layer, and a reflective layer are disposed in the mentioned order as seen from a light-incident side. Not less than 97 atomic % of the composition of the recording film is accounted for by Ge, Bi, and Te.

Owner:HITACHT MAXELL LTD

Field-effect transistor, and process for producing field-effect transistor

ActiveUS8530891B2Poor resistanceEasily deterioratedSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline oxideIndium

To provide a field-effect transistor improved in transparency, electrical properties, stability, uniformity, reproducibility, heat resistance and durability, and as a reduced overlap capacity between electrodes.A field-effect thin film transistor 1001 includes a gate electrode 1025, an active layer, a source electrode 1022 and a drain electrode 1023, wherein a crystalline oxide 1021 containing indium and having an electron carrier concentration of less than 1018 / cm3 is used as the active layer, and the gate electrode 1025 is in self-alignment with the source electrode 1022 and the drain electrode 1023. The crystalline oxide 1021 contains a positive trivalent element different from a positive divalent element or indium.

Owner:IDEMITSU KOSAN CO LTD

Vehicle control apparatus

InactiveUS20070202991A1Prevent promotionEasily deterioratedGearing controlEngine controllersEngineeringTransfer mechanism

A vehicle equipped with a motor-operated mechanism that contains a clutch. The pushing member of the clutch is energized against a friction plane by an energizing mechanism and transfers power from a driving power source when it touches the friction plane. The location of the pushing member can be retained even when power is shut off. This structure prevents promotion of deterioration of a diaphragm spring in a state in which the clutch remains disengaged when the key switch is turned off.After a signal from the key switch stops, the control apparatus stops the driving power source and the vehicle, engages the friction transfer mechanism, and then stops the system.

