Single component room temperature curing epoxy construction glue

A technology of room temperature curing and construction glue, which is applied in the direction of epoxy resin glue, adhesives, non-polymer adhesive additives, etc. It can solve the problems of only being discarded, polluting building materials, and glue that cannot be recycled, and achieves convenient construction and use , the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

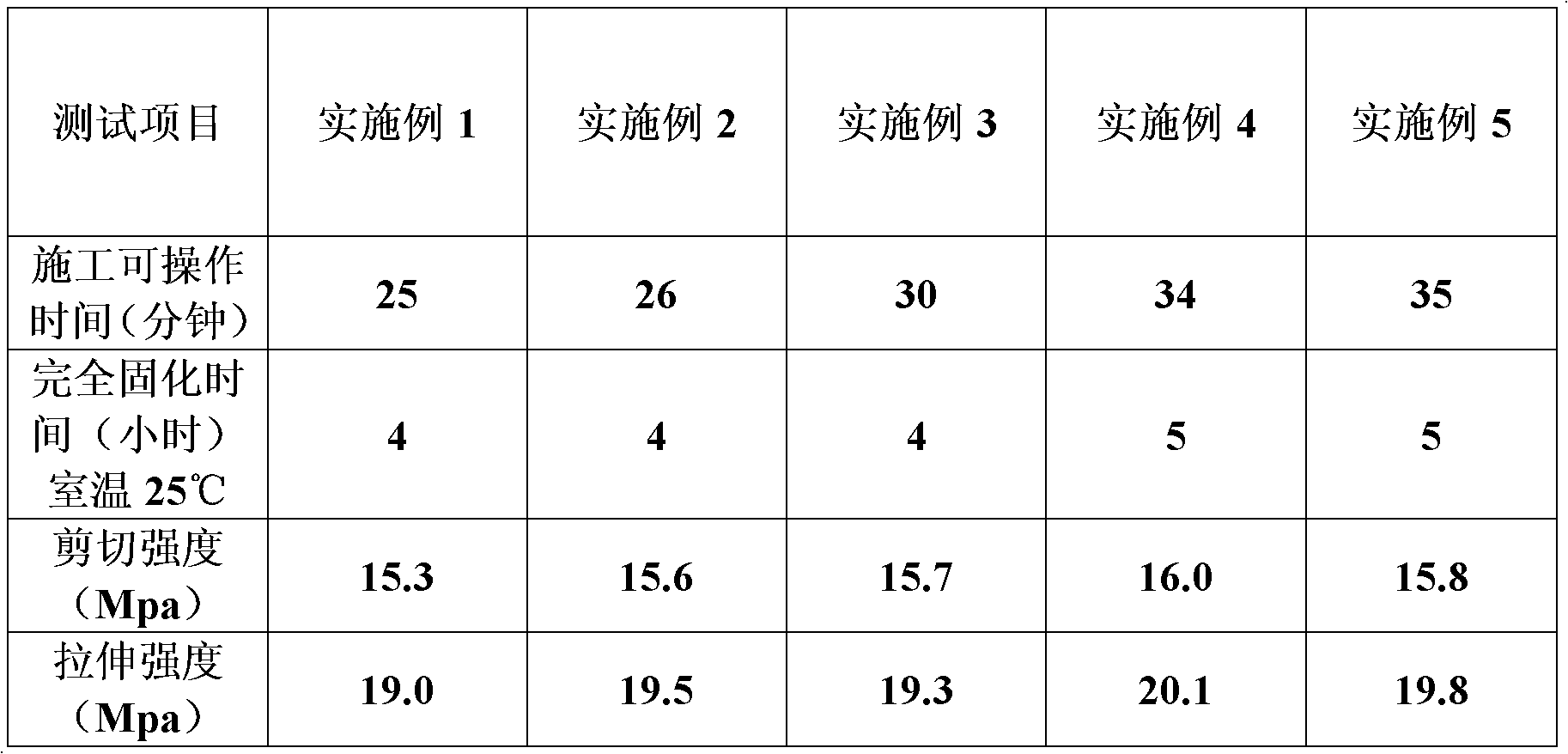

Examples

Embodiment 1

[0022] 80 parts of bisphenol A type epoxy resin;

[0023] 6 parts of ethylene glycol diglycidyl ether;

[0024] 12 parts of diethylenetriamine;

[0025] 3 parts of γ-aminopropyltriethoxysilane;

[0026] 0.5 parts of three-(dimethylaminomethyl)phenol;

[0027] Silicon dioxide 1.2 parts.

[0028] Wherein: the epoxy value of bisphenol A type epoxy resin is 0.52 equivalent / 100g.

Embodiment 2

[0030] Bisphenol F type epoxy resin (epoxy value 0.48 equivalent / 100g) 85 parts;

[0031] 12 parts of 1,4-butanediol diglycidyl ether;

[0032] 14 parts of triethylenetetramine;

[0033] 3.6 parts of γ-aminopropyltriethoxysilane;

[0034] 0.7 parts of three-(dimethylaminomethyl)phenol;

[0035] Precipitated silica 3.0 parts.

Embodiment 3

[0037] 90 parts of polyglycidyl ether epoxy resin (epoxy value 0.46 equivalent / 100g);

[0038] 15 parts of tetraethyl orthosilicate;

[0039] 10 parts of diethylenetriamine;

[0040] 5 parts of hexahydropyridine;

[0041] 4.2 parts of γ-aminopropyltriethoxysilane;

[0042] 1.2 parts of three-(dimethylaminomethyl)phenol;

[0043] 2.0 parts of fumed silica;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com