A prefabricated concrete octagonal column assembly device and its installation method

A technology of prefabricated concrete and assembly devices, applied in the direction of columns, pillars, pier columns, etc., can solve the problems of high mechanical cost, easily damaged column feet, and unqualified conditions, so as to save construction period and cost, improve hoisting accuracy, and improve The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

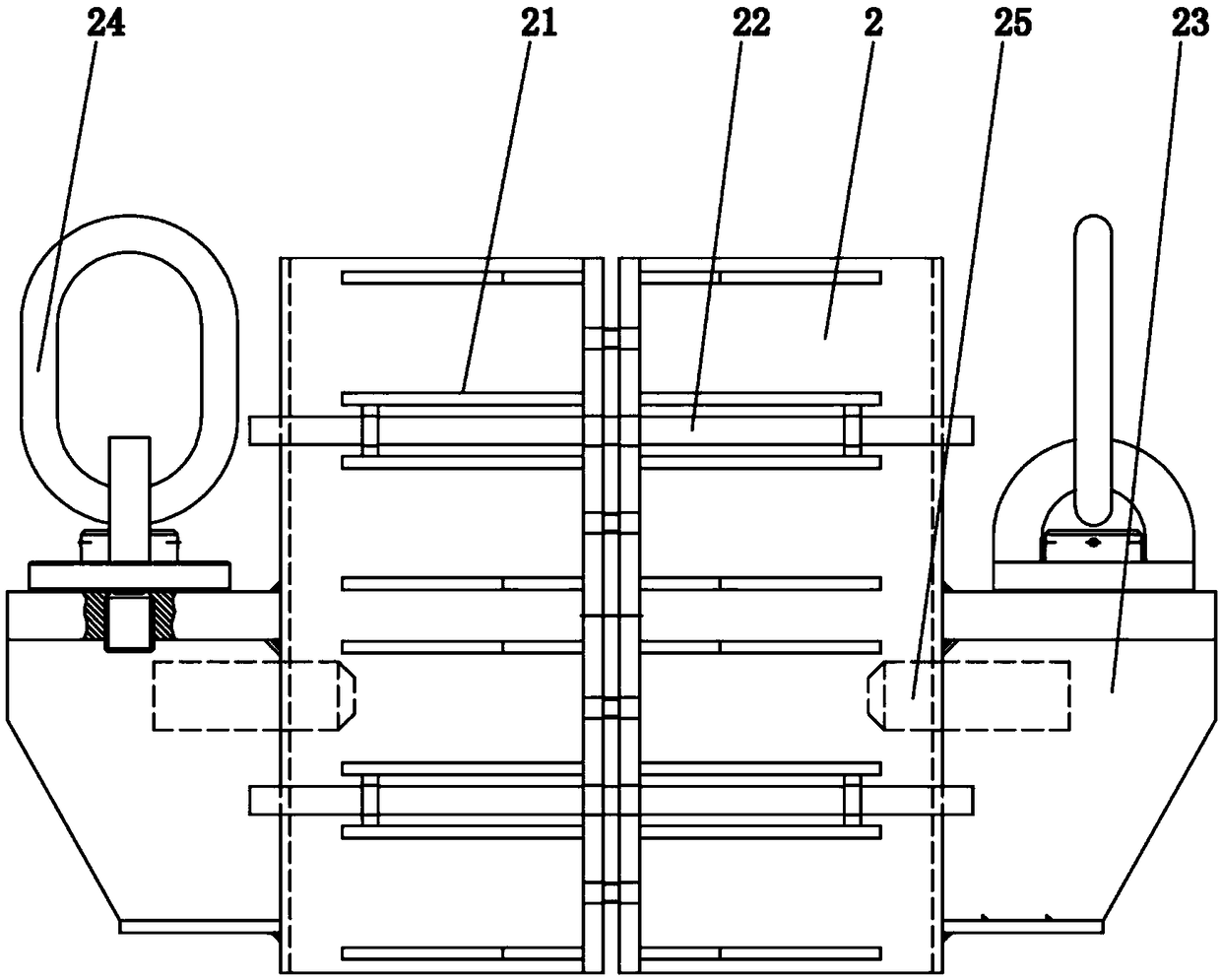

