Homotaxial paddle mixer

A technology of mixers and paddles, which is applied to mixers, mixing methods, mixers with rotating stirring devices, etc., can solve the problems of general crushing effect, easy adhesion, and increased material residue in mixers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

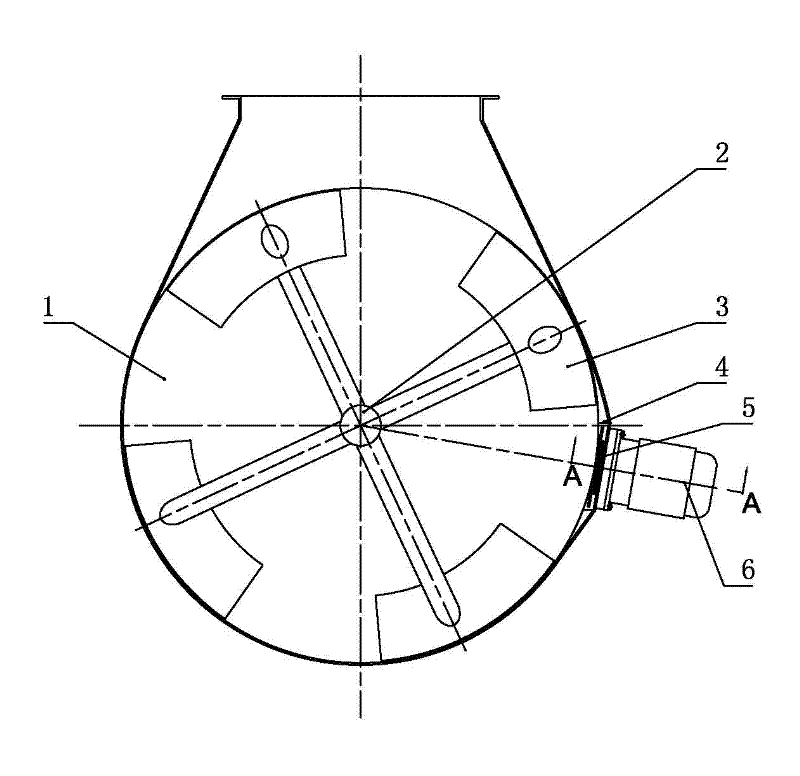

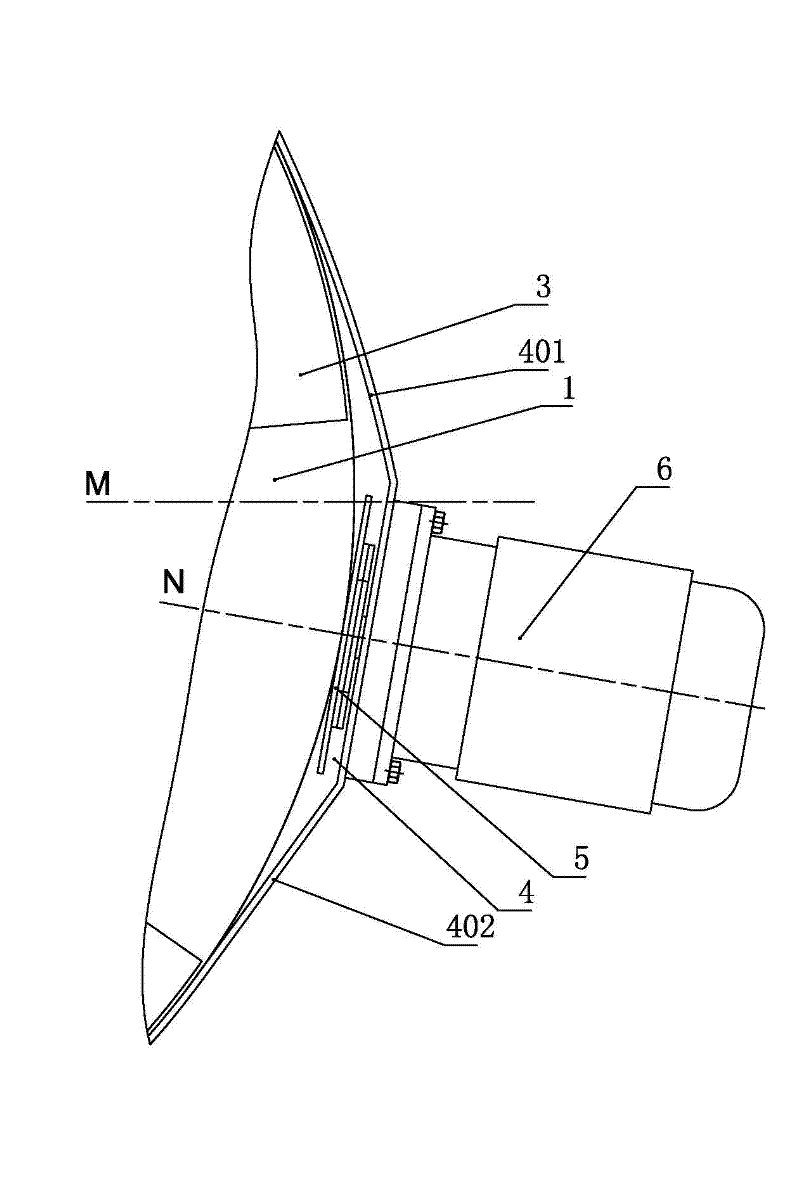

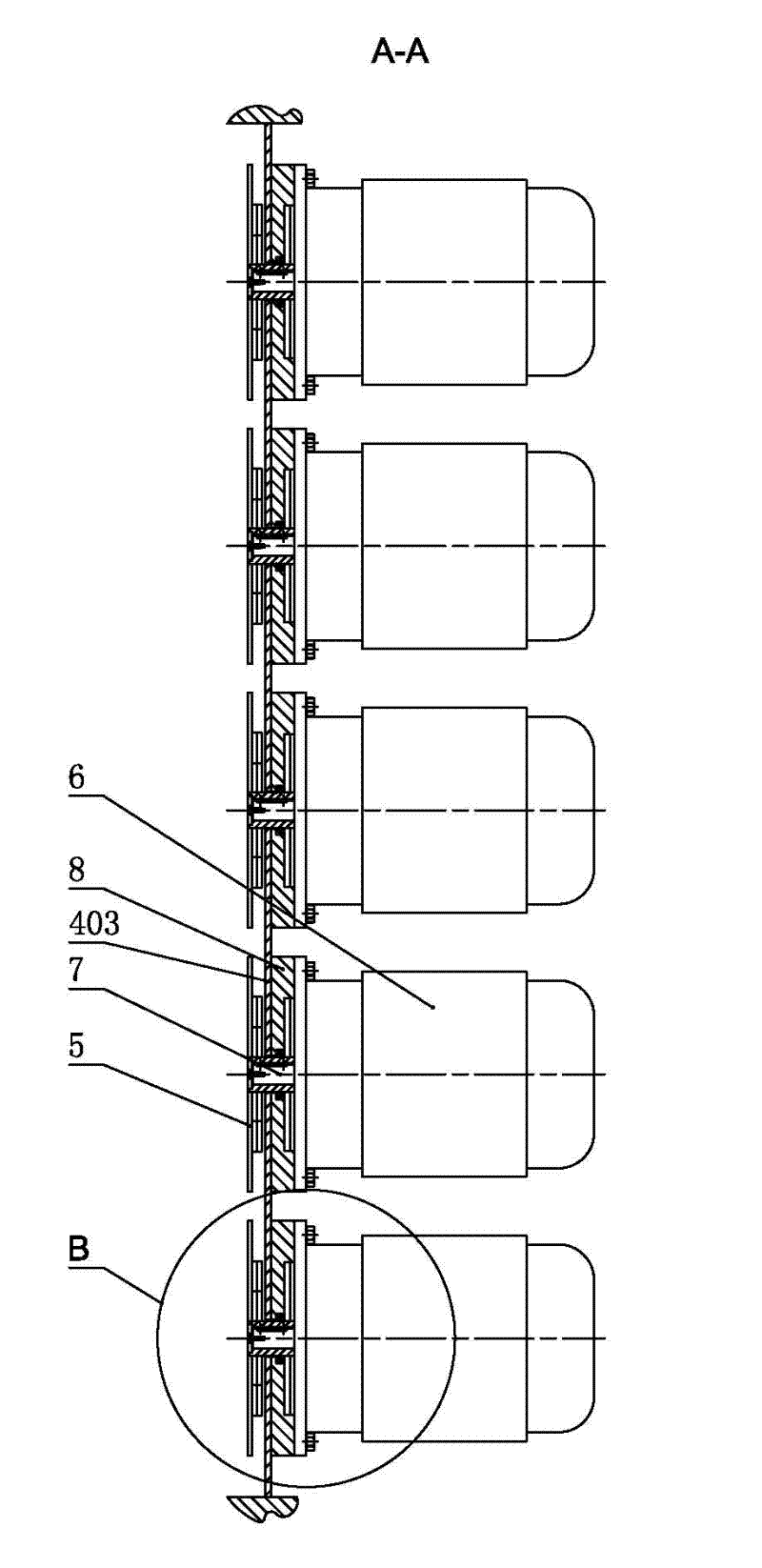

[0018] Such as figure 1 As shown in -5, the single-shaft paddle mixer of the present invention includes a horizontally arranged mixing chamber 1 and a rotor, the rotor is arranged in the mixing chamber 1, and the rotor is composed of a rotating shaft 2 and several paddles 3 arranged on the outer periphery of the rotating shaft , There is a gap between the inner wall of the mixing chamber and the outer edge of the paddle 3, so as to facilitate the rotation of the rotor to stir and mix the materials. The crushing chamber 4 extending outside, the upper and lower sides of the crushing chamber 4 are connected tangentially to the mixing chamber 1 through the material guide plates 401 and 402 respectively, forming a smooth transition connection. The crushing chamber 4 extends from one end of the mixing chamber 1 to the other end of the mixing chamber. 4, along the length direction of the crushing chamber, several hammer-knife groups 5 are arranged side by side. The rotary surfaces of...

Embodiment 2

[0021] The difference with the above-mentioned embodiment 1 is that each hammer knife group 5 includes a disc-shaped hammer blade 5b, and the outer edge of the disc-shaped hammer blade 5b is provided with several grooves 501, and the length direction of the groove 501 is Parallel to the axis of rotation of the disk-shaped hammer blade 5b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com