Hot blast stove of drying equipment

A technology of drying equipment and hot blast stove, applied in lighting and heating equipment, air heaters, fluid heaters, etc., can solve problems affecting equipment use, equipment ash adhesion, slow cooling of residual temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

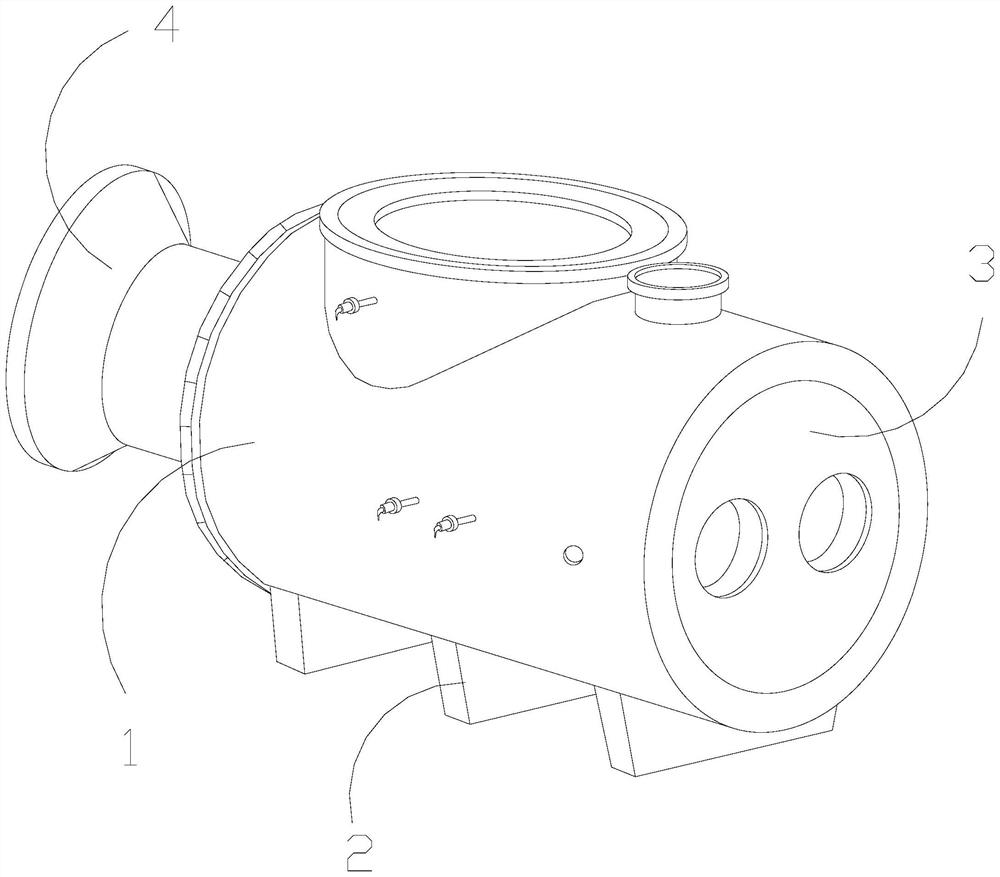

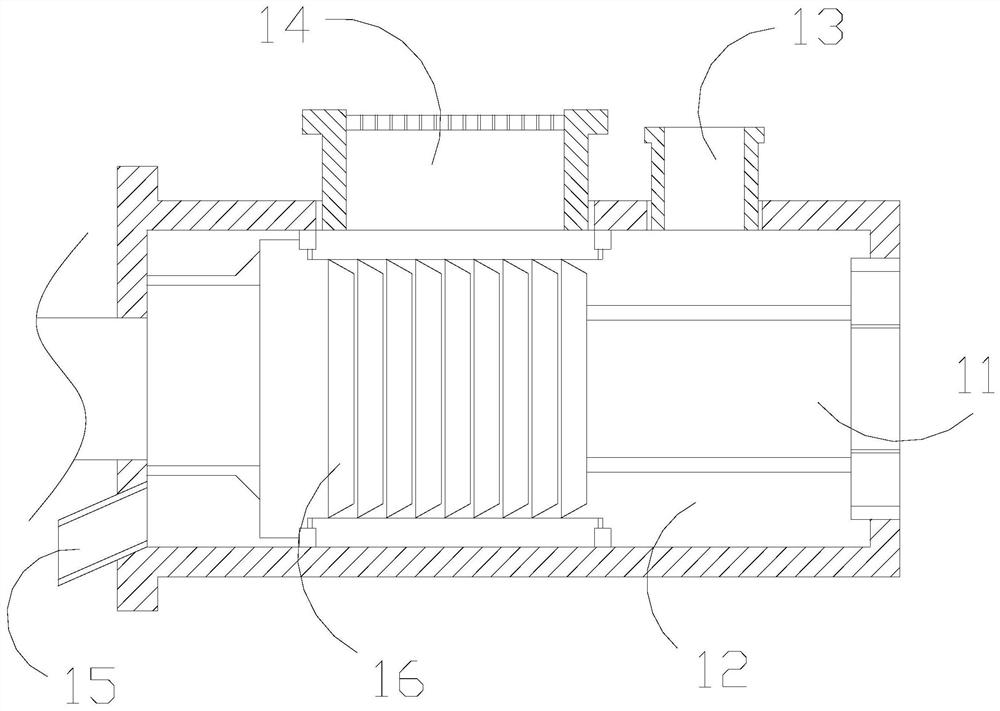

[0028] as attached figure 1 To attach Figure 6 Shown:

[0029] The invention provides a hot blast stove for drying equipment, which is structured with a furnace body 1, a support 2, an air inlet door 3, and a burner 4. The support 2 is welded and connected to the bottom of the furnace body 1, and the air inlet door 3 is movably engaged with and communicated with the furnace body 1 , and the burner 4 is connected to one side end of the furnace body 1 through.

