Automatic compensation device for clutch abrasion for locomotive

An automatic compensation and clutch technology, applied in mechanical drive clutches, clutches, friction clutches, etc., can solve the problems of assembly, complex process, poor automatic compensation effect, and high processing accuracy requirements, and achieve long service life, sensitive response, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

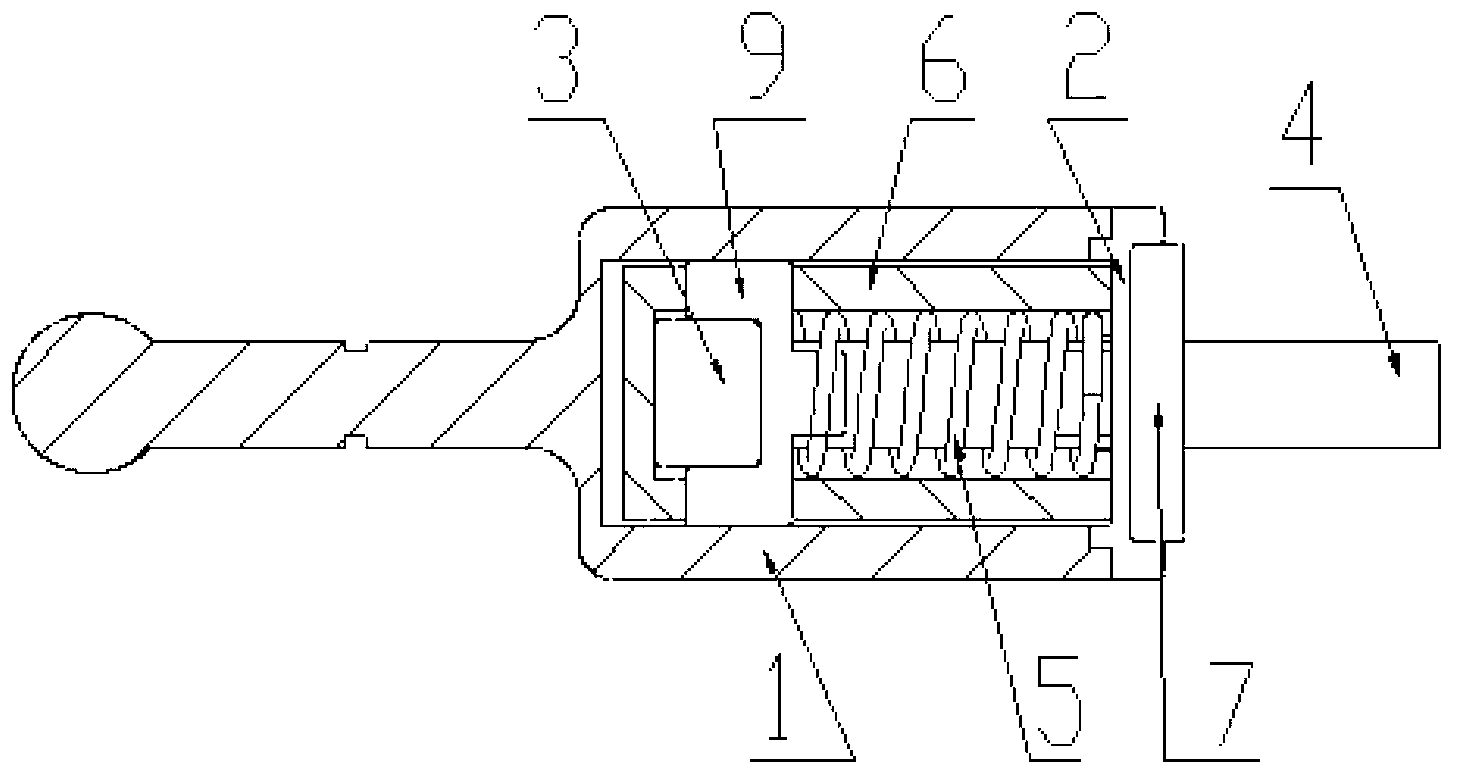

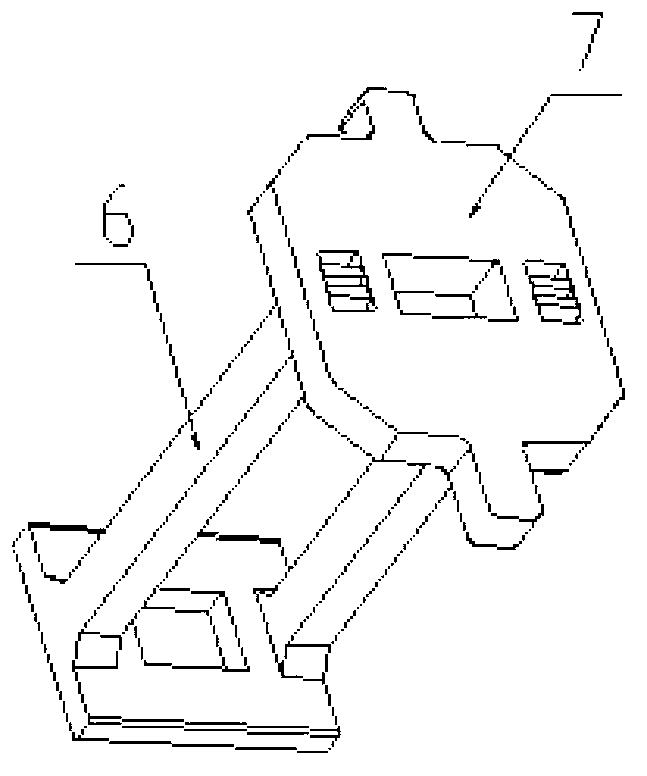

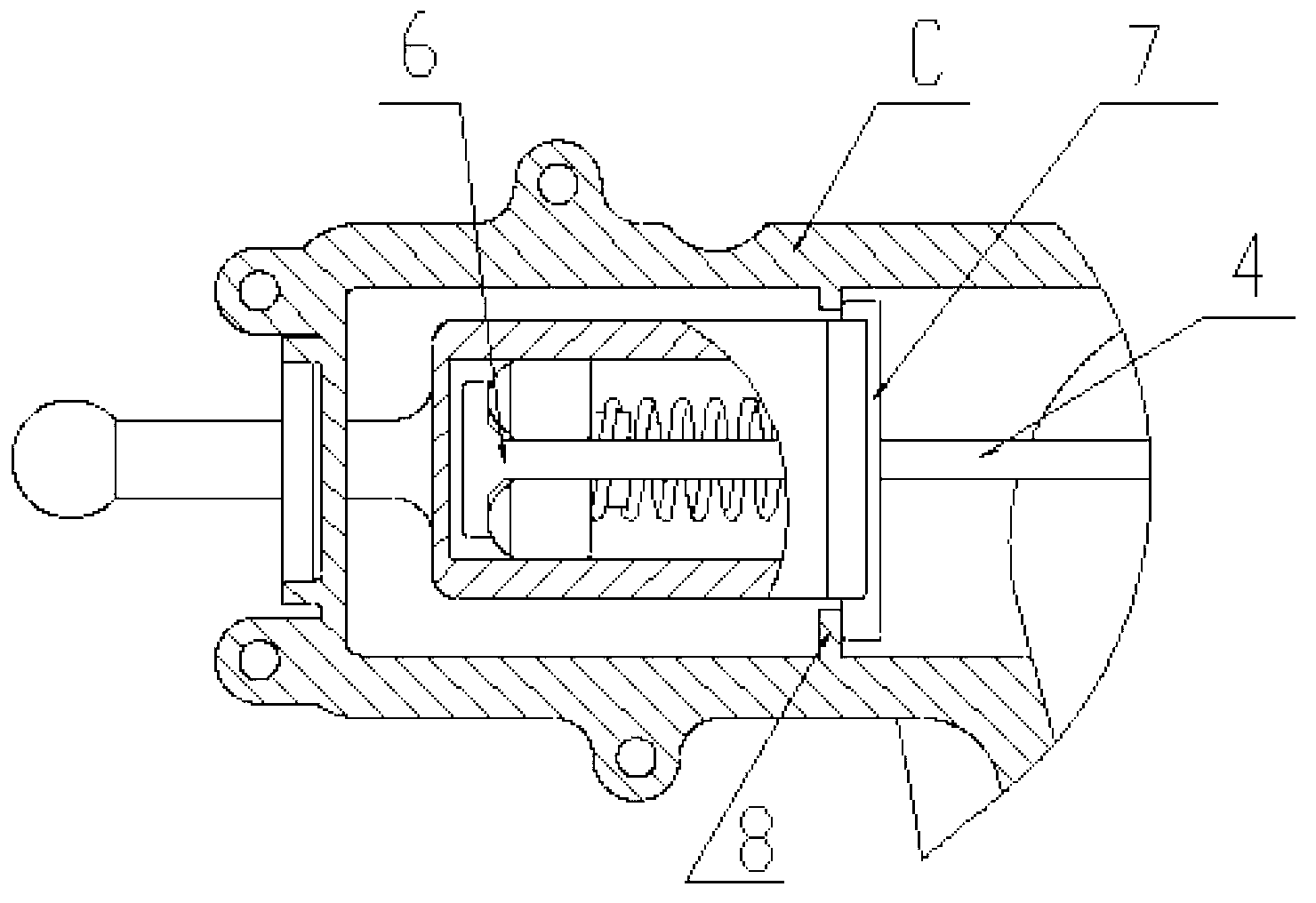

[0027] Referring to accompanying drawings 1 and 2, an automatic clutch wear compensation device of the present invention includes a housing 1, an end cover 2, a roller cage 9, a self-locking roller 3, a pull rod 4, a locking spring 5, a limit plate 6 and a limiter Bit end 7 is composed.

[0028] An automatic compensation device for clutch wear is composed of a casing, an end cover, a locking spring 5 , a self-locking roller 3 , a limiting plate 6 and a pull rod 4 . The shell 1 and the end cover 2 form a closed accommodation space, and the pull rod 4, the roller cage 9, the limit plate 6, the locking spring 5, and the self-locking roller 3 are all contained in the above-mentioned accommodation space.

[0029] When the actuator moves to the initial position, the housing 1 can move freely, and under the action of the diaphragm spring force, the wear of the clutch can be automatically compensated, and a certain pulling force can be output to provide preload for the release bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com