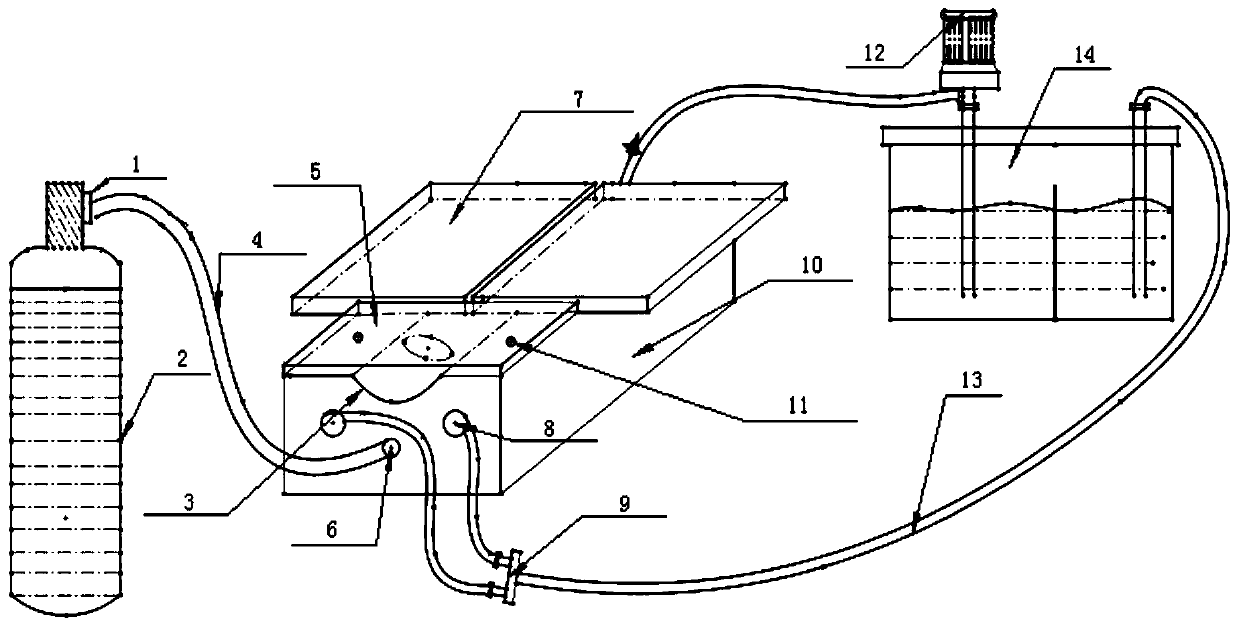

Single-sided welding copper liner device with water cooling and back protection and corresponding welding method

A technology of back protection and copper lining, applied in welding equipment, auxiliary devices, welding accessories, etc., can solve the problems of easy inclusion and short life, and achieve the effect of low processing cost, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Copper pad forming groove width selection D 1 =5mm, depth H=0.5mm, cooling water hole radius R 1 =6mm, air hole radius R 2 =4mm, cooling water flow V 1 =3-5L / min, protective gas flow V 2 =2.5L / min, ventilate the copper liner forming groove for 1-2min before welding.

[0030] The properties of the welded joints obtained in Comparative Examples 1-2 and Example 1 are shown in Table 2.

[0031] Table 2 comparative example and embodiment welded joint performance parameter table

[0032]

Weld Deformation Angle

Back weld color

tensile strength

Comparative example 1

About 1.66°

silver white

About 227.7MPa

Comparative example 2

About 1.09°

silver gray

About 238.3MPa

Example 1

About 1.06°

silver white

About 239.9MPa

[0033] It can be seen from Table 2 that passing cooling water inside the gasket can effectively reduce the deformation angle of the weld, and passing shielding gas under the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com