Vehicle headlight installation assembly and installation method thereof

A technology for installing components and headlights, applied in vehicle parts, signal devices, transportation and packaging, etc., can solve the problems of high labor intensity of workers, increased production costs, low work efficiency, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

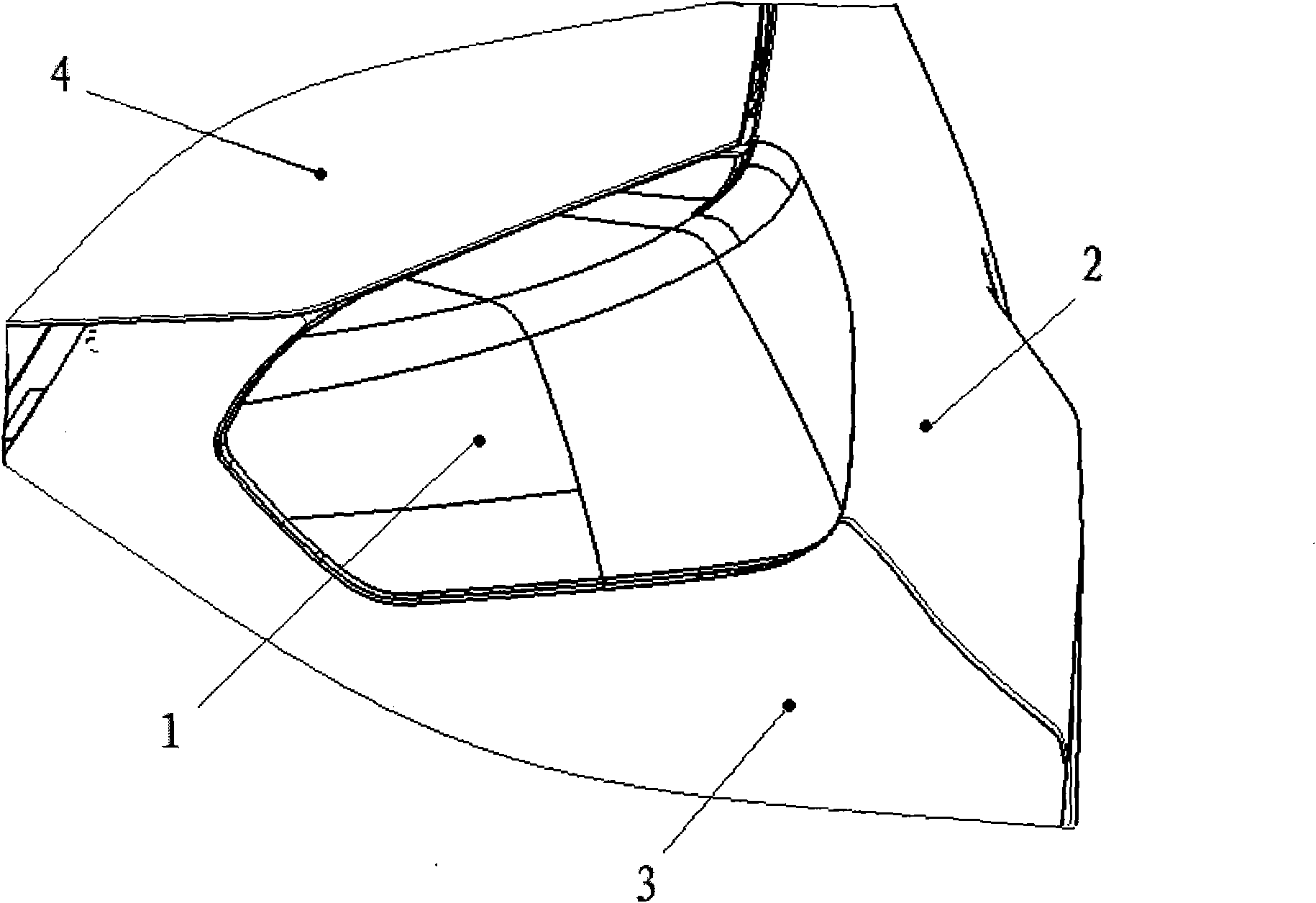

[0040] like Figure 1-10 As shown, a vehicle body headlight 1 installation assembly provided by the embodiment of the present invention, this embodiment and the accompanying drawings are all described by taking the left headlight of the vehicle body as an example. The left and right are defined based on the direction in which the driver sits in the car.