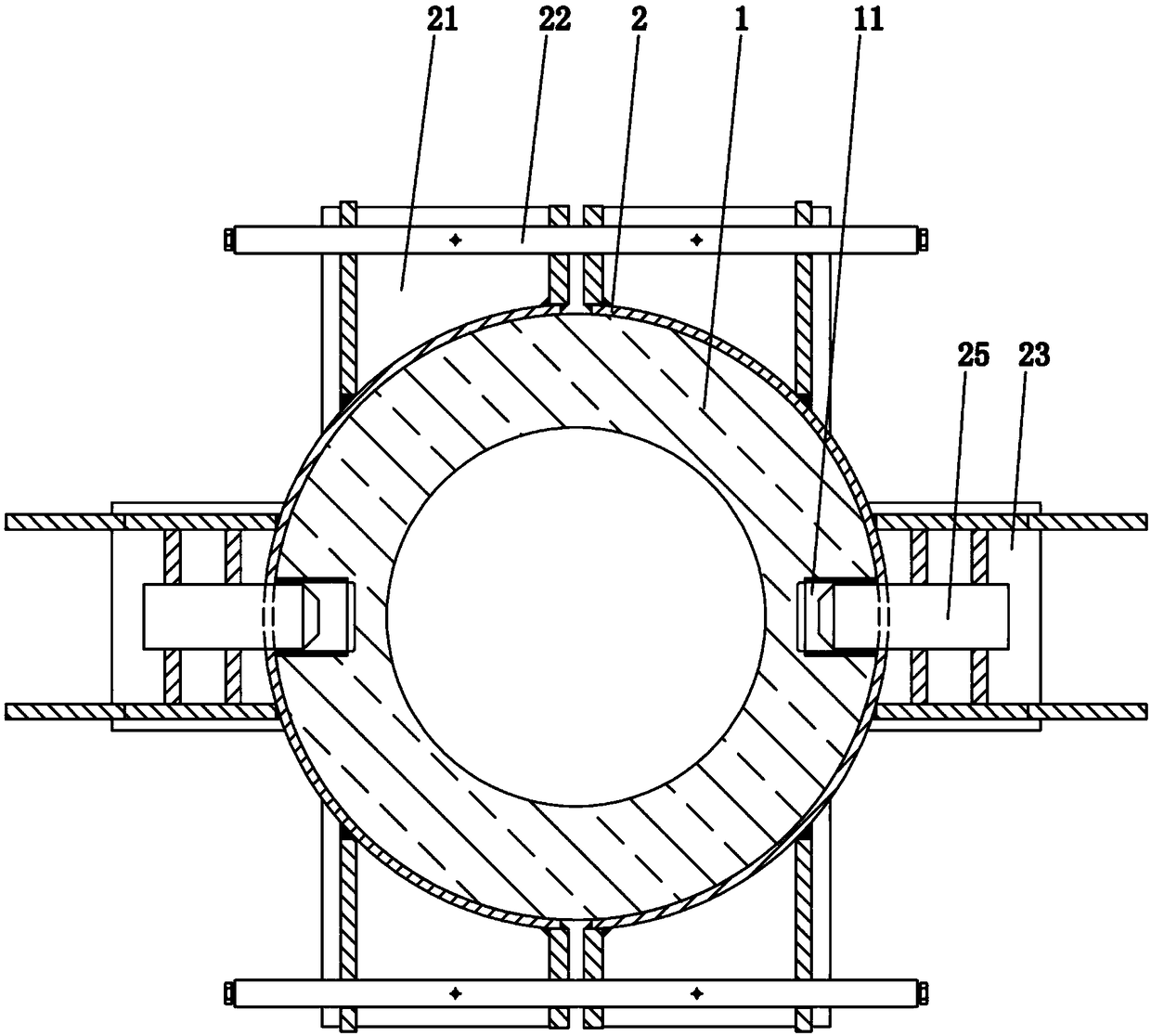

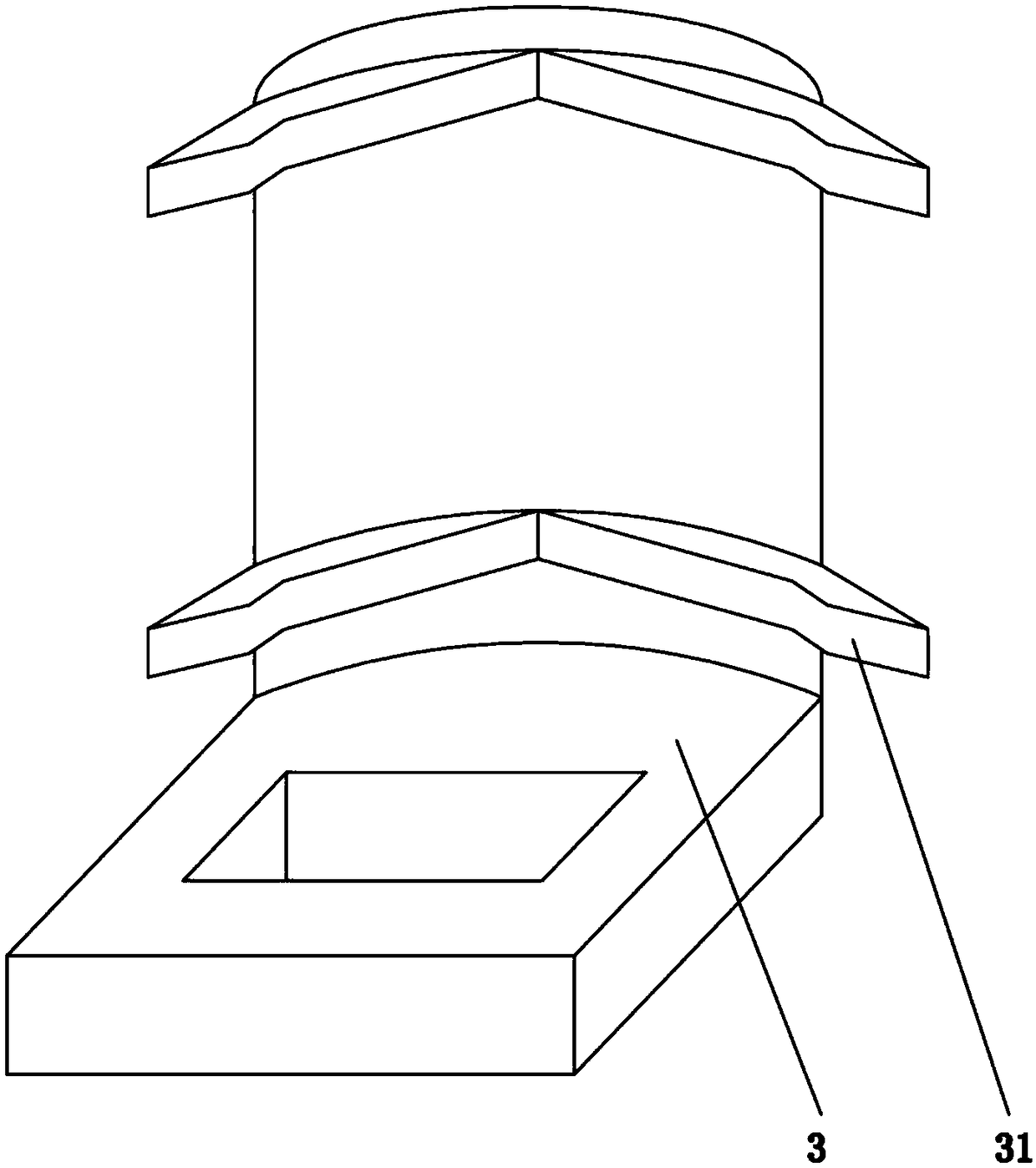

[0032] Such as Figure 1-4 As shown, a precast concrete octagonal column assembly device according to the present invention includes a column body 1 and a clamp, and the clamp includes two semicircle hoops 2 symmetrically arranged on both sides of the column body 1, and the two semicircle hoops 2 Each end is provided with several connecting seats 21, and several connecting seats 21 are arranged in groups opposite to each other and each group of connecting seats 21 is arranged at intervals along the vertical direction; between the corresponding connecting seats 21 on the two semicircular hoops 2 There is a clamping link 22; a base 23 is provided on the outer surface of the two semicircular hoops 2, and a suspension ring 24 is provided on the base 23; the two semicircular hoops 2 are clamped on the cylinder 1 The upper end of the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com