Flexible fixture device applied to assembly of antenna rib plates

A technology of flexible tooling and ribs, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of antenna assembly tooling, such as poor reorganization and utilization, long manual assembly cycle, and low degree of freedom of the mechanism, so as to overcome the reorganization Poor utilization, reduced assembly experience and interference, strong reconfigurability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

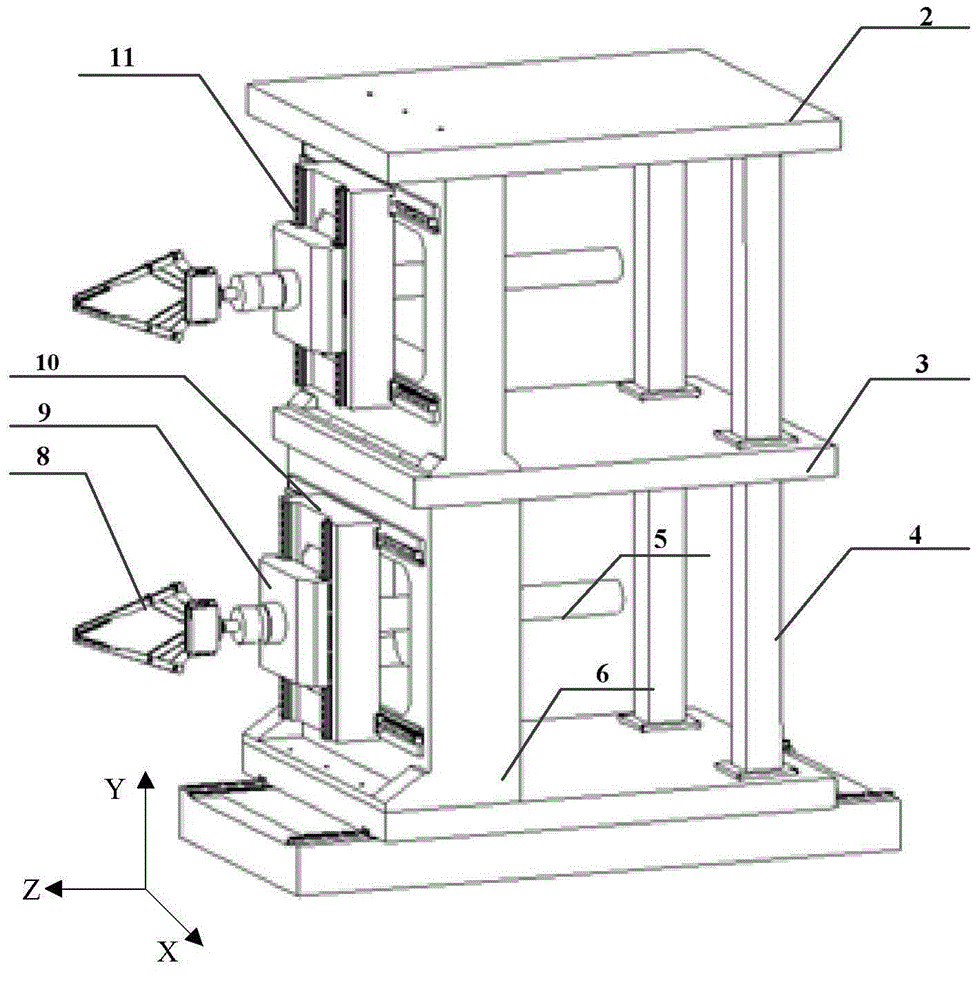

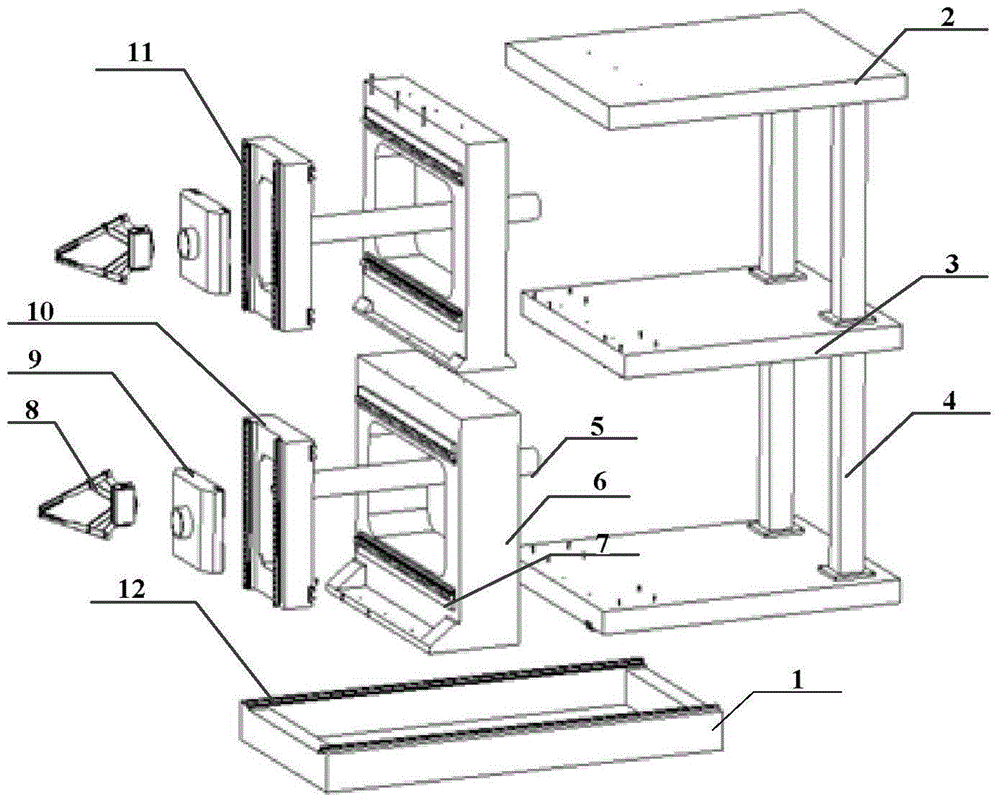

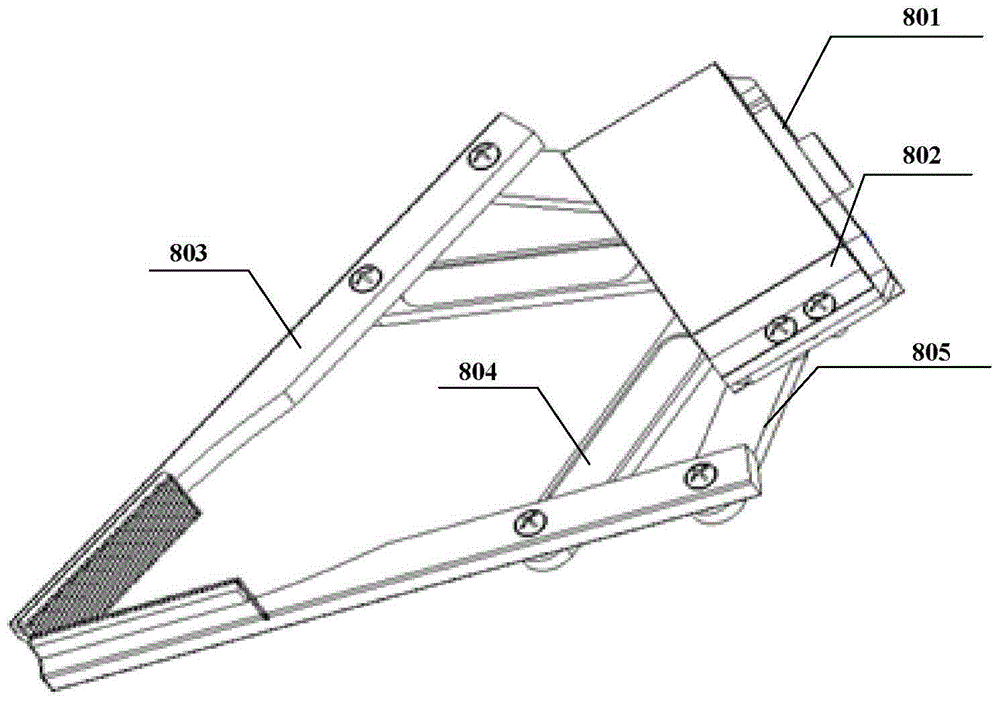

[0017] Such as figure 1 and figure 2 As shown, a flexible tooling device for assembling antenna ribs according to the present invention includes a base 1, a supporting top plate 2, an upper tooling structural unit and a lower tooling structural unit, and two layers of tooling structural units. Each layer of the tooling structure unit includes a support plate 3 , a column 4 , a rotating shaft 5 , a support body 6 , two X-guiding rails 7 , a clamping module assembly 8 , a connecting body 9 and a slide rail seat 10 . The column 4 and the supporting body 6 are respectively fixedly connected to the top surface of the supporting plate 3 . The two X-guiding rails 7 are parallel to each other and are fixedly connected to one end surface of the support body 6 . One end of the rotating shaft 5 cooperates with the connecting body 9 through a bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com