Owner:HITACHI LTD

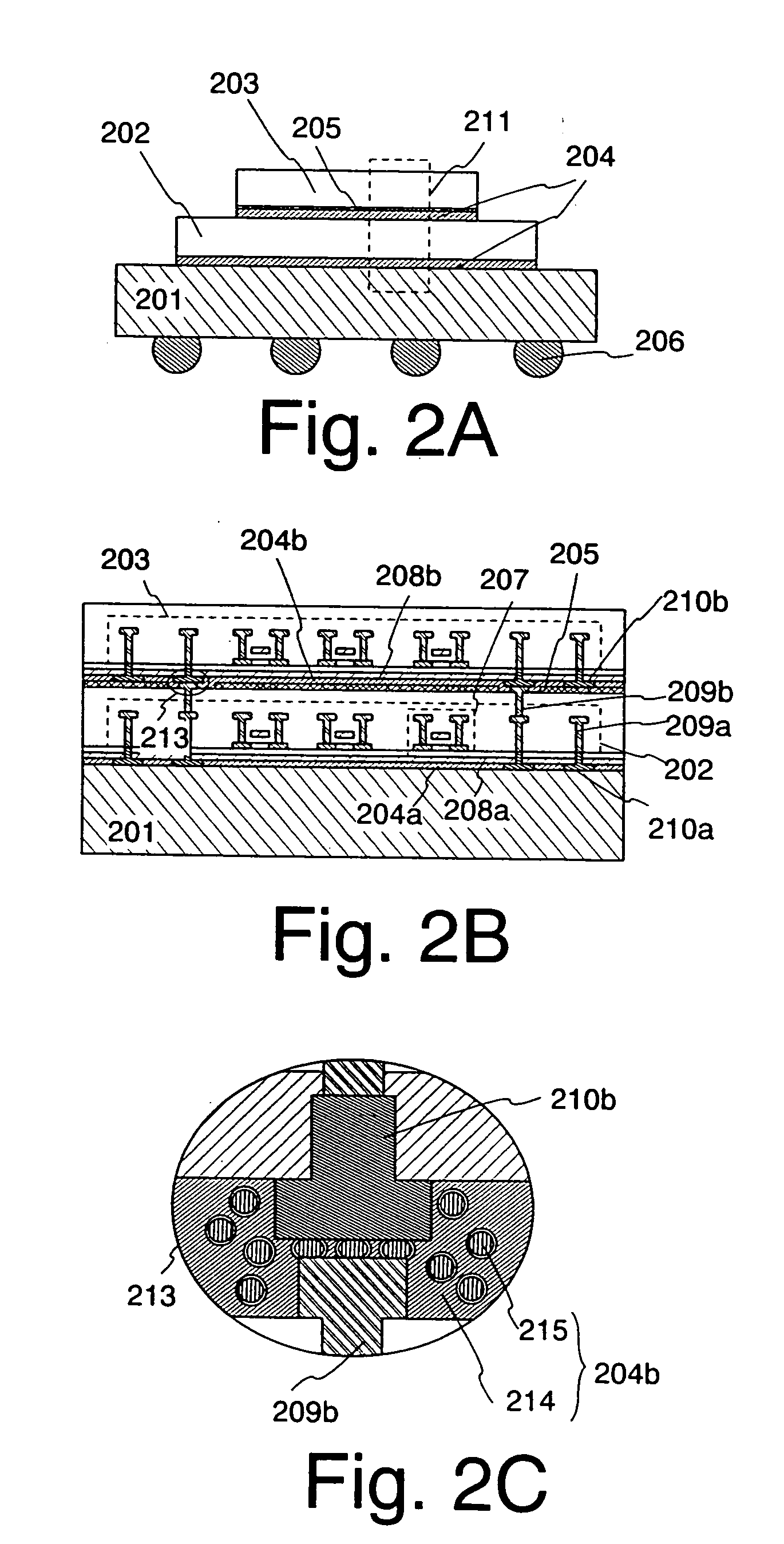

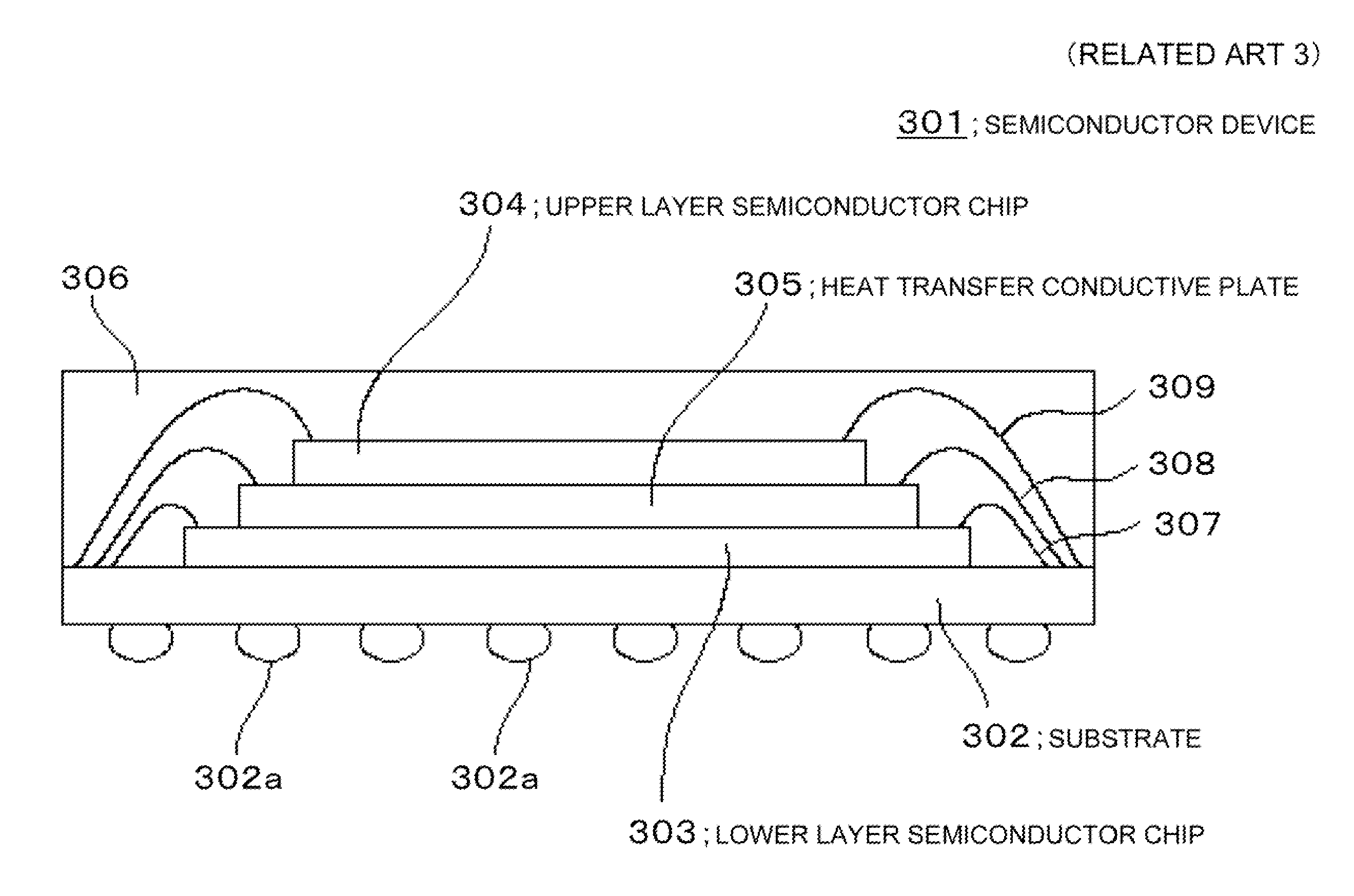

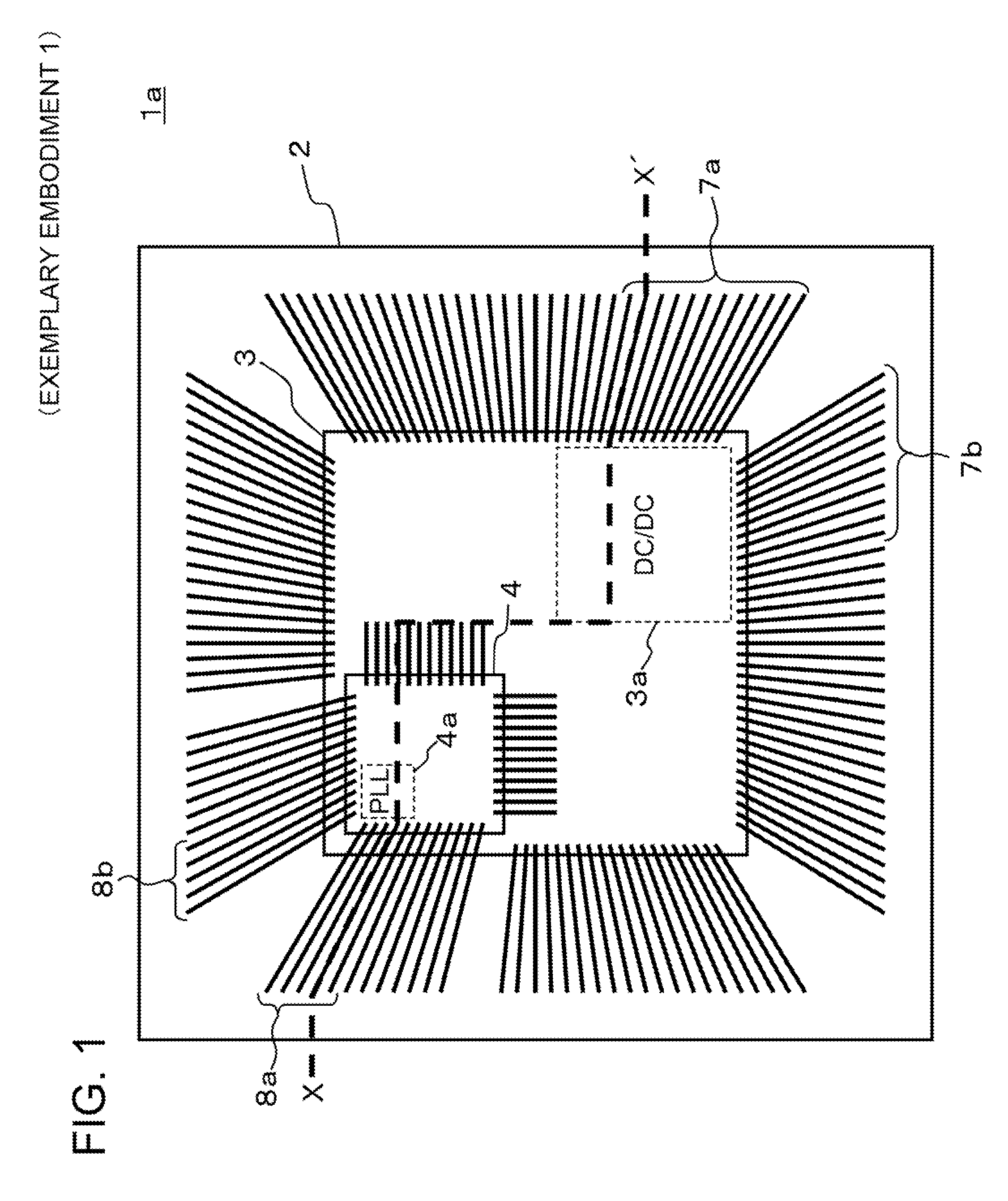

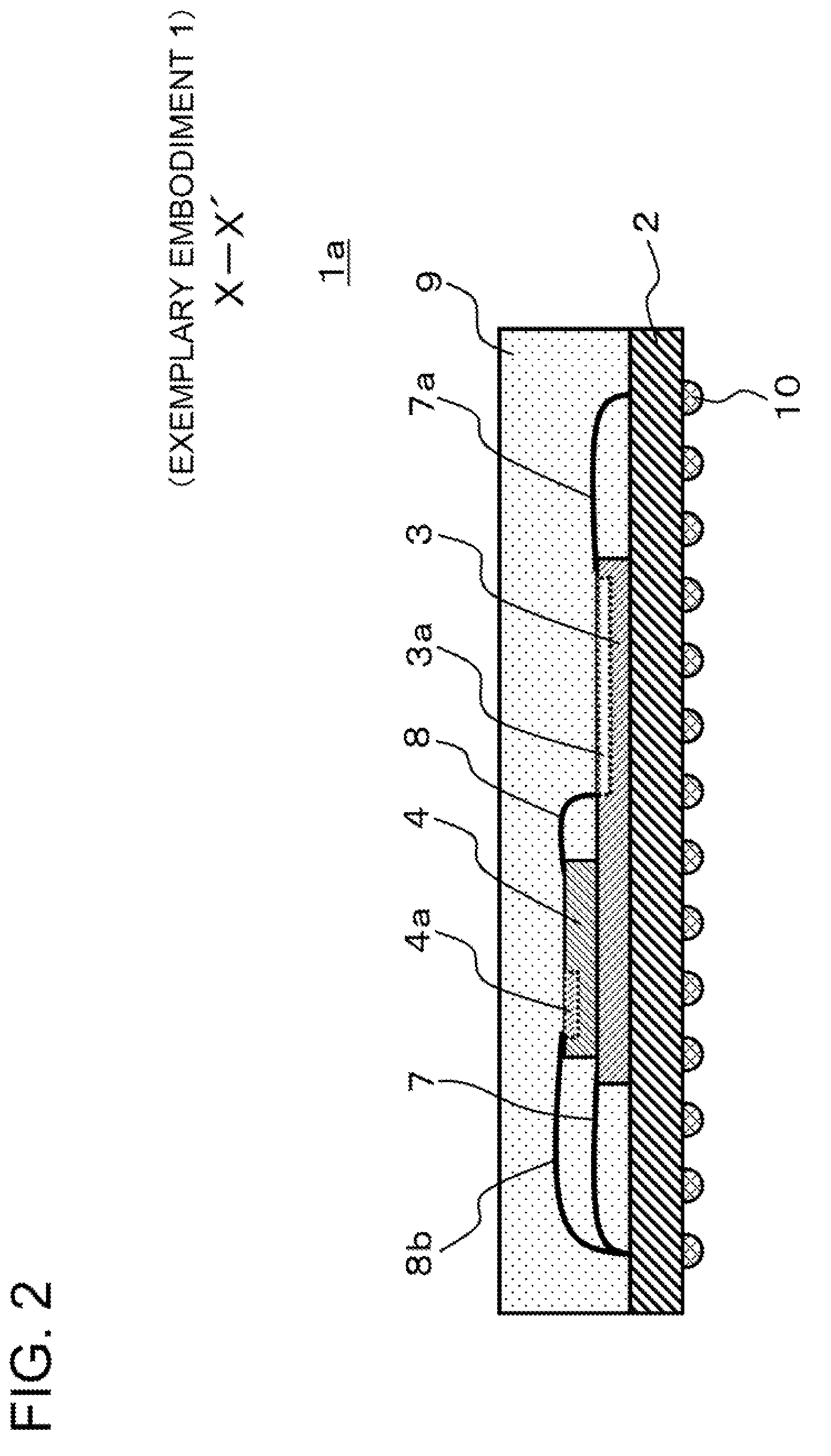

Semiconductor device

ActiveUS20090315167A1Easy to generate noiseImprove noiseSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor device in which a plurality of semiconductor chips is stacked. A first semiconductor chip is stacked in a region, on a second semiconductor chip, in which a circuit that generates noise is not disposed within said second semiconductor chip, and a wire of a circuit that easily receives noise within said first semiconductor chip is disposed so as not to extend over said circuit that generates noise.

