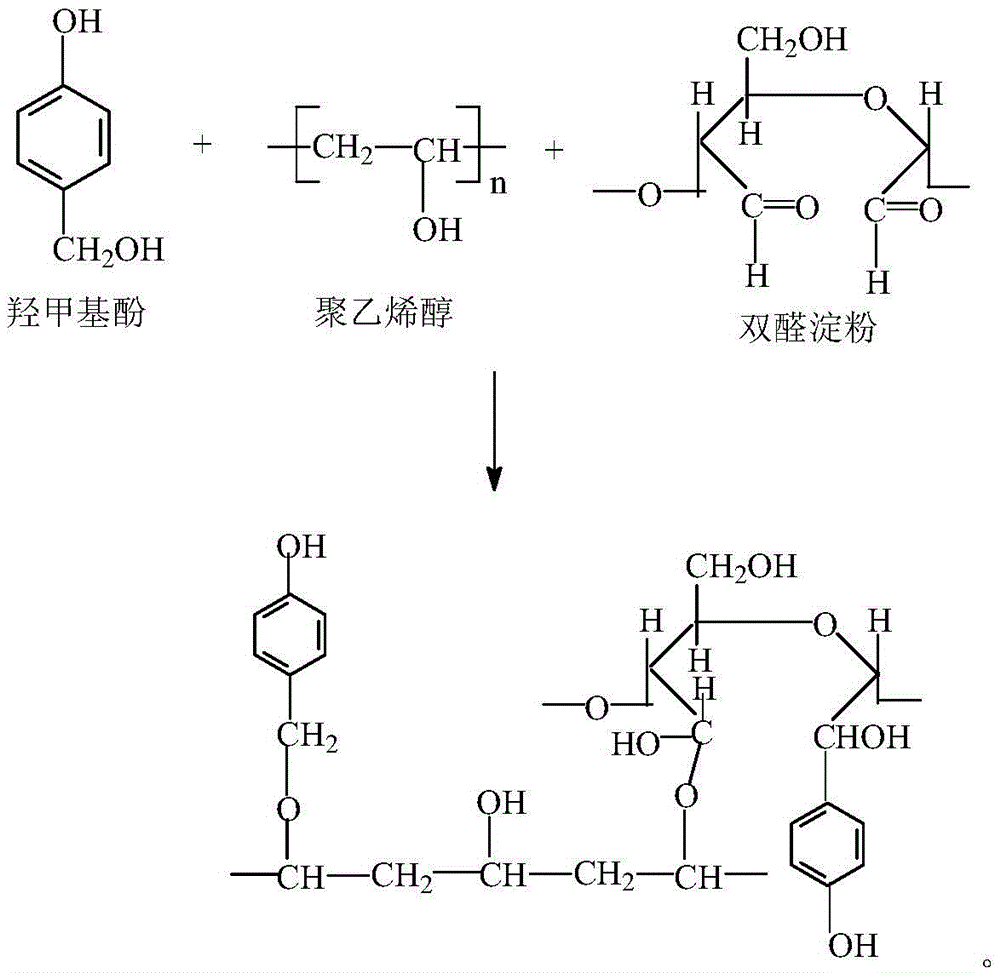

Phenol-dialdehyde starch-formaldehyde resin adhesive and preparation method thereof

A dialdehyde starch, formaldehyde resin technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of restrictions and high prices of resorcinol, achieve low cost and reduce dependence Excellent effect of resistance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

