Method for preparing alum-free vermicelli based on modified starch

A technology for modified starch and starch, applied in the field of vermicelli production, can solve the problems of unsatisfactory improvement effect of inorganic salts, etc., and achieve the effects of good emulsification stability, good film-forming property and increased toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

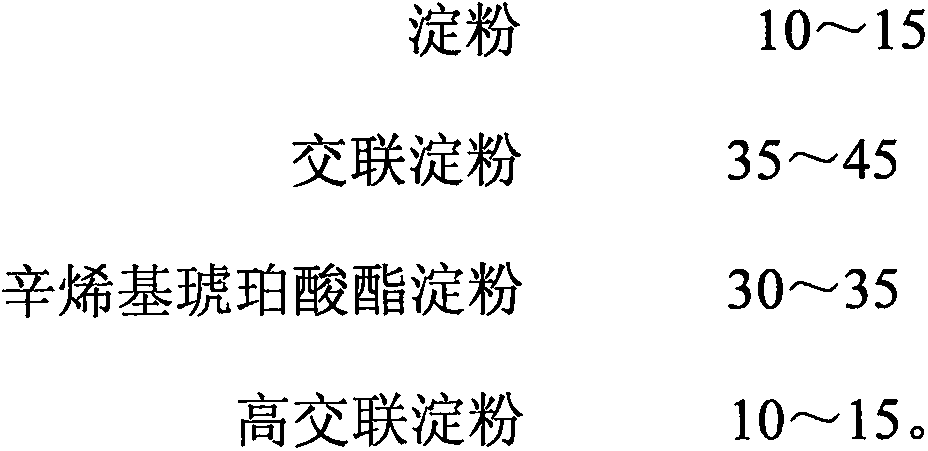

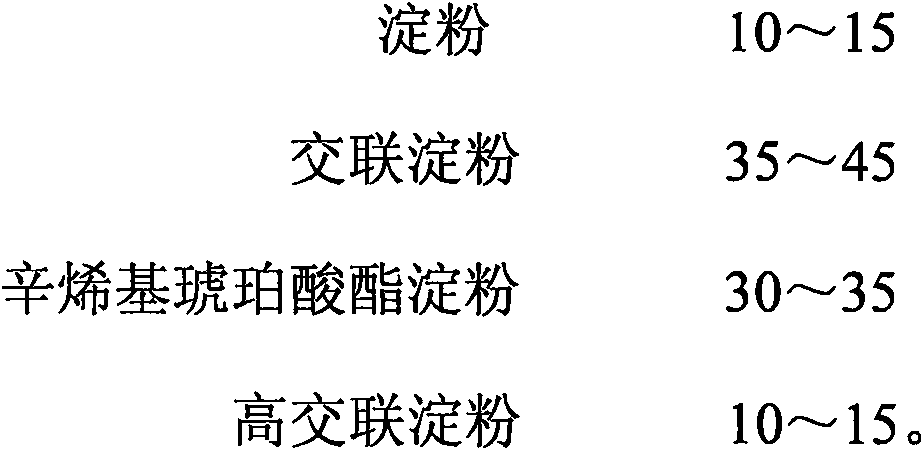

Embodiment 1

[0027] Add 10kg of sweet potato starch to 10kg of water while stirring to make starch milk, heat 50kg of water to boiling and quickly pour it into the starch milk and stir to make gorgon paste, then add 45kg of cross-linked starch, 35kg of octenyl succinate starch, 10kg of high cross-linked starch, stir and knead for 30 minutes to make the mixture uniform, put the mixture into a vermicelli machine, extrude it and quickly put it into a boiling water pot, cook it for 30 seconds, then quickly put it in cold water ≤ 20°C to cool and regenerate for 10 minutes, and dry it The finished product of alum-free vermicelli is obtained.

Embodiment 2

[0029] Add 15kg of potato starch to 15kg of water while stirring to make starch milk, heat 45kg of water to boiling and quickly pour it into the starch milk and stir to make gorgon paste, then add 40kg of cross-linked starch, 30kg of octenyl succinate starch, 15kg of high cross-linked starch, stir and knead for 25 minutes to make the mixture uniform, put the mixture into a vermicelli machine, extrude it and quickly put it into a boiling water pot, cook it for 30 seconds, then quickly put it in cold water ≤ 20 ° C for 10 minutes, and dry it The finished product of alum-free vermicelli is obtained.

Embodiment 3

[0031] Add 10kg of pea starch to 10kg of water while stirring to make starch milk, heat 50kg of water to boiling and quickly pour it into the starch milk and stir to make gorgon paste, then add 40kg of cross-linked starch, 35kg of octenyl succinate starch, 15kg of high cross-linked starch, stir and knead for 30 minutes to make the mixture uniform, put the mixture into a vermicelli machine, extrude it and quickly put it into a boiling water pot, cook it for 30 seconds, then quickly put it in cold water ≤ 20°C to cool and regenerate for 10 minutes, and dry it Promptly make the finished product of vermicelli without alum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com