Owner:GK BRIDGE 1

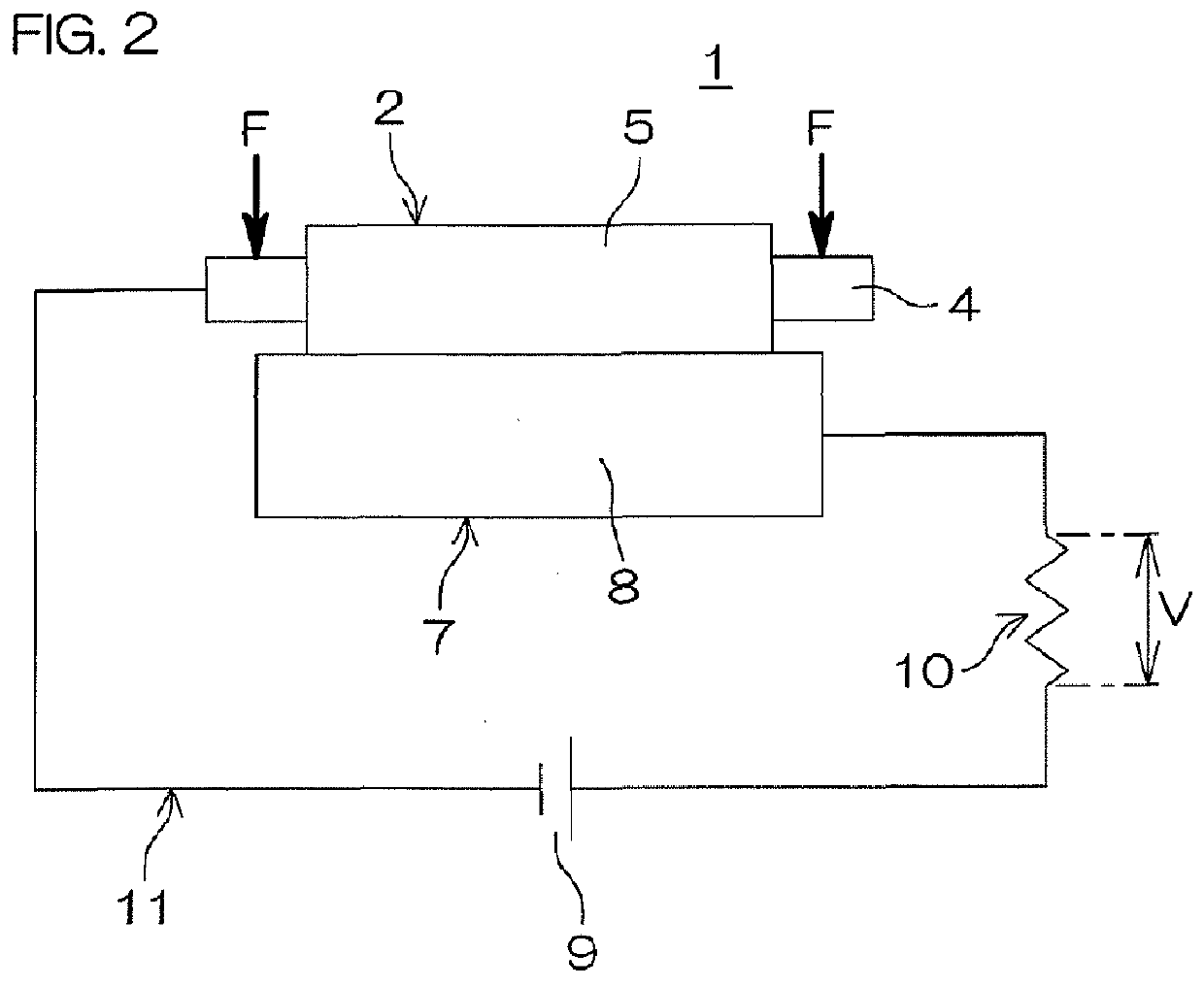

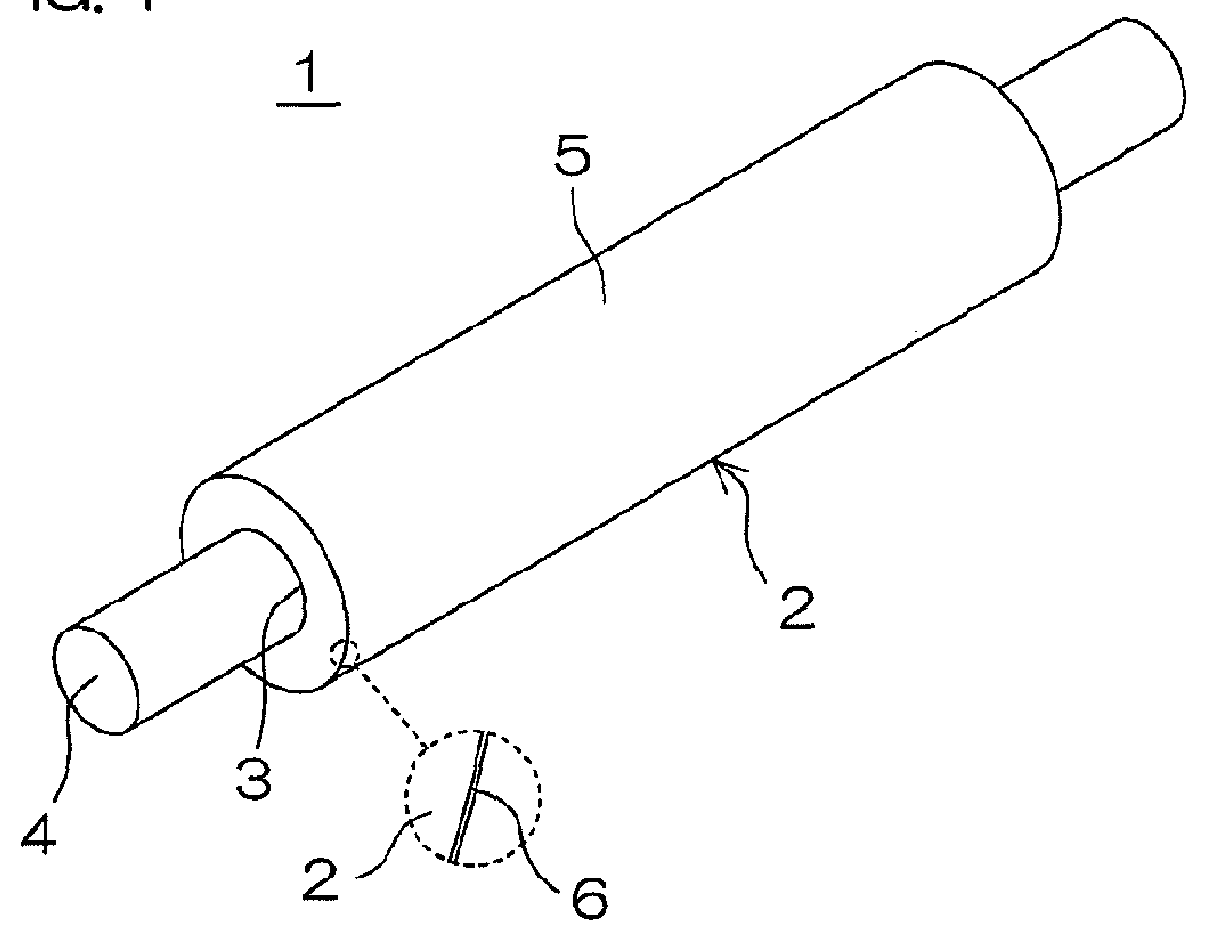

Semiconductive roller

InactiveUS20120202663A1Quality improvementHigh hardnessLiquid surface applicatorsShaft and bearingsPolymer scienceEpichlorohydrin

The semiconductive roller according to the present invention includes a nonporous roller body made of a rubber composition containing styrene-butadiene rubber and epichlorohydrin rubber as rubber components.

Owner:SUMITOMO RUBBER IND LTD

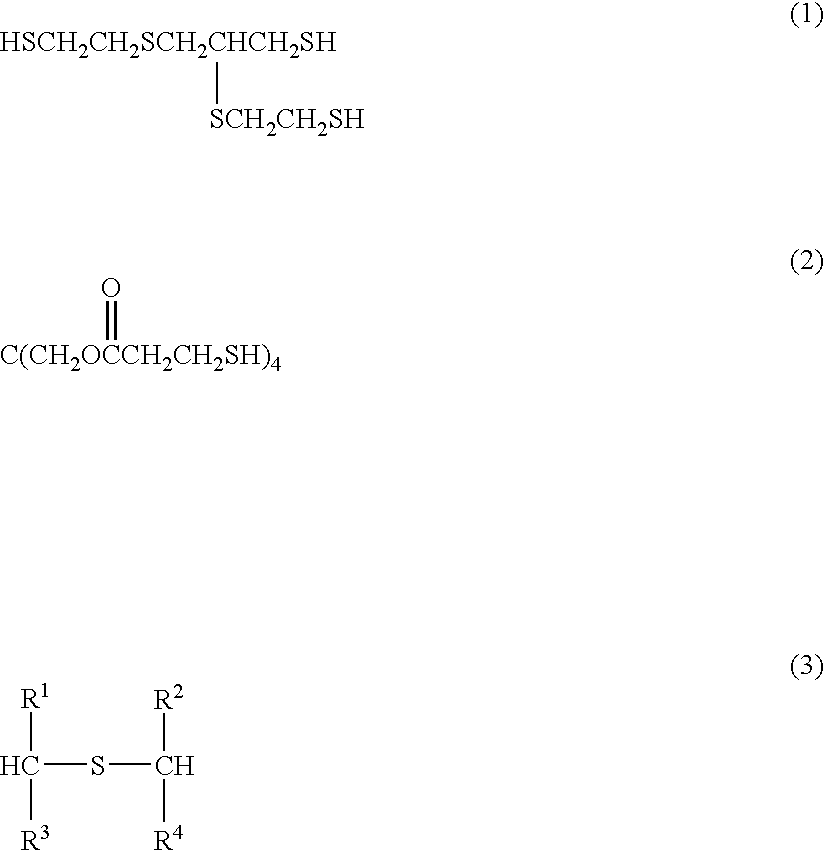

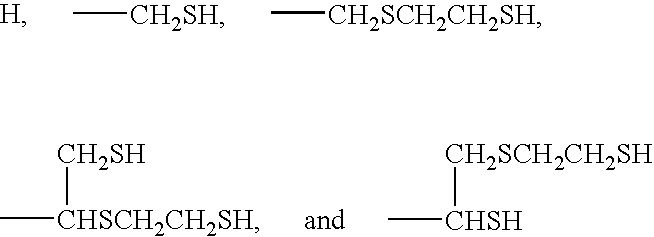

Plastic lens and method for producing plastic lens

InactiveUS20090029153A1Excels in heat resistanceEasily deteriorateLayered productsCoatingsWeather resistanceComposite material

Disclosed herein is a plastic lens which exhibits outstanding weather resistance and light resistance with a minimum of deteriorating effect on the organic antireflection thin film formed thereon. The plastic lens is composed of a plastic lens base material, a hard coating layer formed on the plastic lens base material, and an antireflection film formed on the hard coating layer, wherein the hard coating layer is one which is formed from a coating composition comprising inorganic oxide fine particles containing titanium oxide with a rutile-type crystallite and an organosilicon compound as a binder.

Owner:JGC CATALYSTS & CHEM LTD +1

Light-Emitting Element, Manufacturing Method Thereof, and Lighting Device

InactiveUS20120126277A1Reduction in emission characteristicEasily deterioratedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectroluminescence

A light-emitting element includes a conductive layer functioning as a first electrode, an electroluminescent layer, and a conductive layer functioning as a second electrode, and further includes an insulating material filling a defect portion in the electroluminescent layer so that the defect portion is sealed. In the light-emitting element, the conductive layer functioning as a second electrode overlaps with the conductive layer functioning as a first electrode with the electroluminescent layer and the insulating material interposed therebetween and is in contact with a top surface of the electroluminescent layer.

