Novel graphite biomass fever cooling patch and preparation method thereof

A technology of graphene and antipyretic paste, which is applied to heating appliances for treatment, contraceptives, cooling appliances for treatment, etc., can solve the problems of slow water absorption, low water content, poor heat conduction and heat dissipation, etc., and achieve easy cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

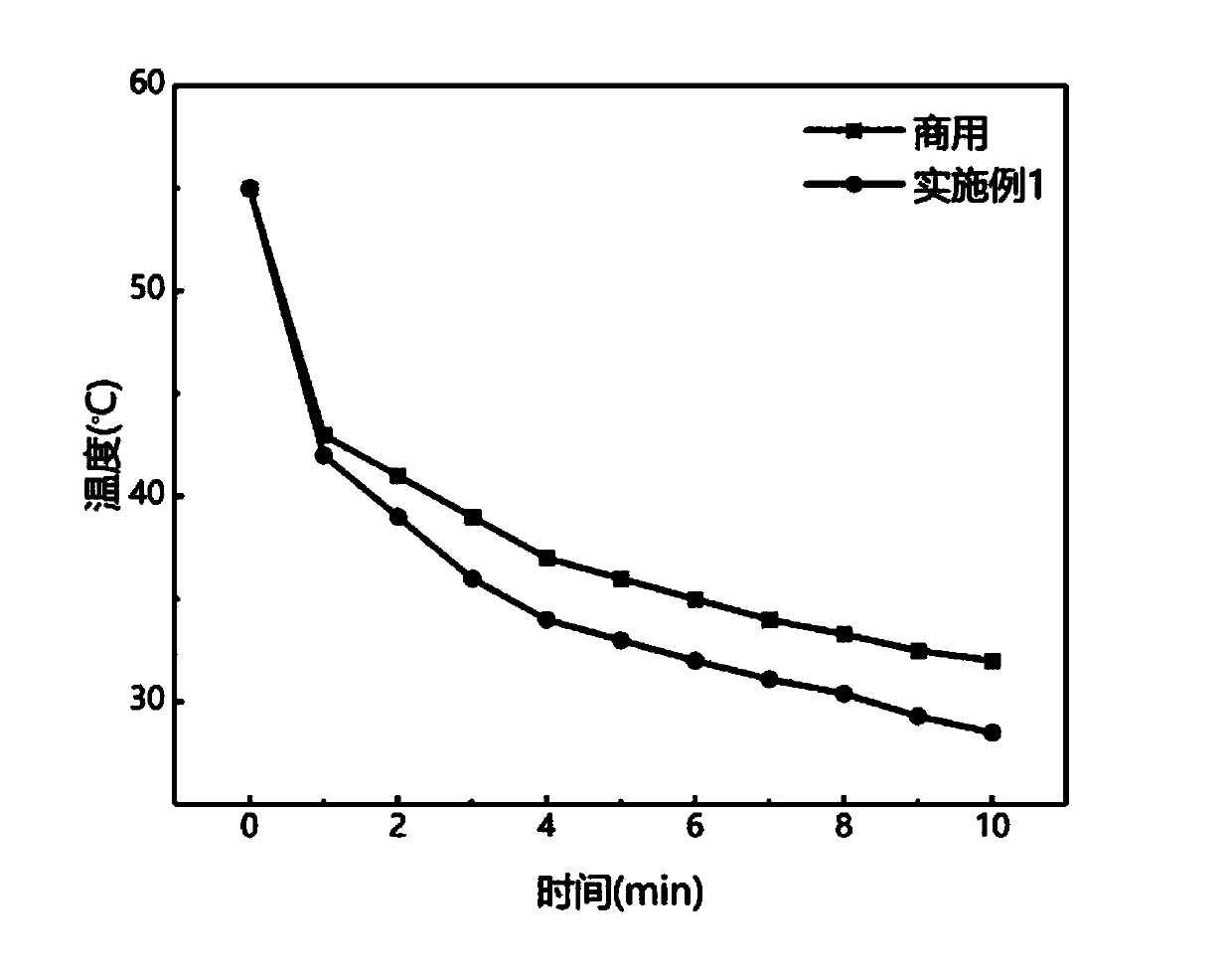

Embodiment 1

[0022] A preparation method of a novel antipyretic patch, the specific steps are as follows:

[0023] 1. Heat and stir 7.75 parts of starch at 60°C, then mix with 33 parts of deionized water to obtain mixture a;

[0024] 2. After heating 42.2 parts of water to boiling, add a to the boiling water, under N 2 Stir continuously in an air atmosphere and continue to heat until it becomes a paste;

[0025] 3. Add 4 parts of graphene and stir thoroughly to obtain mixture b, and put it into an ultrasonic machine at a temperature of 85°C for 2 hours to obtain a uniformly dispersed mixture c;

[0026] 4. Fully stir 12 parts of alcohol and 0.05 part of p-methoxybenzoic acid, then add to mixture c, put mixture c in a water bath in a closed container, at a temperature of 35°C, for 10 minutes;

[0027] 5. When the temperature of the water bath drops to room temperature, apply the target product to the non-woven fabric substrate and let it stand for 24 hours to obtain the target cooling pat...

