Hot melt adhesive composition and preparation method thereof, and hot melt adhesive heat-conducting strip and preparation method thereof

A technology of hot melt adhesives and compositions, applied in the direction of acrylonitrile butadiene styrene polymer adhesives, adhesives, epoxy resin adhesives, etc., can solve problems such as flow and deformation of phase change interface materials, and achieve easy to overcome flowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

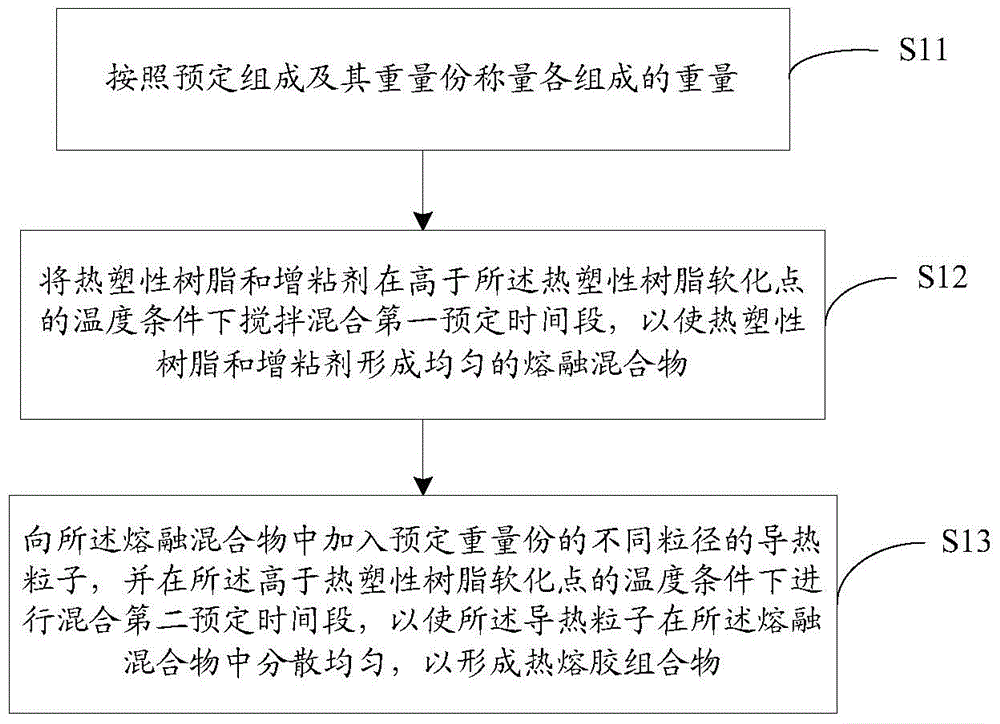

[0062] The embodiment of the present invention also provides a preparation method of the above-mentioned hot melt adhesive composition. Such as figure 1 Shown, the preparation method of above-mentioned hot-melt adhesive composition may further comprise the steps:

[0063] S11. Weigh the weight of each composition according to the predetermined composition and parts by weight:

[0064] Specifically, each component can be weighed according to the composition shown in Table 1 and its parts by weight.

[0065] S12. Mixing the thermoplastic resin and the tackifier at a temperature higher than the softening point of the thermoplastic resin for a first predetermined period of time, so that the thermoplastic resin and the tackifier form a homogeneous molten mixture:

[0066] It should be noted that the temperature higher than the softening point of the thermoplastic resin cannot be raised without limit. It is necessary to ensure that the thermoplastic resin and the tackifier can mel...

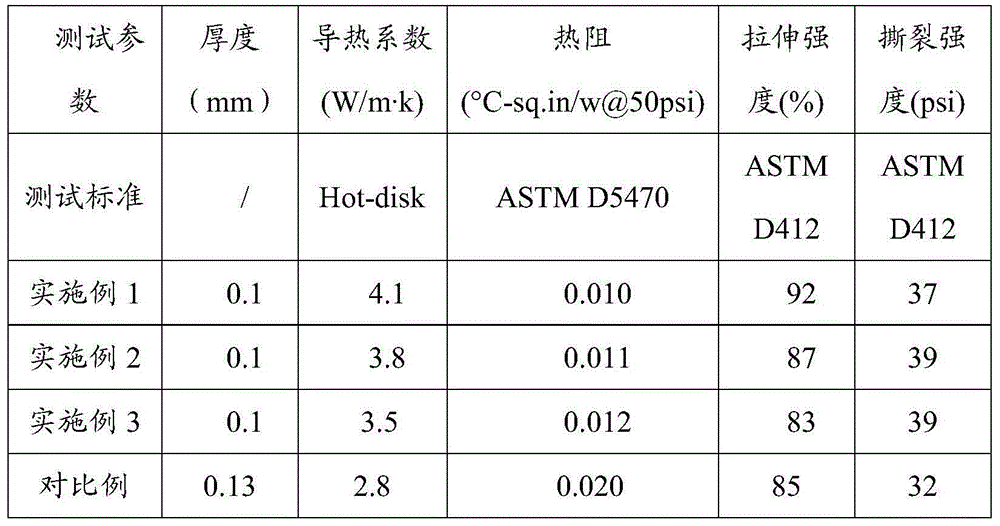

Embodiment 1

[0098] The composition and parts by weight of the hot-melt adhesive composition in embodiment 1 are as shown in table 4:

[0099] Table 4: Formulation of Example 1

[0100] composition

Weight (unit: Kg)

PET resin

2.5

EVA resin

5

0.5

Zinc oxide powder with a particle size of 0.5 microns

25

Zinc oxide powder with a particle size of 5 microns

15

Aluminum powder with a particle size of 30 microns

32

Aluminum powder with a particle size of 4 microns

20

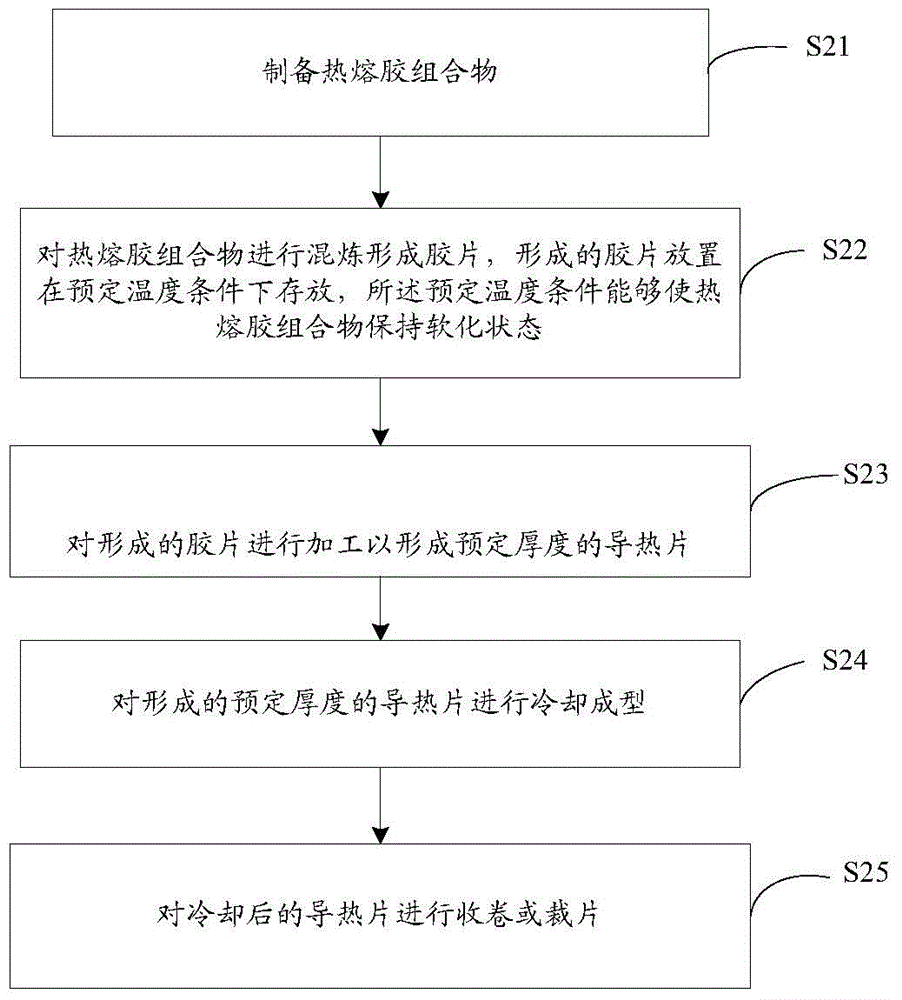

[0101] The preparation method of the hot melt adhesive heat conducting sheet composed of the above components is as follows:

[0102] A, preparation of hot melt adhesive composition:

[0103] 1) Weigh 2.5 kg of PET resin, 5 kg of EVA resin and 0.5 kg of tackifier and mix them together for 15 minutes at 130±5°C to make them fully mixed;

[0104] Add 25 kg of zinc oxide powder with a particle size of 0.5 micron, continue to s...

Embodiment 2

[0112] The composition and parts by weight of the hot melt adhesive composition in embodiment 2 are as shown in table 5:

[0113] Table 5: Formulation of Example 2

[0114] composition

[0115] The preparation method of the hot melt adhesive heat conducting sheet described in Example 2 is the same as that in Example 1. For the sake of brevity, it will not be described in detail here. For details, refer to the detailed description of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com