Owner:SEMICON ENERGY LAB CO LTD

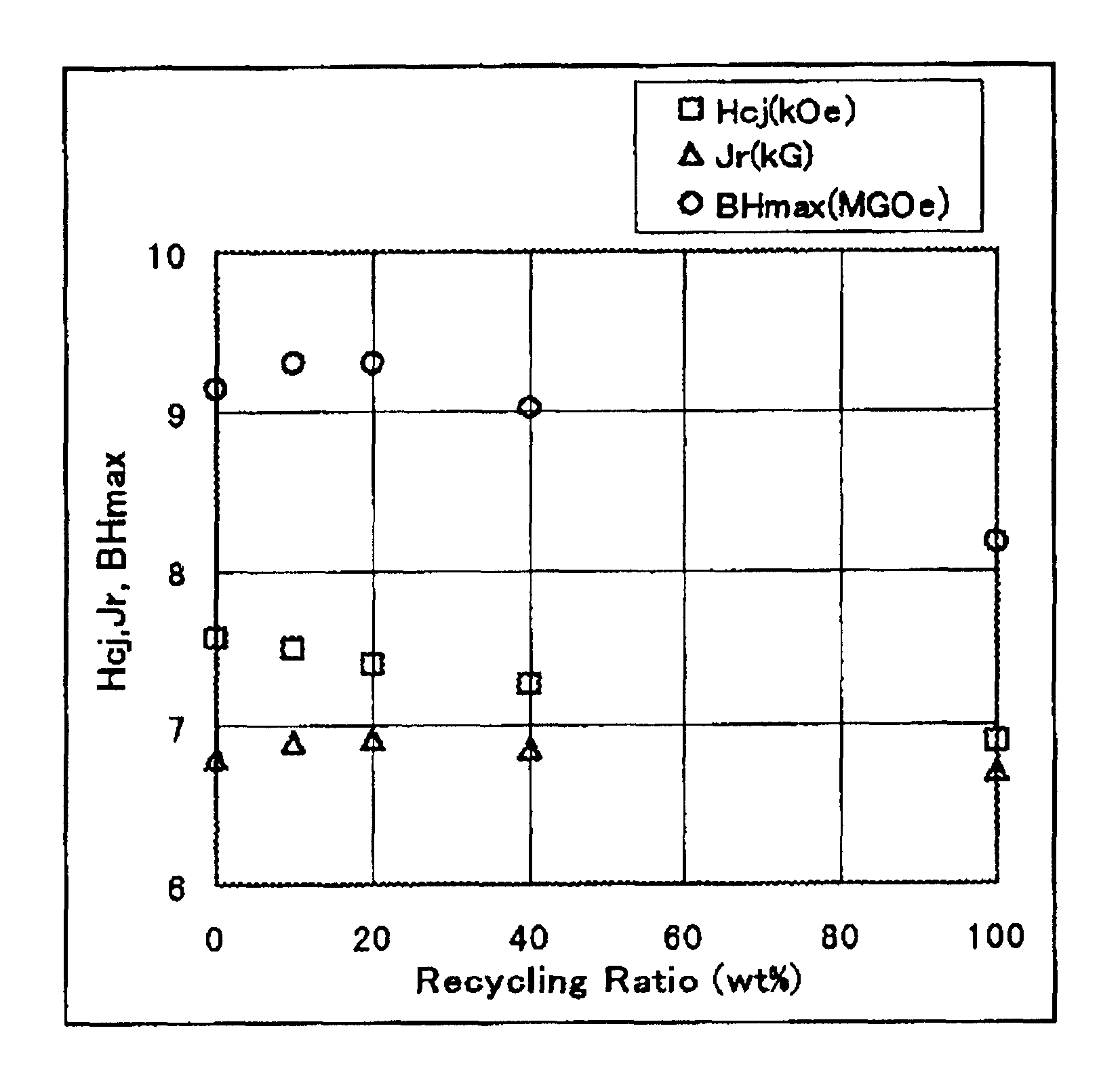

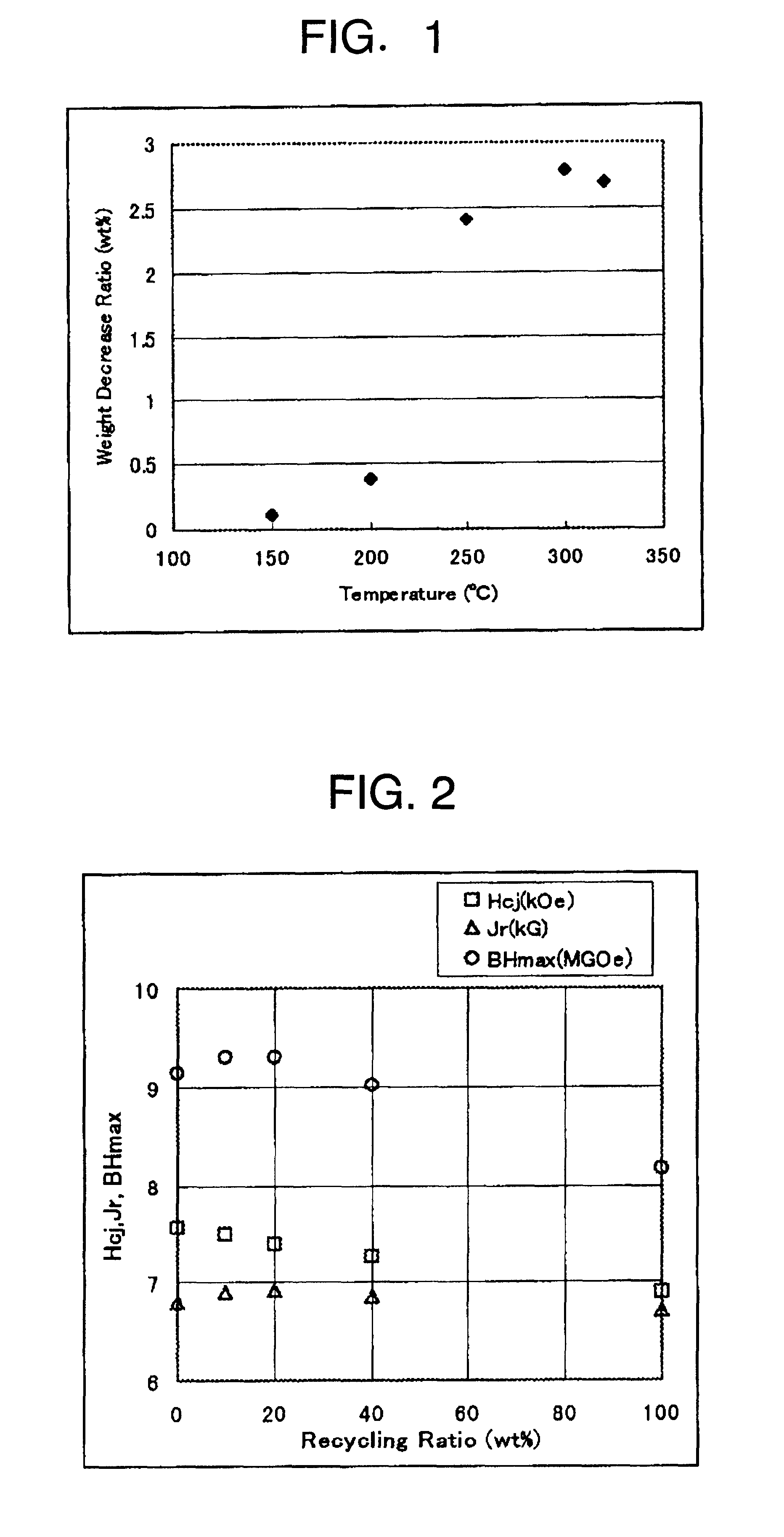

Method of recovering and recycling magnetic powder from rare earth bond magnet

InactiveUS6533837B1Preventing deteriorationReduce pressurePlastic recyclingInorganic material magnetism2-HexanoneDecomposition

A method of recovering magnetic powder from rare earth bond magnet comprising a process of soaking the rare earth bond magnet in a decomposing solution, or holding it in a gas phase of the decomposing solution, containing at least one solvent selected from a group comprising tetralin, naphthalene, 1,4-hydroxynaphthalene, naphthol, biphenyl, 2-hexanone, acetonylacetone, phorone cyclohexanone and methlcyclohexanone, and heating at a temperature not lower than 230° C. A method of recycling recovered magnetic powder by substituting at least a part or all of magnetic powder in the molding compound of a second rare earth bond magnet. For preventing deterioration of magnetic powder from oxidation at surface, air in the decomposition vessel is substituted with nitrogen gas, helium gas and argon gas or is reduced to a pressure not higher than 10-2 Torr.

Owner:PANASONIC CORP

Light source device and display device

ActiveUS8770773B2Color unevenness easilyEasily deterioratedNon-electric lightingPoint-like light sourcePhosphorFluorescence

