Nuclear power plant master control heat dissipation chamber

A heat dissipation chamber and nuclear power plant technology, applied in nuclear power generation, nuclear engineering, greenhouse gas reduction, etc., can solve the problems of less heat storage and low heat storage capacity of concrete, and achieve easy cooling, overcome low heat storage capacity, and large contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

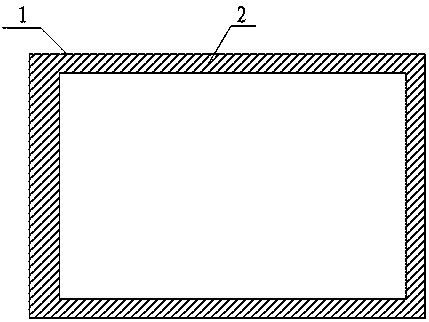

[0023] Such as figure 1 As shown, in the embodiment of the present invention, a nuclear power plant main control cooling room is provided, including a wall 1 and an interlayer 2 arranged inside the wall 1 and used for heat conduction; wherein,

[0024] The wall body 1 is made of metal material so as to conduct heat quickly;

[0025] The interlayer 2 is made of a phase-change heat storage material within a certain range of melting point, so as to start heat storage when the room temperature is higher than the melting point of the phase-change heat storage material, and the phase-change heat storage material should have low cost, stable performance, Large heat storage capacity and other advantages.

[0026] In one embodiment, according to the actual needs of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com