Waterproof anti-corrosion adhesive and preparation method thereof

A corrosion-resistant agent and adhesive technology, which is applied in the direction of monocarboxylate copolymer adhesives, adhesives, adhesive types, etc., can solve the problems of poor corrosion resistance, poor comprehensive performance, and the need to improve tensile strength , achieve good mechanical properties and aging resistance, excellent comprehensive performance, and improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

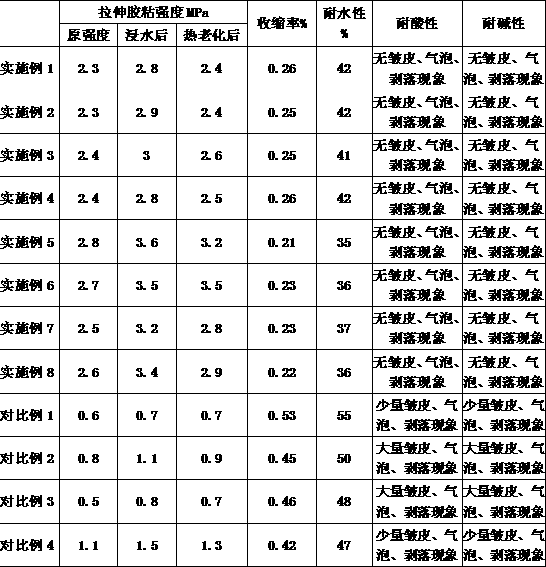

Examples

Embodiment 1

[0028] This embodiment provides a waterproof and corrosion-resistant adhesive, which is made of the following raw materials in parts by weight: 40 parts of trichloropropane, 25 parts of modified acrylic resin, 7 parts of waterproofing agent, 12 parts of corrosion-resistant agent, 5 parts of filler, 6 parts of auxiliary agent.

[0029] The modified acrylic resin is prepared from the following components in parts by weight: 60 parts of acrylic resin, 1.5 parts of silane coupling agent, 1.8 parts of zinc oxide, 18 parts of polyvinyl acetate, 9 parts of polyvinylidene fluoride, and 20 parts of tetrahydrofuran.

[0030] The waterproofing agent is a mixture of sodium methyl siliconate and zinc stearate, and the weight ratio of sodium methyl siliconate: zinc stearate is 5:1.

[0031] The anticorrosion agent is sodium chromate.

[0032] The filler is a mixture of vermiculite powder, manganese trioxide and titanium dioxide, and the weight ratio of vermiculite powder: manganese trioxid...

Embodiment 2

[0041] This embodiment provides a waterproof and corrosion-resistant adhesive, which contains the same raw materials and parts by weight as in Embodiment 1. The difference from Embodiment 1 is that the corrosion-resistant agent used in this embodiment is cinnamaldehyde, and the modified The raw materials and parts by weight included in the acrylic resin are the same as in Example 1.

[0042] The preparation method of the modified acrylic resin is as follows: after mixing the acrylic resin and tetrahydrofuran, place it in a magnetic stirrer at 20°C-25°C and stir for 20min at a speed of 200r / min; keep the speed constant, add a silane coupling agent and oxidize Zinc, continue to stir for 40min; add polyvinyl acetate and polyvinylidene fluoride, adjust the speed to 500r / min, stir for 1.5h, put it into an ultrasonic oscillator with a frequency of 30kHz, a power of 500W, and an oscillation time of 45mim.

[0043] The preparation method of described a kind of waterproof and corrosion...

Embodiment 3

[0049] This embodiment provides a waterproof and corrosion-resistant adhesive, which is made of the following raw materials in parts by weight: 43 parts of trichloropropane, 26 parts of modified acrylic resin, 8 parts of waterproofing agent, 13 parts of corrosion-resistant agent, 6 parts of filler, 7 parts of auxiliary agent.

[0050] The components and parts by weight of the modified acrylic resin are the same as in Example 1.

[0051] The waterproofing agent is a mixture of sodium methyl siliconate and zinc stearate, and the weight ratio of sodium methyl siliconate: zinc stearate is 5:1.

[0052] The anti-corrosion agent is: sodium chromate.

[0053] The filler is: a mixture of vermiculite powder, manganese trioxide and titanium dioxide, and the weight ratio of vermiculite powder: manganese trioxide: titanium dioxide is 1:2.5:6.

[0054] The auxiliary agent is: a mixture of dimethyl tetrachloroterephthalate, nonylphenol polyoxyethylene ether, and p-toluenesulfonic acid, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com