Owner:DEXERIALS CORP

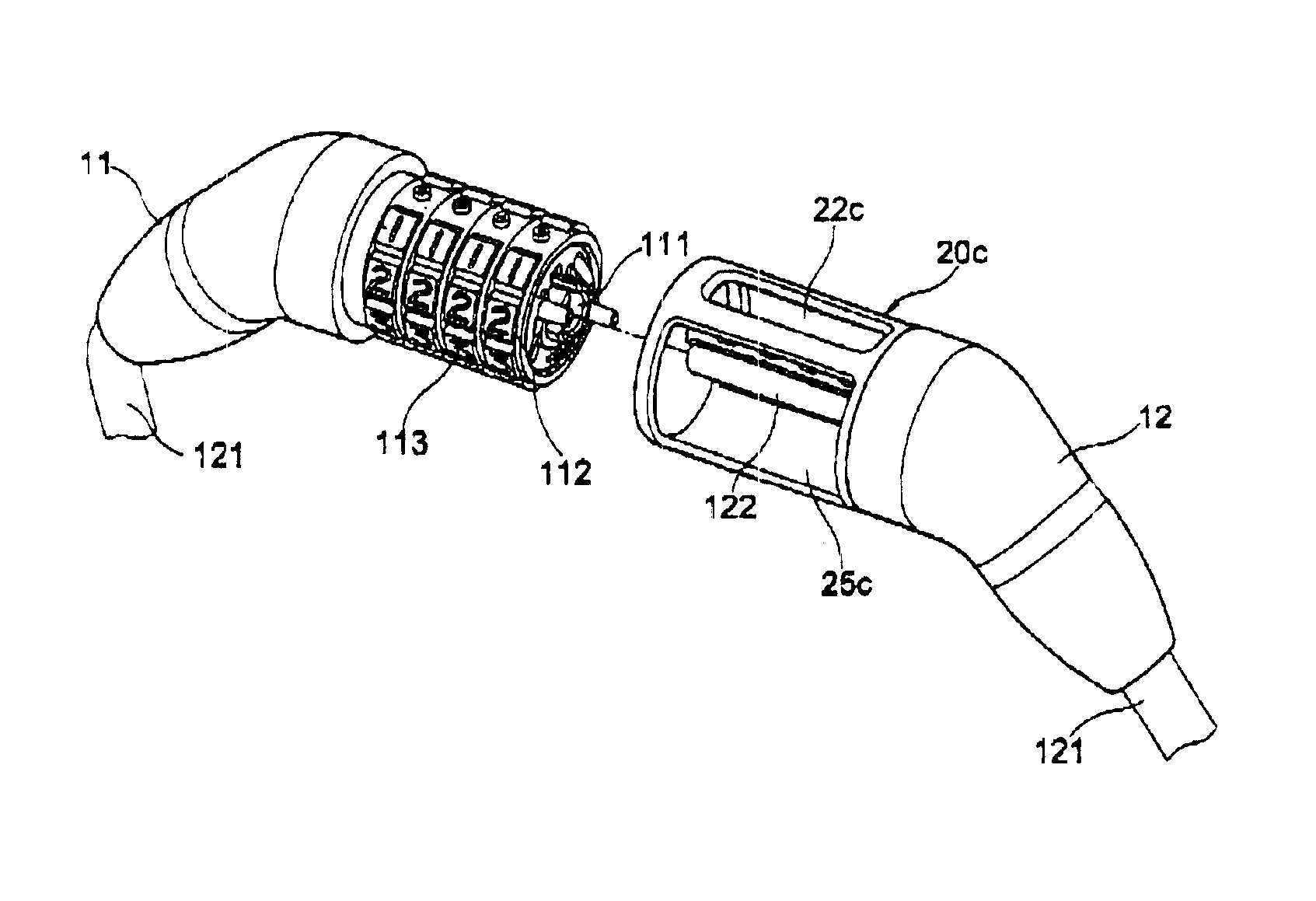

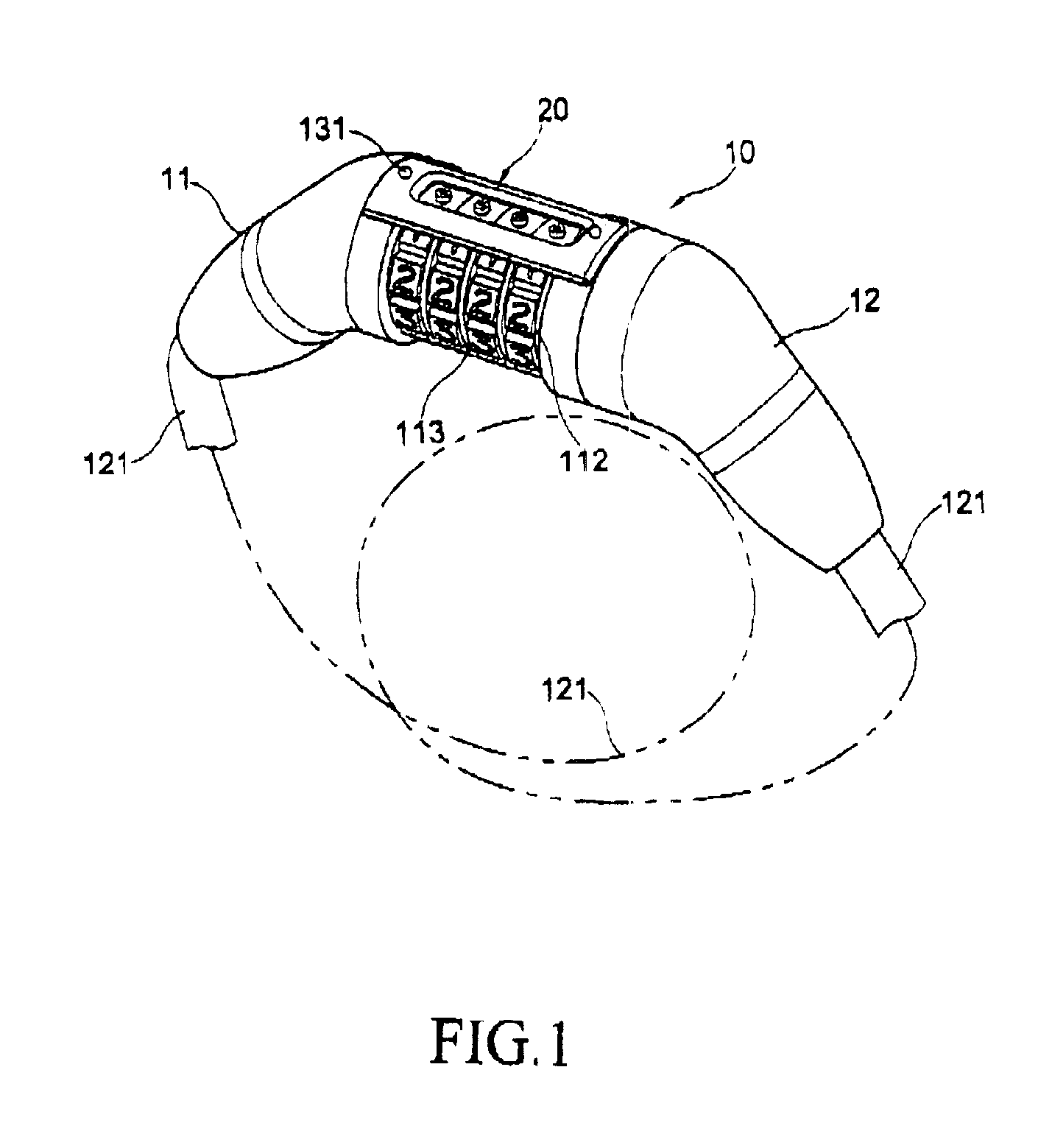

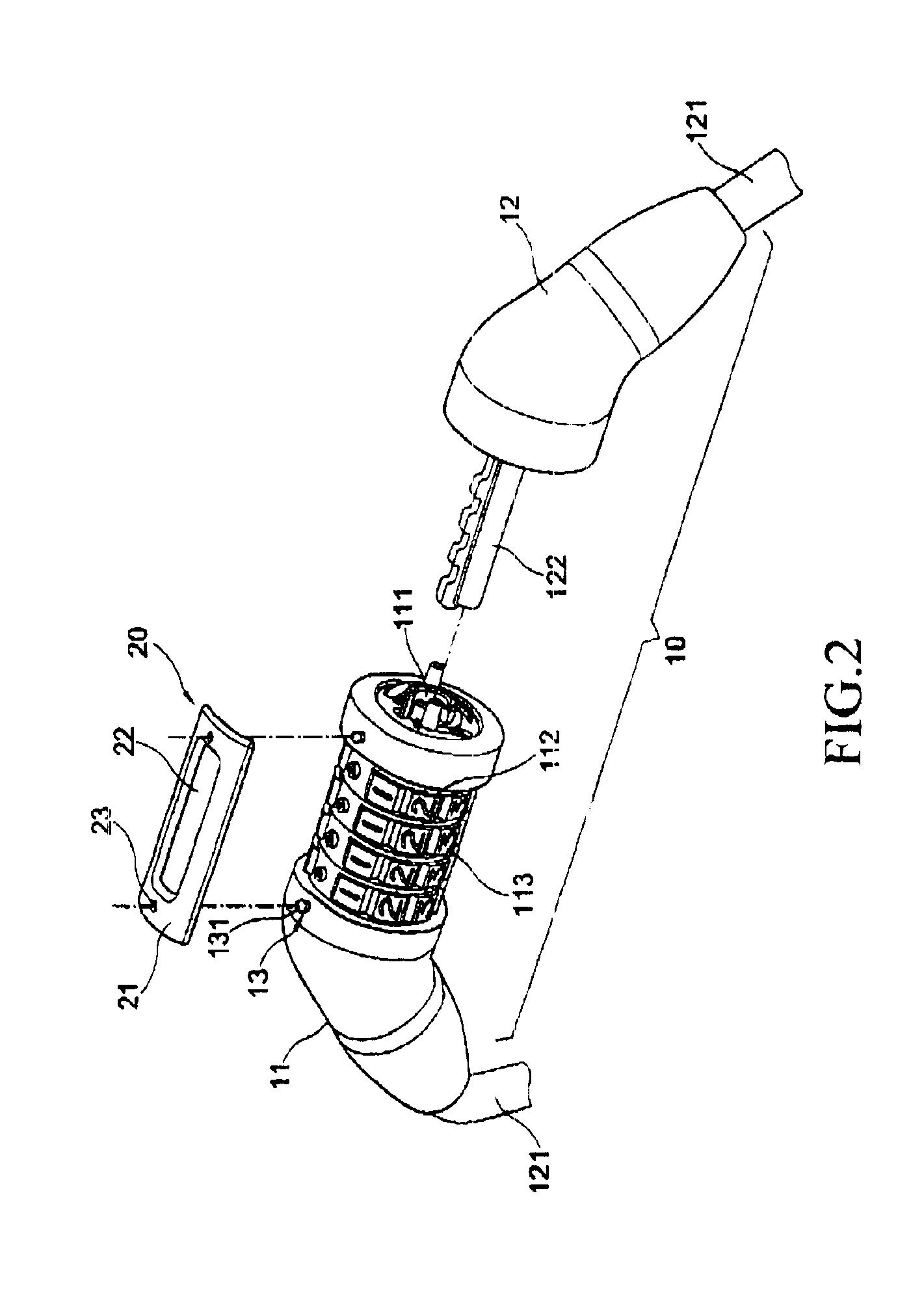

Combination lock with dial displaying window

InactiveUS6860126B2Quick and accurate identificationEasily deterioratedPadlocksPuzzle locksMagnificationEmbedded system

A combination lock with a dial displaying window which is directed to a combination lock with the installation of a dial matching frame placed across all the dials and having at least one window for the users to check the combination numerals or symbols on the dials through the window for unlocking the combination lock. The dial matching frame may be differently constructed to provide the window with the displaying function. A magnification lens may be mounted on the window to further enhance the effectiveness during utilization.

