Cleaning rotating brush and normal juice machine

A rotating brush cleaning technology, applied in the direction of brushes, brush bodies, bristles, etc., can solve the problems of loud friction sound, low comfort, poor cleaning effect, etc., and achieve the effect of low noise and high comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

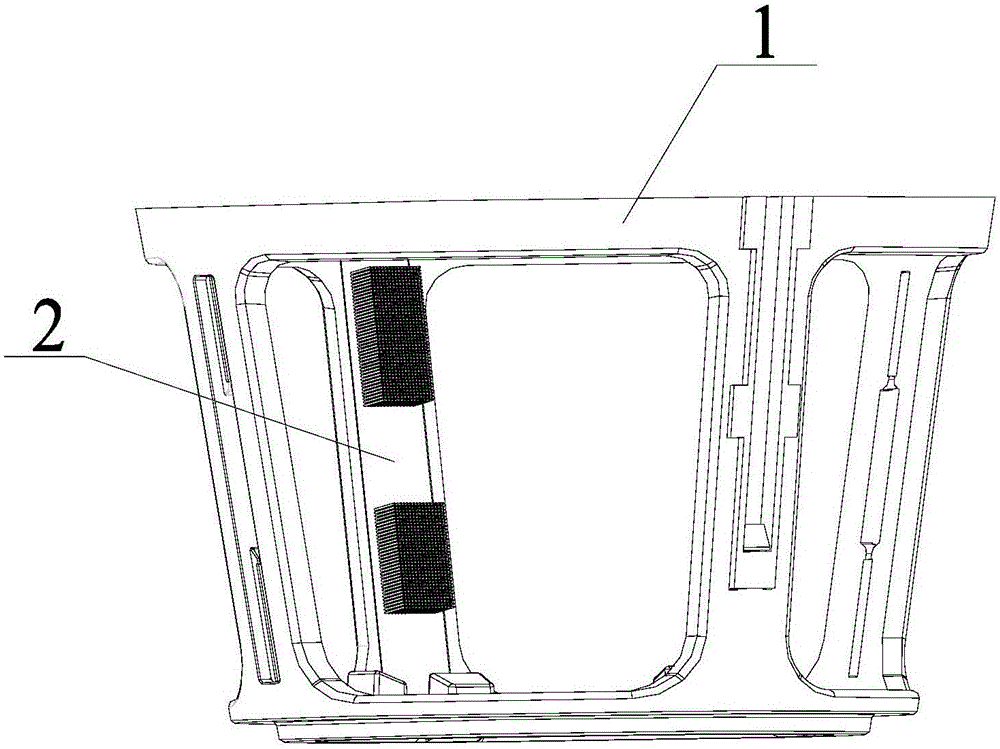

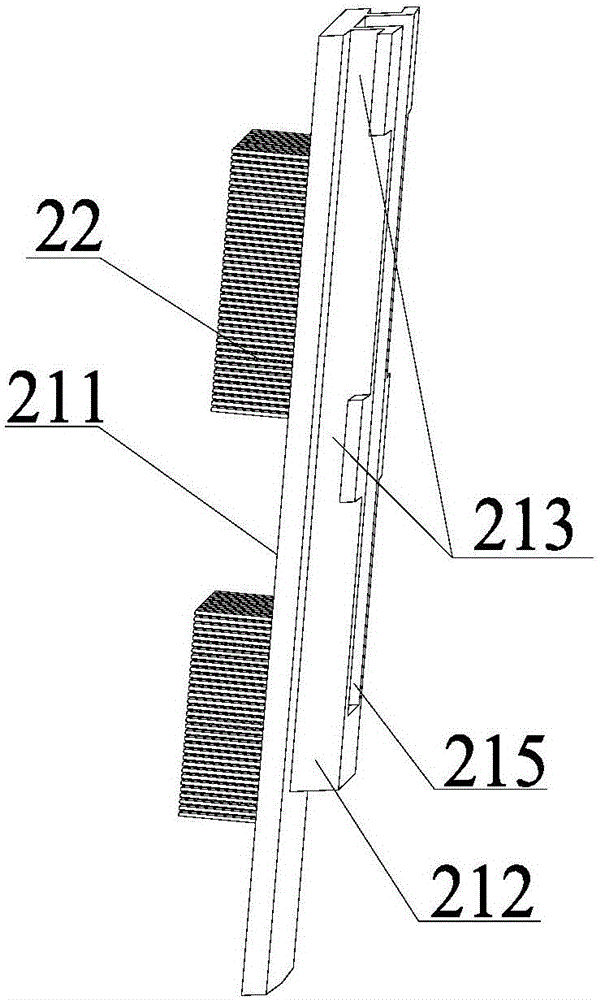

[0028] like Figure 1-3 Shown, a kind of cleaning rotating brush comprises rotating brush frame 1, and rotating brush frame 1 is provided with rotating brush main body 2, and rotating brush main body 2 comprises connecting plate 21, and connecting plate 21 is provided with brush layer 22, and connecting plate 21 It is detachably connected with the rotating brush holder 1 , the brush layer 22 is located inside the rotating brush holder 1 , and the end surface of the brush layer 22 is higher than the surface of the rotating brush holder 1 .

