Impinging stream type ionization high-temperature waste gas harm removal, separation, degradation and circulation treatment device

A high-temperature waste gas, recycling treatment technology, applied in gaseous discharge wastewater treatment, grease/oily substance/float removal device, combined device, etc., can solve the problem of slow filtration speed, air pollution, no harmful gas and solid impurities degradation And separation and other issues, to increase the speed, increase the use time, achieve the effect of eliminating harmful substances and filtering emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be described in further detail below in conjunction with the specific implementation. The technical features or connection relationships described in the present invention are not described in detail. They are all existing technologies adopted.

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

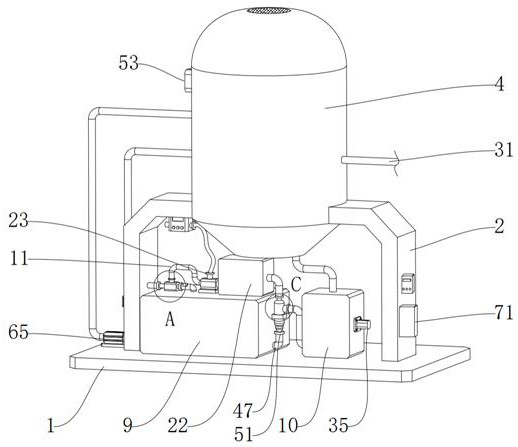

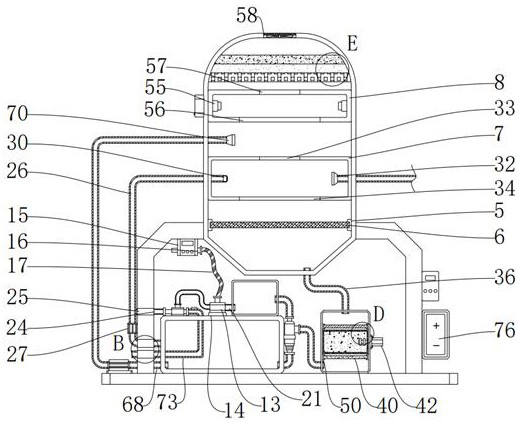

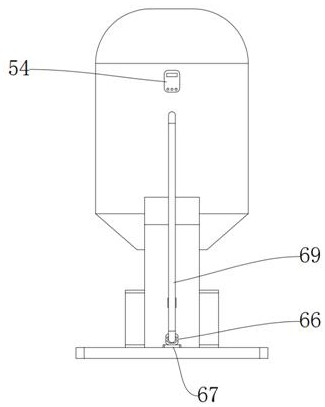

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention provides an impinging flow ionization high-temperature waste gas detoxification separation and degradation cycle treatment device, including a separation bottom support base 1, a separation tower support frame 2, a collision type negative pressure separation and degradation tower 4, an inertial impact Flow mixing periodic swing box 7, adsorption electrostatic state dust cleaning storage box 8, multi-functional integrated waste gas degradation water storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com