Industrial injection molding machine with protection mechanism

A technology of protection mechanism and injection molding machine, which is applied in the field of injection molding machine and can solve the problems of burns, lack of self-cooling function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

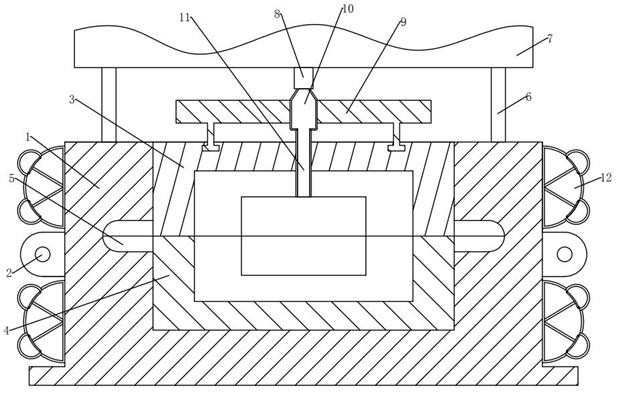

[0039] see Figure 1-2 and Figure 8 , in the embodiment of the present invention, an industrial injection molding machine with a protection mechanism, comprising:

[0040] The injection molding base 1, the middle end of the left and right sides of the injection molding base 1 is fixedly installed with the fixed seat 2, the upper mold 3 and the lower mold 4 are fixedly installed on the inner upper and lower ends of the injection molding base 1, and the upper mold 3 and the lower mold 4 are fixedly installed. The outer surfaces of the left and right sides are fixedly installed with the parting ear seats 5, the left and right ends of the top side outer surface of the injection molding base 1 are fixedly installed with support columns 6, and the top positions of the support columns 6 are fixedly installed with the injection molding machine main body 7. The injection molding machine main body The injection head 8 is fixedly installed through the central position of the bottom end...

Embodiment 2

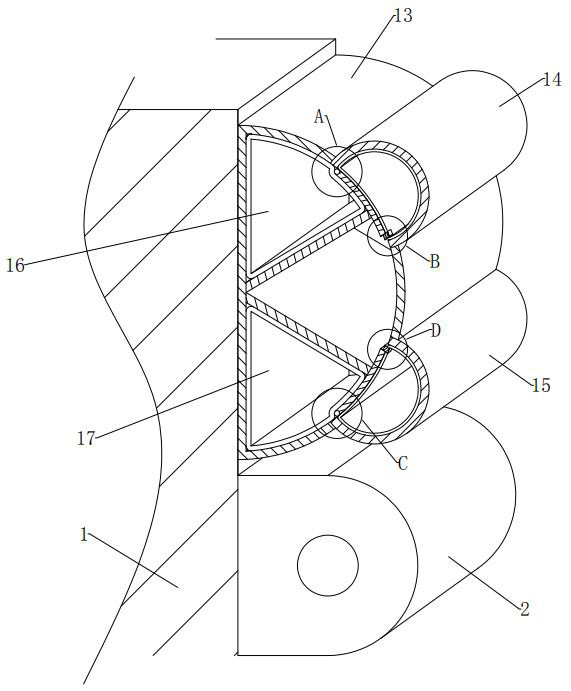

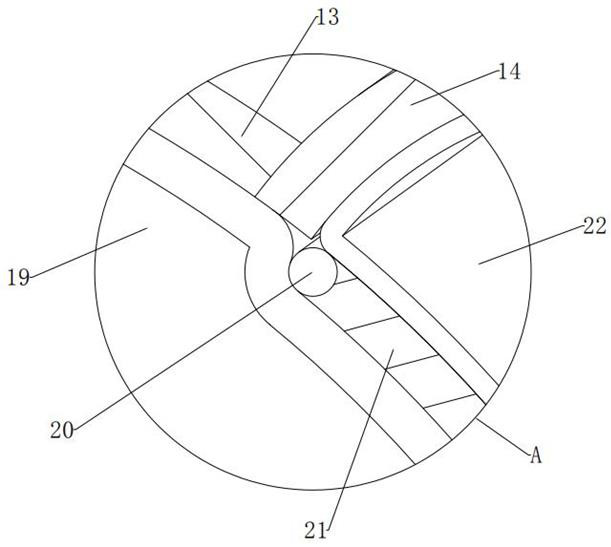

[0054] see Figure 2-4 and Figure 7 , compared with Embodiment 1, the difference between the embodiment of the present invention is that the upper fixing plate 18 is fixed and installed obliquely at the upper end of the left inner wall of the main shell 13, and the angle between the upper fixing plate 18 and the upper and lower vertical planes is 59°;

[0055] The upper fixing plate 18 here is for the convenience of limiting and supporting the upper main air bag 19 together with the inner wall of the main casing 13 , so that the upper main air bag 19 can smoothly expand into the upper auxiliary casing 14 after being heated and expanded.

[0056] In the embodiment of the present invention, the upper main air bag 19 is embedded between the top side outer surface of the upper fixing plate 18 and the upper end surface of the inner wall of the main shell 13 , and the upper main air bag 19 is in the shape of a fan with an inner angle of 59° and an upper right outer convex. ;

[...

Embodiment 3

[0064] see figure 2 and Figure 5-7 , with respect to Embodiment 1, the embodiment of the present invention differs in that the lower end position of the left inner wall of the main shell 13 is obliquely fixed and installed with a lower fixing plate 24, and the angle between the lower fixing plate 24 and the horizontal plane is 31°;

[0065] The lower fixing plate 24 here is for the convenience of limiting and supporting the lower main air bag 25 together with the inner wall of the main casing 13 , so that the lower main air bag 25 can smoothly expand into the lower auxiliary casing 15 after being heated and expanded.

[0066] In the embodiment of the present invention, a lower main air bag 25 is embedded between the outer surface of the bottom side of the lower fixing plate 24 and the lower end surface of the inner wall of the main casing 13 , and the lower main air bag 25 is in the shape of a fan with an inner angle of 59° and a lower right outer convex. shape;

[0067] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com