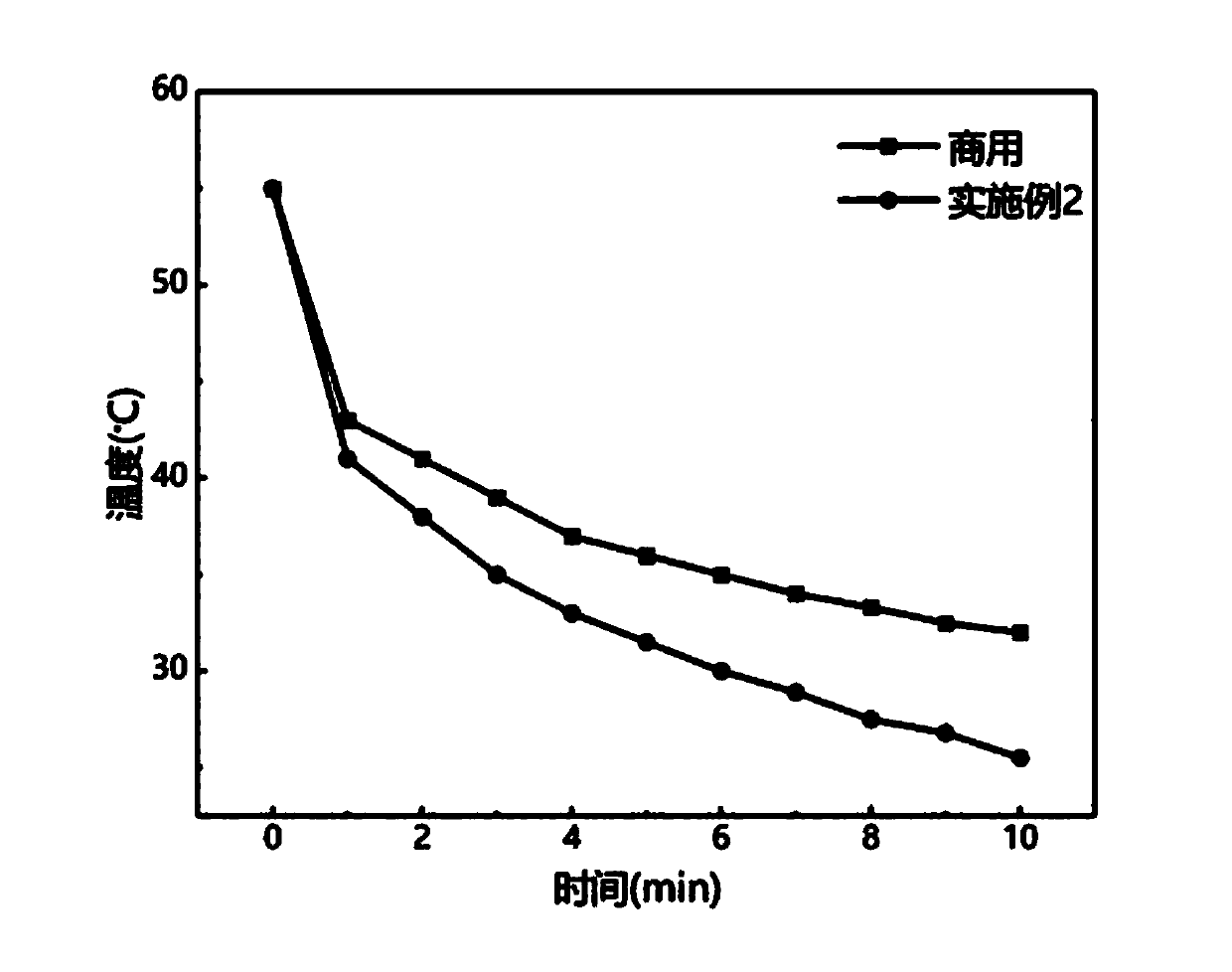

Embodiment 2

[0029] A preparation method of a novel antipyretic patch, the specific steps are as follows:

[0030] 1. Heat and stir 6.75 parts of starch at 60°C, then mix with 32 parts of deionized water to obtain mixture a;

[0031] 2. After heating 42.2 parts of water to boiling, add a to the boiling water, under N 2 Stir continuously in an air atmosphere and continue to heat until it becomes a paste;

[0032] 3. Add 6 parts of graphene and stir thoroughly to obtain mixture b, and put it into an ultrasonic machine at a temperature of 85°C for 2 hours to obtain a uniformly dispersed mixture c;

[0033] 4. Fully stir 12 parts of alcohol and 0.05 part of p-methoxybenzoic acid, then add to mixture c, put mixture c in a water bath in a closed container, at a temperature of 35°C, for 10 minutes;

[0034] 5. When the temperature of the water bath drops to room temperature, apply the target product to the non-woven fabric substrate and let it stand for 24 hours to obtain the target cooling pat...

