Heat dissipation device for underground caterpillar band type four-drive excavator

A heat dissipation device and excavator technology, which is applied to earth movers/excavators, construction, etc., and can solve problems such as coal mine waste floating, slow heat dissipation, and harsh working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

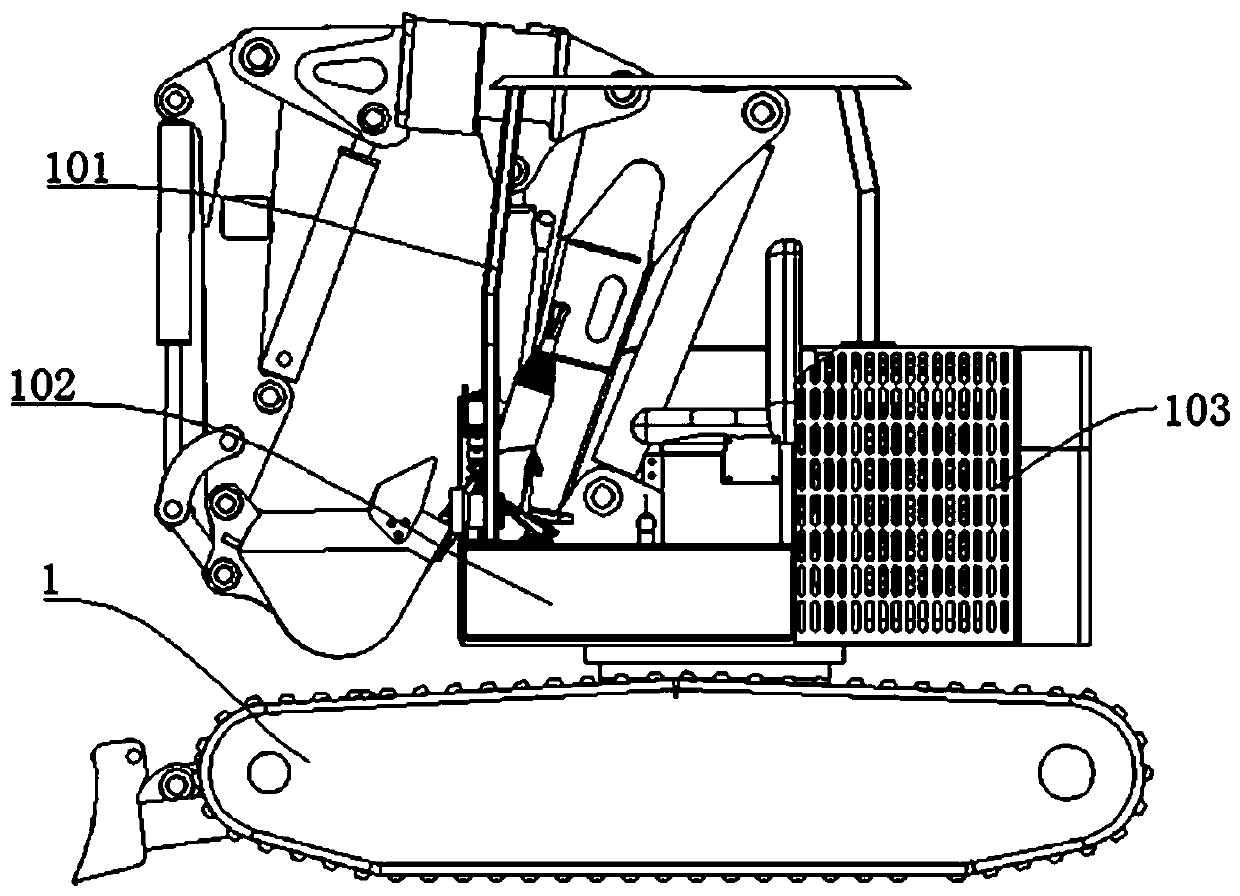

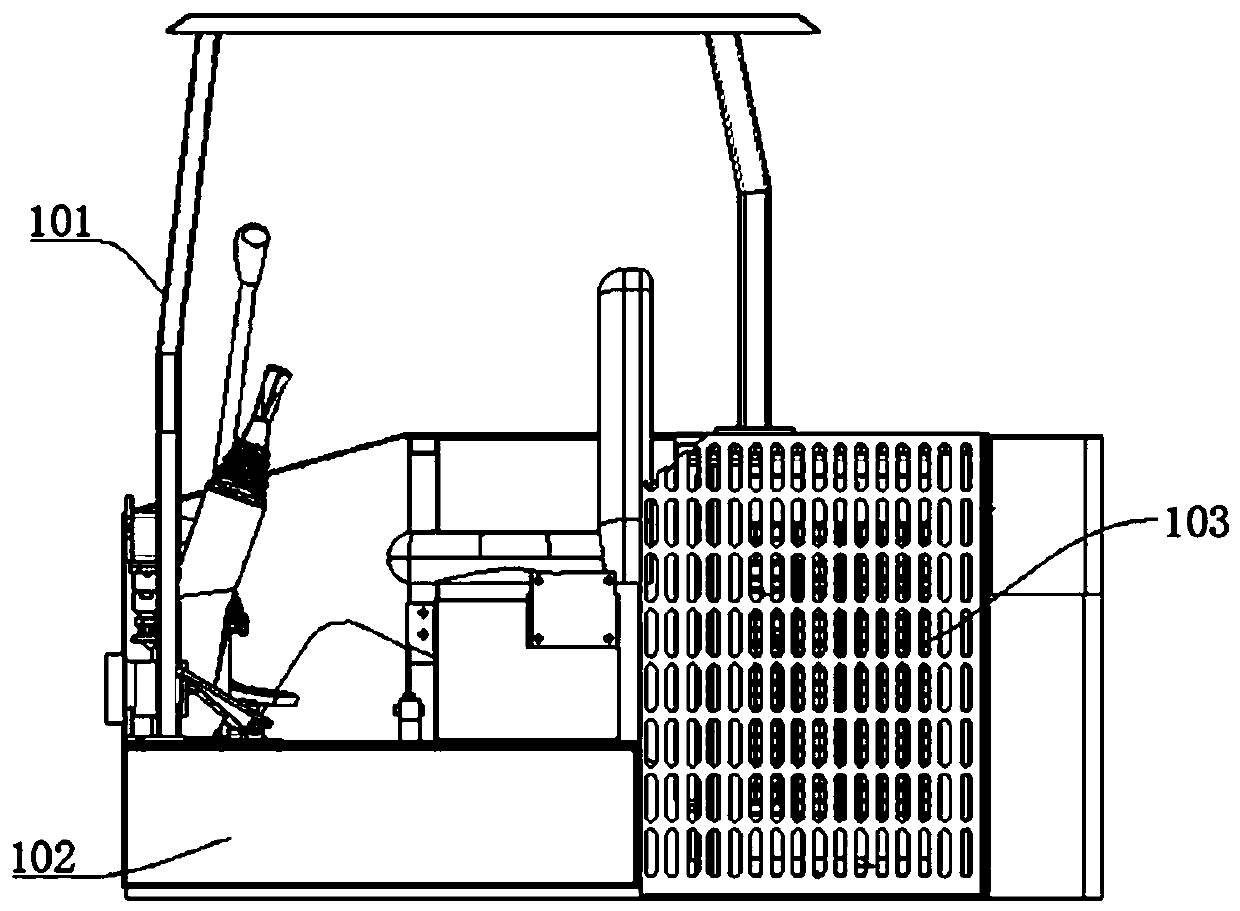

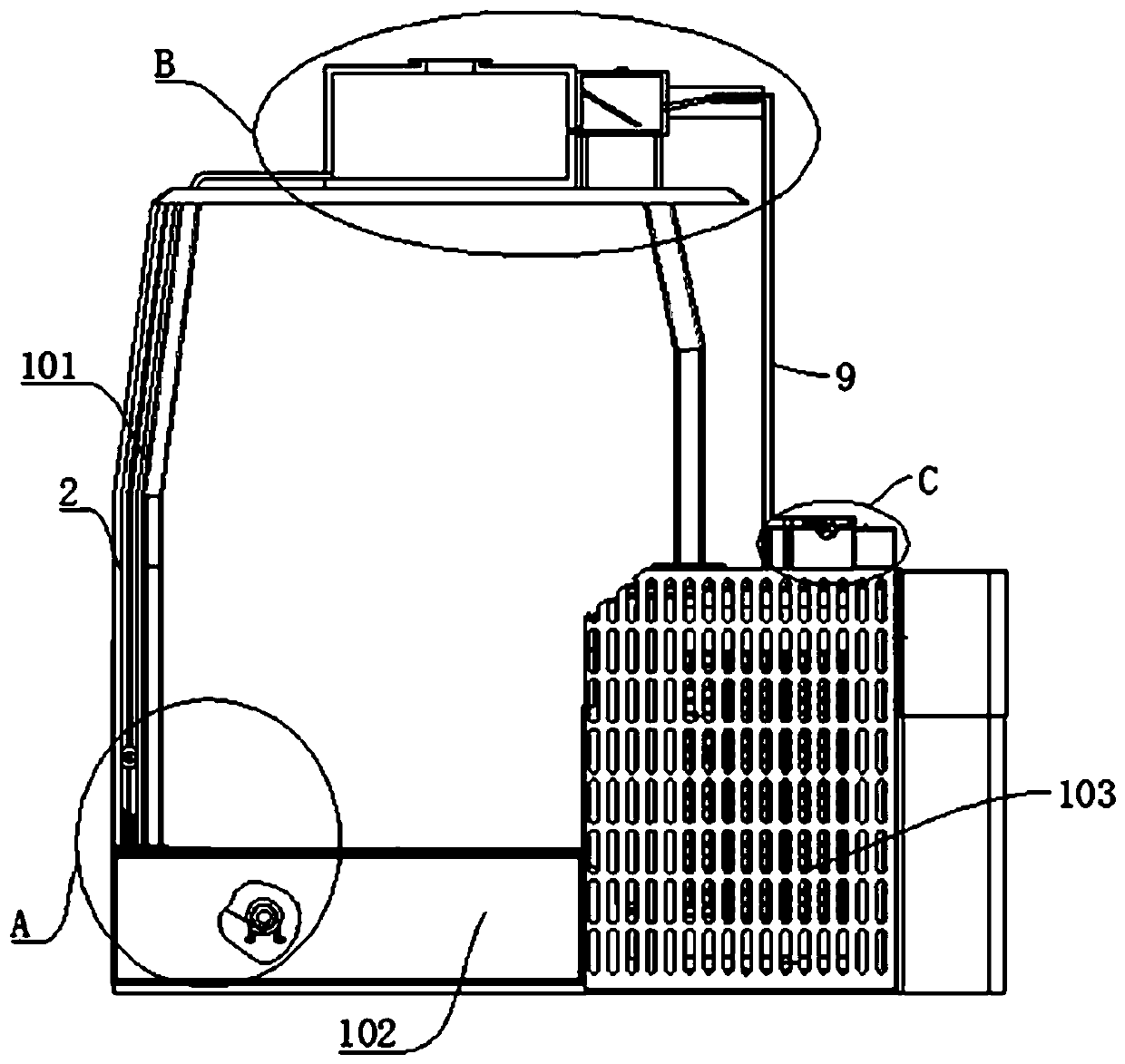

[0044] refer to Figure 1-15 , a cleaning device for an underground crawler-type four-wheel drive excavator, including an excavator unit 1 provided with a seat frame 101 and a seat base 102, the seat frame 101 is connected to the seat base 102, and the seat frame 101 is provided with The transparent plate also includes: cleaning guide rail 2, fixedly connected on the seat frame 101; cleaning slider 201, slidingly connected on the cleaning guide rail 2; cleaning plate 202, connected on the cleaning slider 201, for cleaning the transparent plate; Wherein, the cleaning plate 202 is provided with a hollow groove 2023 and a water outlet 2024 