Epoxy adhesive for LED lamp tube plug and LED lamp tube adhesive

An LED lamp, epoxy glue technology, applied in the direction of epoxy glue, adhesive, adhesive type, etc., can solve the problems of high energy consumption cost, cumbersome use process, large amount of electric energy, etc., to reduce internal stress, reduce The effect of production energy consumption and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

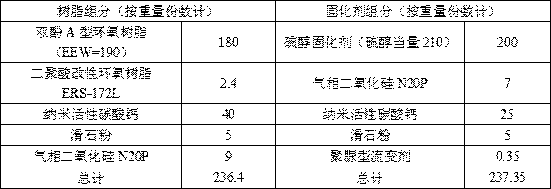

Embodiment 1

[0061]

[0062] The preparation method of the resin component: each component is added to the power mixer according to the proportion of the above resin component and heated to 60°C, dispersed in a vacuum at an appropriate revolution and rotation speed for 1 to 2 hours, and then discharged and packaged;

[0063] The preparation method of the curing agent component is: except for the polyurea rheological agent, each component is added to the power mixer in the proportion of the above curing agent component and heated to 60°C, and dispersed in a vacuum at an appropriate revolution and rotation speed. 2 hours; then add the polyurea type rheological agent in proportion, vacuum disperse for 1~2 hours under suitable revolution and rotation speed, and then discharge and pack.

[0064] The preparation method of polyurea rheological agent: dissolve isophorone diisocyanate and n-butylamine in dibutyl phthalate at an equivalent ratio of 1:1.03~1.08, and control the concentration at 30%. First...

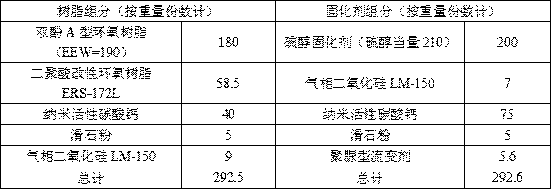

Embodiment 2

[0067]

[0068] The preparation method of the resin component: each component is added to the power mixer according to the proportion of the above resin component and heated to 60°C, dispersed in a vacuum at an appropriate revolution and rotation speed for 1 to 2 hours, and then discharged and packaged;

[0069] Preparation method of curing agent components: In addition to polyurea rheological agents, each component is added to a power mixer in the proportion of the above curing agent components and heated to 60°C, and dispersed in a vacuum at an appropriate revolution and rotation speed for 1~2 Hours; then add the polyurea rheological agent in proportion, and disperse in vacuum for 1~2 hours at the appropriate revolution and rotation speed, and then discharge and pack.

[0070] The preparation method of the polyurea rheological agent is the same as in Example 1.

[0071] Use a dispenser to mix the resin component and the curing agent component at a ratio of 1:1, and spray 0.1~0.3g o...

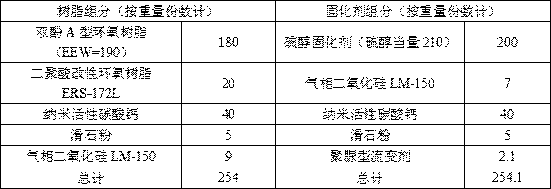

Embodiment 3

[0073]

[0074] The preparation method of the resin component: each component is added to the power mixer according to the proportion of the above resin component and heated to 60°C, dispersed in a vacuum at an appropriate revolution and rotation speed for 1 to 2 hours, and then discharged and packaged;

[0075] Preparation method of curing agent components: In addition to polyurea rheological agents, each component is added to a power mixer in the proportion of the above curing agent components and heated to 60°C, and dispersed in a vacuum at an appropriate revolution and rotation speed for 1~2 Hours; then add the polyurea rheological agent in proportion, and disperse in vacuum for 1~2 hours at the appropriate revolution and rotation speed, and then discharge and pack.

[0076] The preparation method of the polyurea rheological agent is the same as in Example 1.

[0077] Use a dispenser to mix the resin component and the curing agent component at a ratio of 1:1, and spray 0.1~0.3g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com