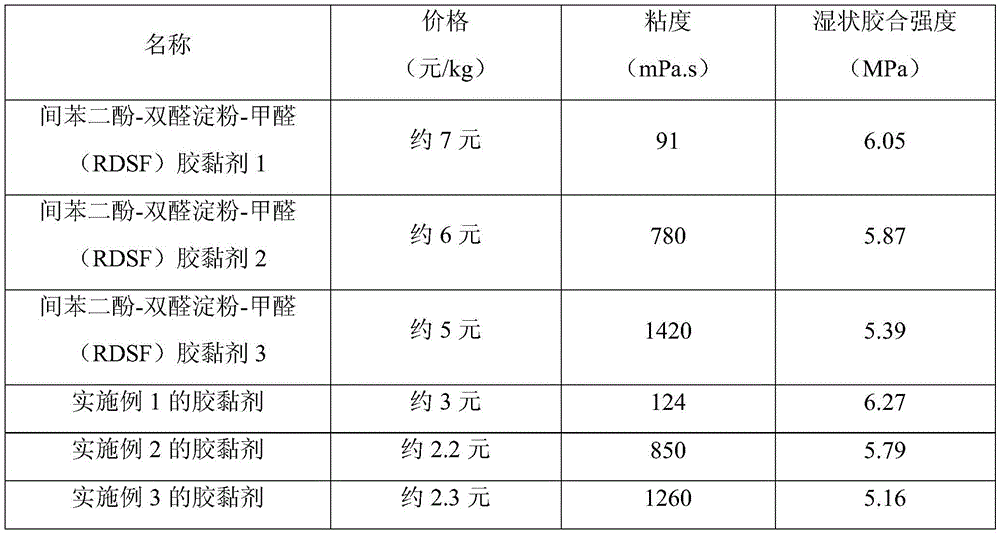

Embodiment 1

[0030] A kind of phenol-dialdehyde starch-formaldehyde resin adhesive of the present invention comprises the raw material of following components: 94.11Kg phenol, 81.2Kg mass concentration is the formaldehyde solution of 37%, 16Kg dialdehyde starch (aldehyde content>80%) ), 24Kg water and 5Kg polyvinyl alcohol 1788.

[0031] The preparation method of the phenol-dialdehyde starch-formaldehyde resin adhesive of the present embodiment may further comprise the steps:

[0032] (1) 94.11Kg of fused phenol is added to the reactor, and the pH is adjusted to 11 with a 10% sodium hydroxide aqueous solution with a mass concentration;

[0033] (2) dissolving 16Kg of dialdehyde starch in 24Kg of water to make starch milk with a mass concentration of 40%, adding it to the reactor, raising the reaction temperature to 60°C, and reacting at this temperature for 2h;

[0034] (3) Cool the mixture after step (2) to 40°C, add 56.8Kg of formaldehyde solution, raise the temperature to 80°C at a uni...

Embodiment 2

[0039] A kind of phenol-dialdehyde starch-formaldehyde resin adhesive of the present invention comprises the raw material of following components: 94.11Kg phenol, 121.74Kg mass concentration is the formaldehyde solution of 37%, 50Kg dialdehyde starch (aldehyde content>80%) ), 200Kg water and 10Kg polyvinyl alcohol 1799.

[0040] The preparation method of the phenol-dialdehyde starch-formaldehyde resin adhesive of the present embodiment may further comprise the steps:

[0041] (1) 94.11Kg of fused phenol is added in the reactor, and the pH is adjusted to 9 with a 20% aqueous sodium hydroxide solution with a mass concentration;

[0042] (2) dissolving 50Kg of dialdehyde starch in 200Kg of water to make starch milk with a mass concentration of 20%, adding it to the reactor, raising the reaction temperature to 80°C, and reacting at this temperature for 3h;

[0043] (3) Cool the mixture after step (2) to 40°C, add 85.22Kg of formaldehyde solution, raise the temperature to 82°C at ...

Embodiment 3

[0048] A kind of phenol-dialdehyde starch-formaldehyde resin adhesive of the present invention comprises the raw material of following components: 94.11Kg phenol, 146.1Kg concentration is the formaldehyde solution of 37%, 100Kg dialdehyde starch (aldehyde group content>80%) , 566.7Kg water and 20Kg polyvinyl alcohol 1788.

[0049] The preparation method of the phenol-dialdehyde starch-formaldehyde resin adhesive of the present embodiment may further comprise the steps:

[0050] (1) 94.11Kg of molten phenol is added to the reactor, and the pH is adjusted to 10 with 30% aqueous sodium hydroxide solution;

[0051] (2) Dissolving 100Kg of dialdehyde starch in 566.7Kg of water to make starch milk with a mass concentration of 15%, adding it to the reaction kettle, raising the reaction temperature to 84°C, and reacting at this temperature for 5h;

[0052] (3) Cool the mixture after step (2) to 40°C, add 102.3Kg of formaldehyde solution, raise the temperature to 84°C at a uniform spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com