Double-component epoxy structural adhesive

A technology of epoxy structural adhesives and adhesives, which is applied in the direction of epoxy resin adhesives, adhesives, and adhesive additives. Convenient transportation and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a two-component epoxy structural adhesive, comprising the following steps:

[0029] Step 1: Preparation of component A

[0030] (1) Weigh the epoxy resin and toughener according to the formula, heat at 50-70°C for 20-30 minutes, and mix well;

[0031] (2) Add fillers and plasticizers according to the formula amount, and after stirring, defoam on a vacuum high-speed stirring degassing machine at a speed of 2000-3000r / min for 180-300 seconds to a uniform mixture, and then obtain component A;

[0032] Step 2: Preparation of component B

[0033] (1) Weigh the curing agent, filler, plasticizer and auxiliary agent according to the formula amount, and after stirring, defoam on a vacuum high-speed stirring defoaming machine at a speed of 2000-3000r / min for 180-300 seconds to a uniform mixture, and then obtain group B share;

[0034] Mix the prepared components A and B according to the mass ratio of 3:1 to obtain a two-component structural adhesive.

Embodiment 1

[0036] (1) Put 40% epoxy resin E51 and 35% nano-core-shell modified resin in an oven at 50-70°C and heat for 20-30 minutes, stirring twice during the process to make the materials evenly mixed;

[0037] (2) Add 5% dodecyl glycidyl ether, 2% fumed white carbon black, and 18% nano-calcium carbonate to the above-mentioned mixed material, and mix them evenly, and put them on a vacuum high-speed stirring defoaming machine Degas at a speed of 2000r / min for 300 seconds to a homogeneous mixture to obtain component A;

[0038] (3) Weighing 3% dicyandiamide curing agent, 15% aliphatic amine curing agent, 10% alicyclic amine curing agent, 15% didecyl phthalate, 2% dicyandiamide curing agent, 2% dicyandiamide curing agent Dialkyl glycidyl ether, 2% coupling agent, 2% anti-aging agent, 6% antioxidant, 40% nano-calcium carbonate and 5% fumed silica, after mixing evenly, stir in vacuum at high speed Degassing at a speed of 2000r / min for 300 seconds on a degassing machine until a homogeneous...

Embodiment 2

[0041] (1) Put 40% epoxy resin E51, 30% nano-core-shell modified resin, and 5% carboxyl-terminated liquid butyronitrile in an oven at 50-70°C for 20-30 minutes by mass, during which time Stir twice to mix the ingredients evenly;

[0042] (2) Add 5% dioctyl phthalate, 5% didecyl phthalate, 4% fumed silica, and 11% light calcium carbonate to the above mixed material. , after mixing evenly, defoam at a speed of 2000r / min for 300 seconds on a vacuum high-speed stirring degassing machine to obtain a uniform mixture, that is, to obtain component A;

[0043] (3) Weigh 3% dicyandiamide curing agent, 20% aliphatic amine curing agent, 8% alicyclic amine curing agent, 10% didecyl phthalate, 5% dicyandiamide curing agent, 5% dicyandiamide curing agent Dialkyl glycidyl ether, 2% coupling agent, 2% anti-aging agent, 6% antioxidant, 40% nano-calcium carbonate and 4% fumed silica, after mixing evenly, stir in vacuum at high speed Degassing at a speed of 2000r / min for 300 seconds on a degass...

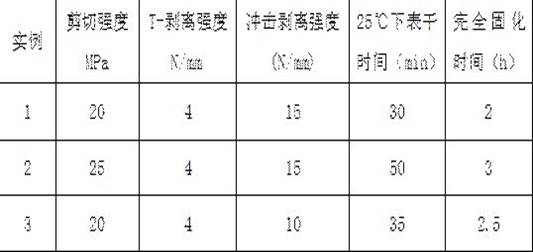

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com