Owner:LING RENNY TSE HAW

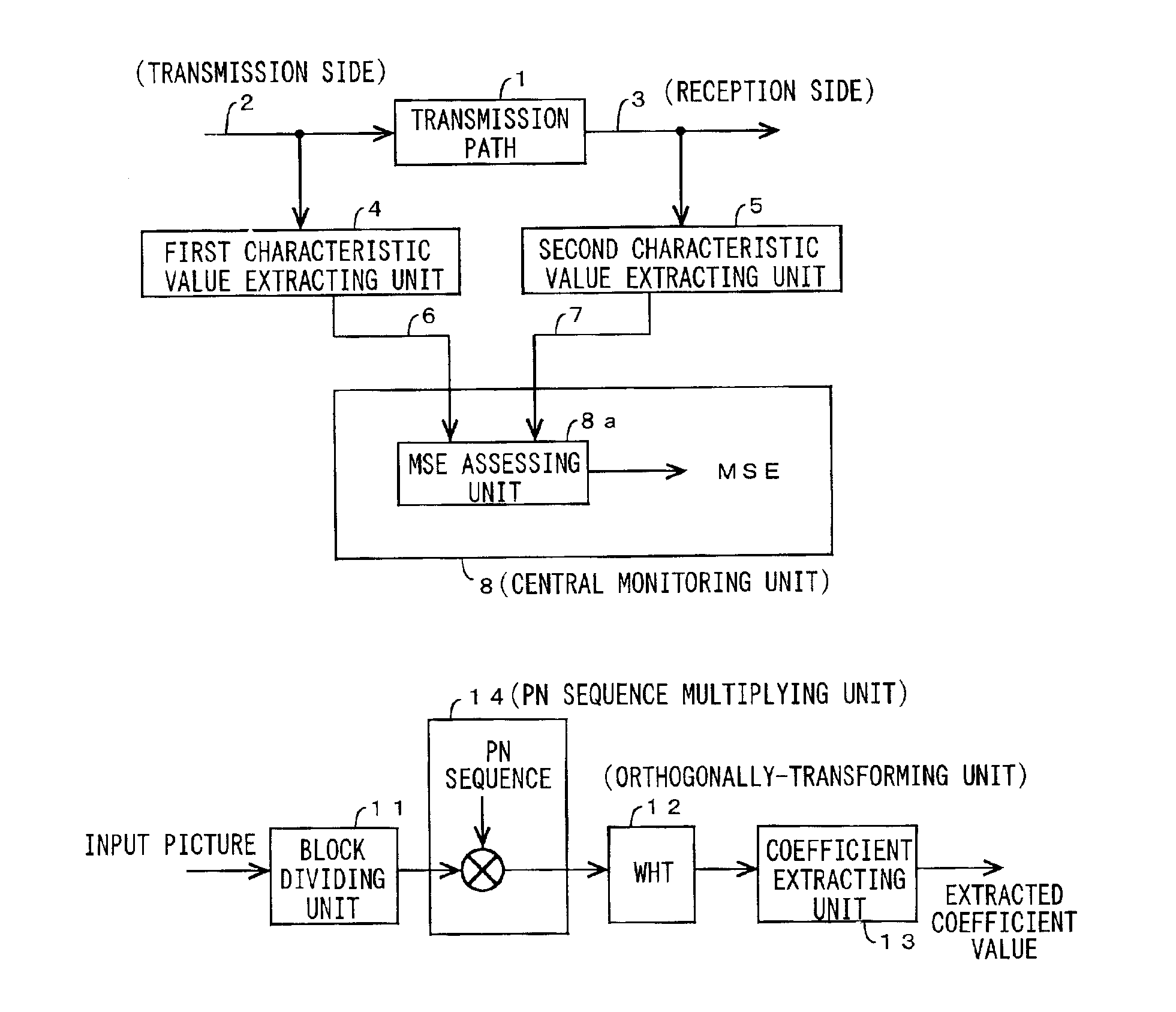

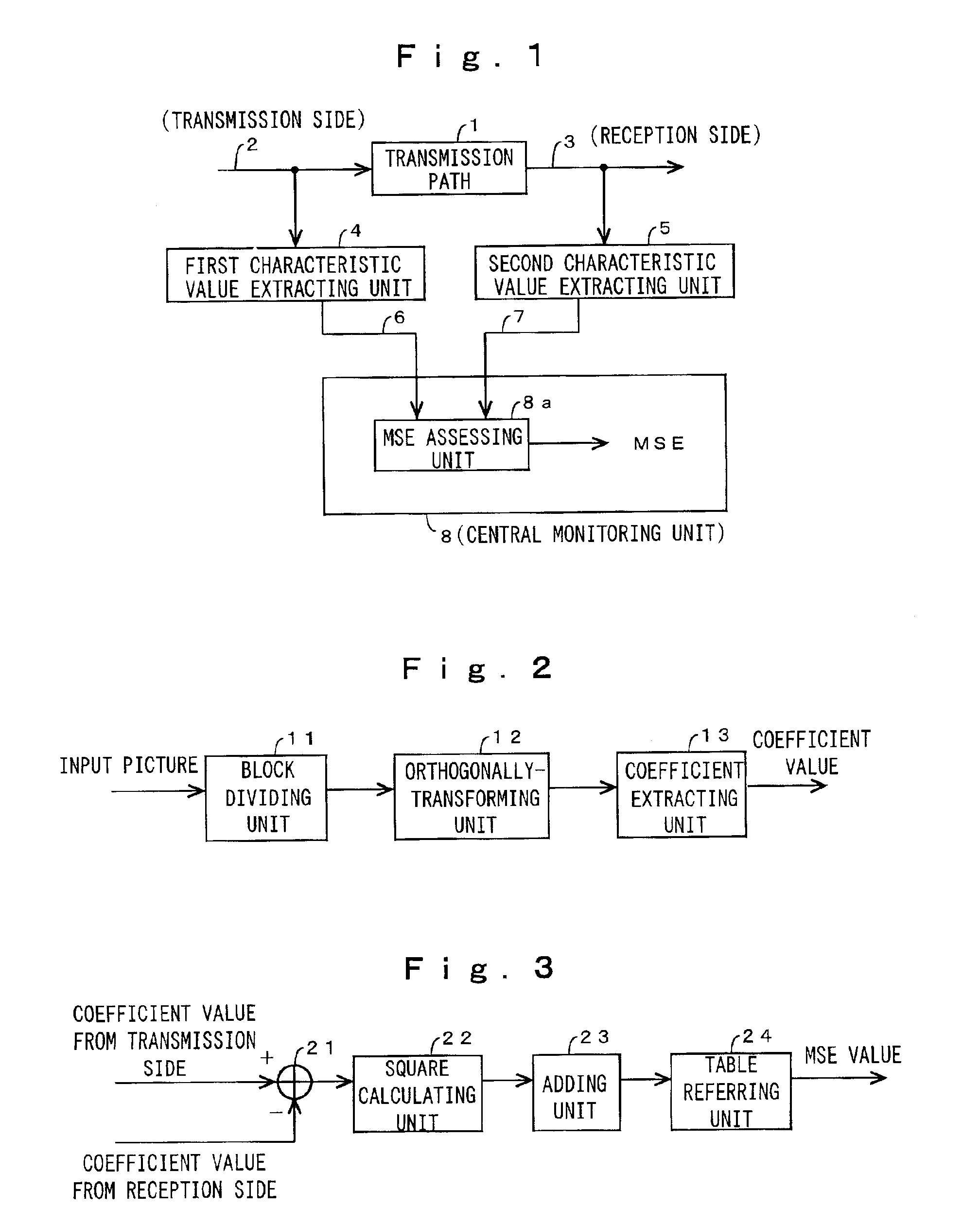

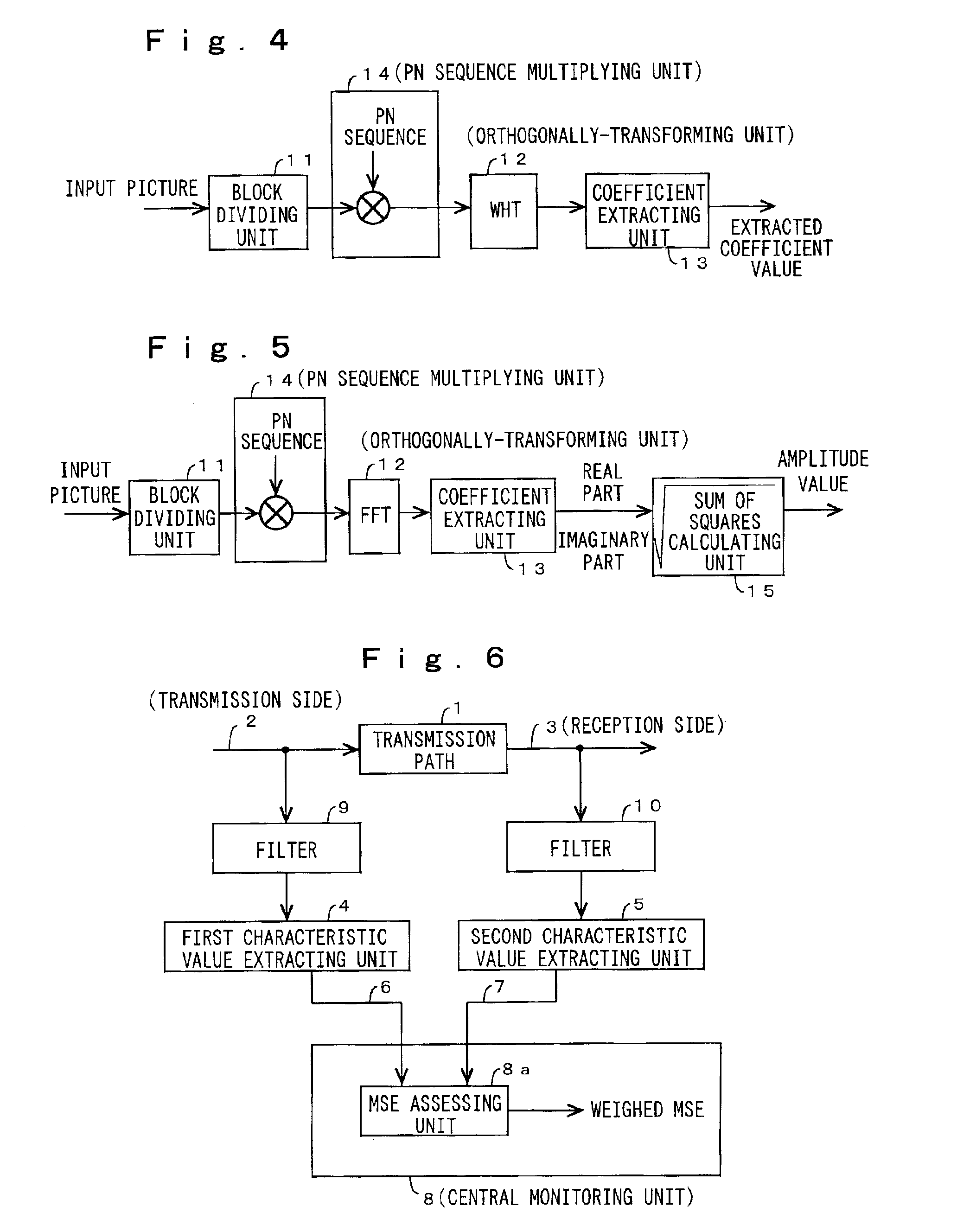

Apparatus for monitoring quality of picture in transmission

ActiveUS6943827B2Effective assessmentAccurate assessmentCharacter and pattern recognitionTelevision systemsMean squareLow speed

A first characteristic value extracting unit extracts a characteristic value from a picture transmitted from a transmission side, and a second characteristic value extracting unit extracts a characteristic value from a picture received on a reception side. These extracted characteristic values are supplied to a central monitoring unit through low speed lines, respectively. In the central monitoring unit, an MSE (mean square error) is assessed from the data by an MSE assessing unit. The first and second characteristic value extracting units divide an input picture into blocks, subject the blocks to an orthogonal transformation, or subject the blocks to PN sequence multiplication before the orthogonal transformation, and extract and output orthogonal transformation coefficients. The MSE assessing unit determines the differences between corresponding coefficients on the transmission side and the reception side and squares the differences, adds the squared differences for every coefficients or every blocks, and assess an MSE based on the added values referred to a table. With this operation, the MSE can be effectively assessed using a smaller amount of extracted data (accordingly, slower speed lines can be used in the central monitoring unit).