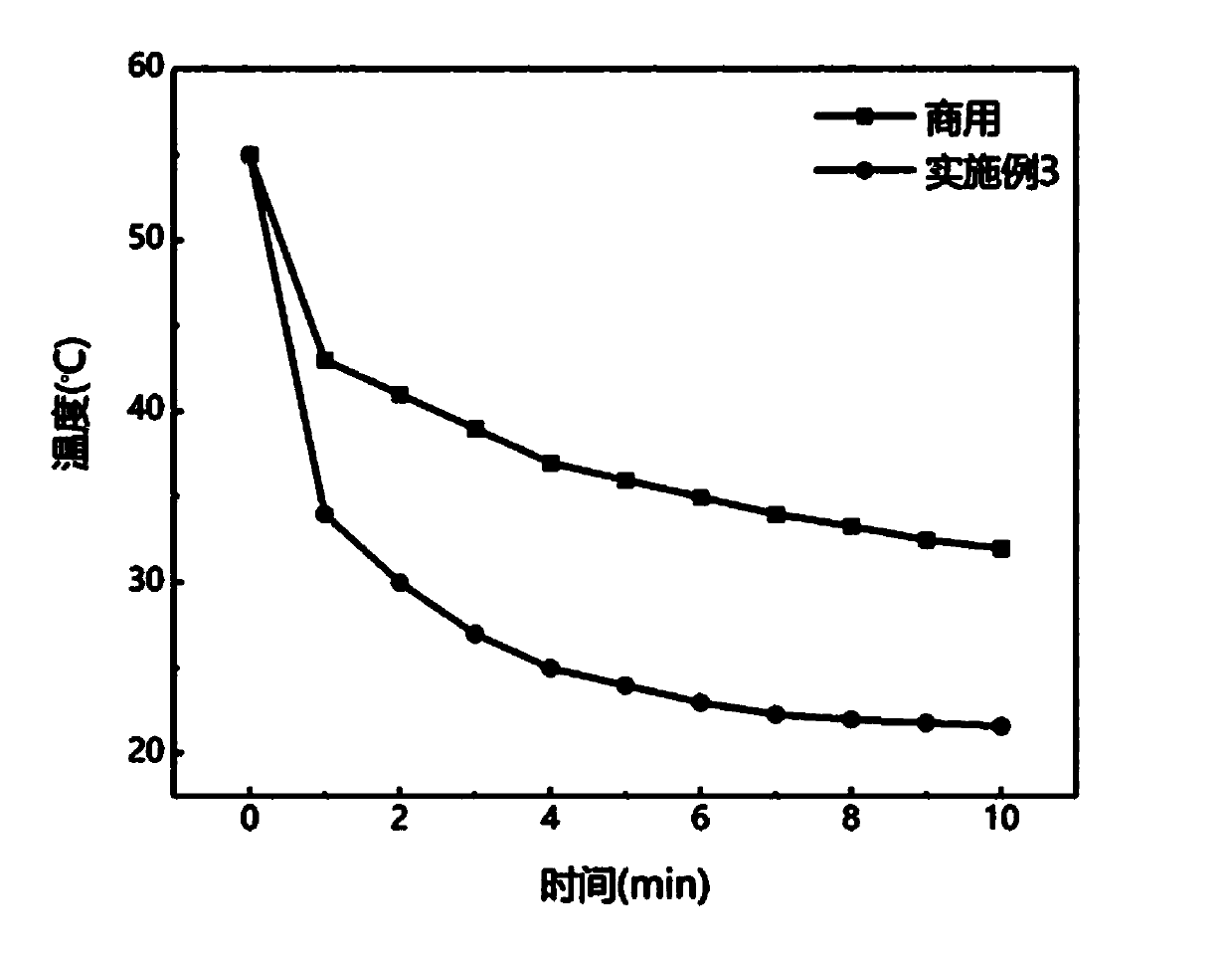

Embodiment 3

[0036] A preparation method of a novel antipyretic patch, the specific steps are as follows:

[0037] 1. Heat and stir 6.75 parts of starch at 60°C, then mix with 32 parts of deionized water to obtain mixture a;

[0038] 2. After heating 42.2 parts of water to boiling, add a to the boiling water, under N 2 Stir continuously in an air atmosphere and continue to heat until it becomes a paste;

[0039] 3. Add 6 parts of graphene and stir thoroughly to obtain mixture b, and put it into an ultrasonic machine at a temperature of 85°C for 2 hours to obtain a uniformly dispersed mixture c;

[0040] 4. Fully stir 12 parts of alcohol and 0.05 part of p-methoxybenzoic acid, then add to mixture c, put mixture c in a water bath in a closed container, at a temperature of 35°C, for 10 minutes;

[0041] 5. When the temperature of the water bath drops to room temperature, apply the target product to the non-woven fabric substrate and let it stand for 24 hours to obtain the target cooling pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com