[0029] The rotating brush holder 1 is cylindrical, and a plurality of rotating brush main bodies 2 are evenly arranged on the rotating brush holder 1 along its circumferential direction. Rotating brush holder 1 is positioned at the outside of metal filter screen 4 during use, therefore, preferably it adopts cylindrical structure, and a plurality of rotating brush main bodies 2 are arranged on it, during cleaning, rotating brush holder 1 dri...

Embodiment 2

[0044] like Figure 1-5 As shown, a kind of raw juice machine, comprises precursor 3, is provided with cylindrical filter screen 4 in the precursor 3, is provided with feed screw 5 in the filter screen 4, and feed screw rod 5 is connected with drive motor, filter screen 4 There is a cleaning rotating brush on the outside;

[0045]The bottom of the feeding screw 5 is connected with the bottom of the rotating brush holder 1 .

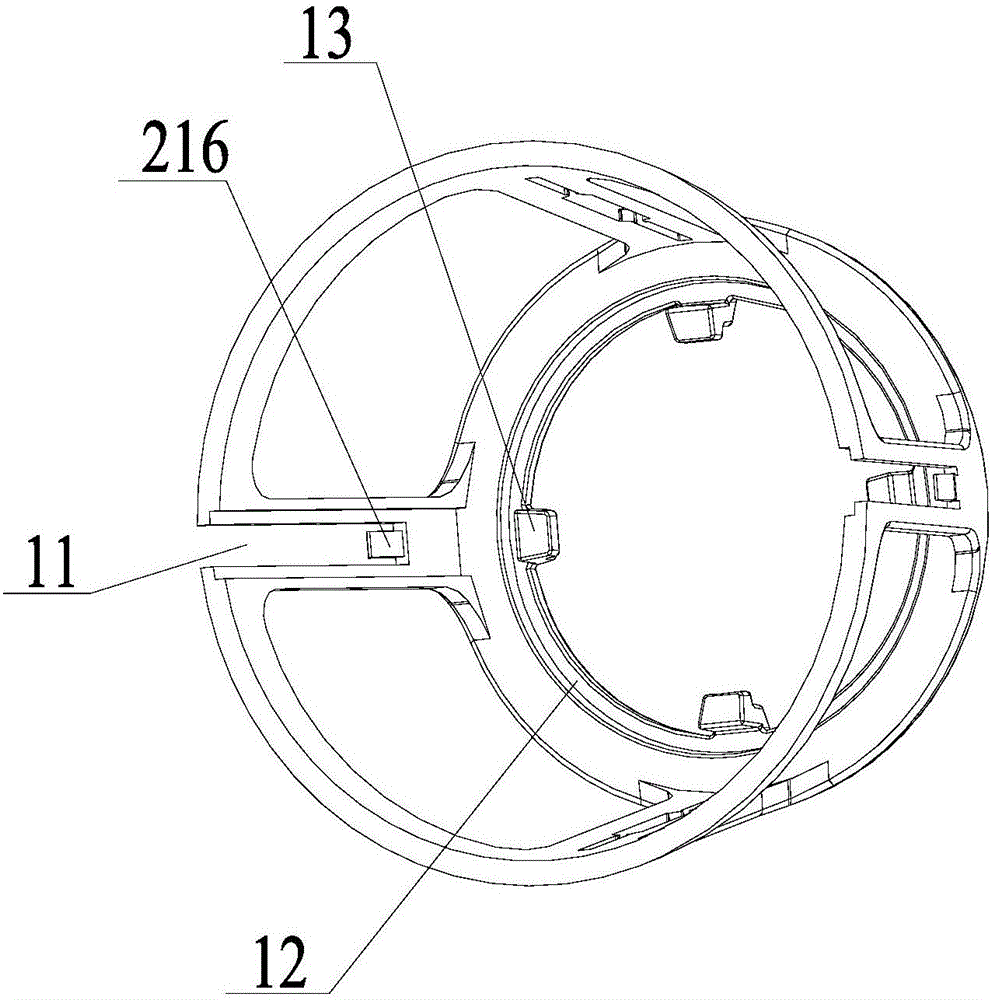

[0046] The bottom of the rotating brush holder 1 is provided with an annular groove 12, the bottom of the filter screen 4 is arranged in the annular groove 12, the side wall of the annular groove 12 is located at the inner side of the filter screen 4, and a clamping portion 13 is provided, and the bottom of the feed screw 5 is provided with There is a connecting part adapted to the clamping part 13 . Wherein, the rotating brush holder 1 can be inclined, that is, in order to cooperate with the cleaning filter 4, the rotating brush holder 1 and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com