Owner:KDDI CORP

Organic field effect transistor and method of manufacturing the same

InactiveUS7372070B2Extend your lifeEasy to carrySolid-state devicesSemiconductor/solid-state device manufacturingCharge injectionOrganic field-effect transistor

To provide an organic field effect transistor with stable characteristics and a long life span, an organic field effect transistor includes a gate electrode 8 formed on an organic semiconductor film 2 made of an organic semiconductor material with a gate insulating film 3 interposed therebetween; and a source electrode 6 and a drain electrode 7 provided so as to come in contacts with the organic semiconductor film with the gate electrode 8 interposed therebetween. At least one of the source electrode 6 and the drain electrode 7 is formed in contact with the organic semiconductor film 2 with charge injection layers 4 and 5 made of an inorganic material interposed therebetween.

Owner:PANASONIC CORP

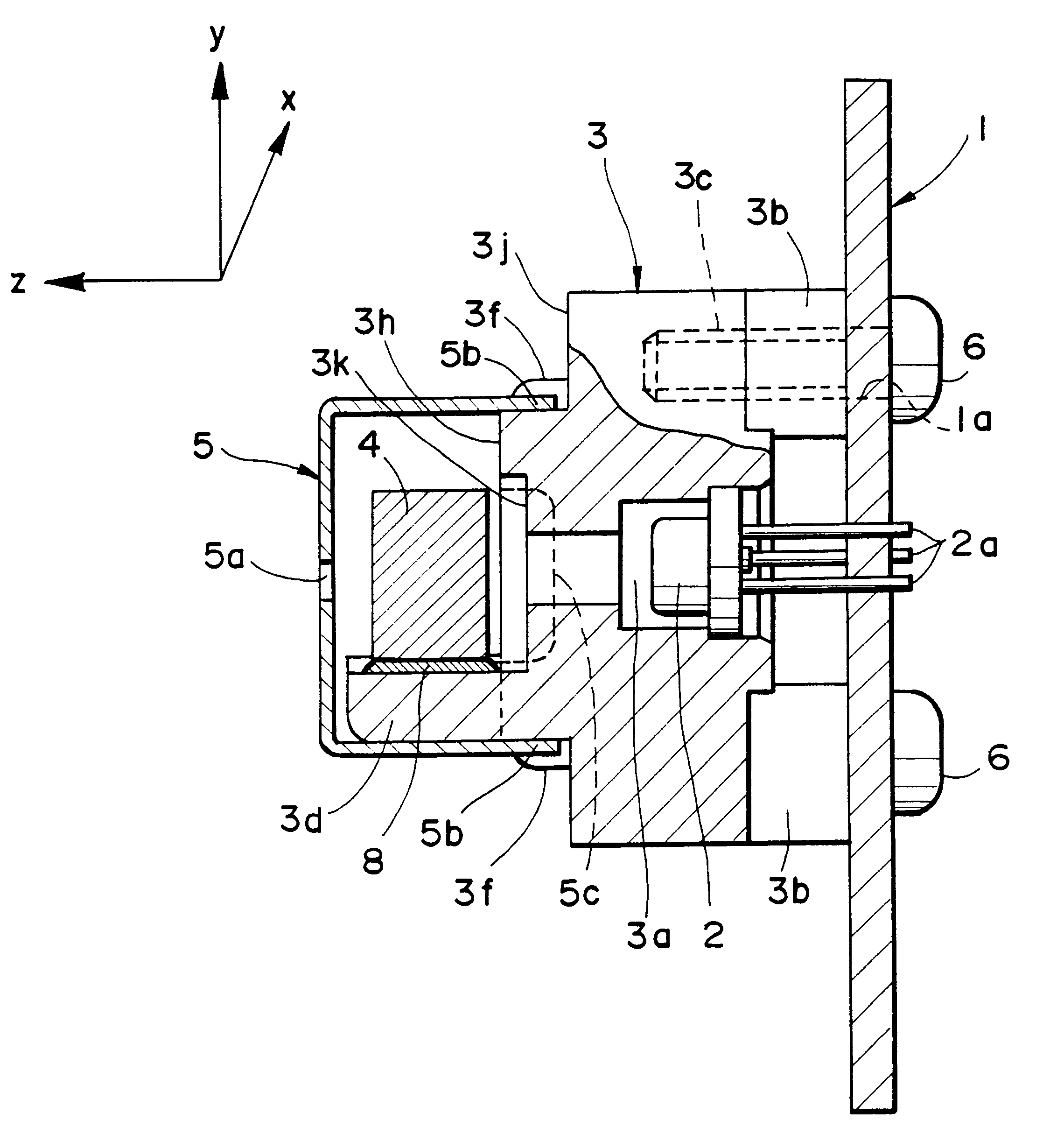

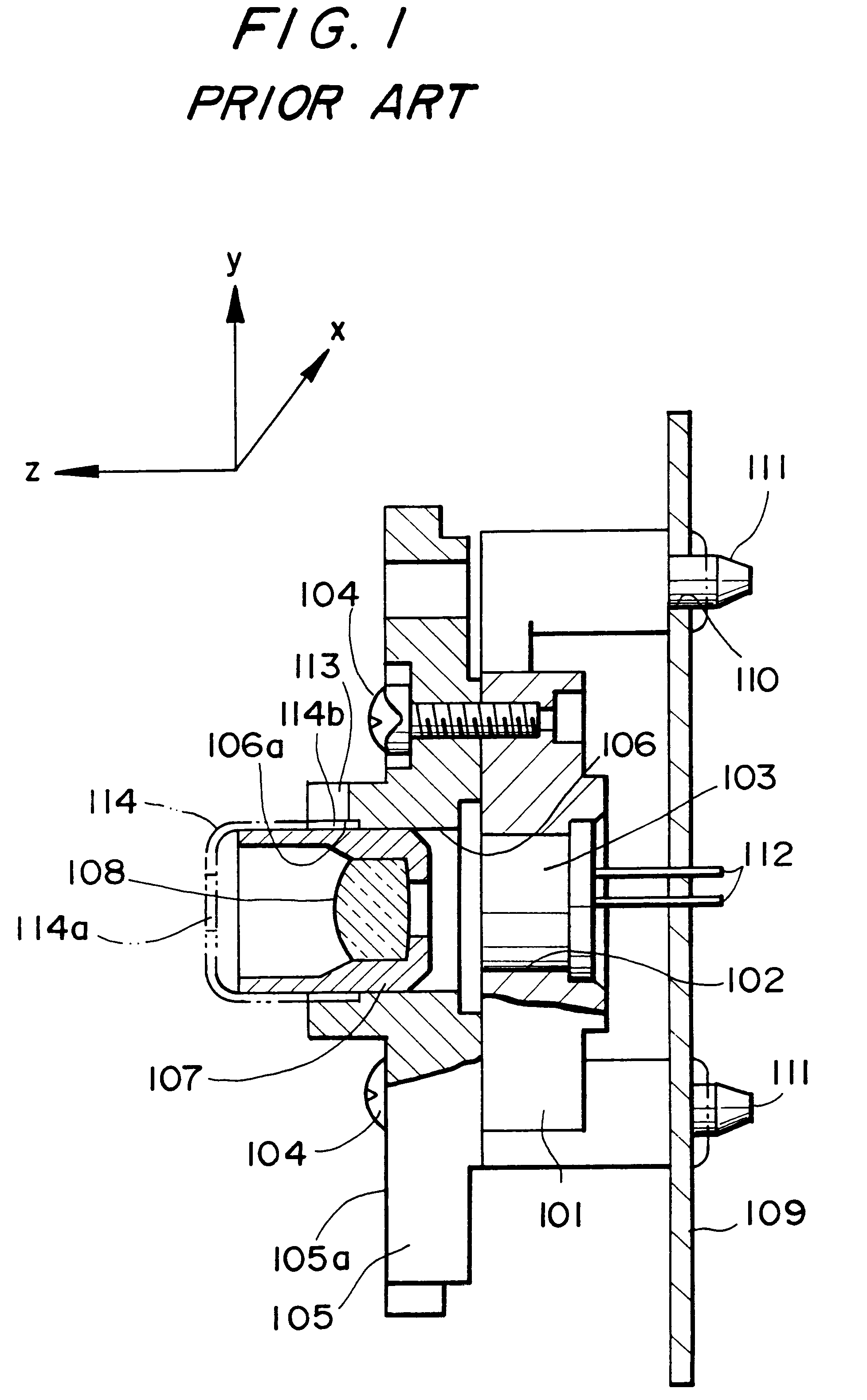

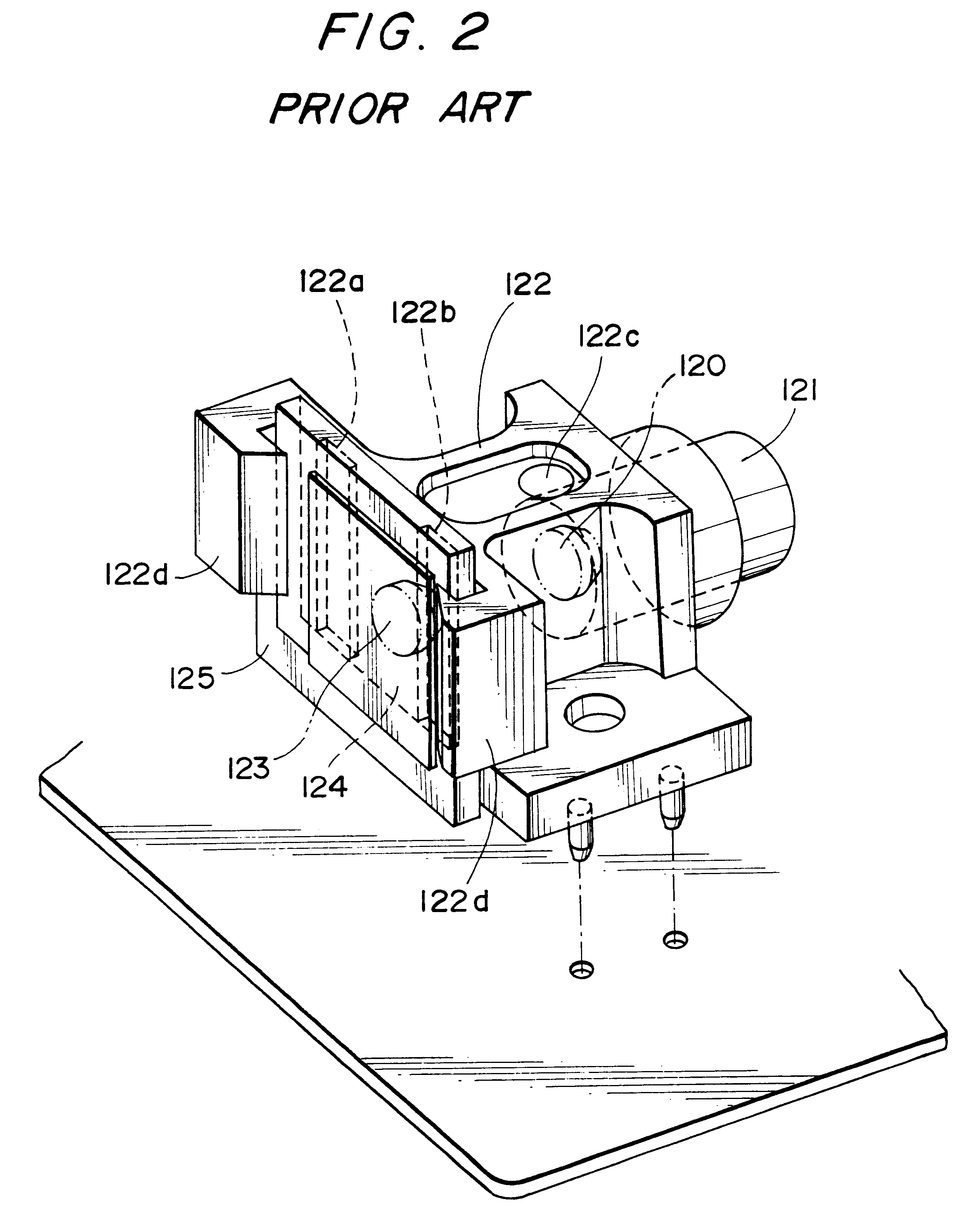

Light source device for an image forming apparatus

InactiveUS6179445B1Inexpensive and highly accurateEasily damagedCoupling light guidesPrintingAdhesiveImage formation

