Low-temperature biodegradable paper bag hot melt adhesive and preparation method thereof

A biodegradable, hot-melt adhesive technology, used in adhesives, graft polymer adhesives, adhesive types, etc., can solve the problems of hot-melt adhesive biodegradation, inability to achieve environmental protection, etc., to reduce colloid carbonization, reduce The number of shutdowns and the effect of protecting health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Object two of the present invention is achieved using the following technical solution: a low temperature with biodegradable paper bag hot melt adhesive preparation method, comprising the following steps:

[0043] (1) Add the formulation amount of maleic anhydride grafted ash and polyester polyol to the reactor, dissolve and heat up to 130±5 °C;

[0044] (2) After the maleic anhydride grafted ash and polyester polyol are completely dissolved, then add the formula amount of polyadipic acid / butylene terephthalate, polycaprolactone stirring, stirring speed of 80r / min, heating to 150 °C, maintaining the pressure in the kettle 5MPa, after the mixing system melts, add the formula of rosin glyceride modified terpenenophenol resin, evenly stirred for 20min;

[0045] (3) Vacuuming, the pressure of vacuum removal bubble is -(0.08-0.1) Pa, the time for vacuuming and removing bubbles is 30-50 minutes, discharging, cooling granulation, and obtaining low temperature with biodegradable...