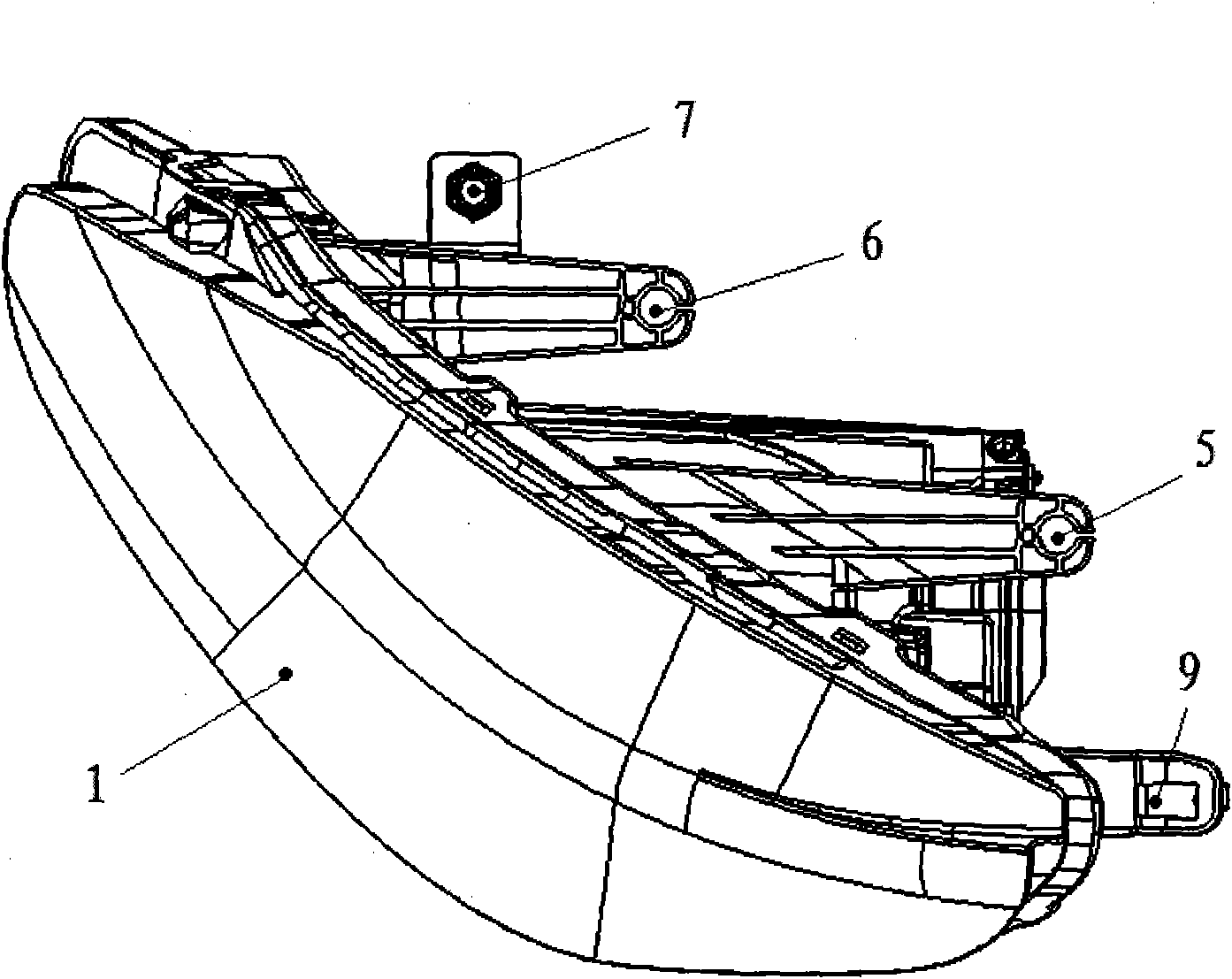

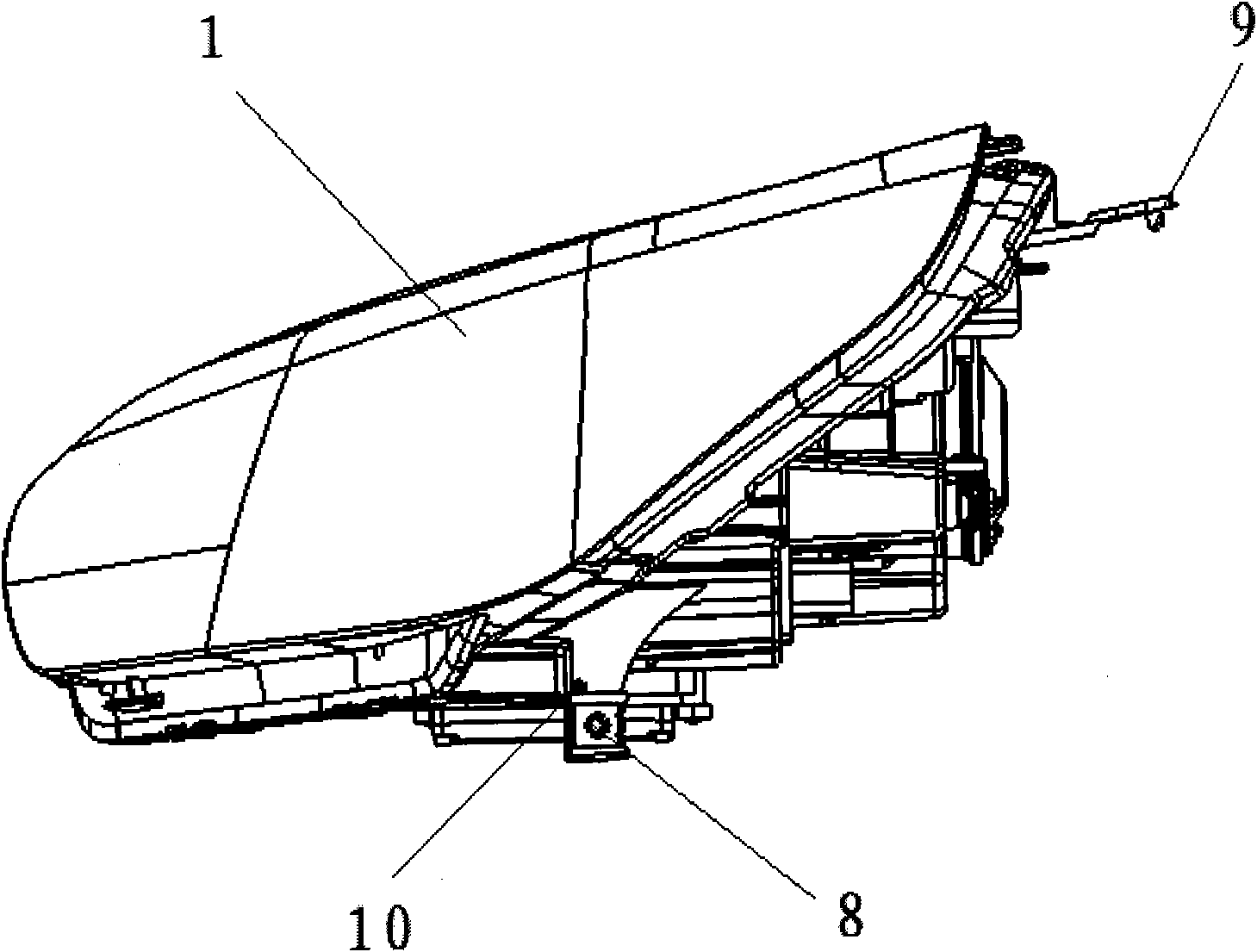

[0041] like figure 1 , Figure 7 , Figure 10 As shown, a vehicle headlight installation assembly includes a vehicle headlight 1, and an engine cover 4, a front fender 2, and a front bumper 3 arranged around the vehicle headlight 1 and having a matching relationship therewith. The headlight 1 of the vehicle body is positioned with the front fender 2 by a positioning member, and the headlight 1 of the vehicle body is fixedly connected with the bracket 20 and the crossbeam 19 of the vehicle body through fasteners, and the front bumper 3 is clamped on the front bumper mounting seat, the front bumper mounting seat is position...

Embodiment 2

[0054] The embodiment of the present invention also provides an installation method applied to the vehicle body headlight installation assembly, which is operated according to the following steps:

[0055] Step 1, see Image 6 , installing and fixing the front fender 2 on the vehicle body;

[0056] Step 2, see Figure 7 The headlight 1 of the vehicle body is installed on the front fender 2 through a positioning piece, specifically, the upper positioning pin 9 on the headlight 1 of the vehicle body is inserted into the upper positioning hole 11 of the front fender 2 , and then insert the lower positioning pin 10 into the lower positioning hole 12 of the front fender 2 to ensure the flatness and clearance fit between the headlight 1 of the vehicle body and the front fender 2;

[0057] Step 3, see Figure 7 , Figure 8 , the vehicle body headlight 1 is fixedly connected with the crossbeam 19 and the bracket 20 of the vehicle body through fasteners,

[0058] Specifically, fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com