Novel optical fiber connector

An optical fiber connector and a new type of technology, which are applied in the coupling of optical waveguides and other directions, can solve the problems of unreasonable structural setting of optical fiber connectors, large processing difficulties and errors, and difficult to master the processing accuracy. , The effect of high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

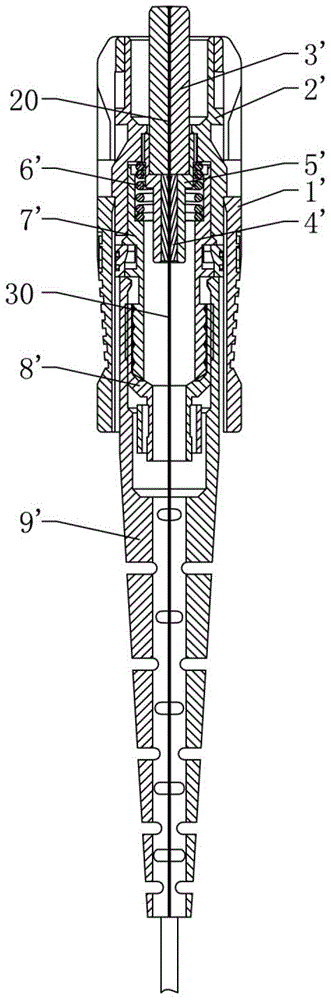

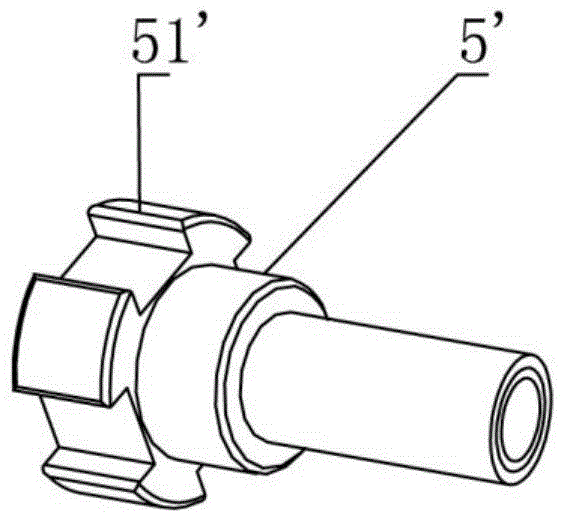

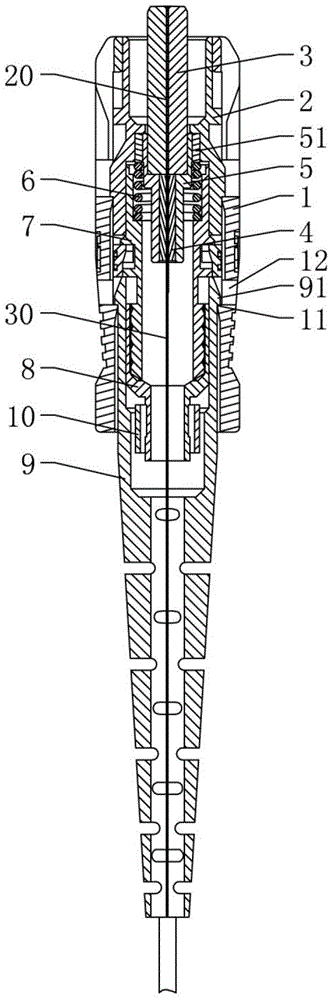

[0018] Such as Figure 3 to Figure 5 The new optical fiber connector shown includes a packaging shell 1, a socket seat 2, a first ferrule 3, a second ferrule 4, a metal tail handle 5, a spring 6, a support seat 7, a collar nut 8, and a rubber sleeve The tube 9, the sleeve socket 2 is sleeved in the packaging shell 1 and snap-fitted with the packaging shell 1, and the ends of the first ferrule 3 and the second ferrule 4 are inserted in the metal A ferrule assembly is formed in the tail handle 5, and the metal tail handle 5 is inserted in the sleeve seat 2. The support seat 7 is sleeved in the packaging shell 1 and its front end is engaged with the sleeve seat 2. The metal tail handle 5 The spring 6 is connected to the supporting seat 7, and the function of the spring 6 is to enable the ferrule assembly formed by the cooperation of the first ferrule 3, the second ferrul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com