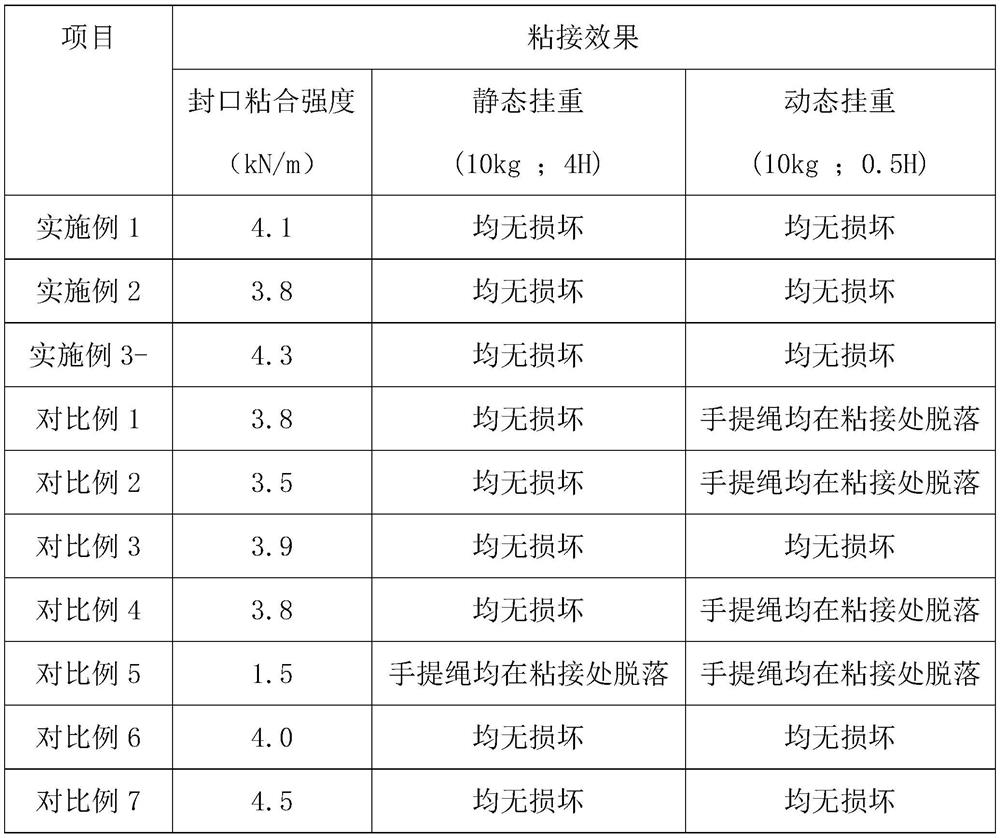

Embodiment 1- Embodiment 3 and comparative example 1-6

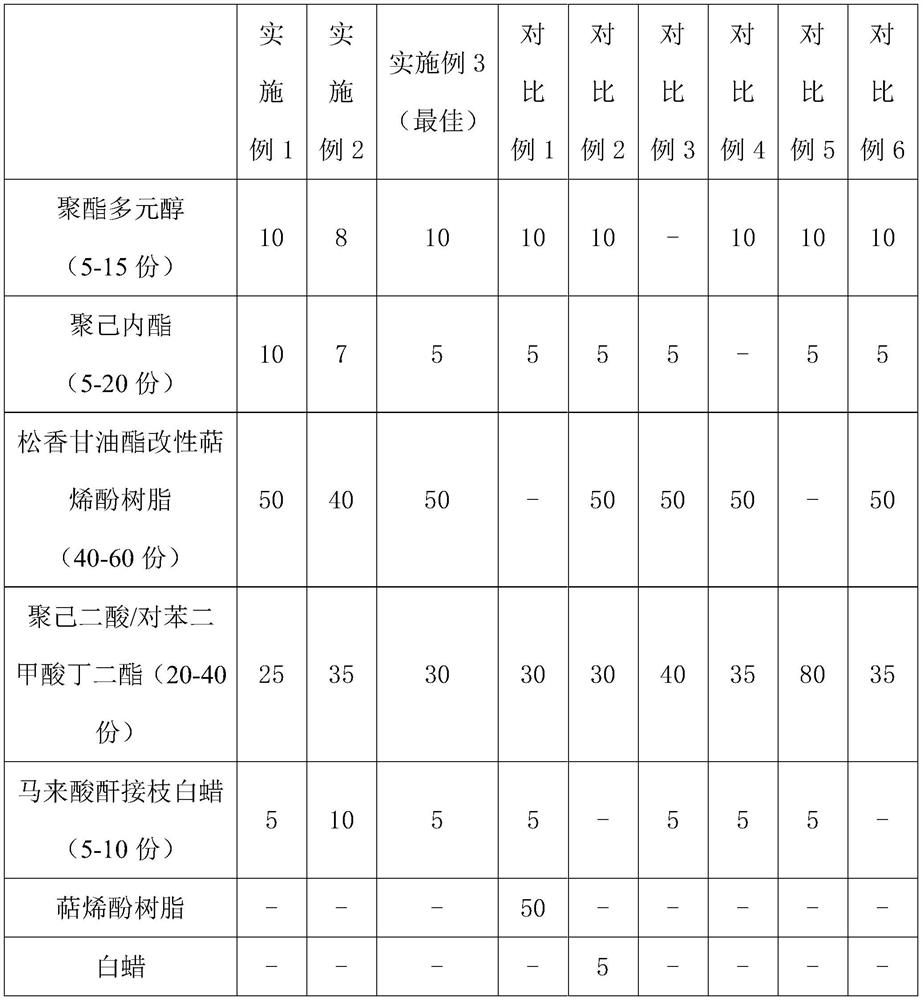

[0049] Respectively, the raw materials are weighed in the ratio in Table 1, and the hot melt adhesive is made according to the preparation method after Table 1, corresponding to the hot melt adhesive of different embodiments, as detailed in Table 1:

[0050] Table 1 Example 1-3 and the proportion of raw materials in proportion to 1-6 table

[0051]

[0052] Among them, the polyester polyols in Table 1 are selected from the polyester polyols of the swedish company Perstorp Company with the model capa2402. Polycaprolactone was selected from the Swedish company Perstorp with a model of 6400 polycaprolactone. Rosin glyceride modified terpenenophenol resin is prepared by the following method: rosin glycerides, terpenephenol resin into the autoclave, heated to dissolve, and then added solid acid catalyst; start the autoclave heating system and stirring system, heat up to 150-170 ° C, keep the pressure in the kettle at 2-10Mpa, Reaction time 0.5-3 hours; stop heating, cooling, granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com