Ball valve seat

A technology for valve seats and ball valves, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of difficult valve installation, low assembly efficiency, and inconvenient maintenance, and achieve high assembly efficiency, slow assembly efficiency, and low assembly time. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the present invention will be described in detail with reference to the drawings and embodiments.

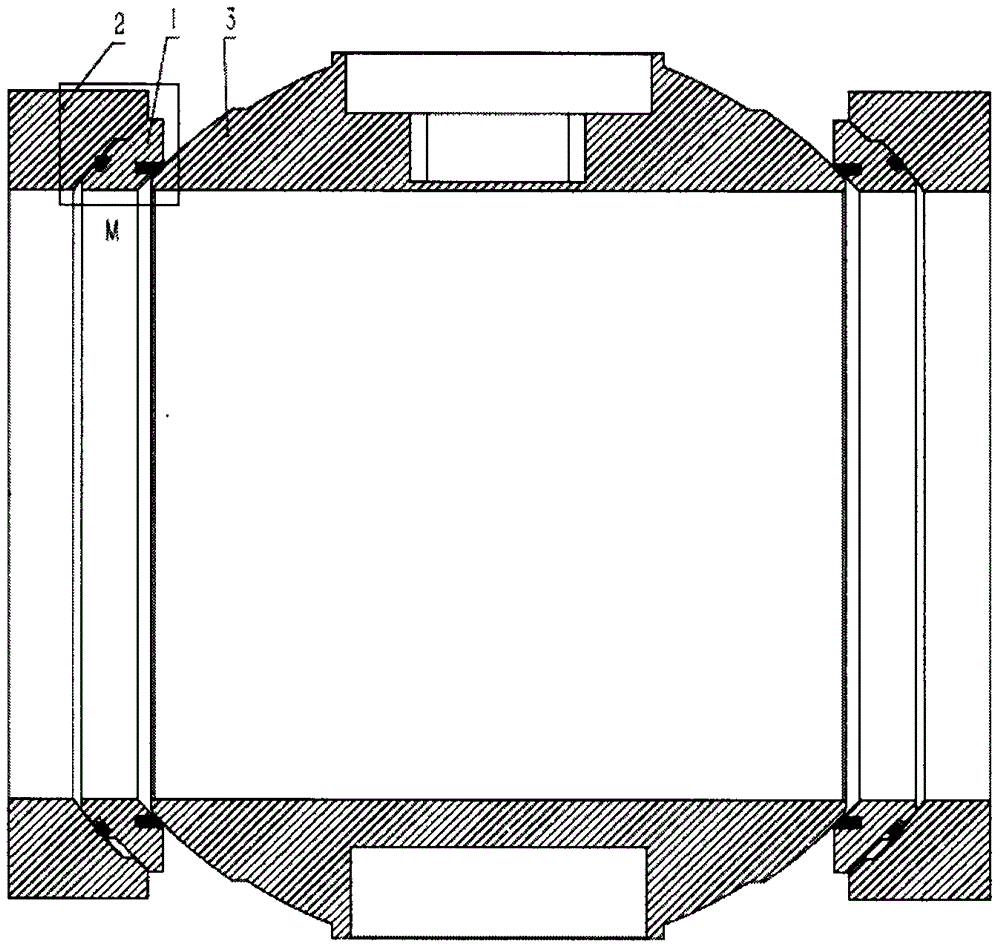

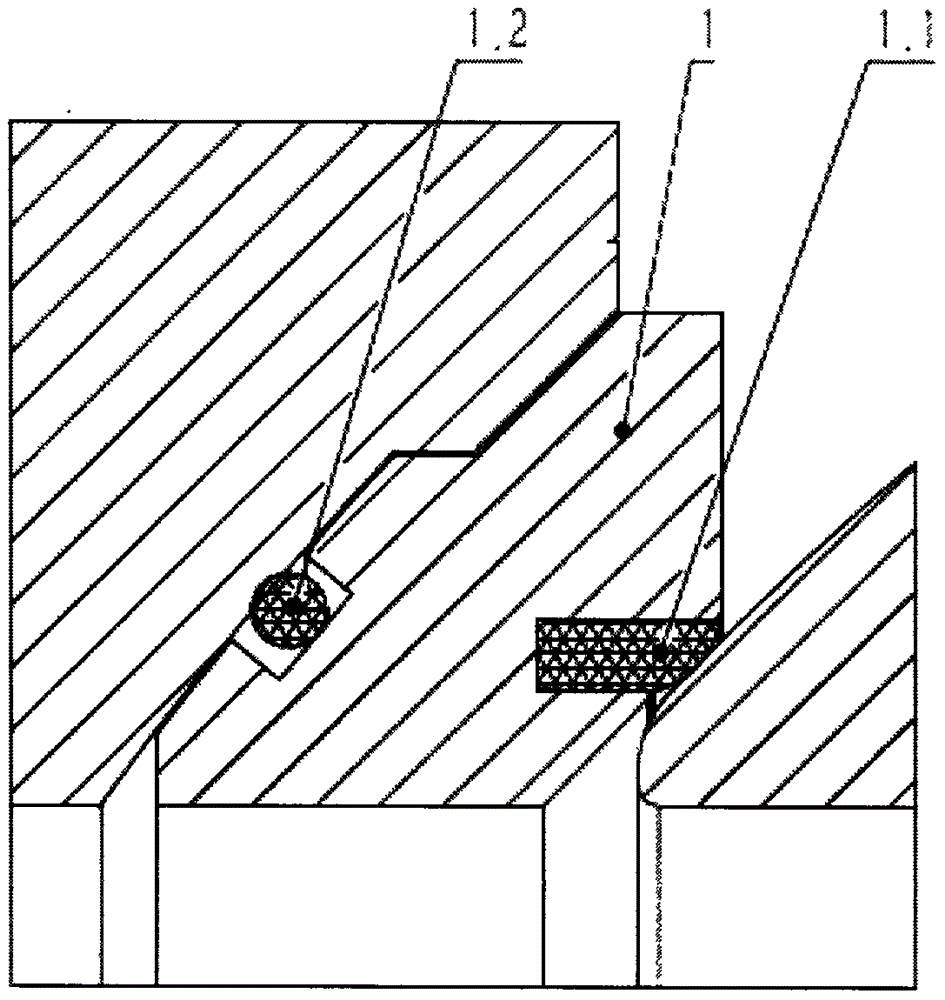

[0017] See figure 1 , figure 2 As shown, a ball valve seat, quick installation and disassembly of top-mounted seat, valve seat (1), valve body (2), designed as an arc surface, passing between the valve seat (1) and the valve body (2) , A seal is set between the valve seat (1) and the ball (3) to form a sealed closed structure. The valve seat (1) and the valve body (2) are designed as an arc surface, and the valve seat can rotate along the arc surface. There are rectangular grooves up and down, and a rectangular boss on the valve body (2), which restricts the valve seat from rotating up and down. Through calculation, the length of the groove and the rotation angle of the valve seat are designed. The assembly process is as follows: The chute rotates downwards. When the opening at both ends of the valve seat is larger than the width of the sphere, the sphere is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com