Radiation modified soybean isolated protein/starch plastic and preparation method thereof

A soybean protein isolate and starch technology, which is applied in the field of environmental science and natural polymer materials, can solve the problems of difficult market operation, difficult filling materials and soybean protein, and difficult to meet the needs of industrial production and processing, so as to improve the surface compactness and tensile strength. Tensile strength, beneficial to the protection of the ecological environment, the effect of improving the tensile strength and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

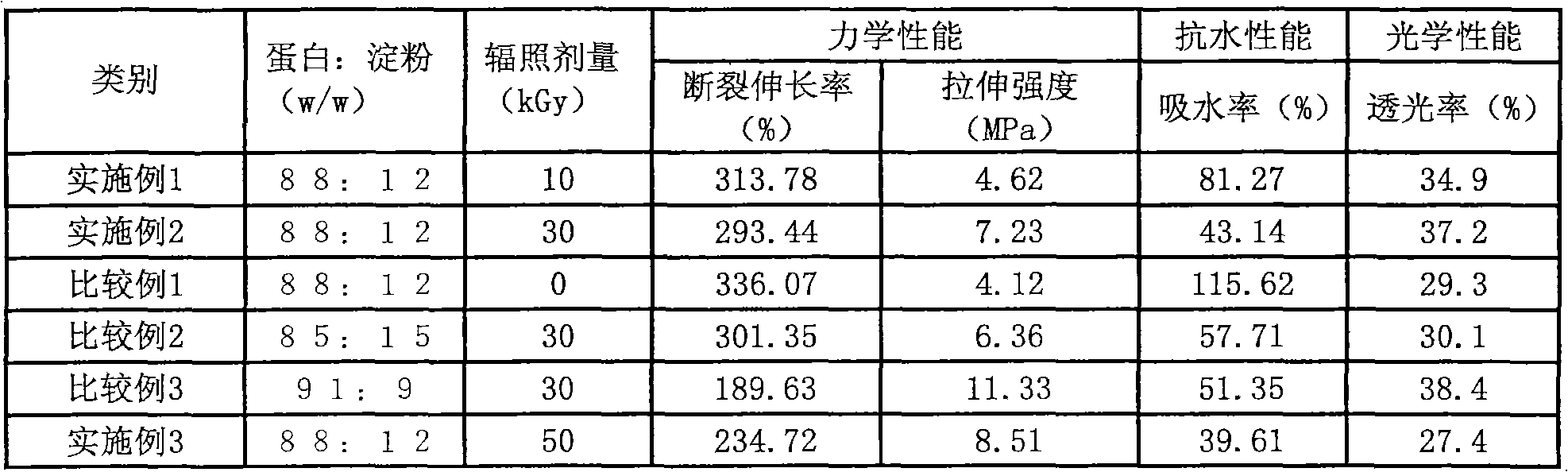

Embodiment 1

[0025] (1) Disperse 100kg of soybean protein isolate and starch (88:12, W / W) mixture in 300kg of methanol or ethanol, mechanically stir the SPI to disperse evenly, and divide into three times (interval 10 minutes) Add 1L of hydrochloric acid (0.1mol / L), and stir for 30 minutes in total. After the reaction is completed, filter with suction and dry naturally to obtain the capped modified raw material for later use;

[0026] (2) Add 1 kg of caprolactam to 15 kg of water, add 15 kg of water to 100 kg of raw materials, mechanically stir until fluffy and free of lumps, vacuum seal, and use a dose of 10 kGy for irradiation cross-linking treatment;

[0027] (3) Weigh 100kg of irradiated soy protein isolate and starch mixture, add 20kg of glycerin, mix these raw materials well, pour them into the flat mold of the flat vulcanizer, and mold them at a molding temperature of 120°C and 15Mpa Under pressure, hot press for 15 minutes, and the hot product is cooled and formed at room temperatu...

Embodiment 2

[0029] (1) Disperse 100kg of soybean protein isolate and starch (88:12, W / W) mixture in 300kg of methanol or ethanol, mechanically stir the SPI to disperse evenly, and divide into three times (interval 10 minutes) Add 1L of hydrochloric acid (0.1mol / L), and stir for 30 minutes in total. After the reaction is completed, filter with suction and dry naturally to obtain the capped modified raw material for later use;

[0030] (2) Add 1 kg of caprolactam to 15 kg of water, add 15 kg of water to 100 kg of raw materials, mechanically stir until fluffy and free of lumps, vacuum seal, and use a dose of 30 kGy for irradiation cross-linking treatment;

[0031] (3) Weigh 100kg of irradiated soy protein isolate and starch mixture, add 20kg of glycerin, mix these raw materials well, pour them into the flat mold of the flat vulcanizer, and mold them at a molding temperature of 120°C and 15Mpa Under pressure, hot press for 15 minutes, and the hot product is cooled and formed at room temperatu...

Embodiment 3

[0045] (1) 100kg of soybean protein isolate and starch (85:15, W / W) mixture is dispersed in 300kg of methanol or ethanol, mechanically stirred to make the SPI evenly dispersed, after stirring, divide into three times (interval 10 minutes) Add 1L of hydrochloric acid (0.1mol / L), and stir for 30 minutes in total. After the reaction is completed, filter with suction and dry naturally to obtain the capped modified raw material for later use;

[0046] (2) Add 1 kg of caprolactam to 15 kg of water, add 15 kg of water to 100 kg of raw materials, mechanically stir until fluffy and free of lumps, vacuum seal, and use a dose of 50 kGy for irradiation cross-linking treatment;

[0047] (3) Weigh 100kg of irradiated soy protein isolate and starch mixture, add 20kg of glycerin, mix these raw materials well, pour them into the flat mold of the flat vulcanizer, and mold them at a molding temperature of 120°C and 15Mpa Under pressure, hot press for 15 minutes, and the hot product is cooled and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com