that communicate with each other, and the water outlet end of the water outlet 2024 can be set as a spray head; the cleaning water storage tank 6 used to store and release water, and the hollow groove 2023 pass through the cleaning outlet pipe 601 is connected; the drive mechanism is arranged on the seat base 102, and is connected with the clea...

Embodiment 2

[0062] refer to Figure 1-15 , a cleaning device for an underground crawler-type four-wheel drive excavator, which is basically the same as that of Embodiment 1. Furthermore, this embodiment is a specific embodiment of a drive mechanism. The drive mechanism includes a drive rope 302 fixed on a seat The two ends of the reciprocating assembly on the base 102 and the driving rope 302 are respectively fixedly connected to the reciprocating assembly and the cleaning slider 201 .

[0063] The reciprocating assembly includes a forward and reverse motor 3 and a drive turntable 301 , the drive turntable 301 is fixedly connected to the output end of the forward and reverse motor 3 , and the drive rope 302 is fixedly connected to the drive turntable 301 .

[0064] It should be noted that the forward and reverse motor 3 and the drive turntable 301 are not fixed components in the reciprocating assembly, and a cam reciprocating mechanism (not shown in the figure) or other reciprocating mech...

Embodiment 3

[0066] refer to Figure 1-15 , a cleaning device for an underground crawler-type four-wheel drive excavator, which is basically the same as that of Embodiment 1, and furthermore, this embodiment is a specific embodiment of a cooling device, and the cooling device includes a cooling frame 8, a cooling connecting pipe 801, the cooling coil 802, the cooling frame 8 is fixedly connected with the separation box 7, the cooling connecting pipe 801 and the cooling coil 802 are fixedly connected on the cooling frame 8, the cooling coil 802 is sleeved on the cooling connecting pipe 801, and the cooling plate Cooling liquid is provided in the pipe 802, and the cooling connecting pipe 801 communicates with the intake pipe 9. It should be noted that the cooling coil 802 is provided with a valve port for replacing the cooling liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com