A light source device for use in an image forming apparatus and using a semiconductor laser is disclosed. The device needs a minimum of constituent parts and frees the individual part from dislocation in the event of assembly. A collimator lens included in the device is fixed in place by photo-curable adhesive. The device is low cost and highly accurate.

Owner:RICOH KK

Optical-semiconductor encapsulating material

InactiveUS20110079816A1Easy to useIncrease temperatureSemiconductor/solid-state device detailsSolid-state devicesInorganic particlePhosphor

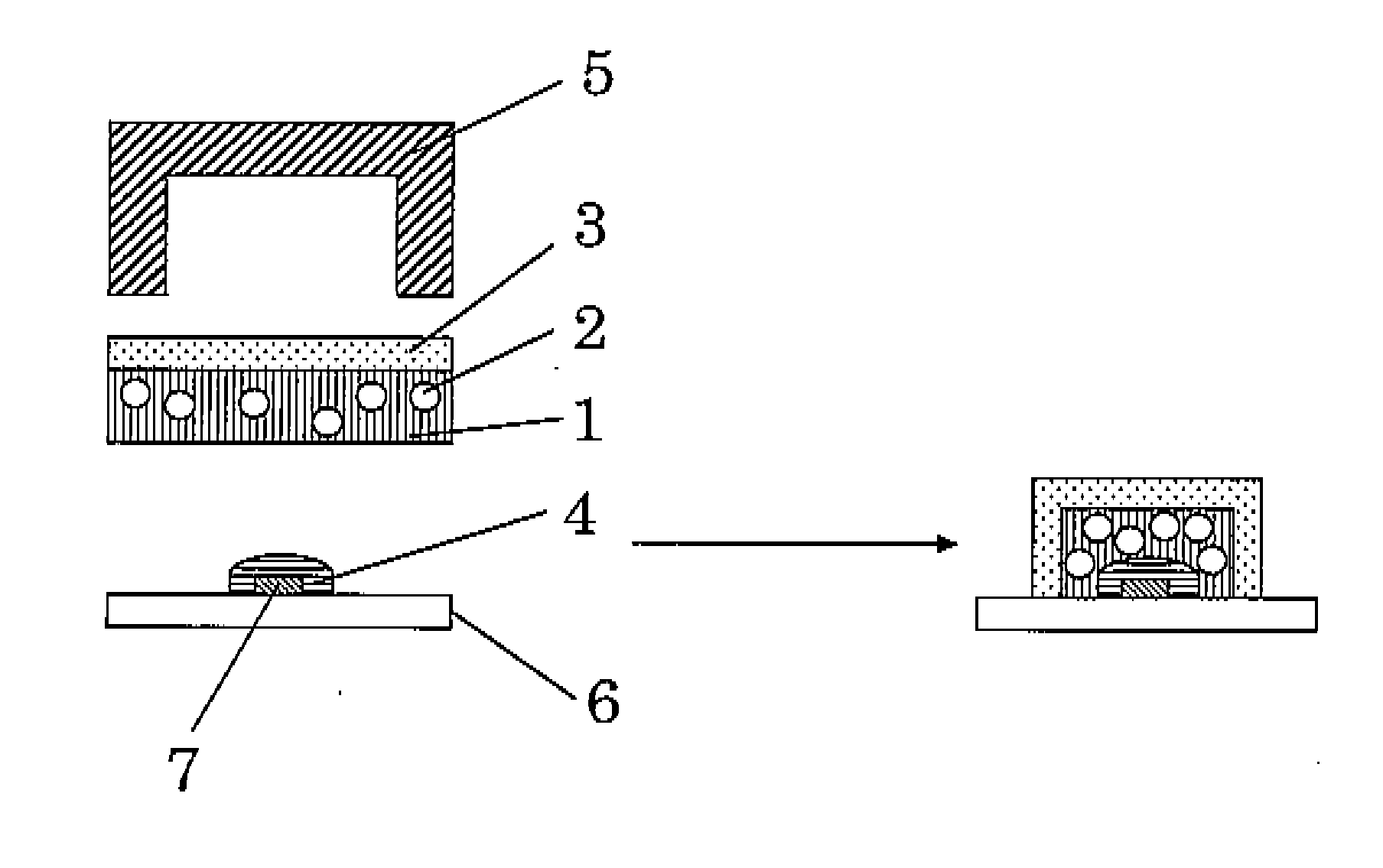

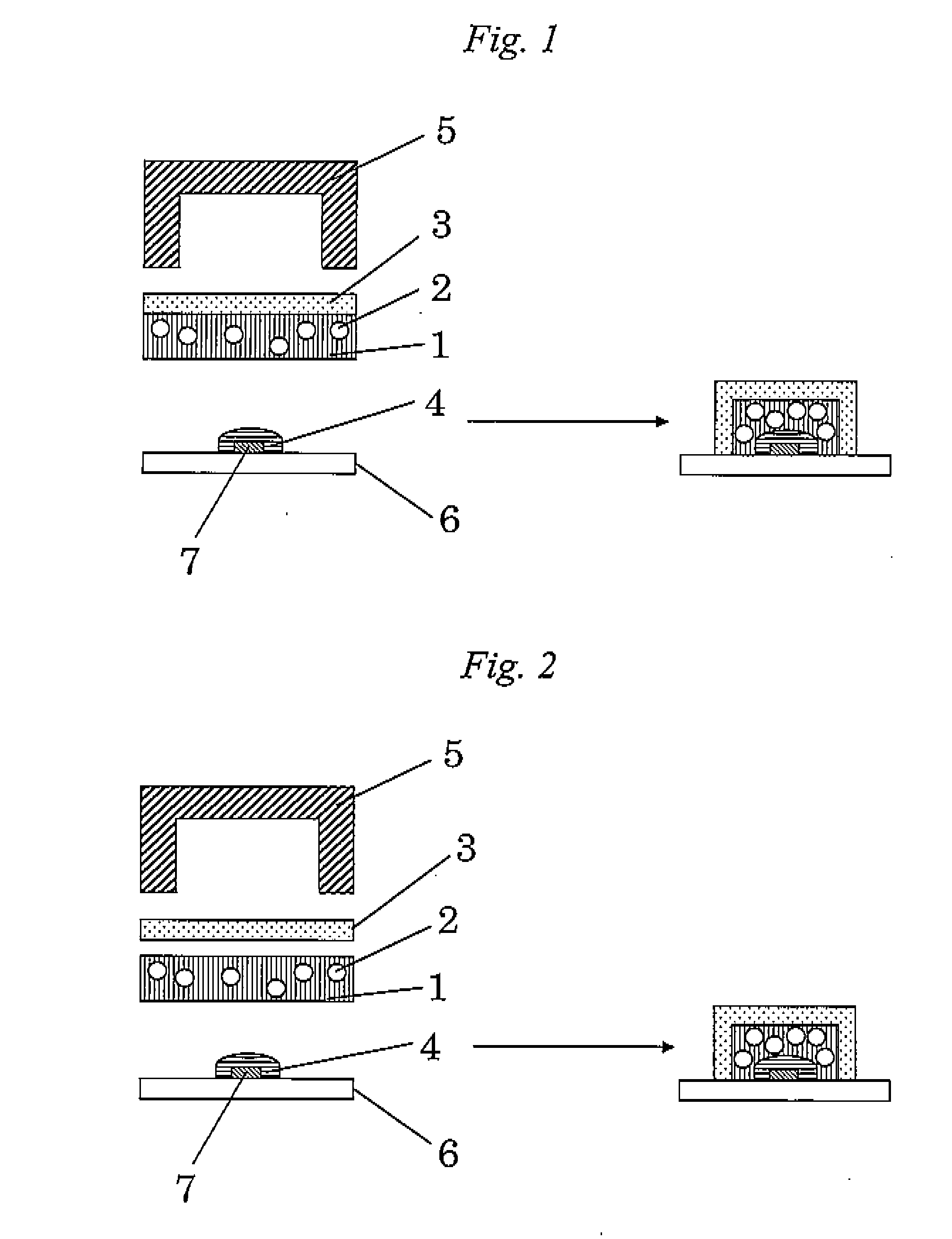

The present invention relates to a sheet-shaped optical-semiconductor encapsulating material including: a first resin layer containing inorganic particles; and a second resin layer containing a phosphor and being superposed directly or indirectly on the first resin layer, and relates to a kit for optical-semiconductor encapsulation including: a sheet-shaped molded body including a first resin layer containing inorganic particles; and a sheet-shaped molded body including a second resin layer containing a phosphor.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com