[0030] The furnace body 1 is provided with an air inlet duct 11, a circulation chamber 12, a smoke outlet 13, a hot gas outlet 14, a slag outlet 15, and a heat generating device 16, and the air inlet duct 11 is embedded and installed inside the furnace body 1 , the circulation chamber 12 and the furnace body 1 are of an integrated structure and located inside it, the smoke exhaust port 13 is connected through the top of the furnace body 1, and the hot gas discharge port 14 is arranged beside the smoke exhaust port 13,...

Embodiment 2

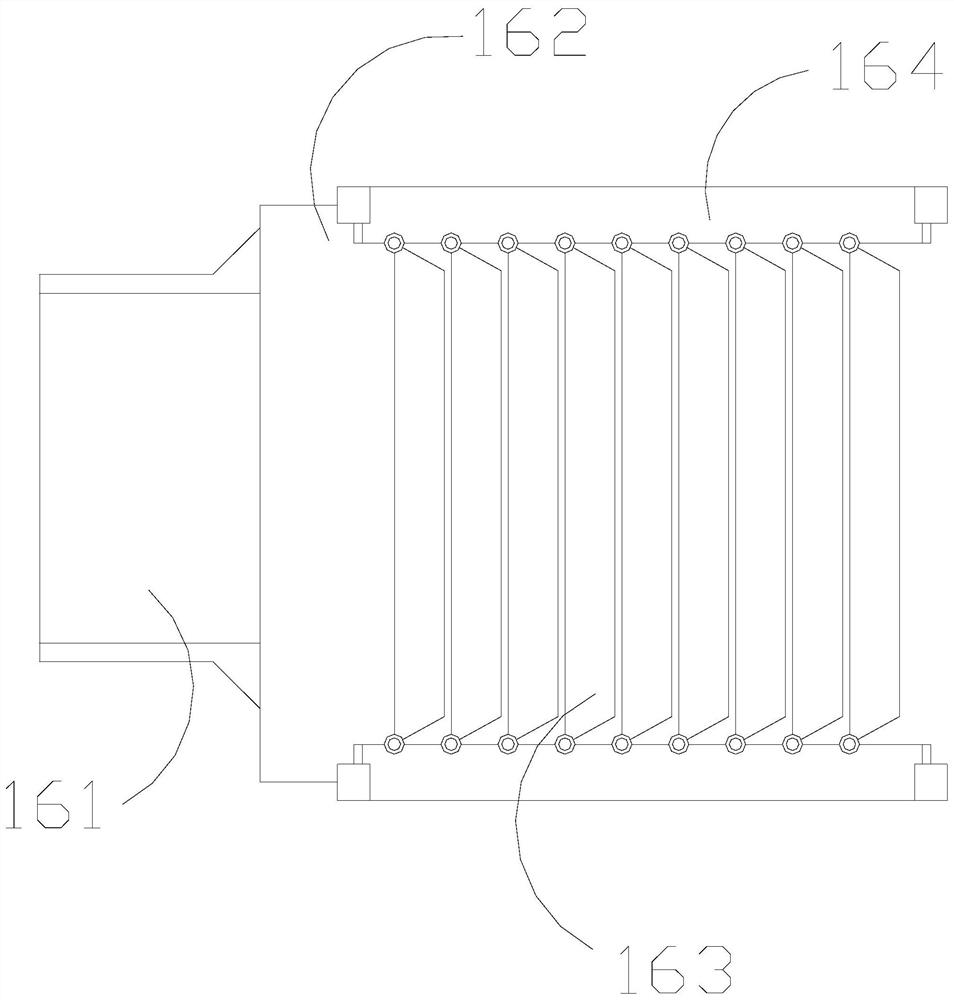

[0036] as attached Figure 7 To attach Figure 8 Shown:

[0037]Wherein, the heat mixing body 163 is provided with a hinge plate 631 and an elliptical flow path 632, and the elliptical flow path 632 is embedded in the hinge plate 631, and the hinge plate 631 is a trapezoidal plate body, and the elliptical flow path There are four diameters 632, which are evenly distributed on the hinge plate 631. When the hinge plate 631 swings, the elliptical flow path 632 is used for the gas to pass through multiple flow paths, and at the same time drive the speed of the airflow, and assist the hinge plate 631. swing force.

[0038] Wherein, the elliptical flow path 632 is provided with a movable cavity 321, a spring 322, a displacement ring 323, a chisel column 324, and a diameter cavity 325, the spring 322 moves inside the movable cavity 321, and the displacement ring 323 is connected with the spring 322 And movable cooperation, the chisel column 324 is fixedly connected with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com