Externally-mounted work platform for fabricated building and method for operating externally-mounted work platform for fabricated building

A working platform and assembled technology, which is applied in the direction of construction, building structure, and building materials processing, can solve the problems of inconvenient erection of scaffolding and safety protection nets, casualties and property, and impact on the construction period, so as to avoid falling objects and The effects of casualties, saving raw materials and construction costs, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

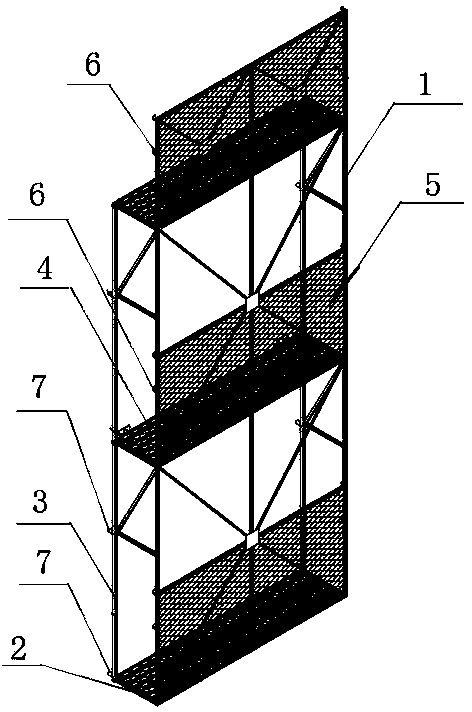

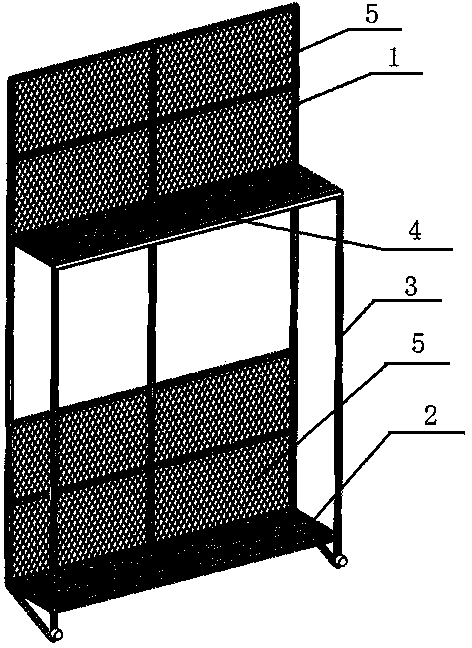

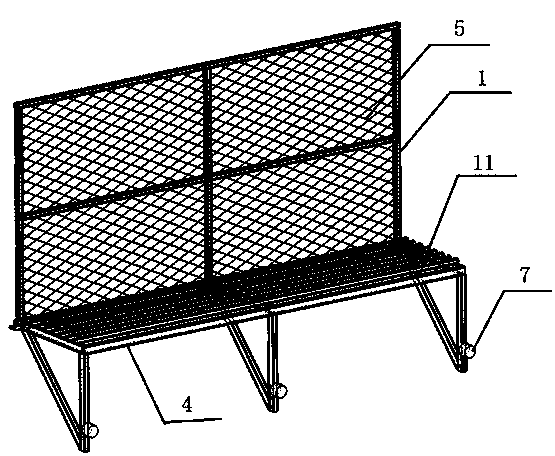

[0040] Referring to the accompanying drawings, the special externally-mounted work platform for prefabricated buildings of the present invention includes one or two or more work platform units arranged horizontally on the outside of the prefabricated exterior wall panels, and a plurality of prefabricated external wall panels. Fastening device, a plurality of hook seats fixedly connected to the corresponding fastening device through fasteners, each of the working platform units includes a one-layer, two-layer, three-layer or multi-layer frame welded by hollow profiles, The protective nets or guardrails arranged on the outside of each frame, and the protective nets or pedals arranged at the bottom of each frame, the working platform unit is hung into the hook seat and fixed on the prefabricated outer wall through the hollow profiles arranged horizontally on the inner side of the frame board outside.

[0041] The above-mentioned fastening device is a pre-embedded sleeve with inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com