The device used for the pre-assembly of the aero-engine combustor flame tube

An aero-engine and flame tube technology, which is applied in the field of pre-assembled devices for combustor flame tubes, can solve the problems of product quality, engine assembly continuity, easy to touch and scratch the engine, and reduce assembly efficiency. Moderate, reduce labor intensity, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

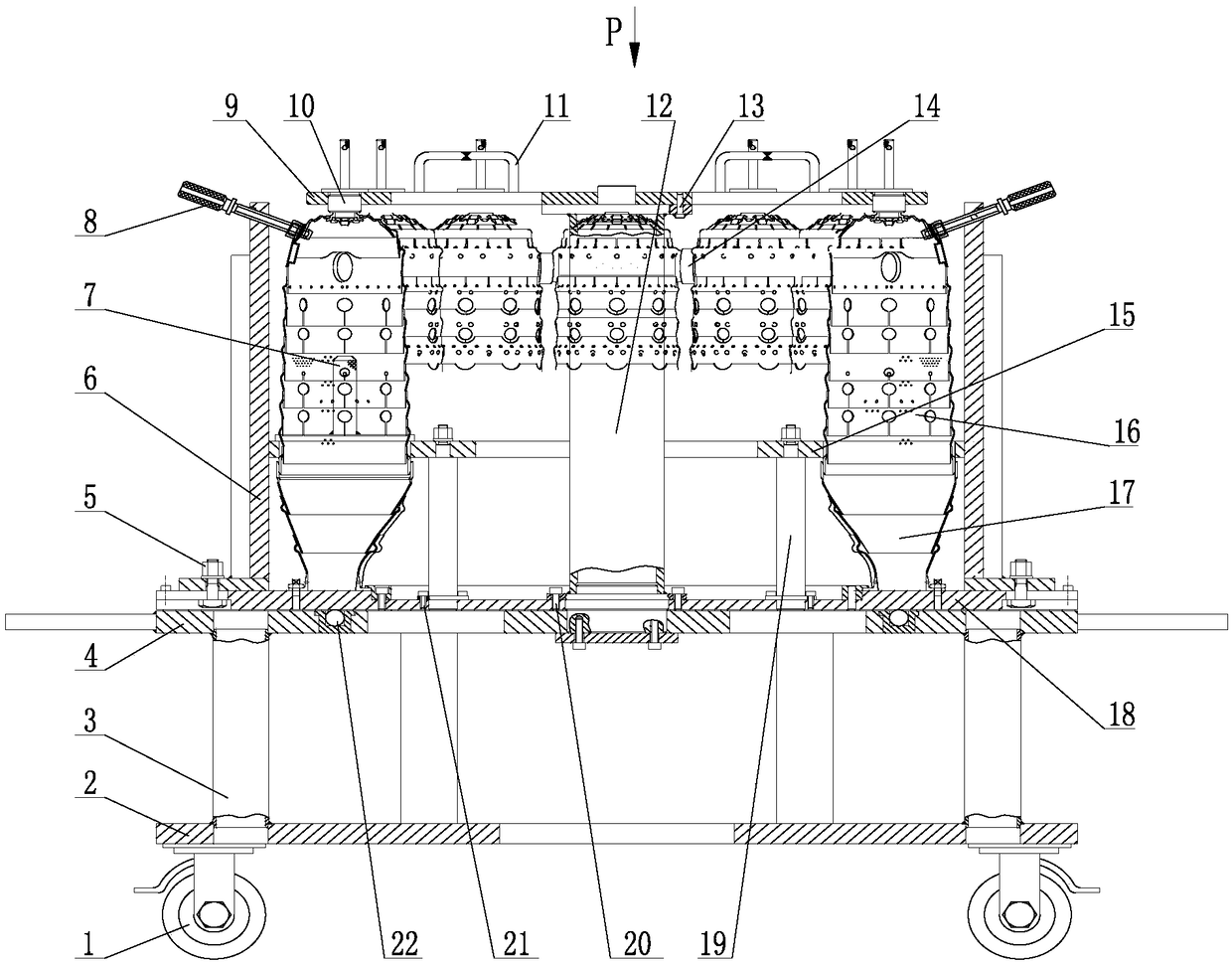

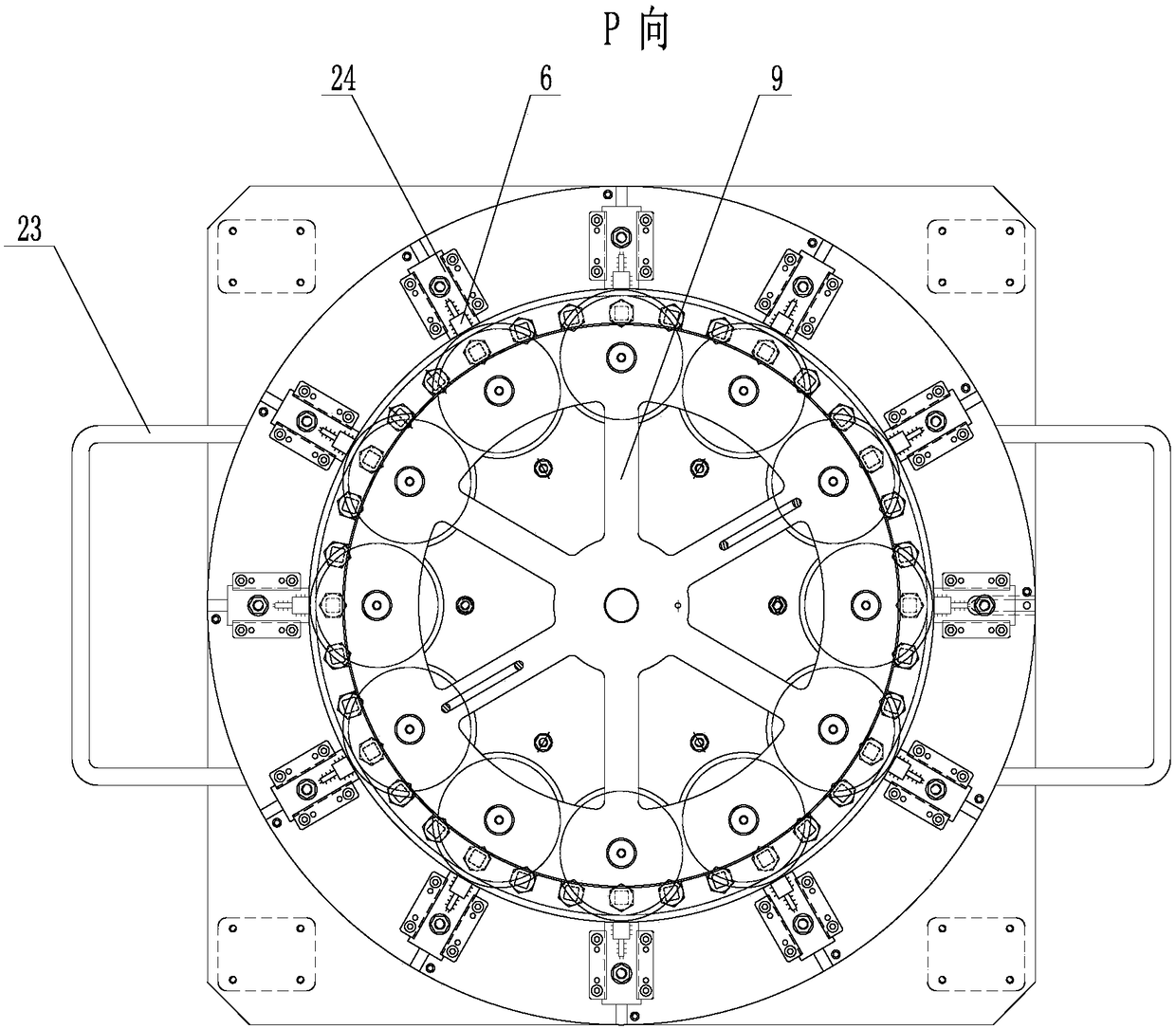

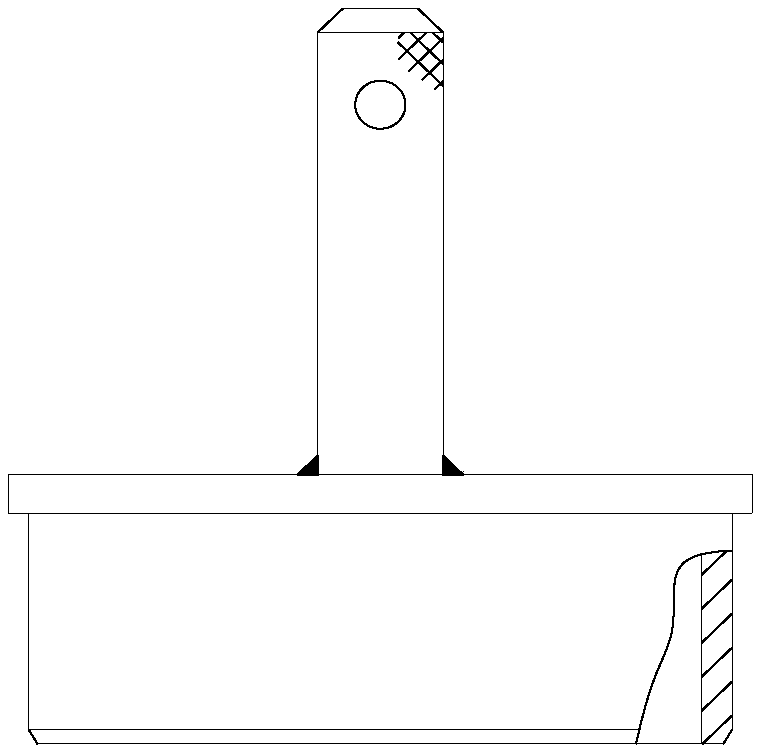

[0027] This embodiment is used for the pre-assembled device of the aero-engine combustor flame tube matching platform. There are twelve groups of pre-assembled aero-engine combustor flame tube matching sets, and its structure is as attached figure 1- As shown in -5, its composition includes a base composed of a lower base plate 2 of a hollow rectangular structure, an upper base plate 4, and six equal-height support columns 3, and the support shaft 12 of the tubular structure is fixedly arranged at the center of the base, and is sleeved on the support Outside the axis, the turntable 18 is rotatably arranged on the upper bottom plate of the base through the rolling groove mechanism of the ball 22, and is used to install the turntable 18 of the collector of the stage component, and the calibration plate 15 fixedly arranged above the turntable is used for angularly positioning the flame tube Twelve groups of bolts 8 are installed on the top of the support shaft to limit and fasten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com