Motorcycle engine exhaust valve rod

An engine and exhaust valve technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of pulling the exhaust valve rod part 2, burning the exhaust valve rod, and not returning the exhaust valve rod in time. and other problems, to ensure that the metallographic structure and strength do not change, prevent breakage or damage to the top of the piston, prevent heat accumulation and sudden temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

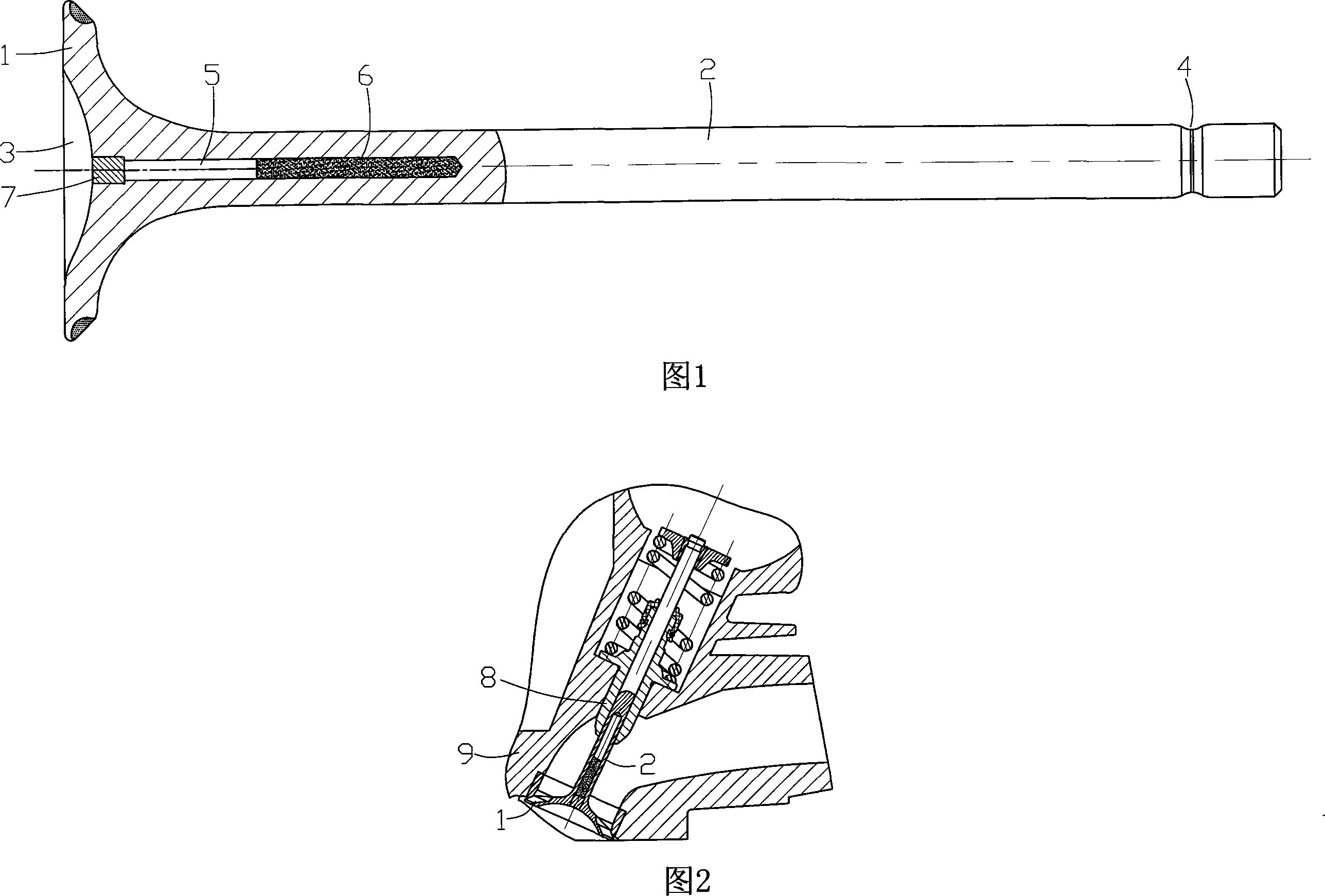

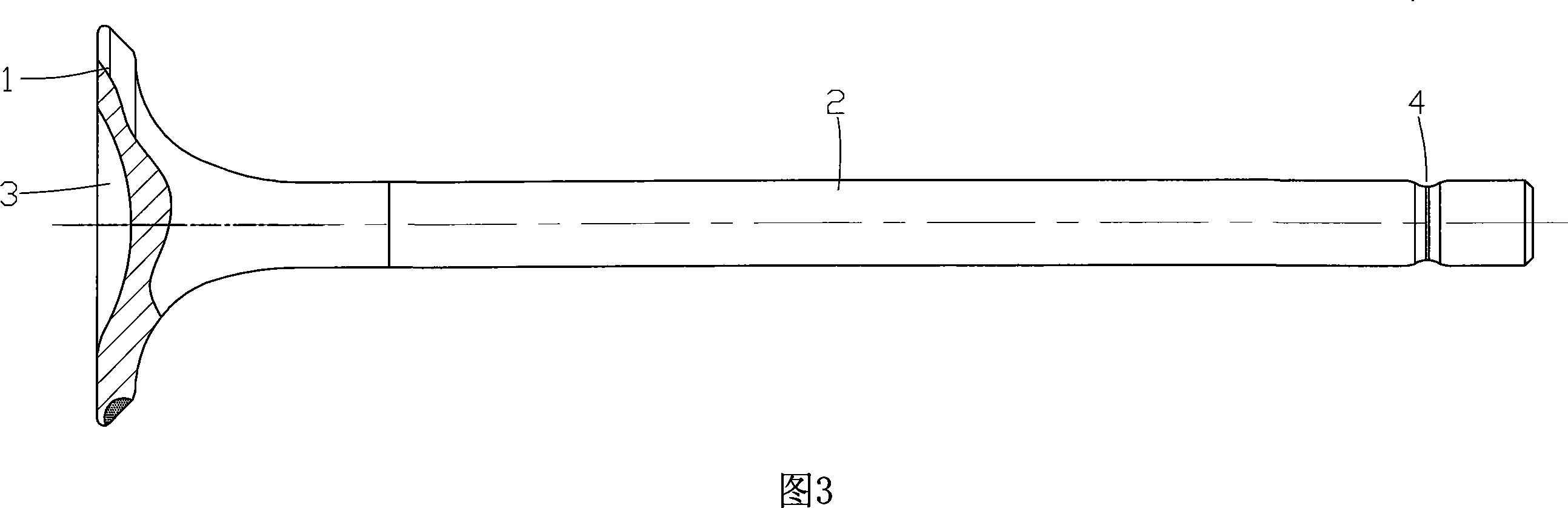

[0015] As shown in Figure 1, the present invention is made of parts such as head 1, rod 2, metal powder 6 and plug 7. The head 1 and the rod 2 are integrally structured, the rod 2 is installed in the valve guide 8 to play a guiding role, and an annular groove 4 is opened on the circumferential surface of one end of the rod 2 to install the locking member; the head 1 Located at the other end of the rod part 2, the axis lines of the two coincide. The head part 1 is a disc structure with a conical slope, which is used to close the exhaust passage of the cylinder head 9. Between the head part 1 and the rod part 2 A smooth transition connection is adopted, and an arcuate groove 3 is provided on the end surface of the head 1 . The groove bottom of the groove 3 is provided with an accommodating hole 5 extending along the rod portion 2, the center line of the accomm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com