Method and composition for high-speed chemically depositing thick silver

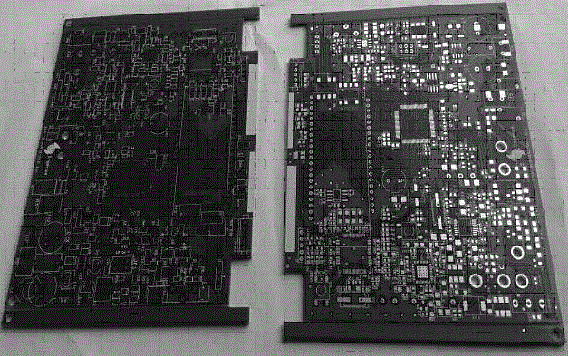

A silver composition and composition technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve problems such as low luminous efficiency, complicated process, hazards to operators and the environment, and achieve good heat dissipation effect , process stability, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

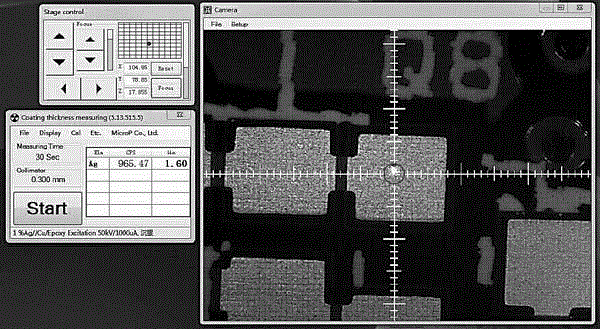

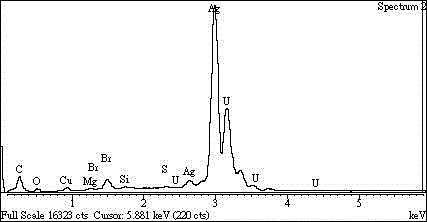

Method used

Image

Examples

Embodiment 1

[0017] Embodiment one: preparation is used for the chemical thickening silver composition of high-speed chemical thickening silver method, preparation steps are as follows: a, under normal temperature, add 0.5-20g silver ion compound to the pure water of 500ml to form silver ion solution, silver ion compound Select one of silver nitrate, silver sulfate or silver carbonate; b, add 0.5-50 mg of photoinhibitor to the silver ion solution in the above step a, stir evenly and add a silver ion reaction accelerator according to the molar ratio of 1:1 in the solution, Stir evenly; choose one of hydroquinone, catechol, resorcinol, 2,4-dimethylphenol or a compound of several of them for photoinhibitor; choose phenolsulfonic acid or p-toluene for accelerator Compounding of one or both of the sulfonic acids; c, adding an inorganic acid having the same functional group as the silver ion compound in the step a to the mixed solution of the above step b, and adjusting its acid value to 0.2-1N; ...

Embodiment 2

[0021] Embodiment 2: This embodiment is the same as the steps of chemically precipitating silver in Example 1, except that the composition used for chemically precipitating silver is different.

[0022] Prepare the chemical heavy silver composition for the high-speed chemical heavy silver precipitation method, the preparation steps are as follows: a, at normal temperature, add 0.5-20g silver ion compound to 500ml of purified water to form a silver ion solution, and the silver ion compound is selected from methyl sulfonate one of silver acid, silver benzoate, silver p-toluenesulfonate, silver lactate or silver acetate; b, add 0.5-50mg of photoinhibitor to the silver ion solution in the above step a, and stir it according to the solution 1:1 Add silver ion reaction accelerator in molar ratio and stir evenly; photoinhibitor chooses one of hydroquinone, catechol, resorcinol, 2,4-dimethylphenol or a combination of several of them; The accelerator is selected from one of phenolsulfo...

Embodiment 3

[0025] Embodiment 3: This embodiment is the same as the steps of chemically precipitating silver in Example 1, except that the composition used for chemically precipitating silver is different.

[0026] Preparation of the chemical heavy silver composition for the high-speed chemical heavy silver precipitation method, the preparation steps are as follows: a, at normal temperature, add 0.5-20g silver ion compound to 500ml of purified water to form a silver ion solution, and the silver ion compound is selected from silver nitrate, Two or all of silver sulfate or silver carbonate are compounded; b, add 0.5-50 mg of photoinhibitor to the silver ion solution in the above step a, stir evenly and add a silver ion reaction accelerator according to the molar ratio of 1:1 in the solution, Stir evenly; choose one of hydroquinone, catechol, resorcinol, 2,4-dimethylphenol or a compound of several of them for photoinhibitor; choose phenolsulfonic acid or p-toluene for accelerator Compounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com